Properties For Design

Diunggah oleh

sharath1199Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Properties For Design

Diunggah oleh

sharath1199Hak Cipta:

Format Tersedia

Chapter

5

Engineering Properties of Soil and Rock

5.1 General

The purpose of this chapter is to identify appropriate methods of geotechnical soil and rock property

assessment to establish engineering parameters for geotechnical design. Geotechnical soil and rock

design parameters should be based on the results of a complete geotechnical investigation, which

includes in-situ field-testing and/or a laboratory-testing program, used separately or in combination.

The geotechnical engineer should determine which geotechnical soil and rock design parameters are

critical to project design - and then determine these critical parameters to an acceptable level of

accuracy. Chapter 2 provides guidance on how to plan a geotechnical investigation.

The detailed measurement and interpretation of soil and rock properties should be consistent with the

guidelines provided in Sabatini, et al, (FHWA, April 2002).

The focus of geotechnical design property assessment and final selection should be on the individual

geologic strata identified at the project site. A geologic stratum is characterized as having the same

geologic depositional history and stress history, and generally has similarities throughout the stratum

in terms of density, source material, stress history, and hydrogeology. It should be recognized that

the properties of a given geologic stratum at a project site are likely to vary significantly from point to

point within the stratum. In some cases, a measured property value may be closer in magnitude to

the measured property value in an adjacent geologic stratum than to the measured properties at

another point within the same stratum. However, soil and rock properties for design should not be

averaged across multiple strata. It should also be recognized that some properties (e.g., undrained

shear strength in normally consolidated clays) may vary as a predictable function of a stratum

dimension (e.g., depth below the top of the stratum). Where the property within the stratum varies in

this manner, the design parameters should be developed taking this variation into account, which

may result in multiple values of the property within the stratum as a function of a stratum dimension

such as depth.

Oregon Department of Transportation 5-1

Geotechnical Design Manual

December 2016

5.2 Influence of Existing and Future Conditions on

Soil and Rock Properties

Geotechnical soil properties used for design are not intrinsic to soil type, but vary depending on

factors, including in-situ soil stresses, groundwater level, seepage forces, and the rate and direction

of foundation loading. Prior to evaluating geotechnical soil properties, it is important to determine how

existing site conditions may change over the life of the project. For example, future construction, such

as new embankments, may place new surcharge loads on the soil profile. It may be necessary to

determine how geotechnical soil properties of geologic strata will change over the design life of the

project. Over time, normally consolidated clays can gain strength with increased effective soil

stresses, over-consolidated clays in cut slopes may lose strength, and embankments composed of

weak rock may lose strength.

5.3 Methods of Determining Soil and Rock

Properties

Geotechnical soil and rock properties of geologic strata are typically determined using one or more of

the following methods:

In-situ testing data from the field exploration program;

Laboratory testing; and

Back analysis based on site performance data.

The most common in-situ test methods are the Standard Penetration Test (SPT) and Electronic

Piezocone Penetrometer Test (CPTu). Other in-situ tests, such as the Pressuremeter, Flat

Dilatometer, and Vane Shear are used less frequently. In-situ tests for rock, including Borehole

Dilatometer, Borehole Jack, Plate Load Test, and Direct Shear Test, are rarely performed.

A variety of laboratory tests to directly measure specific soil and rock engineering properties are

discussed in Sabatini, et al (FHWA, 2002).

Laboratory geotechnical soil and rock-testing programs may utilize soil and rock engineering index

tests with established empirical correlations to estimate preliminary engineering properties of soil and

rock. However, final geotechnical designs should be based on direct measurement of specific soil

and rock engineering properties as discussed in Sabatini, et al (FHWA, 2002).

The observational method, or use of back analysis, may be helpful to estimate the approximate

engineering properties of soil or rock units based on measurement of with slope failures,

embankment settlement, or settlement of existing structures.

Landslides or slope failures: With landslides or slope failures, the process generally starts

with determining the geometry of the failure and then determining the soil/rock parameters or

subsurface conditions that cause the safety factor to approach 1.0. Often the determination of

the back-calculated properties is aided by correlations with index tests or experience on other

projects.

Embankment settlement: For embankment settlement, a range of soil properties is

generally determined based on laboratory performance testing on undisturbed samples.

Monitoring of fill settlement and pore pressure in the soil during construction allows the soil

properties and prediction of the rate of future settlement to be refined.

Oregon Department of Transportation 5-2

Geotechnical Design Manual

December 2016

Structure settlement: For structures such as bridges that experience unacceptable

settlement or retaining walls that have excessive deflection, the engineering properties of the

soils can sometimes be determined if the magnitudes of the loads are known. As with slope

stability analysis, the geometry of the subsurface soil must be adequately known, including

the history of the groundwater level at the site.

5.4 In-Situ Field Testing

Methods, standards, and typical applications regarding in-situ field tests, such as the Standard

Penetration Test (SPT) and Electronic Piezocone Penetrometer Test (CPTu), are provided in

Sabatini, et al (FHWA, 2002) and ASTM (www.astm.org).

In general, correlations between SPT N-values and geotechnical soil properties (i.e., soil peak friction

angle, in-place density, etc.) should only be used for granular, cohesionless soils (Sand or Gravel).

However, Gravel particles can plug the sampler, resulting in higher blow counts and over-estimation

of soil friction angles. SPT N-values are not recommended to determine geotechnical soil properties

of Silt or Clay soils. See Chapter 6 for more information regarding the use of N-values for liquefaction

analysis.

SPT N-values should be corrected for hammer efficiency in accordance with section 4.4.3 of

Sabatini, et al (FHWA, 2002).

ODOT requires that all hammers have an energy measurement performed at the time of drilling of a

boring. Hammer efficiency should be supplied with the boring log.

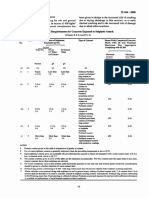

The following values for energy ratios (ER) may be assumed if hammer specific data are not

available:

ER = 60% for conventional drop hammer using rope and cathead

ER = 80% for automatic trip hammer

Hammer efficiency (ER) for specific hammer systems used in local practice may be used in lieu of

the values provided. If used, specific hammer system efficiencies shall be developed in general

accordance with ASTM D-4945 for dynamic analysis of driven piles or another accepted procedure.

Corrections for rod length, hole size, and use of a liner may also be made, if appropriate. In general,

these are only significant in unusual cases or where there is significant variation from standard

procedures. These corrections may be significant for evaluation of liquefaction. Information on these

additional corrections may be found in: Proceedings of the NCEER Workshop on Evaluation of

Liquefaction Resistance of Soils; Publication Number: MCEER-97-0022; T.L. Youd, I.M. Idriss

(1997) and in Cetin, K., Seed, R., et al.

N-values are also affected by overburden pressure, and in general should be corrected for that effect,

if applicable to the design method or correlation being used. N-values corrected for both overburden

and the efficiency of the field procedures used shall be designated as N1(60) as stated in Sabatini, et

al. (2002).

Methods, standards, and typical applications regarding in-situ field tests regarding field measurement

of permeability is presented in Sabatini, et al (FHWA, 2002), and ASTM D 4043. If in-situ test

methods are utilized to determine hydraulic conductivity, one or more of the following methods should

be used:

Oregon Department of Transportation 5-3

Geotechnical Design Manual

December 2016

Well pumping tests

Packer permeability tests

Seepage Tests

Slug tests

Piezocone tests

5.5 Laboratory Testing of Soil and Rock

The primary purpose of laboratory testing is to measure physical soil and rock properties utilizing

standard repeatable procedures to analyze soil or rock behavior under proposed ground loading

conditions. Laboratory test data are also used to check field soil and rock classifications from the

subsurface field exploration program. Details regarding specific types of laboratory tests and their use

are provided in Sabatini, et al (FHWA, 2002).

Improper storage, transportation, and handling of in-situ soil and rock samples can significantly alter

their laboratory -tested geotechnical engineering properties. Quality control (QA) requirements are

provided in Mayne, et al. (FHWA, 1997). Laboratories conducting geotechnical testing shall be

appropriately accredited by ODOT and compliant with all rules, for qualifying testers, calibrating and

verifications of testing equipment.

5.6 Engineering Properties of Soil

5.6.1 Laboratory Testing

Laboratory soil testing is used to estimate strength, stress\strain, compressibility, and permeability

characteristics. See Sabatini, et al. (FHWA, 2002) and Section 10, AASHTO LRFD (2014) for specific

guidance and requirements regarding laboratory testing.

Soil strength tests shall be performed on high quality, relatively undisturbed in-situ specimens.

However, it is difficult and frequently impossible to sample, transport, extrude and set-up testing for

granular, cohesionless soils (Sand or Gravel) without excessively disturbing or completely obliterating

the soil specimen.

5.6.1.1 D i s t ur be d S t r e n g t h T e s t i n g

Disturbed soil strength testing can be used to provide approximate strength data for back-analysis of

existing slopes, or to provide strength data for final stability design and construction quality assurance

of fill placement for highway earthwork and embankment materials.

Strength testing of compacted backfill generally yields good results since the soil placement method,

as well as the in-situ density and moisture content, can be accurately recreated in the laboratory with

a high degree of reliability.

It is difficult to obtain good strength values through lab testing of disturbed (remolded) specimens

since the soil matrix (i.e., cohesion/ bonding of soil particles) is destroyed and the in-situ density and

moisture content are very difficult to recreate. The inaccuracy of this technique must be recognized

when interpreting the test results.

5.7 Engineering Properties of Rock

Engineering properties of rock are generally controlled by the discontinuities within the rock mass and

not the properties of the intact material. Therefore, engineering properties for the rock mass must be

reduced from the measured properties of the intact pieces to account for defects in the rock mass

Oregon Department of Transportation 5-4

Geotechnical Design Manual

December 2016

as a whole - specifically considering discontinuities within the rock mass. A combination of laboratory

testing of small samples, empirical analysis, and field observations should be employed to determine

the engineering properties of rock masses - with greater emphasis placed on visual observations and

quantitative descriptions of the rock mass.

Rock properties can be divided into two categories: intact rock properties and rock mass properties.

Intact rock: Intact rock properties are determined from laboratory tests on small samples

typically obtained from coring, outcrops, or exposures along existing cuts. Engineering

properties typically obtained from laboratory tests include specific gravity, unit weight, point

load, and compressive strength.

Rock mass properties: Rock mass properties are determined by visual examination and

measurement of discontinuities within the rock mass, and how these discontinuities will affect

the behavior of the rock mass when subjected to the proposed construction.

The methodology and related considerations provided by Sabatini, et al (FHWA, 2002) should be

used to assess the design properties for the intact rock and the rock mass - except fractured rock

mass shear strength parameters should be in accordance with Hoek, et al. (2002). This updated

method uses a Geological Strength Index (GSI) to characterize rock mass for estimating strength

parameters, and has been developed based on re-examination of hundreds of tunnel and slope

stability analyses in which both the 1988 and 2002 criteria were used and compared to field results.

Hoek, et al. (2002) is considered the most accurate methodology and should be used for estimating

fractured rock mass shear strength determination. Note that this method is only to be used for highly

fractured rock masses in which the stability of the rock slope is not structurally controlled.

5.8 Final Selection of Design Values

The geotechnical designer should review the quality and consistency of the field and laboratory

testing data and determine if the results are consistent with expectations based on experience from

other projects in the area or in similar soil/rock conditions.

Inconsistencies between laboratory test results should be examined to determine possible causes

and develop procedures to correct, exclude, or downplay the significance of any suspect data.

Chapter 8 of Sabatini, et al. (FHWA, 2002) outlines a systematic procedure for analyzing data and

resolving these inconsistencies.

Engineering judgment, combined with parametric analyses as needed, will be needed to make the

final assessment and determination of each design property. This assessment should include a

decision as to whether the final design value selected should reflect the interpreted average value for

the property, or a value that is somewhere between the most likely average value and the most

conservative estimate of the property. Design property selection should achieve a balance between

the desire for design safety, cost effectiveness, and constructability of the design.

Depending on the availability of soil or rock property data and the variability of the geologic strata

under consideration, it may not be possible to reliably estimate the average value of the properties

needed for design. In such cases, the geotechnical designer may have no choice but to use a more

conservative selection of design parameters to mitigate the additional risks created by potential

variability or the paucity of relevant data. Note that for those resistance factors that were determined

Oregon Department of Transportation 5-5

Geotechnical Design Manual

December 2016

based on calibration by fitting to allowable stress design, this property selection issue is not relevant,

and property selection should be based on the considerations discussed previously.

The process and examples to make the final determination of properties to be used for design

provided by Sabatini, et al. (FHWA, 2002) should be followed.

5.9 Development of the Subsurface Profile

The development of design property values should begin and end with the development of the

subsurface profile. Test results and boring logs will likely be revisited several times as the data is

developed and analyzed before the relation of the subsurface units to each other and their

engineering properties are finalized.

The ultimate goal of a subsurface investigation is to develop a working model that depicts major

subsurface layers exhibiting distinct engineering characteristics.

The end product is the subsurface profile, a two dimensional depiction of the site stratigraphy. The

following steps outline the creation of the subsurface profile:

1. Complete the field and lab work and incorporate the data into the preliminary logs.

2. Lay out the logs relative to their respective field locations and compare and match up the

different soil and rock units at adjacent boring locations, if possible. However, caution should

be exercised when attempting to connect units in adjacent borings, as the geologic

stratigraphy does not always fit into nice neat layers. Field descriptions and engineering

properties will aid in the comparisons.

3. Group the subsurface units based on engineering properties.

4. Create cross sections by plotting borings at their respective elevations and positions

horizontal to one another with appropriate scales. If appropriate, two cross sections should be

developed that are at right angles to each other so that lateral trends in stratigraphy can be

evaluated when a site contains both lateral and transverse extents (i.e. a building or large

embankment).

5. Analyze the profile to see how it compares with expected results and knowledge of geologic

(depositional) history. Have anomalies and unexpected results encountered during

exploration and testing been adequately addressed during the process? Make sure that all of

the subsurface features and properties pertinent to design have been addressed.

Oregon Department of Transportation 5-6

Geotechnical Design Manual

December 2016

5.10 References

AASHTO, 2014, LRFD Bridge Design Specifications, American Association of State

Transportation and Highway Officials, 6th Edition (with current Interims), Washington, D.C.,

USA.

Allen, T. M., Kilian, A. P., 1993, Use of Wood Fiber and Geotextile Reinforcement to Build

Embankment Across Soft Ground, Transportation Research Board Record 1422.

Hoek, E., and Brown, E.T. 1988. The Hoek-Brown Failure Criterion a 1988 Update.

Proceedings, 15th Canadian Rock Mechanics Symposium, Toronto, Canada.

Hoek, E., Carranza-Torres, C., and Corkum, B., 2002, Hoek-Brown Criterion 2002 Edition,

Proceedings NARMS-TAC Conference, Toronto, 2002, 1, pp. 267-273.

Kilian, A. P., Ferry, C. D., 1993, Long Term Performance of Wood Fiber Fills, Transportation

Research Board Record 1422.

Mayne, P. W., Christopher, B. R., DeJong, J., 1997, FHWA-HI-97-021, Subsurface

Investigations, NHI course manual #13201.

Phoon, K.-K., Kulhawy, F. H., Grigoriu, M. D., 1995, Reliability-Based Design of Foundations

for Transmission Line Structures, Report TR-105000, Electric Power Research Institute, Palo

Alto, CA.

Sabatini, P. J., Bachus, R. C., Mayne, P. W., Schneider, T. E., Zettler, T. E., U.S. Department

of Transportation, Federal Highway Administration Evaluation of Soil and Rock Properties,

Geotechnical Engineering Circular No. 5, FHWA-IF-02-034, April, 2002

Oregon Department of Transportation 5-7

Geotechnical Design Manual

December 2016

Anda mungkin juga menyukai

- 1647Dokumen10 halaman1647sharath1199Belum ada peringkat

- Resumen de Las Corridas en Flac 3d y Su Aplicacion Segun El Tipo de Caso A Analizar IIDokumen2 halamanResumen de Las Corridas en Flac 3d y Su Aplicacion Segun El Tipo de Caso A Analizar IIGilberGarayBelum ada peringkat

- Flac 3D 2Dokumen2 halamanFlac 3D 2Robert AguedoBelum ada peringkat

- Flac 3D 2Dokumen2 halamanFlac 3D 2Robert AguedoBelum ada peringkat

- Classification Procedures For Expansive SoilsDokumen7 halamanClassification Procedures For Expansive Soilsdr uday kulkarniBelum ada peringkat

- Load CalculationsDokumen179 halamanLoad Calculationssharath1199Belum ada peringkat

- Is Code For Design of Raft FoundationDokumen30 halamanIs Code For Design of Raft FoundationprashantkothariBelum ada peringkat

- FTDDokumen188 halamanFTDsharath1199Belum ada peringkat

- AGMU 09.1-Seismic Site Class Definition PDFDokumen15 halamanAGMU 09.1-Seismic Site Class Definition PDFsharath1199Belum ada peringkat

- Non Dimensional CircuitDokumen13 halamanNon Dimensional Circuitsharath1199Belum ada peringkat

- Irc 45 - 1972Dokumen36 halamanIrc 45 - 1972kapinjal_Belum ada peringkat

- CPT Theory ManualDokumen18 halamanCPT Theory ManualBhavin ShahBelum ada peringkat

- Mpirical Estimation of Rock Mass Modulus: by E. Hoek and M.S. DiederichsDokumen3 halamanMpirical Estimation of Rock Mass Modulus: by E. Hoek and M.S. Diederichsmilan1115-Belum ada peringkat

- Comparison of Slope Stability Analysis by Various Numerical MethodsDokumen1 halamanComparison of Slope Stability Analysis by Various Numerical Methodssharath1199Belum ada peringkat

- V/AsuDokumen11 halamanV/Asusharath1199Belum ada peringkat

- Privileges of Institutional MembersDokumen3 halamanPrivileges of Institutional MembersAFIA S HAMEED CEBelum ada peringkat

- Adinfm PDFDokumen12 halamanAdinfm PDFsharath1199Belum ada peringkat

- IS 456:2000 Cement Content Limitations for Concrete Exposed to Sulphate AttackDokumen1 halamanIS 456:2000 Cement Content Limitations for Concrete Exposed to Sulphate Attacksharath1199Belum ada peringkat

- VSL Retaining Walls PDFDokumen28 halamanVSL Retaining Walls PDFShaileshRastogiBelum ada peringkat

- Socketing Depth of Piles in RockDokumen4 halamanSocketing Depth of Piles in RockNAUTILUS87100% (1)

- Is 458 2003Dokumen39 halamanIs 458 2003somnathjoyBelum ada peringkat

- Pressure Dispersion From A PreloadedDokumen4 halamanPressure Dispersion From A Preloadedsharath1199Belum ada peringkat

- Irc 45 - 1972Dokumen36 halamanIrc 45 - 1972kapinjal_Belum ada peringkat

- Eng 2016051214110132 PDFDokumen12 halamanEng 2016051214110132 PDFRelu MititeluBelum ada peringkat

- Unit ConversionDokumen15 halamanUnit Conversionsharath1199Belum ada peringkat

- Vertical StressDokumen5 halamanVertical Stresssharath1199Belum ada peringkat

- 4A-1 - A39 - AASHTO LRFD Methodologies For Drilled ShaftDokumen34 halaman4A-1 - A39 - AASHTO LRFD Methodologies For Drilled Shaftsilvereyes18Belum ada peringkat

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5782)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (72)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- A Scanner Data User Survey of 50 Companies Found T...Dokumen2 halamanA Scanner Data User Survey of 50 Companies Found T...BLESSEDBelum ada peringkat

- SG7003 Business Simulation Evaluation and ReflectionDokumen8 halamanSG7003 Business Simulation Evaluation and ReflectionPreethu Gowda0% (1)

- CHEM I 17 Acid Base Titrations OpenDokumen4 halamanCHEM I 17 Acid Base Titrations OpenAchinthya PereraBelum ada peringkat

- The Rcwa Method PDFDokumen28 halamanThe Rcwa Method PDFYuchiangBelum ada peringkat

- Imdb QuestionsDokumen4 halamanImdb QuestionsRahulBelum ada peringkat

- Social Marketing by ITCDokumen32 halamanSocial Marketing by ITCKavita TiwariBelum ada peringkat

- COGNATE209 ReportCURRICULUM DEVELOPMENT AND RECENT TRENDSDokumen2 halamanCOGNATE209 ReportCURRICULUM DEVELOPMENT AND RECENT TRENDSedward_sheed28Belum ada peringkat

- Caesar II Modeling ExcisersDokumen40 halamanCaesar II Modeling ExcisersBùi Văn Hợp100% (2)

- Assessment Task 4: Market Research Evaluation Project Draft Evaluation ReportDokumen3 halamanAssessment Task 4: Market Research Evaluation Project Draft Evaluation ReportnattyBelum ada peringkat

- Ortoll Group of Companies: Checklist of Pre-Employment RequirementsDokumen1 halamanOrtoll Group of Companies: Checklist of Pre-Employment RequirementsAnton FortichBelum ada peringkat

- Q3 JHS Pre TestDokumen6 halamanQ3 JHS Pre Test-09876543123456789Belum ada peringkat

- Structure and Content of Research ProposalDokumen46 halamanStructure and Content of Research ProposalNeølie Abello LatúrnasBelum ada peringkat

- Surgical Audit and Peer Review Guide 2014Dokumen54 halamanSurgical Audit and Peer Review Guide 2014juweriyBelum ada peringkat

- Company Profile PT. Rekanusa Pracipta KonsultindoDokumen17 halamanCompany Profile PT. Rekanusa Pracipta KonsultindoAhmad Renaldy JuraisBelum ada peringkat

- International Journal of Clinical and Health Psychology 1697-2600Dokumen15 halamanInternational Journal of Clinical and Health Psychology 1697-2600choliidBelum ada peringkat

- Recommended Format for Mechanics of Solids Lab ReportsDokumen26 halamanRecommended Format for Mechanics of Solids Lab ReportsDileepBelum ada peringkat

- Artigo Zumbido Com e Sem Perda AudDokumen8 halamanArtigo Zumbido Com e Sem Perda AudTatiana OliveiraBelum ada peringkat

- Validation of People-Dependent ProcessesDokumen2 halamanValidation of People-Dependent ProcessesAngel CvetanovBelum ada peringkat

- Chapter 5Dokumen751 halamanChapter 5bersam05Belum ada peringkat

- The Impact of Parenting Styles of Primary Caregiver On Emotional Intelligence and Resilience of Adolescents in MumbaiDokumen54 halamanThe Impact of Parenting Styles of Primary Caregiver On Emotional Intelligence and Resilience of Adolescents in MumbaiRajshree FariaBelum ada peringkat

- Research Paper Title-Is Service Differentiation NecessaryDokumen27 halamanResearch Paper Title-Is Service Differentiation Necessaryaditya ranjanBelum ada peringkat

- Logistic Regression Modeling for Binary Outcome PredictionDokumen10 halamanLogistic Regression Modeling for Binary Outcome PredictionNikhil GandhiBelum ada peringkat

- Kanbur y Venables. (2005)Dokumen435 halamanKanbur y Venables. (2005)yelida blancoBelum ada peringkat

- (M2S2-POWERPOINT) Control Self-Assessment (CSA) and Evaluating The Internal Audit ActivityDokumen18 halaman(M2S2-POWERPOINT) Control Self-Assessment (CSA) and Evaluating The Internal Audit ActivityJayson J. ManlangitBelum ada peringkat

- Qualitative Versus Quantitative Research: Key Points in A Classic DebateDokumen6 halamanQualitative Versus Quantitative Research: Key Points in A Classic DebateKumarSriAmanBelum ada peringkat

- Nursing Informatics in EBPDokumen61 halamanNursing Informatics in EBPKristle Ann VillarealBelum ada peringkat

- Misuse of Cohesive Devices in Students' Argumentative Essay WritingDokumen21 halamanMisuse of Cohesive Devices in Students' Argumentative Essay WritingThảo NhiBelum ada peringkat

- Suruchi Project NestlyDokumen6 halamanSuruchi Project Nestlylakshit pushkarnaBelum ada peringkat

- Final Year ProjectDokumen17 halamanFinal Year ProjectHarjeet PathaniaBelum ada peringkat

- BA Module 02 - 2.1 + 2.2Dokumen12 halamanBA Module 02 - 2.1 + 2.2ScarfaceXXXBelum ada peringkat