Assignment 1 17

Diunggah oleh

Danial Ahmed0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

35 tayangan2 halamanThis document contains questions about various printing techniques and processes:

1) It asks about the application of color techniques for different printing styles like block, stencil, roller, screen, spray, resist, discharge, and duplex printing. It also asks about flat bed and rotary screen printing.

2) It defines intaglio effect in printing and asks about the function of a color doctor and croquis in roller printing.

3) It asks about limitations of roller printing, the function of a lint doctor, and the term "diapositives" in screen engraving.

4) It asks about steps for engraving screens for roller printing, factors controlling paste flow in screen printing, and definitions

Deskripsi Asli:

Assignment

Hak Cipta

© © All Rights Reserved

Format Tersedia

DOCX, PDF, TXT atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniThis document contains questions about various printing techniques and processes:

1) It asks about the application of color techniques for different printing styles like block, stencil, roller, screen, spray, resist, discharge, and duplex printing. It also asks about flat bed and rotary screen printing.

2) It defines intaglio effect in printing and asks about the function of a color doctor and croquis in roller printing.

3) It asks about limitations of roller printing, the function of a lint doctor, and the term "diapositives" in screen engraving.

4) It asks about steps for engraving screens for roller printing, factors controlling paste flow in screen printing, and definitions

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai DOCX, PDF, TXT atau baca online dari Scribd

0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

35 tayangan2 halamanAssignment 1 17

Diunggah oleh

Danial AhmedThis document contains questions about various printing techniques and processes:

1) It asks about the application of color techniques for different printing styles like block, stencil, roller, screen, spray, resist, discharge, and duplex printing. It also asks about flat bed and rotary screen printing.

2) It defines intaglio effect in printing and asks about the function of a color doctor and croquis in roller printing.

3) It asks about limitations of roller printing, the function of a lint doctor, and the term "diapositives" in screen engraving.

4) It asks about steps for engraving screens for roller printing, factors controlling paste flow in screen printing, and definitions

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai DOCX, PDF, TXT atau baca online dari Scribd

Anda di halaman 1dari 2

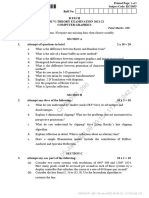

Assignment no 1 ( 2017)

a) Briefly explain the application of color techniques on below styles of printing?

a. Block

b. Stencil

c. Roller

d. Screen Printing

i. Flat Bed Screen Printing?

ii. Rotary Screen Printing?

e. Spray printing

f. Resist printing

g. Discharge printing

h. Duplex printing

b) Define and explain the intaglio effect in printing?

c) What is the function of color doctor on roller printing?

d) What is a Croquis?

e) What are the limitations and disadvantages of roller printing?

f) What is the function of the lint doctor in the above printing technique?

g) Explain the term diapositives in engraving of screens?

h) Discuss the steps of engraving screens being used for roller printing?

i) What variable factors control the amount of paste flow in screen printing?

j) Explain the following printing faults

a. Registration:

Registration It has already been pointed out that accurate

movement of the blanket exactly one screen-repeat distance, each time

it is advanced, is essential for the correct registration of the colours in

the design, and that inadequate adhesion of the fabric to the blanket

will cause local misfitting.

b. Frame marks:

When printing consecutive screen repeats, the screen frame inevitably

falls on part of the area most recently printed and may leave an

impression. This is a particularly difficult problem for blotch screens

where large amounts of print paste are applied.

The problem is reduced in hand screen and semi-automatic screen

printing by printing alternate screen repeats and then moving back to

fill in the gaps, but this is obviously not possible in automatic machines,

since in these the movement of the blanket is always in the same

direction.

To avoid this fault is known as off-contact printing. The screen frame is

lowered to a point only just above the blanket, the gap being so small

that, as the squeegee passes and stretches the screen fabric, the

printing area of the screen makes contact with the fabric being printed.

c. Splashing:

When screens are lifted symmetrically after printing (that is, with the screen

remaining horizontal), print paste in the space beneath the screen can often

remain in contact with the screen momentarily and then splash back on to the

fabric.

This can be avoided, or at least reduced, by lifting the screens at one side just

before the other.

k) Define mesh?

l) Define raster?

m) What are pitch marks?

n) Define the squeegee systems?

o) List and briefly explain the parameters of intermittent movement?

List and briefly explain the parameters affecting the production rate of machines?(flat bed

screen printing)

p) Explain the steps/functions of CAD in the interpretation and development of design for

printing?

q) Explain the three basic design aspects of Repeats? Diagrams appreciated?

r) What is the difference between Step and Repeat?

Anda mungkin juga menyukai

- Slik Screen PrintingDokumen7 halamanSlik Screen PrintingKevin MoshBelum ada peringkat

- Coating Tachnology HandbookDokumen4 halamanCoating Tachnology HandbookteguheafBelum ada peringkat

- Printing With Reactive DyesDokumen8 halamanPrinting With Reactive DyesMonjur MorshedBelum ada peringkat

- Styles & Methods of PrintingDokumen9 halamanStyles & Methods of Printingmdtawhiddewan1Belum ada peringkat

- Study Material - II - Pre Digital Conventional Printing TechniquesDokumen9 halamanStudy Material - II - Pre Digital Conventional Printing TechniquesProtap BallBelum ada peringkat

- AOP Lecture Sheet 01Dokumen7 halamanAOP Lecture Sheet 01Nakib Ibna BasharBelum ada peringkat

- SoftLitho For Dummies 070519Dokumen24 halamanSoftLitho For Dummies 070519Michael DaleyBelum ada peringkat

- SERIGRAFIADokumen7 halamanSERIGRAFIAGustavo DominguezBelum ada peringkat

- Sms Screen Printing Sop 9-26-15 CBDokumen19 halamanSms Screen Printing Sop 9-26-15 CBAnika MishraBelum ada peringkat

- Choosing The Right Emulsion For Your ApplicationDokumen6 halamanChoosing The Right Emulsion For Your ApplicationMichel GarciaBelum ada peringkat

- Hydrographic SDokumen11 halamanHydrographic SRicky FloresBelum ada peringkat

- Screen PrintingDokumen2 halamanScreen PrintingthomasjosephwelshBelum ada peringkat

- Screen Printing Technology Hand BookDokumen57 halamanScreen Printing Technology Hand BookFufa DiribaBelum ada peringkat

- Printing MethodDokumen59 halamanPrinting MethodAbdullah Al Rahad Hossain100% (1)

- Adaptive Unwrapping For Interactive Texture Painting: Takeo Igarashi Dennis CosgroveDokumen9 halamanAdaptive Unwrapping For Interactive Texture Painting: Takeo Igarashi Dennis CosgroveNina DmitrievaBelum ada peringkat

- Vertex Computer Graphics: Exploring the Intersection of Vertex Computer Graphics and Computer VisionDari EverandVertex Computer Graphics: Exploring the Intersection of Vertex Computer Graphics and Computer VisionBelum ada peringkat

- Hidden Surface Determination: Unveiling the Secrets of Computer VisionDari EverandHidden Surface Determination: Unveiling the Secrets of Computer VisionBelum ada peringkat

- DesignTipsVol1 Web Download PDFDokumen14 halamanDesignTipsVol1 Web Download PDFJeffBelum ada peringkat

- Lecture 28 - 34 EngravingDokumen46 halamanLecture 28 - 34 EngravingMujahid MehdiBelum ada peringkat

- Session 3 Review Grade 8 Photoshop Tools IdentificationDokumen2 halamanSession 3 Review Grade 8 Photoshop Tools Identificationyou & me with zkBelum ada peringkat

- Mewt Jury Assignment.Dokumen37 halamanMewt Jury Assignment.Abhivyakti ArunBelum ada peringkat

- Screen PrintingDokumen44 halamanScreen PrintingLKMs HUB100% (1)

- Chapter - 3 - Flexography & Packaging-MAH - 12-2022Dokumen21 halamanChapter - 3 - Flexography & Packaging-MAH - 12-2022ah.flexomasterBelum ada peringkat

- PDFDokumen51 halamanPDFMULYADI100% (1)

- Printing Techniques and Printing DefectsDokumen32 halamanPrinting Techniques and Printing DefectsMeenal GuptaBelum ada peringkat

- Crawling: RystallizationDokumen10 halamanCrawling: Rystallizationpavan4samudralaBelum ada peringkat

- 2012 (V.Sanz, Etc) - Technical Evolution of Ceramic Tile PrintingJIST - 2012 - Art00003 - V - Sanz PDFDokumen7 halaman2012 (V.Sanz, Etc) - Technical Evolution of Ceramic Tile PrintingJIST - 2012 - Art00003 - V - Sanz PDFNguyễn Tri TàiBelum ada peringkat

- 2015 Phillip Reu All About Speckles - Speckle DensityDokumen2 halaman2015 Phillip Reu All About Speckles - Speckle DensityGilberto LovatoBelum ada peringkat

- Baby Lock Ellisimo Gold BLSOG Sewing Machine Instruction ManualDokumen37 halamanBaby Lock Ellisimo Gold BLSOG Sewing Machine Instruction ManualiliiexpugnansBelum ada peringkat

- Screen Printing Circuit Workshop: by Anne-Marie LAVIGNE & Celine MARCQ E - Textile Summer Camp 2014Dokumen17 halamanScreen Printing Circuit Workshop: by Anne-Marie LAVIGNE & Celine MARCQ E - Textile Summer Camp 2014supriyanto sayanBelum ada peringkat

- The Steps of Engraving Screens Being Used For Roller PrintingDokumen1 halamanThe Steps of Engraving Screens Being Used For Roller PrintingDanial AhmedBelum ada peringkat

- Grade 10-COMPUTER 2nd MonthlyDokumen2 halamanGrade 10-COMPUTER 2nd Monthlylloydgail76Belum ada peringkat

- Sentence CombinationDokumen7 halamanSentence CombinationQuyên LụcBelum ada peringkat

- Speedball Screenprinting InstructionsDokumen16 halamanSpeedball Screenprinting InstructionsSally PuddleBelum ada peringkat

- Localized Dyeing Is Called Printing: Key Purpose of PrintingDokumen10 halamanLocalized Dyeing Is Called Printing: Key Purpose of PrintingShailendra MishraBelum ada peringkat

- Trapping Info PDFDokumen50 halamanTrapping Info PDFMichel Portela100% (1)

- TP Solidworks 13 PagesDokumen13 halamanTP Solidworks 13 PagesRedouane KerrajBelum ada peringkat

- MAPEH Q3 Week6 Sikscreen PrintingDokumen17 halamanMAPEH Q3 Week6 Sikscreen PrintingJoan SikatBelum ada peringkat

- Printing Ink Problems-Causes and RemediesDokumen21 halamanPrinting Ink Problems-Causes and Remediestiga_blas100% (3)

- Semiautomatic Hosiery Printing Machine: Ananthi K, Priyadharshini R, Arun Kumar P.M, Indirapriyadharshini J, Jaipraba VDokumen5 halamanSemiautomatic Hosiery Printing Machine: Ananthi K, Priyadharshini R, Arun Kumar P.M, Indirapriyadharshini J, Jaipraba VSaha Sanjeeb sancharBelum ada peringkat

- ManeulDokumen48 halamanManeulAndriwOchoaBelum ada peringkat

- Get Production Rolling With Rotary Screen PrintingDokumen8 halamanGet Production Rolling With Rotary Screen PrintingK.SaravananBelum ada peringkat

- Lab3 Winter2016Dokumen3 halamanLab3 Winter2016ENBelum ada peringkat

- The Influence of The Structure of The Offset Rubber On The Screen ReproductionDokumen10 halamanThe Influence of The Structure of The Offset Rubber On The Screen Reproductionlaucoy25Belum ada peringkat

- Unit II Principles of Printing ProcessesDokumen11 halamanUnit II Principles of Printing ProcessesMirza MughalBelum ada peringkat

- Screen Printing Technology Hand BookDokumen10 halamanScreen Printing Technology Hand Bookspsubash4409Belum ada peringkat

- Screen PrintingDokumen8 halamanScreen PrintingRumitBelum ada peringkat

- VOF Ansys Fluent TutorialDokumen30 halamanVOF Ansys Fluent TutorialFawwaz MananBelum ada peringkat

- DTP PM Ps Ms in OtDokumen60 halamanDTP PM Ps Ms in OtTekchand RajputBelum ada peringkat

- Printing TechnologyDokumen27 halamanPrinting TechnologySunil DarjiBelum ada peringkat

- Karis Nanite SIGGRAPH Advances 2021 FinalDokumen155 halamanKaris Nanite SIGGRAPH Advances 2021 FinalMarko FucekBelum ada peringkat

- Blanket For Offset Printing - Offset Printing Technology - Offset LithographyDokumen3 halamanBlanket For Offset Printing - Offset Printing Technology - Offset Lithographyvarol66Belum ada peringkat

- Product Surfacing With T-Splines and Parametric Solid Modeling ToolsDokumen5 halamanProduct Surfacing With T-Splines and Parametric Solid Modeling ToolsAndy ReynoldsBelum ada peringkat

- Review Questions: ScreeningDokumen2 halamanReview Questions: ScreeningJohn P. BandoquilloBelum ada peringkat

- A Defect Analysis of Rotary Screen vs. Digital Textile PrintingDokumen2 halamanA Defect Analysis of Rotary Screen vs. Digital Textile Printingfathi mustafaBelum ada peringkat

- July 2018 1531571158 117Dokumen2 halamanJuly 2018 1531571158 117jai anandBelum ada peringkat

- Unit 1 - Computer Graphics & Multimedia - WWW - Rgpvnotes.inDokumen17 halamanUnit 1 - Computer Graphics & Multimedia - WWW - Rgpvnotes.inJamesBelum ada peringkat

- Cloth Simulation and Collision Detection Using Geometry ImagesDokumen10 halamanCloth Simulation and Collision Detection Using Geometry ImagesOm PatriBelum ada peringkat

- 7 Common Flame RetardantsDokumen2 halaman7 Common Flame RetardantsDanial AhmedBelum ada peringkat

- Finishing Assignment 1Dokumen6 halamanFinishing Assignment 1Danial Ahmed100% (2)

- Textile Finishing: TXCH 458Dokumen38 halamanTextile Finishing: TXCH 458Danial AhmedBelum ada peringkat

- The Steps of Engraving Screens Being Used For Roller PrintingDokumen1 halamanThe Steps of Engraving Screens Being Used For Roller PrintingDanial AhmedBelum ada peringkat

- L16-17 DA and DB BlendsDokumen28 halamanL16-17 DA and DB BlendsDanial AhmedBelum ada peringkat

- Apparel Manufacturing ProcessDokumen4 halamanApparel Manufacturing ProcessDanial AhmedBelum ada peringkat

- HJJJJJJDokumen7 halamanHJJJJJJLUIS MIGUEL VARGAS ARANGOBelum ada peringkat

- Jachimo SlidesCarnivalDokumen29 halamanJachimo SlidesCarnivalChristelle Joy CorderoBelum ada peringkat

- InDesign MagazineDokumen46 halamanInDesign Magazinezos1969Belum ada peringkat

- The Study of Color: Information For Artists From Daniel SmithDokumen7 halamanThe Study of Color: Information For Artists From Daniel Smithtaunbv7711100% (1)

- Value Proposition: HP Indigo 7500 Digital Press PresentationDokumen57 halamanValue Proposition: HP Indigo 7500 Digital Press PresentationCristian Zhino Olivares ABelum ada peringkat

- Hello From Luxadesigns!: Basic EditingDokumen10 halamanHello From Luxadesigns!: Basic EditingMwagachristianBelum ada peringkat

- Black White Minimalist CV ResumeDokumen1 halamanBlack White Minimalist CV ResumeErfan AkbariBelum ada peringkat

- Hi! I'am Paddma Sambhav: Graphic Design Intern - Jan-Mar 2022 2019-2023Dokumen1 halamanHi! I'am Paddma Sambhav: Graphic Design Intern - Jan-Mar 2022 2019-2023Tanya rajBelum ada peringkat

- Ink-Jet Printing TechnologyDokumen30 halamanInk-Jet Printing Technologyanon_593710497Belum ada peringkat

- Indian Garment Design BookDokumen122 halamanIndian Garment Design Bookkhushisharma261103Belum ada peringkat

- Abhisravanam TamilDokumen67 halamanAbhisravanam Tamilvigneshwaranm100% (2)

- PDF RNDokumen1 halamanPDF RNAusBelum ada peringkat

- 17ucse01 - MultimediaDokumen91 halaman17ucse01 - MultimediaSatheesh KoothanBelum ada peringkat

- Impact of FontsDokumen4 halamanImpact of FontsBre PfostBelum ada peringkat

- Eeken A4Dokumen36 halamanEeken A4Dilip KumarBelum ada peringkat

- MIT Press, 50th Anniversary CatalogDokumen36 halamanMIT Press, 50th Anniversary CatalogThe MIT Press100% (2)

- Fishbone Diagram Free Powerpoint TemplateDokumen7 halamanFishbone Diagram Free Powerpoint TemplateAndhika PercekaBelum ada peringkat

- Basics of Corel DrawDokumen34 halamanBasics of Corel DrawAlakh Sahgal100% (1)

- 2014 09 MArch611 Advanced Rhino Tutorial 5Dokumen1 halaman2014 09 MArch611 Advanced Rhino Tutorial 5KostasBaliotisBelum ada peringkat

- Humano 06CafeRest CatalogDokumen31 halamanHumano 06CafeRest CatalogAntezanaFernandoBelum ada peringkat

- Goals Essay ExamplesDokumen5 halamanGoals Essay Examplesafhbgrgbi100% (2)

- 2 Java2D Slides PDFDokumen16 halaman2 Java2D Slides PDFpankajsoni2010Belum ada peringkat

- ISO 12647-2 Instructions Ed2010 enDokumen11 halamanISO 12647-2 Instructions Ed2010 enAlbertoCidMoralesBelum ada peringkat

- Independencia de Panamá - Wikipedia, La Enciclopedia LibreDokumen81 halamanIndependencia de Panamá - Wikipedia, La Enciclopedia LibreJose Angel AguirreBelum ada peringkat

- Standing Line: NameDokumen19 halamanStanding Line: NameFrances ColoradoBelum ada peringkat

- Color Part 1 QuestionsDokumen6 halamanColor Part 1 Questionsapi-268171789Belum ada peringkat

- DanHammondResume 2021 (UI UX)Dokumen1 halamanDanHammondResume 2021 (UI UX)Daniel HammondBelum ada peringkat

- Btech Cs 5 Sem Computer Graphics kcs053 2022Dokumen2 halamanBtech Cs 5 Sem Computer Graphics kcs053 2022nitinrathore597yBelum ada peringkat

- Arts 6 Quarter 4Dokumen12 halamanArts 6 Quarter 4vic noel arcalaBelum ada peringkat

- Competency Based Curriculum (CBC)Dokumen102 halamanCompetency Based Curriculum (CBC)Carlo Bibal100% (3)