Cheat Sheet

Diunggah oleh

Anonymous dApWCj6quHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Cheat Sheet

Diunggah oleh

Anonymous dApWCj6quHak Cipta:

Format Tersedia

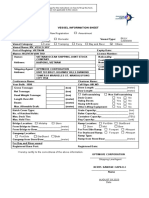

Coefficients GoaloftheShipbuilder:Tobecompetitiveinmeetingtheclientsspecificationwithsolutionsthat Shipyard Facilities: Hull production, Outfitting, Pipe work, Painting, Erection and launching Tutorial2:Ashipyardwishestoinvestonapanellinetohelpintheproductionof3

are cost effective at an acceptable level of safety. Success in shipbuilding depends on facilities,Shiprepairanddisposal,Supportfacilities. ships/year.

Block Midshipsection Waterplanearea simultaneously meeting following criteria: clients specification, competitiveness, cost Facilities for Hull Production: Steel stockyard, Steel treatment, Plate and section preparation SHIPDATA;No.ofpanels/ship=200,No.ofplates/panel=4,No.ofsections/panel=

AM AWP effectiveness,safety. areas, Fabrication workshops, subassembly, assembly and unit assembly, Block assembly, 15,Boughtinplatesize=12m*3m,Boughtinsectionsize=12m.SHIPYARDDATA;No.

CB CM CWP CWL

L * B *T B *T L*B Usual owners requirements (Client Spec): Deadweight, Capacity (bulk or liquid, number of outfitting,paintingworkshops. ofworkingweeks/year==47,No.ofworkinghours/week=40,Overallutilizationfactor

containers, number of cars and passengers), Sea trial speed (engine(s) at maximum rating), SteelStockyardBackground:Accessfromroadorsea,Plate/sectionstockyardisarrangedfora =70%.EQUIPMENTDATA;No.ofE.O.T.cranes=1,Timetoliftandalignaplate==6

Prismatic Verticprismatic

C C Endurance,Classsociety/Flag. direct feed of material into the preparation shops, Stacking plates, flat or vertical, Material mins,Timetoturnoverapanel=30mins,Timetotransportfinishedpanel=20mins.

CP B CVP B KeyfeaturesoftheProduct:Ashipisafloatingstructurethatnotonlysupportsitsownweightin handling (gantry cranes, overhead cranes, roller conveyors, trailers, flat cars) in plate/section EQUIPMENT DATA; Welding speed of submergedarc machines = 0.4 m/min, Setup

L * AM L * B * T * CM C M AWP * T CWP * L * B * T CWP

water,butcansafelycarryapayloadofcargoandpassengersfromoneporttoanother.Shipsare storageareas,Structureofground,cementortimber,Accessbetweenpiles time/seam = 5 mins, Speed of filletweld (gravity) machines = 0.7 m/min, Setup

ForceDisplacement(or)Buoyancy also used for the exploitation of the ocean resources. Most ships will have some means of Factors Influencing Steel Stockyard: Holding capacity and turnover, Provision of adequate time/stiffener=5mins/side,

W F g * * g * w* propulsionsuchasdieselengines,gasturbines,steamenginesorevensails.Crewhavetoliveon offloadingareas,allocatingstoragepilesforhighturnoversteel,Provisionofsortingareas,Areas a)No.ofE.O.T.(ElectricOverheadTravelling)cranes

board;accommodationandothersupportfacilitiesmustbeprovided.Shipshavevariousrolesto for return of outgoing or rejected materials Additionally: No. of piles required for standard Timetoliftandalignplates=3x200x4x6/60=240hrs

LightShip Displacement

Lightship Deadweight

performandcanbe:Shipsfortransportation,Shipsforwork,Shipsformiscellaneouspurposes. plates/sections,No.ofpilesrequiredforpreparationmachines,No.ofpilesrequiredforweekly Timetoturnoverpanel=3x200x30/60=300hrs

LS WST WM WOUT

The Life Cycle of Ships: Bid Preparation, Concept design, Preliminary design, Detailed design, loads,howtodealwithprioritymaterial,howtodealwithQ.C.inspections. Timetotransportfinishedpanel=3x200x20/60=200hrs

Procurement,Production,Commissioningandtrail,Operational/Service(includingmaintenance), SteelStockyardSurfaceLoadingandCraneUtilization: Totalrequiredcranetime=240+300+200=740hrs

Scrapping/Disposal Surface loading = Weight per pile (tones) / Area (m^2). Stockyard efficiency can greatly be Craneutilisation=740/1,316x100=56.23%

Characteristics of Shipbuilding: Ship owner has a large influence on the production. Production affected by the handling facilities, i.e.: The number of stockyard cranes available, The (1,316hrs=47x40x0.7),concluding1craneisadequate

stagesthataredependentofeachother.Shipbuildingemploysvaryingmanufacturingprinciplesat transverse/longitudinaltravelspeedofcrane,Capabilityofcranetoliftsingleormultipleplate b)Portablesubmergedarcweldingmachines

differentstagesofproduction.Shipbuildingrequiresahighdegreeofcraftskill.Differenttypesof lifts using magnets, Crane Utilization = Actual hours worked / Total hours available Crane No.ofseamstobewelded=3x200x3=1800

equipmentareneededforthefabricationprocess.Thedesign,planningandmanufacturingalways Utilizationshouldbelessthan1. Setuptime=1,800x5/60=150hrs

overlap.Theworkingenvironmentmaybeharsh(e.g.exposedtoweatherconditions,noise,etc.). Steel Treatment: Plates are generally blasted and primed at the shipyard before fabrication. Totalweldedlength=1,800x12=21,600m

Final(complete)definitionoftheshipisknownafterthecontractissigned.Theshipbuilderhasto Blastingremovesmillscale andcleanstheplate.Millscaleis formedontheoutersurfacesof Weldingtime=21,600/(0.4x60)=900hrs

makeimportantdecisionsduringtheproductdefinitionstagebasedonuncertaininformation.It plates,sheetsorprofileswhentheyarebeingproducedbyrollingredhotironorsteelbilletsin Totaltime=900+150=1,050hrs

takesalongtimetocompleteanddelivertheproduct.Shipshaveahighproductvalue(oneoff rollingmills;initiallyprotecttheplate,butifthereisanybreakonthescale,wehaveaccelerated Submergedarcweldingmachineutilisation=1,050/1,316x100=79.8%

products).Shipsarelargeinsizeintermsofbothweightandvolume.Shipshavealongproductlife corrosion.Primerprotectsthesteelduringfabricationandprovidesasurfaceonwhichfinalcoats (1,316hrs=47x40x0.7),concluding1machineisadequate

of around 20 to 25 years (in passenger ships even longer e.g. 30 years and more after certain of paint can be applied without a major cleaning operation. Plates are lifted from stockyard, c)Filletweldingmachines

conditionsaremet) processedandthendeliveredtoplatepreparationareaforsubsequentoperations. No.ofsections=15x200x3=9000

Typical ship systems: Steel hull structure, Power generation system for main propulsion. Power PlatePreparationAreaandItsProcesses:Thefunctionoftheplatepreparationareaistoprepare Setuptime(bothsides)=9000x5x2/60=1500hrs

generation system for auxiliaries. Power transmission system for main propulsion. Power plate edges and form the plates into required shapes for subsequent welding and assembly Totalfilletlength(bothsides)=9000x2x12=216000m

transmissionforauxiliaryrequirements.Maneuveringandcontrolsystem.Cargohandlingsystem. activities.Platepreparationitselfmayrequiremarking,cuttingand/orshaping.Marking.Cutting: Weldingtime=216,000/(0.7x60)=5,143hrs

Systems to distribute services: sea water and fresh water, steam and condensate, air, fuel and Mechanical(forthinplates)Shearing,Planning,Milling.Oxicutting,plasmacutting(820mm), Totaltime=5,143+1,500=6,643hrs,

dieseloil,lubricatingoil,hydraulicoil.Systemsfor:transmissionofinformation,communication, lasercutting.Shaping(eithercoldformingorlineheating):Rolling,Flanging,Pressing,Lineheat Filletweldingmachineutilisation=6,643/1,316x100=505%

monitoringandcontrol. shaping(applyheat,expansion,contraction,bend). Layout Performance: CRITERIA Cost minimization, Transport distance minimization,

Ship Design and Production: Ship design is a topdown process starting from the requirements Plate Preparation Area Requirements: Treatment, Preparation, then Marshalling. For Maximizationofthevolumeoftransportedunits,Maximizationofcommunicationand

specification and simple parametric relationships and eventually leading to the definition of full maximizationofareautilization:Workingareasneedtoincludemachiningitself,workingarea control CRITERIA SELECTION Physical attributes of the product, Volume of units

configuration of the ship, her systems and components. Ship production is a bottomup process aroundmachineryandstowageareaetc.Platestowageareastowageplatesintomachinepiles. travellingamongstprocesses,Frequencyoftransportationamongstprocesses,Material

where production starts from the fabrication and/or acquisition of the smallest components or Bridging area. Repair of burned plates. Wooden pallets. Containers for scrap materials. handlingcost(costpermovementxnumberofmovements).

parts,andthroughanorderlyassemblyofthosepartsthefinalshipconfigurationtakesshape.The Marshallingarea.Walkwaysandroadways ShipyardLayoutFactorseffectingthedevelopmentoffacilities:Weldedships,Block

ship at the design and production stage is divided first into zones, i.e. parts of the ship having SectionPreparationArea:Thefunctionofthisareaistomark,burn,punch,formandmarshal assembly, Cranes, Ship types, Ship dimensions, Dry docks, Gantry cranes, Cutting

configurationalandfunctionalsimilarity.Theneachzoneisdividedintoanumberofblocks.The sectionsreadyforthenextoperationoffabrication.Sequenceofflowisasfollows:Sections systems, Panel & Web lines, Automated welding systems, Preoutfitting, Type and

sizeandnumberofblocksarelargelydeterminedbythephysicalabilitiesoftheshipyard(i.e.space, fromthestockyard,Sectiontreatment. numberofshipstobebuilt,Arearequirement,Existingarea,Degreeofmechanization,

size of the enclosed buildings, crane lifting capacities, etc.). From the production point of view, SectionPreparationAreaTypicalMachinery:Beambender:tobendvarioustypesofsections, Material handling and transfer systems, Productionmethods adopted, NC processes,

blocks constitute interim. products or planning units and design information required by i.e. camber deck beams, also used to straighten sections which might have been distorted PanelLines,Blockandsubassemblies,Shotblastandpainting,Coveredspace

productiondepartmentareforblocks.Thisstageofdesignisknownastransitiondesign. (shipyard preference for straightening sections), typical production rate is 20 sections/hour. Differentshipyardtypesandlayoutsdependingon:Sizeofshipsbeingbuilt/repaired.

Tasksofdesigndepartment:Determinetheshapeoftheshipwithdefinedfunctionsandacceptable Framebender:tobendshellframesbyprogressivemethod:theframesareclamped,bent,fed Specificsiteselectedforshipyardlayout(e.g.portarea,remotelocation,waterdepth,

performance. Examine with what materials, equipment, and methods a ship can be built at a throughcontinuouslyandprogressivelyafootatatime,typicalproductionrateis3pairs/dayfor nearbyresidentialarea,workersaccommodationetc.).Proximity to sources of raw

reasonable cost while at the same time satisfying the desired functions and performance S shaped frames and 22 pairs/day for simple parabolic shaped frames. Portable bending material etc. Proximity to ship operations (e.g. North Sea, Far East, Middle

specifications. Provide the Materials Procurement Department, within a defined time schedule, machines:sectionsaremoreirregularthanplatesand,onaverage,eachsectioniscutinto21/2 East, Mediterranean Sea), Environmental conditions, Governmental

informationonspecifications,quantities,anddeliverydatesformaterials.Systematicanalysisof facilitation, Financial resources available

parts/section.Eachpartcanhaveanendpreparation.

thedifferencesbetweenestimatesandactualfiguresintermsofcosts,qualityandperformance

SectionPreparationAreaLayoutConsiderations:Machinesandbufferareasshouldbearranged

bothduringthebuildingprocessandatthecompletionoftheship.

to provide an orderly flow of material without the needto backtrack. The section bay can be

DesignforProduction:Preparingdesignwithfullcognitionofproductionfacilitiesanddifficulties

consideredtohave4majorflowlines(acombinationofaseries/parallelarrangement).Buffer

in fabrication and erection is known as design for production. The main issues of design for

areas should be allocated and adjacent to work sites. Finally, sufficient space must also be

production are: Reduction of variety and use of standard details Use of standard components.

providedforwalkways,clearwaysforforklifttrucks,containersforscrap.

Employment of modularity and cellularity concepts for distributed systems. Full knowledge of

SteelworkFabrication:Thetopicscovereduptonowlookedathowplatesandsections(profiles)

shipyardproductionfacilitiesandcapabilities.

aretobestockedinitially,treated,cut,edgepreparedandshapedintocomponentparts.Steel

Offshore Construction: The structure is usually stationed at a particular offshore site for a

Fabricationdealswiththemannerinwhichthecomponentpartsarefabricated,undercoverin

considerable portion of its working life and therefore cannot be dry docked for periodic

shops, into an assemblage for subsequent joining on an erection berth or building dock. The

maintenance and repair. the steel plates used in offshore construction are of relatively higher

sequenceofworkinthiscategoryisbroadlydivided,dependingonsizeandtypeofshiptobe

thickness.thetopsidesofoffshorestructuresareconsiderablyheavythanthesuperstructuresof

built,intosubassemblyandassembly.Subassemblies:aregenerallyregardedasbeingminor

shipsandareoftenmanufacturedandinstalledseparatelyfromthemainstructure.thestructure

fabrications,assembledfrompreparedplatesandsections.Suchfabricationsareofarepetitive

isdesignedandconstructedtowithstandlongtermenvironmentalloads.considerationsfor(ease

naturewithsimilargeometryandscantlingsoveralargeproportionoftheshipslength.

of)decommissioningofthestructureattheendofitsproductivelife.

Steelwork Fabrication Types of Assemblies: Subassemblies. Main unit assemblies: Flat unit

Production organization: Craft based (or jobshop) Organization: Craft based production

assemblies, Curved unit assemblies, Threedimensional unit assemblies, Block assemblies.

organization uses welltrained and skilled workers to perform a wide variety of tasks in one or

Orthogonalassembliesornonorthogonalassemblies.

several locations.Semiprocess Organisation: This form of production organisation, like the craft

Tutorial1:Ashipyardistenderingforten60,000DWTtankersalltobedeliveredwithinoneyear.

basedorganisation,alsoutiliseswelltrainedandskilledworkerstocarryoutsimilarprocessesat

Information available is as follows: SHIP DATA: No. of plates/ship = 5000. Weight of steel

specificareasProcess(orBatch)Organisation:Inprocess(orbatch)organisation,specificareasare

plates/ship==9,000tones.Averageplatedimensions==9m*3m.SHIPYARDDATA:Stockyard

usedforspecialisedactivities.Here,theequipmentisfixedwhereastheworkobjectandtheworker

handlingfacilities=1Goliathcrane.Areaavailableforplatepiles=5,000m2.Surfaceloading==

who is trained for a specific task are moved to the production equipment. Product (or Group)

3tones/m2.Averagestockturnover=8weeks,Companyholidays=3weeks(summer),2weeks

Organisation:Product(orgroup)productionorganisationfocusesontheintermediateproductand

(winter),Productionweek==Two8hourshifts,5days/week.Assumethataveragenumberof

alltheprocessesrequiredtocompleteit.Insuchanorganisationtheworkerandhisequipmentis

movesperplateis4(unload,sort,2ndsortandpile),andthattheaveragetimepermoveis3

fixed and the working object moves from one workstation to another. Mass Production

minutes.

OrganisationMassproductionorganizationmaximisestheuseofmechanisation,continuousflow

a)Calculatetheaveragenumberofplates/pile.

lines,andspecialisationofactivitiesatsequentialworkstations.Materialhandlingisdecidedatthe

Numberofplatesinstockyard=8/47x10x5,000=8510

timeoffacilitydesign.

Numberofavailablepiles==5,000/(9x3)=185

Numberofplatesperpile==8510/185=46

b)Whatisthesurfaceloadingofthisallocation?

Weightofplatesinstockyard==8/47x10x9,000=15,319tones

Weightofplatesperpile=15,319/185=82.8tones

Surfaceloading=82.8/(9x3)=3.07tones/m2

c)Whatisthecraneutilization?

Numberofplatesperannum=50,000(10x5,000)

Numberofmovesperannum=4x50,000=200,000

Actualhoursrequiredperannum=4x50,000x3/60=10,000

Availablehoursperannum=(2x8)x5x47=3760hours

Craneutilization=actual/available=10,000/3,760=2.661craneunabletomeetdemand

d)Commentupontheresults.Recommendeither:purchaseoftwomorecranes;ortenderingfor

partofordertomatchexistingcranefacilities;orcreatingadditionalstockyardfacility;or

reducenumberofplatemovementsinstockyardthroughplanning.

Anda mungkin juga menyukai

- Part I. DemographicsDokumen5 halamanPart I. DemographicsRizza Mae EudBelum ada peringkat

- Practical 2Dokumen12 halamanPractical 2Rohit ReddyBelum ada peringkat

- Reed111 Handouts-Prelim PDFDokumen24 halamanReed111 Handouts-Prelim PDFCrissa BajallaBelum ada peringkat

- 2012 Genesis SeriesDokumen6 halaman2012 Genesis Seriesliber45Belum ada peringkat

- Apartment Damage Claim Form - SampleDokumen1 halamanApartment Damage Claim Form - SampleVoldBelum ada peringkat

- Node - Js Design Patterns WhitepaperDokumen10 halamanNode - Js Design Patterns WhitepaperPradeep Kr KaushalBelum ada peringkat

- A+ Part 2Dokumen179 halamanA+ Part 2Ayesha Christina100% (1)

- Fundamentals Cheat SheetDokumen2 halamanFundamentals Cheat SheetUDeconBelum ada peringkat

- Artificial Viva Exam Scheduler Final Project DocumentDokumen82 halamanArtificial Viva Exam Scheduler Final Project DocumentCompileSyntaxErrorr33% (3)

- Hardware & Networking CoursesDokumen6 halamanHardware & Networking CoursesAnusha ReddyBelum ada peringkat

- 2017-18 M.B.A PDFDokumen167 halaman2017-18 M.B.A PDFrdan00313Belum ada peringkat

- SG1 001 2Dokumen110 halamanSG1 001 2CHONG CHEN NENGBelum ada peringkat

- Estimating GuideDokumen62 halamanEstimating GuideNhiel DazaBelum ada peringkat

- Artificial Intelligence Fact SheetDokumen2 halamanArtificial Intelligence Fact SheetMARIA PANĂBelum ada peringkat

- Accounting Concepts and PrinciplesDokumen55 halamanAccounting Concepts and PrinciplesNino GabreraBelum ada peringkat

- Artificial Intelligence - Unit 1Dokumen100 halamanArtificial Intelligence - Unit 1Madhu Rajesh100% (3)

- The Path of The PC TechDokumen18 halamanThe Path of The PC TecharturoBelum ada peringkat

- Faculty of Business & Economics 2014 Undergraduate Course GuideDokumen46 halamanFaculty of Business & Economics 2014 Undergraduate Course GuideMonash UniversityBelum ada peringkat

- Virtual KeyboardDokumen24 halamanVirtual Keyboardid.arun526088% (8)

- Correl 2 Compile Ip PDFDokumen549 halamanCorrel 2 Compile Ip PDFpclr07Belum ada peringkat

- This Study Resource Was: Case 01: Reformed Hacker?Dokumen3 halamanThis Study Resource Was: Case 01: Reformed Hacker?Jemuel Flores0% (1)

- 220 702Dokumen188 halaman220 702i_s_a_m_a_nBelum ada peringkat

- Artificial Intelligence QuestionsDokumen3 halamanArtificial Intelligence Questionsምንሼ ነው ዘመኑ100% (2)

- RPLL NewDokumen74 halamanRPLL NewMeta learnBelum ada peringkat

- COSH Heavy Equipmen SafetyDokumen37 halamanCOSH Heavy Equipmen SafetyKaizzer Minerales GamuyaoBelum ada peringkat

- Week2 GEM314e-2012Dokumen36 halamanWeek2 GEM314e-2012Kendal YeltekinBelum ada peringkat

- Capacity Planning Calculations For Shipyards: Week 7Dokumen21 halamanCapacity Planning Calculations For Shipyards: Week 7Dilara ÖZTÜRKBelum ada peringkat

- Shipyard LayoutDokumen5 halamanShipyard LayouttxjiangBelum ada peringkat

- Kuliah 10 Desain Pelabuhan 1Dokumen20 halamanKuliah 10 Desain Pelabuhan 1farhanBelum ada peringkat

- 6 Esential Elements of Ship ProductionDokumen18 halaman6 Esential Elements of Ship Productionryan310393Belum ada peringkat

- A.Nazarov - Small Patrol Boats - SelfRightingDokumen9 halamanA.Nazarov - Small Patrol Boats - SelfRightingVladBelum ada peringkat

- Chapter 2 Shipyard-Layout Lecture Notes From South Hampton UniversityDokumen10 halamanChapter 2 Shipyard-Layout Lecture Notes From South Hampton UniversityJonnada KumarBelum ada peringkat

- NA-II Approved Notes.Dokumen147 halamanNA-II Approved Notes.vishalBelum ada peringkat

- Site Layout PlanningDokumen34 halamanSite Layout PlanningESAM ALHASHEDI100% (1)

- Deadweight or DisplacementDokumen5 halamanDeadweight or DisplacementSergeyBelum ada peringkat

- Chapter 3 Productivity of Construction Equipment3Dokumen48 halamanChapter 3 Productivity of Construction Equipment3hailu100% (3)

- Feature of Shipbuilding IndustryDokumen38 halamanFeature of Shipbuilding IndustryarvindkaushikBelum ada peringkat

- Berthing PlanDokumen44 halamanBerthing PlanPatel Tushar100% (1)

- Case Study Parque Das Conchas (BC-10)Dokumen5 halamanCase Study Parque Das Conchas (BC-10)egy pureBelum ada peringkat

- Delivery of An Advanced Double-Hull Ship Welding System Using RobocraneDokumen7 halamanDelivery of An Advanced Double-Hull Ship Welding System Using RobocranealiBelum ada peringkat

- Berth Planning July 2004Dokumen33 halamanBerth Planning July 2004Estelle LiliaBelum ada peringkat

- Barge 180Ft Deck Load Capacity & Strength-Rev1Dokumen52 halamanBarge 180Ft Deck Load Capacity & Strength-Rev1Wahyu Codyr86% (7)

- Offshore Platform LN1 AU 06-12-2019Dokumen67 halamanOffshore Platform LN1 AU 06-12-2019Gobi HaiBelum ada peringkat

- Dimensional Constraints in Ship DesignDokumen6 halamanDimensional Constraints in Ship DesignTat-Hien LeBelum ada peringkat

- 19 1 Estimated Capacity of The PortDokumen2 halaman19 1 Estimated Capacity of The PortmeeBelum ada peringkat

- GBSL Fs SteelDokumen2 halamanGBSL Fs SteelmjlknelnBelum ada peringkat

- BMT Caimen 90 Fast DatasheetDokumen2 halamanBMT Caimen 90 Fast DatasheetVictor PileggiBelum ada peringkat

- Handbook On Railway Construction-401-500Dokumen100 halamanHandbook On Railway Construction-401-500yamegBelum ada peringkat

- IJSERStress and Resistance Analysis For The Design of A Work BargeDokumen18 halamanIJSERStress and Resistance Analysis For The Design of A Work BargepidutBelum ada peringkat

- A.Nazarov - Power Catamarans - Design For PerformanceDokumen11 halamanA.Nazarov - Power Catamarans - Design For PerformanceVlad100% (2)

- SPE/IADC 67706 Offshore Drilling Experience With Dual Derrick OperationsDokumen6 halamanSPE/IADC 67706 Offshore Drilling Experience With Dual Derrick OperationsSuryo AhmedBelum ada peringkat

- Indian Maritime University: (A Central University, Govt. of India)Dokumen2 halamanIndian Maritime University: (A Central University, Govt. of India)pramodBelum ada peringkat

- An Integrated Quay Crane Assignment and Scheduling ProblemDokumen9 halamanAn Integrated Quay Crane Assignment and Scheduling ProblemAshish Edwin HansdaArtsBelum ada peringkat

- Kuliah 2 Desain Pelabuhan 1Dokumen45 halamanKuliah 2 Desain Pelabuhan 1ibnu fajarBelum ada peringkat

- Structural Modifications For The Longitudinal StreDokumen10 halamanStructural Modifications For The Longitudinal StreTea JevtićBelum ada peringkat

- Advantages of Advanced OutfittingDokumen9 halamanAdvantages of Advanced OutfittingImanustBelum ada peringkat

- Development of Trial Ship For Naval Syst PDFDokumen9 halamanDevelopment of Trial Ship For Naval Syst PDFDarwin Neil MoranoBelum ada peringkat

- To Abg Shipyard: 1.1 About The Training OrganizationDokumen26 halamanTo Abg Shipyard: 1.1 About The Training Organizationavis_in2000Belum ada peringkat

- Track Record Seafastenings PDFDokumen14 halamanTrack Record Seafastenings PDFashaikhBelum ada peringkat

- Conceptual Design and Parametric Optimization of Self PropelledDokumen14 halamanConceptual Design and Parametric Optimization of Self PropelledmailokeBelum ada peringkat

- PHD Thesis Marcus AvevaDokumen446 halamanPHD Thesis Marcus AvevaArnold QuispeBelum ada peringkat

- Lamb T.World-Class Shipbuil.2001.TRANS PDFDokumen24 halamanLamb T.World-Class Shipbuil.2001.TRANS PDFairlanggaputraBelum ada peringkat

- Merchant Ship StabilityDokumen212 halamanMerchant Ship StabilityJosé Ramón Devan Devan100% (1)

- p122p enDokumen143 halamanp122p enviyfBelum ada peringkat

- All VesselsDokumen16 halamanAll Vesselskucherok93Belum ada peringkat

- Ejercicios KGDokumen2 halamanEjercicios KGzandryta2000Belum ada peringkat

- SE9 - A Preliminary Study On The Relevance of Quantity Surveyors in The Shipbuilding Industry - Ahmed Mohammed KamaruddeenDokumen15 halamanSE9 - A Preliminary Study On The Relevance of Quantity Surveyors in The Shipbuilding Industry - Ahmed Mohammed KamaruddeenMario VisicBelum ada peringkat

- q88 For Vessel Spike in China WatersDokumen7 halamanq88 For Vessel Spike in China WatersMorgan MackBelum ada peringkat

- Works 201291714531Dokumen80 halamanWorks 201291714531George PonparauBelum ada peringkat

- 4.15 Loadline MarkingsDokumen5 halaman4.15 Loadline MarkingsKush UpadhyayBelum ada peringkat

- B-01 List of Finished Drawings (Basic Part)Dokumen3 halamanB-01 List of Finished Drawings (Basic Part)Metarak SondeeBelum ada peringkat

- Double Hull Tanker - Typical Transverse Bulkhead - IACS Rec.96Dokumen6 halamanDouble Hull Tanker - Typical Transverse Bulkhead - IACS Rec.96danielBelum ada peringkat

- Ship DimensionsDokumen23 halamanShip Dimensionsenglisgo100% (1)

- Recruitment and SelectionDokumen94 halamanRecruitment and SelectionTech Yuva100% (1)

- Angle of LollDokumen27 halamanAngle of Lollashwin.devaliya6923100% (1)

- Vessel Information Sheet PPADokumen4 halamanVessel Information Sheet PPAIvy Amistad Dela Cruz-CabalzaBelum ada peringkat

- Damen Year Book No4 PDFDokumen55 halamanDamen Year Book No4 PDFCarlos Marcelo CostaBelum ada peringkat

- SSI Technical BrochureDokumen16 halamanSSI Technical BrochureCanh Sanh LoBelum ada peringkat

- Steffy - Ancient Ship RepairsDokumen14 halamanSteffy - Ancient Ship RepairsutvrdaBelum ada peringkat

- Longitudinal Stability For ShipsDokumen4 halamanLongitudinal Stability For ShipsGiorgi Kandelaki100% (1)

- MPS 2017 LRDokumen226 halamanMPS 2017 LRKrzysztofBelum ada peringkat

- Glossary of Nautical TermsDokumen12 halamanGlossary of Nautical TermsAboody AL-ghamdyBelum ada peringkat

- 19 JG Summit Holdings V CA, GR No. 124293, September 24, 2003Dokumen29 halaman19 JG Summit Holdings V CA, GR No. 124293, September 24, 2003Edgar Calzita AlotaBelum ada peringkat

- 12-NAC-Deterministic Damage Stability (160213)Dokumen15 halaman12-NAC-Deterministic Damage Stability (160213)SundeepBelum ada peringkat

- Class 4 Safety Oral Ship Construction & Naval FileDokumen72 halamanClass 4 Safety Oral Ship Construction & Naval Fileclinton100% (4)

- Stability Discussion Questions and Answers-2Dokumen15 halamanStability Discussion Questions and Answers-2Devesh KhareBelum ada peringkat

- Ship Geometry PDFDokumen81 halamanShip Geometry PDFignasius wisnu100% (1)

- Horizons No 29 - tcm155-199091Dokumen48 halamanHorizons No 29 - tcm155-199091Irina MaltopolBelum ada peringkat

- Ship Geometry Lecture NotesDokumen46 halamanShip Geometry Lecture NotespothirajkalyanBelum ada peringkat

- Brodogradnja 63 (2012)Dokumen12 halamanBrodogradnja 63 (2012)AntoniusCroataBelum ada peringkat