HVAC Basic Concepts of Air Conditioning

Diunggah oleh

Anonymous vepcpIVn70 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

29 tayangan2 halamanHvac - most common questions for interview

Hak Cipta

© © All Rights Reserved

Format Tersedia

DOCX, PDF, TXT atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHvac - most common questions for interview

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai DOCX, PDF, TXT atau baca online dari Scribd

0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

29 tayangan2 halamanHVAC Basic Concepts of Air Conditioning

Diunggah oleh

Anonymous vepcpIVn7Hvac - most common questions for interview

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai DOCX, PDF, TXT atau baca online dari Scribd

Anda di halaman 1dari 2

HVAC Basic Concepts of Air Conditioning

1. 1. Basic Concepts of Air Conditioning Prepared exclusively for COACH LEATHERWARE

2. 2. PanelModerator:Bob KeingsteinBoss Facilities Services631-361-7430bobk@bossfacilityservices.com

Slide 1

3. 3. COIL COOL AIR HEATSOURCE OF COOL AIR COIL Slide 3

4. 4. TYPICAL ALL-AIR SYSTEM S.A. DUCTCOIL COOL AIR HEAT S.A. FAN Slide 4

5. 5. TYPICAL ALL-AIR SYSTEM S.A. S.A. DUCT TERMINALCOIL COOL AIR HEAT S.A. FAN Slide 5

6. 6. TYPICAL ALL-AIR SYSTEM R.A. GRILL S.A. S.A. DUCT TERMINAL COOL WARM AIRCOIL AIR HEAT

S.A. FAN Slide 6

7. 7. TYPICAL ALL-AIR SYSTEM R.A DUCT R.A. GRILL S.A. S.A. DUCT TERMINALCOIL COOL AIR HEAT

S.A. FAN Slide 7

8. 8. TYPICAL ALL-AIR SYSTEM R.A. FAN R.A DUCT R.A. GRILL S.A. S.A. DUCT TERMINAL COIL COOL

AIR HEAT S.A. FAN Slide 8

9. 9. TYPICAL ALL-AIR SYSTEM R.A. FAN R.A DUCT R.A. GRILL S.A. S.A. DUCT TERMINAL R.A.

DAMPER COIL COOL AIR FRESHOUTDOOR HEAT AIR S.A. FAN O.A. DAMPER FILTER Slide 9

10. 10. TYPICAL ALL-AIR SYSTEM E.A.EXHAUST DAMPER AIR R.A. FAN R.A DUCT R.A. GRILL S.A. S.A.

DUCT TERMINAL R.A. DAMPER COIL COOL AIR FRESHOUTDOOR HEAT AIR S.A. FAN O.A. DAMPER

FILTER Slide 10

11. 11. Economizer Provides cooling to space when outdoor air temperatures are below 55 degrees Switches

over automatically from mechanical cooling Adjusts R.A. and F.A. dampers to maintain space temp May

incorporate enthalpy control Mandatory in some states based on unit capacity Slide 11

12. 12. TYPICAL ALL-AIR SYSTEM E.A.EXHAUST DAMPER AIR R.A. FAN R.A DUCT R.A. GRILL S.A. S.A.

DUCT TERMINAL R.A. DAMPER COIL COOL AIR FRESHOUTDOOR HEAT AIR S.A. FAN O.A. DAMPER

WATER PIPING FILTER CHILLED WATER WATER PUMP CHILLER Slide 12

13. 13. TYPICAL ALL-AIR SYSTEM E.A.EXHAUST DAMPER AIR R.A. FAN R.A DUCT R.A. GRILL S.A. S.A.

DUCT TERMINAL R.A. DAMPER COIL COOL AIR FRESHOUTDOOR HEAT AIR S.A. FAN O.A. DAMPER

WATER PIPING FILTER HEAT COOLING TOWER CHILLED WATER WATER PUMP CHILLER

CONDENSER PUMP Slide 13

14. 14. TYPICAL ALL-AIR SYSTEM E.A.EXHAUST DAMPER AIR R.A. FAN R.A DUCT R.A. GRILL S.A. S.A.

DUCT TERMINAL R.A. DAMPER COIL COOL AIR FRESHOUTDOOR HEAT AIR S.A. FAN O.A. DAMPER

WATER PIPING FILTER HEAT BOILER COOLING TOWER CHILLED WATER WATER PUMP CHILLER

CONDENSER PUMP Slide 14

15. 15. Equipment Types ROOFTOP PACKAGE UNIT SPLIT SYSTEM CHILLED WATER AIR HANDLER

VARIABLE AIR VOLUME (VAV) AIR TO AIR HEAT PUMP Life expectancy 10 to 12 yrs for rooftop and

split systems Expect increase in repair costs as equipment ages Typically largest expense to operation of

store, energy/repair costs Repair or Replace? Slide 15

16. 16. Single Package Roof Top UnitMost commonEntire hvac system islocated on mall roofMost common to

haveroof leaks from roof curb,condensate overflow orroof punctures Slide 16

17. 17. Single Package Roof Top Unit HEAT COMP CONDR ELECTRIC COIL HEATERO.A. FANE.A. S.A.

DUCT S.A. R.A. DUCT TERMINAL HEAT Slide 17

18. 18. Single Package Roof Top Unit Rooftop package unit Mounted on adaptor curb Power exhaust and

economizer installed Slide 18

19. 19. Split System HVAC system split into 2 pieces Condensing unit located on roof (houses compressor,

condenser coil, condenser fan motor) Air handler located in space above ceiling (houses blower assembly,

evap coil, air filters) Connected electrically and with refrigerant piping Most prone to refrigerant leaks

especially if long distance between components Many times refrigerant lines are buried in construction and

inaccessible Slide 19

20. 20. SPLIT SYSTEM CONDENSING UNIT HEAT REFRIGERANT C LINES C O O N M AIR P D R AIR

HANDLING UNIT COILO.A. POSSIBLE FAN ELECTRIC HEATE.A. S.A. DUCT R.A. DUCT HEAT

OPTIONAL SUPPLEMENTARY HEATING SYSTEM Slide 20

21. 21. SPLIT SYSTEM Slide 21

22. 22. Split System Air cooled condensing unit Compressor, condenser coil and condenser fans Connected

to indoor air handler Slide 22

23. 23. VAV BOXConsists of VAV terminal Variable Air Volumebox located in the spaceabove ceilingMay have

supplementalblower motor for positiveairflow to spaceMay have air filtrationHas a damper inside thatopens

and closes on demandfrom thermostat to allowmore or less airflow tospace Slide 23

24. 24. Major System Components Compressor Condenser coil Evaporator coil Condenser fan motor

Evaporator fan motor Thermostatic expansion valve Evaporator blower assembly Economizers (Optional)

Slide 24

25. 25. HEAT REJECTION 95F DB (HIGH TEMPERATURE) 78F DB HEAT 95F 105F CONDENSER

CONDITIONED SPACE 85F COOLING TOWER COMPRESSOR95F 55F 75F 35F COOLER 45F

REFRIGERATION MACHINE HEAT GATHERING (REFRIGERATION CYCLE) (LOW TEMPERATURE)

Slide 25

26. 26. Compressor This component is the heart of the system.. Pumps refrigerant and oil throughout system

Separates the high pressure side of the system from the low pressure side If compressor fails, no cooling is

possible Slide 26

27. 27. Condenser Condenser coil is what gets rid of the heat in the system Can be water or air cooled,

however most are air cooled in retail application Located outdoors (air cooled) Fins on coil are subject to

corrosion in salt water environment. Special coatings can be applied. Fins are subject to damage from hail

Traps dirt and requires periodic cleanings Slide 27

28. 28. Evaporator Coil Provides cold air to the space Located after the system air filters Return air is blown

over the coil and chilled Removes moisture from air (condensate) Traps dirt that gets past air filters,

reducing cooling capacity (95% is bacterial) Requires periodic chemical cleaning Slide 28

29. 29. Evaporator Fan Motor Located behind condenser coil Draws ambient air across condenser coil

System may have up to 4 or more motors based on system capacity Motors are direct drive with fan blades

attached Requires little if any maintenance (sealed bearings) Slide 29

30. 30. TXV Thermal Expansion Valve Located at the evaporator coil Provides the correct amount of

refrigerant to the evaporator coil for proper cooling Separates the high pressure side of the system from the

low pressure side Failure could cause compressor failure and loss of system cooling capacity Frequently

overlooked in diagnosing system problems Requires manual setting of superheat for proper operation. Slide

30

31. 31. Evaporator Blower Assembly Consists of: Blower motor Pulleys and fan belts Bearings Fan shaft

Fan wheels Housings Can be located indoors or outdoors Slide 31

32. 32. Control Types CONVENTIONAL THERMOSTAT DIGITAL PROGRAMMABLE THERMOSTAT

PNEUMATIC LCD SYSTEM MALL INTERFACE Slide 32

33. 33. Low Ambient Controls Low ambient controls May be added to air cooled systems that must operate

when outdoor temperatures are below 55 degrees Cycles condenser fan/s to maintain correct system

pressures Used when economizer is not present Much less costly to install Much more costly to operate

Slide 33

34. 34. Conventional Thermostat Completely manual operation Will maintain a single heat or cool setting

System must be switched from heat to cool No energy savings Will allow system to operate all night while

store is closed wasting energy Easy to tamper with Least expensive to install Slide 34

35. 35. Programmable Thermostat Provides auto changeover from heat to cool Provides up to 4 heat/cool

settings per 24 hour period Can provide different weekend settings Keyboard can be locked out Set it and

forget it Slide 35

36. 36. Pneumatic Thermostat Uses air provided by mall to operate thermostat Very commonly used with VAV

systems Least commonly found in malls Parts are fairly expensive Slide 36

37. 37. LCD Thermostat Used in newer stores Programmable type Can be dialed into by monitoring company

for data Slide 37

38. 38. Rules Of Thumb1HP = 1KW = 1KVA 1KW = 3413 BTU1 Ton Cooling = 12,000 BTU 1 Ton = 400

CFMRetail = 380 SQ FT/ Ton coolingDelta T = 18 F across coil cooling Delta T = 25 F for heating CFM =

Building Volume in Cubic Feet Minute/Air Change Delta T = Difference between entering and leaving DB =

T Slide 39

39. 39. Servpro of Great Neck / Port Washington For Further Information Please Contact Us: 516-767-9600

ServproOfGreatNeck.com Slide 40

Anda mungkin juga menyukai

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Reheat and Regenerative Rankine Cycle: Presented by M.Suriyaprakash AP/MechDokumen12 halamanReheat and Regenerative Rankine Cycle: Presented by M.Suriyaprakash AP/MechVasanth KumarBelum ada peringkat

- OS-02-24 - Ashrae Journal Hybrid VentilationDokumen18 halamanOS-02-24 - Ashrae Journal Hybrid VentilationHnin PwintBelum ada peringkat

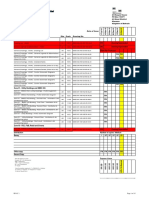

- Drawing Register & Transmittal Drawing Register & Transmittal Drawing Register & Transmittal Drawing Register & TransmittalDokumen13 halamanDrawing Register & Transmittal Drawing Register & Transmittal Drawing Register & Transmittal Drawing Register & Transmittalsachin231979Belum ada peringkat

- DBKB Kirim KJPP Okt'13Dokumen5 halamanDBKB Kirim KJPP Okt'13arsushanBelum ada peringkat

- Solar Energy: Zongwei Han, Xiaomei Ju, Lejian Qu, Jiangzhen Liu, Xiao Ma, Shuiwei ZhangDokumen8 halamanSolar Energy: Zongwei Han, Xiaomei Ju, Lejian Qu, Jiangzhen Liu, Xiao Ma, Shuiwei ZhangChatchai MikeBelum ada peringkat

- LG Multi V IV - Kanalne (Low Static)Dokumen1 halamanLG Multi V IV - Kanalne (Low Static)Muhidin KozicaBelum ada peringkat

- Supplier Database 2018Dokumen113 halamanSupplier Database 2018Islam SolimanBelum ada peringkat

- Refrigeration Cycle ExperimentDokumen10 halamanRefrigeration Cycle ExperimentJay NgBelum ada peringkat

- Copra Oil Mill Process FlowDokumen3 halamanCopra Oil Mill Process FlowJohn WilrichBelum ada peringkat

- Air Conditioning System (Presentation 1)Dokumen26 halamanAir Conditioning System (Presentation 1)dreamst4rBelum ada peringkat

- VRF Directory AHRI CertifiedDokumen66 halamanVRF Directory AHRI CertifiedsachinmangrulkarBelum ada peringkat

- Freezer: Cooling Thermally Insulated Heat Pump Food Storage TechniqueDokumen24 halamanFreezer: Cooling Thermally Insulated Heat Pump Food Storage TechniquegowthammuthusamyBelum ada peringkat

- RJ1802 WebDokumen92 halamanRJ1802 WebPaulo FerreiraBelum ada peringkat

- 機編號Metallic Blower Version PDFDokumen2 halaman機編號Metallic Blower Version PDFRyan WongBelum ada peringkat

- Carrier 466Dokumen40 halamanCarrier 466Raul E. SoliBelum ada peringkat

- AHU Owners ManualDokumen84 halamanAHU Owners ManualTom MurphyBelum ada peringkat

- Ventilation System Comparison - Constant Air Volume (CAV) and Variable Air Volume (VAV)Dokumen15 halamanVentilation System Comparison - Constant Air Volume (CAV) and Variable Air Volume (VAV)ankurBelum ada peringkat

- Industrial Heat Pump Brochure July 2017 PDFDokumen4 halamanIndustrial Heat Pump Brochure July 2017 PDFfrikkie@Belum ada peringkat

- Ansi Ashrae Acca 183-2007 (Ra 2014)Dokumen10 halamanAnsi Ashrae Acca 183-2007 (Ra 2014)Ahmed Labib100% (3)

- D-Mart Mysore PPT - (11-02-2020)Dokumen11 halamanD-Mart Mysore PPT - (11-02-2020)Raju KsnBelum ada peringkat

- 30XA Product Data PDFDokumen36 halaman30XA Product Data PDFanoopkumar1231150100% (2)

- Inspection Checklist Solar Water HeatersDokumen4 halamanInspection Checklist Solar Water HeatersREMYABelum ada peringkat

- Cooling Load Rough Calculation (Clean RM & Normal) - 1Dokumen3 halamanCooling Load Rough Calculation (Clean RM & Normal) - 1api-266996130% (2)

- Car Park VentilationDokumen3 halamanCar Park VentilationBayhonElmer67% (3)

- Ahu DesignDokumen17 halamanAhu DesignMohamed Aboobucker Mohamed IrfanBelum ada peringkat

- Installation ManualDokumen120 halamanInstallation ManualAmyt SrivastavBelum ada peringkat

- TE 5311 Technical Seminar - IIDokumen18 halamanTE 5311 Technical Seminar - IIRaghul AravinthBelum ada peringkat

- Cassette YCKW BB PDFDokumen2 halamanCassette YCKW BB PDFar013108Belum ada peringkat

- Technical Training CoilsDokumen46 halamanTechnical Training CoilsrasheedillikkalBelum ada peringkat

- Dr. Eugene A. Ermac: Refrigeration & Air ConditioningDokumen41 halamanDr. Eugene A. Ermac: Refrigeration & Air ConditioningGalvez ChaCha100% (1)