Hea Rubrics 1

Diunggah oleh

api-313716520Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Hea Rubrics 1

Diunggah oleh

api-313716520Hak Cipta:

Format Tersedia

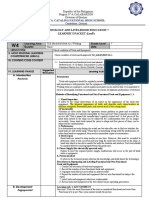

HEAVY EQUIPMENT TECHNICIAN APPRENTICESHIP ASSESSMENT

COURSE HEA3400: BASIC TOOLS & MATERIALS

Level: First Period Apprenticeship, Section One

Prerequisite: HEA3900: Apprenticeship Safety

Description: Students develop knowledge, skills and attitudes in the practice of workshop safety, communication and the use of

specialty hand tools, measuring tools and fasteners.

Parameters: Access to a materials work centre, complete with basic measuring tools, specialty hand tools and fastening devices, and to

instruction from an individual with journeyperson certification in the trade(s) of heavy duty mechanic; heavy duty

equipment mechanic (off-road); truck and transport mechanic; or transport-trailer mechanic.

ILM Resources: Materials and Fastening Devices 190101f; Hand, Shop and Power Tools 190101g; Measuring Tools 190101h

This sample rubric is for assessing technical elements that students need to know to be successful if they challenge the first-period apprenticeship

exam. The rubric does not include the last two common outcomes that address the demonstration of teamwork and personal management and

identification of steps to achieve personal goals. It is the certificated teachers responsibility to ensure that all outcomes are taught and assessed.

Assessment Tools Notes

Checklist Prior to instruction, a copy of the checklist should be provided to the student to review outcomes that will need to

be demonstrated.

The student may use this checklist as a guide when completing this course.

The teacher should review and sign the checklist when the course is complete to ensure student outcomes have

been successfully demonstrated.

Rubric Prior to instruction, a copy of the rubric should be provided to the student to review and reflect on meeting

expectations set out in the criteria.

This rubric may be used as one element of an assessment process. Teachers should use both formative and

summative assessments to ensure students competency in this course.

COURSE HEA3400: BASIC TOOLS & MATERIALS

Checklist

Heavy Equipment Technician Apprenticeship Assessment CTS, TMT: HEA3400 / 1

Alberta Education, Alberta, Canada 2015

Student Outcomes Student Teacher Student, Teacher or Instructor Comments

Check Check

1. identify materials and

fasteners commonly used in

the trade

2. demonstrate the correct use

of hand, shop and power

tools common to the trade

1. demonstrate the correct use

of measuring tools common

to the trade

Teacher Signature Date

2 / CTS, TMT: HEA3400 Heavy Equipment Technician Apprenticeship Assessment

2015 Alberta Education, Alberta, Canada

COURSE HEA3400: BASIC TOOLS & MATERIALS

Rubric

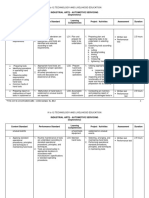

Student Name: Date:

Level Not Yet

Excellent Proficient Adequate Limited

Demonstrated

Criteria

1. identify materials and fasteners commonly used in the trade

1.1 identify common metallic I can consistently I can usually identify I sometimes need I often need assistance I have not yet

materials and their identify common common metallic assistance to identify to identify common provided evidence of

applications metallic materials and materials and their common metallic metallic materials and this performance task.

their applications. applications. materials and their their applications.

applications.

1.2 identify characteristics I can consistently I can usually identify I sometimes need I often need assistance I have not yet

and properties common to identify characteristics characteristics and assistance to identify to identify provided evidence of

metal and properties common properties common to characteristics and characteristics and this performance task.

to metal. metal. properties common to properties common to

metal. metal.

1.3 identify common I can consistently I can usually identify I sometimes need I often need assistance I have not yet

non-metallic materials and identify common common non-metallic assistance to identify to identify common provided evidence of

their applications non-metallic materials materials and their common non-metallic non-metallic materials this performance task.

and their applications. applications. materials and their and their applications.

applications.

1.4 identify types of threaded I can consistently I can usually identify I sometimes need I often need assistance I have not yet

fasteners and their identify types of types of threaded assistance to identify to identify types of provided evidence of

applications threaded fasteners and fasteners and their types of threaded threaded fasteners and this performance task.

their applications. applications. fasteners and their their applications.

applications.

1.5 describe fastener I can consistently I can usually describe I sometimes need I often need assistance I have not yet

classification and sizing describe fastener fastener classification assistance to describe to describe fastener provided evidence of

classification and and sizing. fastener classification classification and this performance task.

sizing. and sizing. sizing.

Heavy Equipment Technician Apprenticeship Assessment CTS, TMT: HEA3400 / 3

Alberta Education, Alberta, Canada 2015

1.6 identify various types of I can consistently I can usually identify I sometimes need I often need assistance I have not yet

torque wrenches, identify various types various types of assistance to identify to identify various types provided evidence of

including dial, indicating of torque wrenches, torque wrenches, various types of torque of torque wrenches, this performance task.

click type, digital and including dial, including dial, wrenches, including including dial,

indicating click type, indicating click type, dial, indicating click indicating click type,

deflecting beam

digital and deflecting digital and deflecting type, digital and digital and deflecting

beam. beam. deflecting beam. beam.

1.7 explain torque procedures I can consistently I can usually explain I sometimes need I often need assistance I have not yet

and precautions when explain torque torque procedures and assistance to explain to explain torque provided evidence of

securing fastening devices procedures and precautions when torque procedures and procedures and this performance task.

precautions when securing fastening precautions when precautions when

securing fastening devices. securing fastening securing fastening

devices. devices. devices.

1.8 identify types of I can consistently I can usually identify I sometimes need I often need assistance I have not yet

non-threaded fasteners identify types of types of non-threaded assistance to identify to identify types of provided evidence of

and their applications non-threaded fasteners fasteners and their types of non-threaded non-threaded fasteners this performance task.

and their applications. applications. fasteners and their and their applications.

applications.

1.9 identify various types of I can consistently I can usually identify I sometimes need I often need assistance I have not yet

adhesives and sealants and identify various types of various types of assistance to identify to identify various types provided evidence of

their applications adhesives and sealants adhesives and sealants various types of of adhesives and this performance task.

and their applications. and their applications. adhesives and sealants sealants and their

and their applications. applications.

2. demonstrate the correct use of hand, shop and power tools common to the trade

2.1 describe types, uses and I can consistently I can usually describe I sometimes need I often need assistance I have not yet

care of hammers describe types, uses and types, uses and care of assistance to describe to describe types, uses provided evidence of

care of hammers. hammers. types, uses and care of and care of hammers. this performance task.

hammers.

2.2 describe types, uses and I can consistently I can usually describe I sometimes need I often need assistance I have not yet

care of screwdrivers describe types, uses and types, uses and care of assistance to describe to describe types, uses provided evidence of

care of screwdrivers. screwdrivers. types, uses and care of and care of this performance task.

screwdrivers. screwdrivers.

2.3 identify the various types I can consistently I can usually identify I sometimes need I often need assistance I have not yet

of punches and their uses identify the various the various types of assistance to identify to identify the various provided evidence of

types of punches and punches and their the various types of types of punches and this performance task.

their uses. uses. punches and their uses. their uses.

4 / CTS, TMT: HEA3400 Heavy Equipment Technician Apprenticeship Assessment

2015 Alberta Education, Alberta, Canada

2.4 identify the various types I can consistently I can usually identify I sometimes need I often need assistance I have not yet

of chisels and their uses identify the various the various types of assistance to identify to identify the various provided evidence of

types of chisels and chisels and their uses. the various types of types of chisels and this performance task.

their uses. chisels and their uses. their uses.

2.5 describe the various types I can consistently I can usually describe I sometimes need I often need assistance I have not yet

of wrenches and their uses describe the various the various types of assistance to describe to describe the various provided evidence of

types of wrenches and wrenches and their the various types of types of wrenches and this performance task.

their uses. uses. wrenches and their uses. their uses.

2.6 identify the various types I can consistently I can usually identify I sometimes need I often need assistance I have not yet

of pliers and their uses identify the various the various types of assistance to identify to identify the various provided evidence of

types of pliers and their pliers and their uses. the various types of types of pliers and their this performance task.

uses. pliers and their uses. uses.

2.7 identify various types of I can consistently I can usually identify I sometimes need I often need assistance I have not yet

holding devices identify various types of various types of assistance to identify to identify various types provided evidence of

holding devices. holding devices. various types of holding of holding devices. this performance task.

devices.

2.8 identify various tools for I can consistently I can usually identify I sometimes need I often need assistance I have not yet

removing broken identify various tools various tools for assistance to identify to identify various tools provided evidence of

fasteners and explain for removing broken removing broken various tools for for removing broken this performance task.

how to use them fasteners and explain fasteners and explain removing broken fasteners and explain

how to use them. how to use them. fasteners and explain how to use them.

how to use them.

2.9 describe the procedures I can consistently I can usually describe I sometimes need I often need assistance I have not yet

required to safely operate describe the procedures the procedures assistance to describe to describe the provided evidence of

various types and required to safely required to safely the procedures required procedures required to this performance task.

capacities of shop puller operate various types operate various types to safely operate various safely operate various

and capacities of shop and capacities of shop types and capacities of types and capacities of

and pressing equipment

puller and pressing puller and pressing shop puller and pressing shop puller and pressing

equipment. equipment. equipment. equipment.

2.10 describe and use cutting I can consistently I can usually describe I sometimes need I often need assistance I have not yet

hand tools common to describe and use cutting and use cutting hand assistance to describe to describe and use provided evidence of

the trade hand tools common to tools common to the and use cutting hand cutting hand tools this performance task.

the trade. trade. tools common to the common to the trade.

trade.

2.11 demonstrate how to I can consistently I can usually I sometimes need I often need assistance I have not yet

sharpen a twist drill demonstrate how to demonstrate how to assistance to to demonstrate how to provided evidence of

sharpen a twist drill. sharpen a twist drill. demonstrate how to sharpen a twist drill. this performance task.

sharpen a twist drill.

Heavy Equipment Technician Apprenticeship Assessment CTS, TMT: HEA3400 / 5

Alberta Education, Alberta, Canada 2015

2.12 identify tools and I can consistently I can usually identify I sometimes need I often need assistance I have not yet

demonstrate proper identify tools and tools and demonstrate assistance to identify to identify tools and provided evidence of

thread repair techniques demonstrate proper proper thread repair tools and demonstrate demonstrate proper this performance task.

thread repair techniques. proper thread repair thread repair

techniques. techniques. techniques.

2.13 demonstrate the use of I can consistently I can usually I sometimes need I often need assistance I have not yet

tubing flaring; sheet demonstrate the use of demonstrate the use of assistance to to demonstrate the use provided evidence of

abrasives and grinding tubing flaring; sheet tubing flaring; sheet demonstrate the use of of tubing flaring; sheet this performance task.

compounds; and lapping abrasives and grinding abrasives and grinding tubing flaring; sheet abrasives and grinding

compounds; and compounds; and abrasives and grinding compounds; and

blocks and honing stones

lapping blocks and lapping blocks and compounds; and lapping blocks and

honing stones. honing stones. lapping blocks and honing stones.

honing stones.

2.14 demonstrate the care and I can consistently I can usually I sometimes need I often need assistance I have not yet

safe use of common demonstrate the care demonstrate the care assistance to to demonstrate the care provided evidence of

power hand tools and safe use of common and safe use of demonstrate the care and safe use of common this performance task.

power hand tools. common power hand and safe use of common power hand tools.

tools. power hand tools.

2.15 demonstrate knowledge I can consistently I can usually I sometimes need I often need assistance I have not yet

of personal protective demonstrate knowledge demonstrate assistance to to demonstrate provided evidence of

equipment and tool of personal protective knowledge of personal demonstrate knowledge knowledge of personal this performance task.

safety equipment and tool protective equipment of personal protective protective equipment

safety. and tool safety. equipment and tool and tool safety.

safety.

3. demonstrate the correct use of measuring tools common to the trade

3.1 perform calculations I can consistently I can usually perform I sometimes need I often need assistance I have not yet

related to measurement, perform calculations calculations related to assistance to perform to perform calculations provided evidence of

using imperial and metric related to measurement, measurement, using calculations related to related to measurement, this performance task.

units using imperial and imperial and metric measurement, using using imperial and

metric units. units. imperial and metric metric units.

units.

3.2 perform linear I can consistently I can usually perform I sometimes need I often need assistance I have not yet

measurements using basic perform linear linear measurements assistance to perform to perform linear provided evidence of

non-precision measuring measurements using using basic linear measurements measurements using this performance task.

tools basic non-precision non-precision using basic basic non-precision

measuring tools. measuring tools. non-precision measuring tools.

measuring tools.

6 / CTS, TMT: HEA3400 Heavy Equipment Technician Apprenticeship Assessment

2015 Alberta Education, Alberta, Canada

3.3 perform linear I can consistently I can usually perform I sometimes need I often need assistance I have not yet

measurements, using perform linear linear measurements, assistance to perform to perform linear provided evidence of

precision measuring tools measurements, using using precision linear measurements, measurements, using this performance task.

precision measuring measuring tools. using precision precision measuring

tools. measuring tools. tools.

3.4 perform accurate torque I can consistently I can usually perform I sometimes need I often need assistance I have not yet

measurements perform accurate torque accurate torque assistance to perform to perform accurate provided evidence of

measurements. measurements. accurate torque torque measurements. this performance task.

measurements.

Teacher feedback and

assessment.

Heavy Equipment Technician Apprenticeship Assessment CTS, TMT: HEA3400 / 7

Alberta Education, Alberta, Canada 2015

HEAVY EQUIPMENT TECHNICIAN APPRENTICESHIP ASSESSMENT

COURSE HEA3405: BEARINGS & SEALS

Level: First Period Apprenticeship, Section Two

Prerequisites: HEA3900: Apprenticeship Safety

HEA3400: Basic Tools & Materials

Description: Students develop the knowledge, skills and attitudes necessary to service and maintain vehicle bearings and seals and

to use oxyfuel heating and cutting systems.

Parameters: Access to a materials work centre, complete with basic hand tools, specialty hand tools, fastening devices and oxy-fuel

heating and cutting equipment, and to instruction from an individual with journeyperson certification in the trade(s) of

heavy duty mechanic; heavy duty equipment mechanic (off-road); truck and transport mechanic; or transport-trailer

mechanic.

ILM Resources: Bearings and Seals 190102c; Oxyacetylene Equipment, Heating and Cutting 190101i

This sample rubric is for assessing technical elements that students need to know to be successful if they challenge the first-period apprenticeship

exam. The rubric does not include the last two common outcomes that address the demonstration of teamwork and personal management and

identification of steps to achieve personal goals. It is the certificated teachers responsibility to ensure that all outcomes are taught and assessed.

Assessment Tools Notes

Checklist Prior to instruction, a copy of the checklist should be provided to the student to review outcomes that will need to

be demonstrated.

The student may use this checklist as a guide when completing this course.

The teacher should review and sign the checklist when the course is complete to ensure student outcomes have

been successfully demonstrated.

Rubric Prior to instruction, a copy of the rubric should be provided to the student to review and reflect on meeting

expectations set out in the criteria.

This rubric may be used as one element of an assessment process. Teachers should use both formative and

summative assessments to ensure students competency in this course.

COURSE HEA3405: BEARINGS & SEALS

Checklist

8 / CTS, TMT: HEA3405 Heavy Equipment Technician Apprenticeship Assessment

2015 Alberta Education, Alberta, Canada

Student Outcomes Student Teacher Student, Teacher or Instructor Comments

Check Check

1. service common bearings

and seals

2. perform metal cutting and

heating operations safely,

using oxyacetylene

equipment

Teacher Signature Date

Heavy Equipment Technician Apprenticeship Assessment CTS, TMT: HEA3405/ 9

Alberta Education, Alberta, Canada 2015

COURSE HEA3405: BEARINGS & SEALS

Rubric

Student Name: Date:

Level Not Yet

Excellent Proficient Adequate Limited

Demonstrated

Criteria

1. service common bearings and seals

1.1 state bearing functions and I can consistently state I can usually state I sometimes need I often need assistance I have not yet

applications bearing functions and bearing functions and assistance to state to state bearing provided evidence of

applications. applications. bearing functions and functions and this performance

applications. applications. task.

1.2 state seal functions, I can consistently state I can usually state seal I sometimes need I often need assistance I have not yet

classifications and seal functions, functions, assistance to state seal to state seal functions, provided evidence of

applications classifications and classifications and functions, classifications and this performance

applications. applications. classifications and applications. task.

applications.

1.3 diagnose common bearing I can consistently I can usually diagnose I sometimes need I often need assistance I have not yet

and seal faults diagnose common common bearing and assistance to diagnose to diagnose common provided evidence of

bearing and seal faults. seal faults. common bearing and bearing and seal faults. this performance

seal faults. task.

1.4 perform bearing and seal I can consistently I can usually perform I sometimes need I often need assistance I have not yet

service perform bearing and bearing and seal assistance to perform to perform bearing and provided evidence of

seal service. service. bearing and seal seal service. this performance

service. task.

10 / CTS, TMT: HEA3405 Heavy Equipment Technician Apprenticeship Assessment

2015 Alberta Education, Alberta, Canada

2. perform metal cutting and heating operations safely, using oxyacetylene equipment

2.1 describe the characteristics I can consistently I can usually describe I sometimes need I often need assistance I have not yet

and handling procedures describe the the characteristics and assistance to describe to describe the provided evidence of

for oxygen, propane and characteristics and handling procedures the characteristics and characteristics and this performance

acetylene handling procedures for for oxygen, propane handling procedures for handling procedures for task.

oxygen, propane and and acetylene. oxygen, propane and oxygen, propane and

acetylene. acetylene. acetylene.

2.2 demonstrate handling I can consistently I can usually I sometimes need I often need assistance I have not yet

procedures for regulators demonstrate handling demonstrate handling assistance to to demonstrate handling provided evidence of

and hoses procedures for procedures for demonstrate handling procedures for this performance

regulators and hoses. regulators and hoses. procedures for regulators and hoses. task.

regulators and hoses.

2.3 demonstrate the use, care I can consistently I can usually I sometimes need I often need assistance I have not yet

and maintenance of demonstrate the use, demonstrate the use, assistance to to demonstrate the use, provided evidence of

torches and tips care and maintenance of care and maintenance demonstrate the use, care and maintenance of this performance

torches and tips. of torches and tips. care and maintenance of torches and tips. task.

torches and tips.

2.4 demonstrate the use of I can consistently I can usually I sometimes need I often need assistance I have not yet

personal protective demonstrate the use of demonstrate the use of assistance to to demonstrate the use provided evidence of

equipment and safety personal protective personal protective demonstrate the use of of personal protective this performance

precautions equipment and safety equipment and safety personal protective equipment and safety task.

precautions. precautions. equipment and safety precautions.

precautions.

2.5 perform heating and I can consistently I can usually perform I sometimes need I often need assistance I have not yet

cutting operations, using perform heating and heating and cutting assistance to perform to perform heating and provided evidence of

oxygen and acetylene cutting operations, operations, using heating and cutting cutting operations, this performance

using oxygen and oxygen and acetylene. operations, using using oxygen and task.

acetylene. oxygen and acetylene. acetylene.

Teacher feedback and

assessment.

Heavy Equipment Technician Apprenticeship Assessment CTS, TMT: HEA3405/ 11

Alberta Education, Alberta, Canada 2015

HEAVY EQUIPMENT TECHNICIAN APPRENTICESHIP ASSESSMENT

COURSE HEA3410: FRAMES & SUSPENSION

Level: First Period Apprenticeship, Section Two

Prerequisites: HEA3900: Apprenticeship Safety

HEA3400: Basic Tools & Materials

HEA3405: Bearings & Seals

Description: Students develop the knowledge, skills and attitudes necessary to service and maintain vehicle frames and suspension

systems.

Parameters: Access to a materials work centre, complete with basic measuring tools, specialty hand tools and fastening devices, and to

instruction from an individual with journeyperson certification in the trade(s) of heavy duty mechanic; heavy duty

equipment mechanic (off-road); truck and transport mechanic; or transport-trailer mechanic.

ILM Resources: Frame and Suspension Fundamentals 190102a; Frame and Suspension Service 190102b

This sample rubric is for assessing technical elements that students need to know to be successful if they challenge the first-period apprenticeship

exam. The rubric does not include the last two common outcomes that address the demonstration of teamwork and personal management and

identification of steps to achieve personal goals. It is the certificated teachers responsibility to ensure that all outcomes are taught and assessed.

Assessment Tools Notes

Checklist Prior to instruction, a copy of the checklist should be provided to the student to review outcomes that will need to

be demonstrated.

The student may use this checklist as a guide when completing this course.

The teacher should review and sign the checklist when the course is complete to ensure student outcomes have

been successfully demonstrated.

Rubric Prior to instruction, a copy of the rubric should be provided to the student to review and reflect on meeting

expectations set out in the criteria.

This rubric may be used as one element of an assessment process. Teachers should use both formative and

summative assessments to ensure students competency in this course.

COURSE HEA3410: FRAMES & SUSPENSION

Checklist

12 / CTS, TMT: HEA3410 Heavy Equipment Technician Apprenticeship Assessment

2015 Alberta Education, Alberta, Canada

Student Outcomes Student Teacher Student, Teacher or Instructor Comments

Check Check

1. explain the operating

principles and design

features of common frame

and suspension systems

2. repair common types of

frame and suspension

systems

Teacher Signature Date

Heavy Equipment Technician Apprenticeship Assessment CTS, TMT: HEA3410 / 13

Alberta Education, Alberta, Canada 2015

COURSE HEA3410: FRAMES & SUSPENSION

Rubric

Student Name: Date:

Level Not Yet

Excellent Proficient Adequate Limited

Demonstrated

Criteria

1. explain the operating principles and design features of common frame and suspension systems

1.1 state the functions of a I can consistently state I can usually state the I sometimes need I often need assistance I have not yet

vehicle frame the functions of a functions of a vehicle assistance to state the to state the functions of provided evidence of

vehicle frame. frame. functions of a vehicle a vehicle frame. this performance task.

frame.

1.2 identify types, designs, I can consistently I can usually identify I sometimes need I often need assistance I have not yet

structural considerations identify types, designs, types, designs, assistance to identify to identify types, provided evidence of

and components of frames structural structural types, designs, designs, structural this performance task.

commonly used in truck considerations and considerations and structural considerations and

components of frames components of frames considerations and components of frames

and trailer applications

commonly used in truck commonly used in components of frames commonly used in truck

and trailer applications. truck and trailer commonly used in truck and trailer applications.

applications. and trailer applications.

1.3 explain the functions of a I can consistently I can usually explain I sometimes need I often need assistance I have not yet

vehicle suspension system explain the functions of the functions of a assistance to explain the to explain the functions provided evidence of

a vehicle suspension vehicle suspension functions of a vehicle of a vehicle suspension this performance task.

system. system. suspension system. system.

1.4 explain the operating I can consistently I can usually explain I sometimes need I often need assistance I have not yet

principles and components explain the operating the operating assistance to explain the to explain the operating provided evidence of

of common suspension principles and principles and operating principles and principles and this performance task.

systems components of common components of components of common components of common

suspension systems. common suspension suspension systems. suspension systems.

systems.

14 / CTS, TMT: HEA3410 Heavy Equipment Technician Apprenticeship Assessment

2015 Alberta Education, Alberta, Canada

2. repair common types of frame and suspension systems

2.1 demonstrate frame I can consistently I can usually I sometimes need I often need assistance I have not yet

inspection and repair demonstrate frame demonstrate frame assistance to to demonstrate frame provided evidence of

procedures inspection and repair inspection and repair demonstrate frame inspection and repair this performance task.

procedures. procedures. inspection and repair procedures.

procedures.

2.2 explain the suspension I can consistently I can usually explain I sometimes need I often need assistance I have not yet

noise inspection process explain the suspension the suspension noise assistance to explain the to explain the provided evidence of

and the causes of noise inspection process inspection process and suspension noise suspension noise this performance task.

suspension system and the causes of the causes of inspection process and inspection process and

suspension system suspension system the causes of suspension the causes of

malfunctions

malfunctions. malfunctions. system malfunctions. suspension system

malfunctions.

2.3 demonstrate suspension I can consistently I can usually I sometimes need I often need assistance I have not yet

system repair procedures demonstrate suspension demonstrate assistance to to demonstrate provided evidence of

system repair suspension system demonstrate suspension suspension system this performance task.

procedures. repair procedures. system repair repair procedures.

procedures.

Teacher feedback and

assessment.

Heavy Equipment Technician Apprenticeship Assessment CTS, TMT: HEA3410 / 15

Alberta Education, Alberta, Canada 2015

HEAVY EQUIPMENT TECHNICIAN APPRENTICESHIP ASSESSMENT

COURSE HEA3415: WHEELS & PREVENTIVE MAINTENANCE

Level: First Period Apprenticeship, Section Two

Prerequisites: HEA3900: Apprenticeship Safety

HEA3400: Basic Tools & Materials

Description: Students develop the knowledge, skills and attitudes necessary to service and maintain vehicle wheels, tires and hubs

and to perform preventive maintenance procedures.

Parameters: Access to a materials work centre, complete with basic hand tools, specialty hand tools, tire machines and balancing

equipment, and to instruction from an individual with journeyperson certification in the trade(s) of heavy duty

mechanic; heavy duty equipment mechanic (off-road); truck and transport mechanic; or transport-trailer mechanic.

ILM Resources: Wheels, Tires and Hubs 190102d; Preventive Maintenance 190102i

This sample rubric is for assessing technical elements that students need to know to be successful if they challenge the first-period apprenticeship

exam. The rubric does not include the last two common outcomes that address the demonstration of teamwork and personal management and

identification of steps to achieve personal goals. It is the certificated teachers responsibility to ensure that all outcomes are taught and assessed.

Assessment Tools Notes

Checklist Prior to instruction, a copy of the checklist should be provided to the student to review outcomes that will need to

be demonstrated.

The student may use this checklist as a guide when completing this course.

The teacher should review and sign the checklist when the course is complete to ensure student outcomes have

been successfully demonstrated.

Rubric Prior to instruction, a copy of the rubric should be provided to the student to review and reflect on meeting

expectations set out in the criteria.

This rubric may be used as one element of an assessment process. Teachers should use both formative and

summative assessments to ensure students competency in this course.

COURSE HEA3415: WHEELS & PREVENTIVE MAINTENANCE

Checklist

16 / CTS, TMT: HEA3415 Heavy Equipment Technician Apprenticeship Assessment

2015 Alberta Education, Alberta, Canada

Student Outcomes Student Teacher Student, Teacher or Instructor Comments

Check Check

1. service wheels, tires and

hubs

2. explain typical maintenance

programs used with off-road

and on-road equipment

Teacher Signature Date

Heavy Equipment Technician Apprenticeship Assessment CTS, TMT: HEA3415 / 17

Alberta Education, Alberta, Canada 2015

COURSE HEA3415: WHEELS & PREVENTIVE MAINTENANCE

Rubric

Student Name: Date:

Level Not Yet

Excellent Proficient Adequate Limited

Demonstrated

Criteria

1. service wheels, tires and hubs

1.1 identify common wheel I can consistently I can usually identify I sometimes need I often need assistance I have not yet

types and mounting identify common wheel common wheel types assistance to identify to identify common provided evidence of

designs types and mounting and mounting designs. common wheel types wheel types and this performance task.

designs. and mounting designs. mounting designs.

1.2 explain tire construction, I can consistently I can usually explain I sometimes need I often need assistance I have not yet

care and maintenance in explain tire tire construction, care assistance to explain to explain tire provided evidence of

relation to design and construction, care and and maintenance in tire construction, care construction, care and this performance task.

sizing maintenance in relation relation to design and and maintenance in maintenance in relation

to design and sizing. sizing. relation to design and to design and sizing.

sizing.

1.3 state the safety procedures I can consistently state I can usually state the I sometimes need I often need assistance I have not yet

required when handling the safety procedures safety procedures assistance to state the to state the safety provided evidence of

tires and wheels required when handling required when safety procedures procedures required this performance task.

tires and wheels. handling tires and required when handling when handling tires and

wheels. tires and wheels. wheels.

1.4 perform wheel removal, I can consistently I can usually perform I sometimes need I often need assistance I have not yet

inspection and installation perform wheel removal, wheel removal, assistance to perform to perform wheel provided evidence of

inspection and inspection and wheel removal, removal, inspection and this performance task.

installation. installation. inspection and installation.

installation.

18 / CTS, TMT: HEA3415 Heavy Equipment Technician Apprenticeship Assessment

2015 Alberta Education, Alberta, Canada

1.5 explain wheel balancing I can consistently I can usually explain I sometimes need I often need assistance I have not yet

procedures and problems explain wheel balancing wheel balancing assistance to explain to explain wheel provided evidence of

procedures and procedures and wheel balancing balancing procedures this performance task.

problems. problems. procedures and and problems.

problems.

1.6 diagnose wheel and tire I can consistently I can usually diagnose I sometimes need I often need assistance I have not yet

faults diagnose wheel and tire wheel and tire faults. assistance to diagnose to diagnose wheel and provided evidence of

faults. wheel and tire faults. tire faults. this performance task.

2. explain typical maintenance programs used with off-road and on-road equipment

2.1 explain the types of I can consistently I can usually explain I sometimes need I often need assistance I have not yet

maintenance systems and explain the types of the types of assistance to explain the to explain the types of provided evidence of

concerns maintenance systems maintenance systems types of maintenance maintenance systems this performance task.

and concerns. and concerns. systems and concerns. and concerns.

2.2 explain the principles of I can consistently I can usually explain I sometimes need I often need assistance I have not yet

preventive maintenance explain the principles of the principles of assistance to explain the to explain the principles provided evidence of

and their effects preventive maintenance preventive principles of preventive of preventive this performance task.

and their effects. maintenance and their maintenance and their maintenance and their

effects. effects. effects.

2.3 explain the principles of I can consistently I can usually explain I sometimes need I often need assistance I have not yet

predictive maintenance explain the principles of the principles of assistance to explain the to explain the principles provided evidence of

and their effects predictive maintenance predictive principles of predictive of predictive this performance task.

and their effects. maintenance and their maintenance and their maintenance and their

effects. effects. effects.

2.4 demonstrate basic I can consistently I can usually I sometimes need I often need assistance I have not yet

preventive maintenance demonstrate basic demonstrate basic assistance to to demonstrate basic provided evidence of

and service procedures preventive maintenance preventive demonstrate basic preventive maintenance this performance task.

and service procedures. maintenance and preventive maintenance and service procedures.

service procedures. and service procedures.

Teacher feedback and

assessment.

Heavy Equipment Technician Apprenticeship Assessment CTS, TMT: HEA3415 / 19

Alberta Education, Alberta, Canada 2015

HEAVY EQUIPMENT TECHNICIAN APPRENTICESHIP ASSESSMENT

COURSE HEA3420: TRAILER SYSTEMS

Level: First Period Apprenticeship, Section Two

Prerequisites: HEA3900: Apprenticeship Safety

HEA3400: Basic Tools & Materials

Description: Students develop the knowledge, skills and attitudes necessary to inspect, service and maintain trailer systems and

components.

Parameters: Access to a materials work centre, complete with basic hand tools, specialty hand tools and equipment, and to instruction

from an individual with journeyperson certification in the trade(s) of heavy duty mechanic; heavy duty equipment

mechanic (off-road); truck and transport mechanic; or transport-trailer mechanic.

ILM Resources: Trailer Systems and Components 190102e; Coupling Units Fundamentals and Service 190102f; Landing Gear

Fundamentals and Service 190102g; Orientation to Trailer Inspection 190102h

This sample rubric is for assessing technical elements that students need to know to be successful if they challenge the first-period apprenticeship

exam. The rubric does not include the last two common outcomes that address the demonstration of teamwork and personal management and

identification of steps to achieve personal goals. It is the certificated teachers responsibility to ensure that all outcomes are taught and assessed.

Assessment Tools Notes

Checklist Prior to instruction, a copy of the checklist should be provided to the student to review outcomes that will need to

be demonstrated.

The student may use this checklist as a guide when completing this course.

The teacher should review and sign the checklist when the course is complete to ensure student outcomes have

been successfully demonstrated.

Rubric Prior to instruction, a copy of the rubric should be provided to the student to review and reflect on meeting

expectations set out in the criteria.

This rubric may be used as one element of an assessment process. Teachers should use both formative and

summative assessments to ensure students competency in this course.

20 / CTS, TMT: HEA3420 Heavy Equipment Technician Apprenticeship Assessment

2015 Alberta Education, Alberta, Canada

Heavy Equipment Technician Apprenticeship Assessment CTS, TMT: HEA3420 / 21

Alberta Education, Alberta, Canada 2015

COURSE HEA3420: TRAILER SYSTEMS

Checklist

Student Outcomes Student Teacher Student, Teacher or Instructor Comments

Check Check

1. identify common trailer

systems and components

2. service trailer coupling

systems

3. service trailer landing gear

4. explain trailer inspection

according to Commercial

Vehicle Inspection (CVI)

regulations

Teacher Signature Date

22 / CTS, TMT: HEA3420 Heavy Equipment Technician Apprenticeship Assessment

2015 Alberta Education, Alberta, Canada

COURSE HEA3420: TRAILER SYSTEMS

Rubric

Student Name: Date:

Level Not Yet

Excellent Proficient Adequate Limited

Demonstrated

Criteria

1. identify common trailer systems and components

1.1 describe types and I can consistently I can usually describe I sometimes need I often need assistance I have not yet

configurations of describe types and types and assistance to describe to describe types and provided evidence of

on-highway trailers configurations of configurations of types and configurations of this performance task.

on-highway trailers. on-highway trailers. configurations of on-highway trailers.

on-highway trailers.

1.2 identify trailer I can consistently I can usually identify I sometimes need I often need assistance I have not yet

configurations according identify trailer trailer configurations assistance to identify to identify trailer provided evidence of

to number of axles and configurations according to number trailer configurations configurations this performance task.

hitch points according to number of of axles and hitch according to number of according to number of

axles and hitch points. points. axles and hitch points. axles and hitch points.

1.3 identify trailer axle I can consistently I can usually identify I sometimes need I often need assistance I have not yet

configurations identify trailer axle trailer axle assistance to identify to identify trailer axle provided evidence of

configurations. configurations. trailer axle configurations. this performance task.

configurations.

Heavy Equipment Technician Apprenticeship Assessment CTS, TMT: HEA3420 / 23

Alberta Education, Alberta, Canada 2015

2. service trailer coupling systems

2.1 identify common types of I can consistently I can usually identify I sometimes need I often need assistance I have not yet

trailer coupling units identify common types common types of assistance to identify to identify common provided evidence of

of trailer coupling units. trailer coupling units. common types of trailer types of trailer coupling this performance task.

coupling units. units.

2.2 explain fifth wheel ratings I can consistently I can usually explain I sometimes need I often need assistance I have not yet

and capacity concerns explain fifth wheel fifth wheel ratings and assistance to explain to explain fifth wheel provided evidence of

ratings and capacity capacity concerns. fifth wheel ratings and ratings and capacity this performance task.

concerns. capacity concerns. concerns.

2.3 service fifth wheel I can consistently I can usually service I sometimes need I often need assistance I have not yet

couplings service fifth wheel fifth wheel couplings. assistance to service to service fifth wheel provided evidence of

couplings. fifth wheel couplings. couplings. this performance task.

2.4 service a no-slack pintle I can consistently I can usually service a I sometimes need I often need assistance I have not yet

hitch service a no-slack pintle no-slack pintle hitch. assistance to service a to service a no-slack provided evidence of

hitch. no-slack pintle hitch. pintle hitch. this performance task.

2.5 explain procedures and I can consistently I can usually explain I sometimes need I often need assistance I have not yet

safety precautions explain procedures and procedures and safety assistance to explain to explain procedures provided evidence of

required when coupling safety precautions precautions required procedures and safety and safety precautions this performance task.

and uncoupling trailer required when coupling when coupling and precautions required required when coupling

and uncoupling trailer uncoupling trailer when coupling and and uncoupling trailer

systems and when using

systems and when using systems and when uncoupling trailer systems and when using

landing gear landing gear. using landing gear. systems and when using landing gear.

landing gear.

24 / CTS, TMT: HEA3420 Heavy Equipment Technician Apprenticeship Assessment

2015 Alberta Education, Alberta, Canada

3. service trailer landing gear

3.1 identify common types of I can consistently I can usually identify I sometimes need I often need assistance I have not yet

trailer landing gear and identify common types common types of assistance to identify to identify common provided evidence of

explain their purpose of trailer landing gear trailer landing gear common types of trailer types of trailer landing this performance task.

and explain their and explain their landing gear and gear and explain their

purpose. purpose. explain their purpose. purpose.

3.2 service common types of I can consistently I can usually service I sometimes need I often need assistance I have not yet

trailer landing gear service common types common types of assistance to service to service common provided evidence of

of trailer landing gear. trailer landing gear. common types of trailer types of trailer landing this performance task.

landing gear. gear.

4. explain trailer inspection according to Commercial Vehicle Inspection (CVI) regulations

4.1 outline trailer inspection I can consistently I can usually outline I sometimes need I often need assistance I have not yet

regulations and standards outline trailer trailer inspection assistance to outline to outline trailer provided evidence of

inspection regulations regulations and trailer inspection inspection regulations this performance task.

and standards. standards. regulations and and standards.

standards.

4.2 identify conditions caused I can consistently I can usually identify I sometimes need I often need assistance I have not yet

by damage, wear or identify conditions conditions caused by assistance to identify to identify conditions provided evidence of

corrosion that would make caused by damage, damage, wear or conditions caused by caused by damage, this performance task.

a trailer unsafe or wear or corrosion that corrosion that would damage, wear or wear or corrosion that

would make a trailer make a trailer unsafe corrosion that would would make a trailer

inoperable

unsafe or inoperable. or inoperable. make a trailer unsafe or unsafe or inoperable.

inoperable.

Teacher feedback and

assessment.

Heavy Equipment Technician Apprenticeship Assessment CTS, TMT: HEA3420 / 25

Alberta Education, Alberta, Canada 2015

HEAVY EQUIPMENT TECHNICIAN APPRENTICESHIP ASSESSMENT

COURSE HEA3425: BRAKE FUNDAMENTALS

Level: First Period Apprenticeship, Section Three

Prerequisites: HEA3900: Apprenticeship Safety

HEA3400: Basic Tools & Materials

Description: Students develop the knowledge, skills and attitudes necessary to inspect, service and maintain hydraulic brake systems

and components.

Parameters: Access to a materials work centre, complete with basic hand tools, specialty hand tools and equipment, and to instruction

from an individual with journeyperson certification in the trade(s) of heavy duty mechanic; heavy duty equipment

mechanic (off-road); truck and transport mechanic; or transport-trailer mechanic.

ILM Resources: Hydraulic Brake System Fundamentals 190103a; Hydraulic Brake System (Drum and Disc) 190103b; Hydraulic Brake

System Diagnosis and Service 190103c

This sample rubric is for assessing technical elements that students need to know to be successful if they challenge the first-period apprenticeship

exam. The rubric does not include the last two common outcomes that address the demonstration of teamwork and personal management and

identification of steps to achieve personal goals. It is the certificated teachers responsibility to ensure that all outcomes are taught and assessed.

Assessment Tools Notes

Checklist Prior to instruction, a copy of the checklist should be provided to the student to review outcomes that will need to

be demonstrated.

The student may use this checklist as a guide when completing this course.

The teacher should review and sign the checklist when the course is complete to ensure student outcomes have

been successfully demonstrated.

Rubric Prior to instruction, a copy of the rubric should be provided to the student to review and reflect on meeting

expectations set out in the criteria.

This rubric may be used as one element of an assessment process. Teachers should use both formative and

summative assessments to ensure students competency in this course.

26 / CTS, TMT: HEA3425 Heavy Equipment Technician Apprenticeship Assessment

2015 Alberta Education, Alberta, Canada

Heavy Equipment Technician Apprenticeship Assessment CTS, TMT: HEA3425 / 27

Alberta Education, Alberta, Canada 2015

COURSE HEA3425: BRAKE FUNDAMENTALS

Checklist

Student Outcomes Student Teacher Student, Teacher or Instructor Comments

Check Check

1. apply scientific principles to

braking system operation

2. explain the operation of

hydraulic drum and disc

brake systems

3. service hydraulic drum and

disc brake systems

Teacher Signature Date

28 / CTS, TMT: HEA3425 Heavy Equipment Technician Apprenticeship Assessment

2015 Alberta Education, Alberta, Canada

COURSE HEA3425: BRAKE FUNDAMENTALS

Rubric

Student Name: Date:

Level Not Yet

Excellent Proficient Adequate Limited

Demonstrated

Criteria

1. apply scientific principles to braking system operation

1.1 explain braking principles, I can consistently I can usually explain I sometimes need I often need assistance I have not yet

with emphasis on heat, explain braking braking principles, assistance to explain to explain braking provided evidence of

friction and hydraulic principles, with with emphasis on heat, braking principles, with principles, with this performance task.

forces emphasis on heat, friction and hydraulic emphasis on heat, emphasis on heat,

friction and hydraulic forces. friction and hydraulic friction and hydraulic

forces. forces. forces.

1.2 explain the properties, I can consistently I can usually explain I sometimes need I often need assistance I have not yet

specifications and explain the properties, the properties, assistance to explain the to explain the provided evidence of

handling procedures of specifications and specifications and properties, properties, this performance task.

brake fluid handling procedures of handling procedures specifications and specifications and

brake fluid. of brake fluid. handling procedures of handling procedures of

brake fluid. brake fluid.

2. explain the operation of hydraulic drum and disc brake systems

2.1 explain the principles of I can consistently I can usually explain I sometimes need I often need assistance I have not yet

operation of drum brake explain the principles of the principles of assistance to explain the to explain the principles provided evidence of

systems operation of drum brake operation of drum principles of operation of operation of drum this performance task.

systems. brake systems. of drum brake systems. brake systems.

2.2 explain the principles of I can consistently I can usually explain I sometimes need I often need assistance I have not yet

operation of disc brake explain the principles of the principles of assistance to explain the to explain the provided evidence of

systems operation of disc brake operation of disc principles of operation principles of operation this performance task.

systems. brake systems. of disc brake systems. of disc brake systems.

Heavy Equipment Technician Apprenticeship Assessment CTS, TMT: HEA3425 / 29

Alberta Education, Alberta, Canada 2015

2.3 explain the construction I can consistently I can usually explain I sometimes need I often need assistance I have not yet

and operation of master explain the construction the construction and assistance to explain the to explain the provided evidence of

cylinders and operation of master operation of master construction and construction and this performance task.

cylinders. cylinders. operation of master operation of master

cylinders. cylinders.

2.4 explain the purpose and I can consistently I can usually explain I sometimes need I often need assistance I have not yet

construction of brake lines explain the purpose and the purpose and assistance to explain the to explain the purpose provided evidence of

and hoses construction of brake construction of brake purpose and and construction of this performance task.

lines and hoses. lines and hoses. construction of brake brake lines and hoses.

lines and hoses.

2.5 explain the construction I can consistently I can usually explain I sometimes need I often need assistance I have not yet

and operation of wheel explain the construction the construction and assistance to explain the to explain the provided evidence of

cylinders and calipers and operation of wheel operation of wheel construction and construction and this performance task.

cylinders and calipers. cylinders and calipers. operation of wheel operation of wheel

cylinders and calipers. cylinders and calipers.

2.6 explain the purpose and I can consistently I can usually explain I sometimes need I often need assistance I have not yet

operation of the metering, explain the purpose and the purpose and assistance to explain the to explain the purpose provided evidence of

proportioning and operation of the operation of the purpose and operation and operation of the this performance task.

pressure differential metering, proportioning metering, of the metering, metering, proportioning

and pressure differential proportioning and proportioning and and pressure differential

valves

valves. pressure differential pressure differential valves.

valves. valves.

3. service hydraulic drum and disc brake systems

3.1 list safety responsibilities I can consistently list I can usually list I sometimes need I often need assistance I have not yet

required when servicing safety responsibilities safety responsibilities assistance to list safety to list safety provided evidence of

and repairing brake required when servicing required when responsibilities required responsibilities required this performance task.

systems and repairing brake servicing and when servicing and when servicing and

systems. repairing brake repairing brake repairing brake systems.

systems. systems.

3.2 diagnose brake system I can consistently I can usually diagnose I sometimes need I often need assistance I have not yet

faults diagnose brake system brake system faults. assistance to diagnose to diagnose brake provided evidence of

faults. brake system faults. system faults. this performance task.

3.3 service a typical drum I can consistently I can usually service a I sometimes need I often need assistance I have not yet

brake assembly service a typical drum typical drum brake assistance to service a to service a typical provided evidence of

brake assembly. assembly. typical drum brake drum brake assembly. this performance task.

assembly.

30 / CTS, TMT: HEA3425 Heavy Equipment Technician Apprenticeship Assessment

2015 Alberta Education, Alberta, Canada

3.4 service a typical disc brake I can consistently I can usually service a I sometimes need I often need assistance I have not yet

assembly service a typical disc typical disc brake assistance to service a to service a typical disc provided evidence of

brake assembly. assembly. typical disc brake brake assembly. this performance task.

assembly.

3.5 describe reconditioning I can consistently I can usually describe I sometimes need I often need assistance I have not yet

procedures required for describe reconditioning reconditioning assistance to describe to describe provided evidence of

master cylinders, wheel procedures required for procedures required reconditioning reconditioning this performance task.

cylinders and brake master cylinders, wheel for master cylinders, procedures required for procedures for master

cylinders and brake wheel cylinders and master cylinders, wheel cylinders, wheel

calipers

calipers. brake calipers. cylinders and brake cylinders and brake

calipers. calipers.

3.6 demonstrate brake I can consistently I can usually I sometimes need I often need assistance I have not yet

flushing and bleeding demonstrate brake demonstrate brake assistance to to demonstrate brake provided evidence of

procedures on hydraulic flushing and bleeding flushing and bleeding demonstrate brake flushing and bleeding this performance task.

brake systems procedures on hydraulic procedures on flushing and bleeding procedures on hydraulic

brake systems. hydraulic brake procedures on hydraulic brake systems.

systems. brake systems.

Teacher feedback and

assessment.

Heavy Equipment Technician Apprenticeship Assessment CTS, TMT: HEA3425 / 31

Alberta Education, Alberta, Canada 2015

HEAVY EQUIPMENT TECHNICIAN APPRENTICESHIP ASSESSMENT

COURSE HEA3430: BRAKE SERVICE & REPAIR

Level: First Period Apprenticeship, Section Three

Prerequisites: HEA3900: Apprenticeship Safety

HEA3400: Basic Tools & Materials

HEA3425: Brake Fundamentals

Description: Students develop the knowledge, skills and attitudes necessary to inspect, service and maintain hydraulic, electric and

parking brake systems and components.

Parameters: Access to a materials work centre, complete with basic hand tools, specialty hand tools and equipment, and to instruction

from an individual with journeyperson certification in the trade(s) of heavy duty mechanic; heavy duty equipment

mechanic (off-road); truck and transport mechanic; or transport-trailer mechanic.

ILM Resources: Hydraulic Brake Booster System Fundamentals and Service 190103d; Parking Brake System Fundamentals and

Service 190103e; Electric Brake Fundamentals and Service 190103f

This sample rubric is for assessing technical elements that students need to know to be successful if they challenge the first-period apprenticeship

exam. The rubric does not include the last two common outcomes that address the demonstration of teamwork and personal management and

identification of steps to achieve personal goals. It is the certificated teachers responsibility to ensure that all outcomes are taught and assessed.

Assessment Tools Notes

Checklist Prior to instruction, a copy of the checklist should be provided to the student to review outcomes that will need to

be demonstrated.

The student may use this checklist as a guide when completing this course.

The teacher should review and sign the checklist when the course is complete to ensure student outcomes have

been successfully demonstrated.

Rubric Prior to instruction, a copy of the rubric should be provided to the student to review and reflect on meeting

expectations set out in the criteria.

This rubric may be used as one element of an assessment process. Teachers should use both formative and

32 / CTS, TMT: HEA3430 Heavy Equipment Technician Apprenticeship Assessment

2015 Alberta Education, Alberta, Canada

summative assessments to ensure students competency in this course.

Heavy Equipment Technician Apprenticeship Assessment CTS, TMT: HEA3430 / 33

Alberta Education, Alberta, Canada 2015

COURSE HEA3430: BRAKE SERVICE & REPAIR

Checklist

Student Outcomes Student Teacher Student, Teacher or Instructor Comments

Check Check

1. explain power braking

system service procedures

2. explain service procedures

for parking brake systems

3. explain service procedures

of electric parking systems

Teacher Signature Date

34 / CTS, TMT: HEA3430 Heavy Equipment Technician Apprenticeship Assessment

2015 Alberta Education, Alberta, Canada

COURSE HEA3430: BRAKE SERVICE & REPAIR

Rubric

Student Name: Date:

Level Not Yet

Excellent Proficient Adequate Limited

Demonstrated

Criteria

1. explain power braking system service procedures

1.1 identify common power I can consistently I can usually identify I sometimes need I often need assistance I have not yet

assist braking systems identify common power common power assist assistance to identify to identify common provided evidence of

assist braking systems. braking systems. common power assist power assist braking this performance task.

braking systems. systems.

1.2 explain the principles of I can consistently I can usually explain I sometimes need I often need assistance I have not yet

operation for vacuum explain the principles of the principles of assistance to explain the to explain the principles provided evidence of

brake booster systems operation for vacuum operation for vacuum principles of operation of operation for vacuum this performance task.

brake booster systems. brake booster systems. for vacuum brake brake booster systems.

booster systems.

1.3 describe the diagnosis and I can consistently I can usually describe I sometimes need I often need assistance I have not yet

repair procedures for describe the diagnosis the diagnosis and assistance to describe to describe the provided evidence of

vacuum brake booster and repair procedures repair procedures for the diagnosis and repair diagnosis and repair this performance task.

systems for vacuum brake vacuum brake booster procedures for vacuum procedures for vacuum

booster systems. systems. brake booster systems. brake booster systems.

1.4 explain the principles I can consistently I can usually I sometimes need I often need assistance I have not yet

of operation of explain the principles explain the principles assistance to explain the to explain the principles provided evidence of

air-over-hydraulic brake of operation of of operation of principles of operation of operation of this performance task.

booster systems air-over-hydraulic air-over-hydraulic of air-over-hydraulic air-over-hydraulic brake

brake booster systems. brake booster systems. brake booster systems. booster systems.

1.5 describe the diagnosis I can consistently I can usually describe I sometimes need I often need assistance I have not yet

and repair procedures for describe the diagnosis the diagnosis and assistance to describe to describe the provided evidence of

air-over-hydraulic brake and repair procedures repair procedures for the diagnosis and diagnosis and repair this performance task.

booster systems for air-over-hydraulic air-over-hydraulic repair procedures for procedures for

brake booster systems. brake booster systems. air-over-hydraulic brake air-over-hydraulic brake

booster systems. booster systems.

Heavy Equipment Technician Apprenticeship Assessment CTS, TMT: HEA3430 / 35

Alberta Education, Alberta, Canada 2015

1.6 explain the principles I can consistently I can usually explain I sometimes need I often need assistance I have not yet

of operation for explain the principles of the principles of assistance to explain the to explain the principles provided evidence of

hydraulic-over-hydraulic operation for hydraulic- operation for principles of operation of operation for this performance task.

brake booster systems over-hydraulic brake hydraulic-over- for hydraulic-over- hydraulic-over-

booster systems. hydraulic brake hydraulic brake booster hydraulic brake booster

booster systems. systems. systems.

1.7 describe the diagnosis and I can consistently I can usually describe I sometimes need I often need assistance I have not yet

repair procedures for describe the diagnosis the diagnosis and assistance to describe to describe the provided evidence of

hydraulic-over-hydraulic and repair procedures repair procedures for the diagnosis and repair diagnosis and repair this performance task.

brake booster systems for hydraulic-over- hydraulic-over- procedures for procedures for

hydraulic brake booster hydraulic brake hydraulic-over- hydraulic-over-

systems. booster systems. hydraulic brake booster hydraulic brake booster

systems. systems.

2. explain service procedures for parking brake systems

2.1 explain the principles of I can consistently I can usually explain I sometimes need I often need assistance I have not yet

operation for common explain the principles of the principles of assistance to explain the to explain the principles provided evidence of

parking brake systems operation for common operation for common principles of operation of operation for this performance task.

parking brake systems. parking brake for common parking common parking brake

systems. brake systems. systems.

2.2 describe the adjusting I can consistently I can usually describe I sometimes need I often need assistance I have not yet

procedures for common describe the adjusting the adjusting assistance to describe to describe the adjusting provided evidence of

parking brake systems procedures for common procedures for the adjusting procedures procedures for common this performance task.

parking brake systems. common parking for common parking parking brake systems.

brake systems. brake systems.

2.3 describe repair procedures I can consistently I can usually describe I sometimes need I often need assistance I have not yet

for common parking brake describe repair repair procedures for assistance to describe to describe repair provided evidence of

systems procedures for common common parking repair procedures for procedures for common this performance task.

parking brake systems. brake systems. common parking brake parking brake systems.

systems.

3. explain service procedures of electric braking systems

3.1 explain the principles of I can consistently I can usually explain I sometimes need I often need assistance I have not yet

operation for electric explain the principles of the principles of assistance to explain the to explain the principles provided evidence of

braking systems operation for electric operation for electric principles of operation of operation for electric this performance task.

braking systems. braking systems. for electric braking braking systems.

systems.

36 / CTS, TMT: HEA3430 Heavy Equipment Technician Apprenticeship Assessment

2015 Alberta Education, Alberta, Canada

3.2 identify basic electric I can consistently I can usually identify I sometimes need I often need assistance I have not yet

braking system failures identify basic electric basic electric braking assistance to identify to identify basic electric provided evidence of

braking system failures. system failures. basic electric braking braking system failures. this performance task.

system failures.

Teacher feedback and

assessment.

Heavy Equipment Technician Apprenticeship Assessment CTS, TMT: HEA3430 / 37

Alberta Education, Alberta, Canada 2015

HEAVY EQUIPMENT TECHNICIAN APPRENTICESHIP ASSESSMENT

COURSE HEA3435: HYDRAULIC SYSTEMS

Level: First Period Apprenticeship, Section Three

Prerequisites: HEA3900: Apprenticeship Safety

HEA3400: Basic Tools & Materials

Description: Students develop the knowledge, skills and attitudes necessary to inspect, service and maintain hydraulic systems and

components.

Parameters: Access to a materials work centre, complete with basic hand tools, specialty hand tools and equipment, and to instruction

from an individual with journeyperson certification in the trade(s) of heavy duty mechanic; heavy duty equipment

mechanic (off-road); truck and transport mechanic; or transport-trailer mechanic.

ILM Resources: Hydraulic Fundamentals 190103g; Hydraulic System Components: Reservoir, Filters, Hoses and Coolers 190103h;

Hydraulic System Components: Pumps, Valves and Cylinders 190103i

This sample rubric is for assessing technical elements that students need to know to be successful if they challenge the first-period apprenticeship

exam. The rubric does not include the last two common outcomes that address the demonstration of teamwork and personal management and

identification of steps to achieve personal goals. It is the certificated teachers responsibility to ensure that all outcomes are taught and assessed.

Assessment Tools Notes

Checklist Prior to instruction, a copy of the checklist should be provided to the student to review outcomes that will need to

be demonstrated.

The student may use this checklist as a guide when completing this course.

The teacher should review and sign the checklist when the course is complete to ensure student outcomes have

been successfully demonstrated.

Rubric Prior to instruction, a copy of the rubric should be provided to the student to review and reflect on meeting

expectations set out in the criteria.

This rubric may be used as one element of an assessment process. Teachers should use both formative and

summative assessments to ensure students competency in this course.

38 / CTS, TMT: HEA3435 Heavy Equipment Technician Apprenticeship Assessment

2015 Alberta Education, Alberta, Canada

Heavy Equipment Technician Apprenticeship Assessment CTS, TMT: HEA3435 / 39

Alberta Education, Alberta, Canada 2015

COURSE HEA3435: HYDRAULIC SYSTEMS

Checklist

Student Outcomes Student Teacher Student, Teacher or Instructor Comments

Check Check

1. explain hydraulic principles

2. explain the function of the

following hydraulic

components: hydraulic oils,

reservoirs, filters,

conductors and heat

exchangers

3. explain the functions and

principles of operation of

hydraulic system

components

Teacher Signature Date

40 / CTS, TMT: HEA3435 Heavy Equipment Technician Apprenticeship Assessment

2015 Alberta Education, Alberta, Canada

COURSE HEA3435: HYDRAULIC SYSTEMS

Rubric

Student Name: Date:

Level Not Yet

Excellent Proficient Adequate Limited

Demonstrated

Criteria

1. explain hydraulic principles

1.1 define basic hydraulic I can consistently I can usually define I sometimes need I often need assistance I have not yet

terminology common to define basic hydraulic basic hydraulic assistance to define to define basic provided evidence of

all hydraulic systems terminology common to terminology common basic hydraulic hydraulic terminology this performance task.

all hydraulic systems. to all hydraulic terminology common to common to all

systems. all hydraulic systems. hydraulic systems.

1.2 explain, using I can consistently I can usually explain, I sometimes need I often need assistance I have not yet

mathematical calculations, explain, using using mathematical assistance to explain, to explain, using provided evidence of

the hydraulic principles of mathematical calculations, the using mathematical mathematical this performance task.

pressure, force and area calculations, the hydraulic principles of calculations, the calculations, the

hydraulic principles of pressure, force and hydraulic principles of hydraulic principles of

pressure, force and area. pressure, force and area. pressure, force and area.

area.

1.3 draw and interpret basic I can consistently draw I can usually draw and I sometimes need I often need assistance I have not yet

hydraulic schematics and interpret basic interpret basic assistance to draw and to draw and interpret provided evidence of

hydraulic schematics. hydraulic schematics. interpret basic hydraulic basic hydraulic this performance task.

schematics. schematics.

1.4 identify hydraulic I can consistently I can usually identify I sometimes need I often need assistance I have not yet

conductors identify hydraulic hydraulic conductors. assistance to identify to identify hydraulic provided evidence of

conductors. hydraulic conductors. conductors. this performance task.

1.5 identify hydraulic valves I can consistently I can usually identify I sometimes need I often need assistance I have not yet

identify hydraulic hydraulic valves. assistance to identify to identify hydraulic provided evidence of

valves. hydraulic valves. valves. this performance task.

1.6 identify hydraulic I can consistently I can usually identify I sometimes need I often need assistance I have not yet

accessories identify hydraulic hydraulic accessories. assistance to identify to identify hydraulic provided evidence of

accessories. hydraulic accessories. accessories. this performance task.

Heavy Equipment Technician Apprenticeship Assessment CTS, TMT: HEA3435 / 41

Alberta Education, Alberta, Canada 2015

1.7 state the safety precautions I can consistently state I can usually state the I sometimes need I often need assistance I have not yet

that must be observed the safety precautions safety precautions that assistance to state the to state the safety provided evidence of

when working with that must be observed must be observed safety precautions that precautions that must be this performance task.

hydraulic systems when working with when working with must be observed when observed when working

hydraulic systems. hydraulic systems. working with hydraulic with hydraulic systems.

systems.

2. explain the function of the following hydraulic components: hydraulic oils, reservoirs, filters, conductors and heat exchangers

2.1 explain the functions of I can consistently I can usually explain I sometimes need I often need assistance I have not yet

hydraulic oil explain the functions of the functions of assistance to explain the to explain the functions provided evidence of

hydraulic oil. hydraulic oil. functions of hydraulic of hydraulic oil. this performance task.

oil.

2.2 state the primary quality I can consistently state I can usually state the I sometimes need I often need assistance I have not yet

characteristics of the primary quality primary quality assistance to state the to state the primary provided evidence of

hydraulic oil characteristics of characteristics of primary quality quality characteristics this performance task.