DBR

Diunggah oleh

keerthivasan_mrvJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

DBR

Diunggah oleh

keerthivasan_mrvHak Cipta:

Format Tersedia

Epoxy-based proprietary type non-shrink grout shall be used for filling the space under base plates

and in sleeves around anchor bolts to vibrating equipment including all pumps, compressors, etc.

Anchor Bolts & Cast-in Items

Anchor bolts and nuts shall be galvanised and shall be grade 8.8 to BS 3692. Except for the

foundation bolts which shall conform to BS 7419, any bolt which will be under direct tension shall

conform to BS 4395.

Lock nuts shall be provided for anchor bolts to vibrating equipment. Anchor bolts, nuts and washers

shall be galvanised in accordance with BS EN ISO 1461. All other structural steel items cast-in to

concrete shall be hot dip galvanised accordance with BS EN ISO 1461 unless noted otherwise in the

project documents. Each anchor bolt shall be adequately anchored into concrete.

Washers and lock nuts shall be as per QCS Section 16, Parts 2.5.5 and 2.5.6, respectively.

The minimum distance from centre line of anchor bolt to edge of concrete plinth shall be the larger of 4

times the bolt diameter and below given values:

Bolt Size Minimum Edge Distance

20mm diameter 100mm

> 20mm diameter 150mm

The minimum distance from base plate to edge of concrete plinth shall be 75mm.

Adequate reinforcement shall be provided in concrete plinths to transfer the design tension and shear

from anchor bolts to the foundation. Vertical reinforcement in concrete plinths shall be provided with

sufficient anchorage length above and below the bottom of anchor bolts.

18.2.6 Steel Structures

18.2.6.1 General

The following provisions are applicable to steel structures, buildings, stairways and other

miscellaneous steelwork.

The design, details, fabrication and erection of structural steel shall be in accordance with BS 5950 (or

the latest BS-EN code superseding it).

All structural steel shall be of steel S275 JR conforming to BS EN 10025, or equivalent, as a minimum.

Minimum thickness of structural members and connections shall be as follows:

1. Except for the web of rolled steel sections, the minimum thickness of structural members shall

be 6mm; and

2. Minimum thickness for gusset plates in structural connections shall be 10mm.

18.2.6.2 Allowable Deflections

In addition to BS 5950 the allowable deflections given in the following table shall be adhered to.

Table 18-7: Deflection Requirements in Addition to BS 5950

Vertical Horizontal

Structure Member Type

Deflection Deflection

Purlins, girts L/200

Floor beams : without equipment L/300

Steel

: with equipment L/500

Members L/500

Crane runway girders L/750

Hoist monorail beams L/750

New Port Project

NPP/0085: Strategic Food Security Facilities

15 June 2016 Page 80

Cantilever Beams L/400

without equipment H/200

with equipment

Steel frames

-including wind allowance H/300

-not including wind allowance H/200

Main supporting beams

L/400

Combined deflections of intermediate beams and longitudinal tie

Pipe Racks L/200

beams

H/300

Pipe rack frames

H equals the height of frames and L equals the span of beams.

18.2.6.3 Connections

Bolted connections shall preferably be designed based on bearing type connections.

Unless noted otherwise in the project documents, all bearing type structural connections shall be

made using galvanised bolts of grade 8.8 conforming to BS 3692 in normal tolerance holes using a

minimum of 2 x M20 bolts; High strength steel bolts with minimum of 16 mm diameter of grade 8.8

conforming to BS 3692 shall be used for cast-in holding down bolts, walkway structures, joists, girts,

stair stringers, handrails and minor connections;

For structural connections other than bearing-type such as those where bolts are subject to direct

tension or those classified as slip-critical connections, the bolts shall conform to BS 4395.

Connection designs shall be based upon field bolting and shop welding.

Welding of structural steel shall be in accordance with AWS D1.1, BS EN 1011 Part 1 and BS EN

1011 Part 2;

Welded joints shall be seal welded. All welded joints exposed to the weather or to a corrosive

atmosphere shall be seal welded;

For steel sections fabricated from plate, connection between flange and web of section shall have fillet

weld both sides of web;

Unless noted otherwise, fillet welds shall be minimum 6mm leg length;

All welds shall be made using the following class electrodes as a minimum:

1. Class 35 electrodes to BS EN 440 or BS EN 499 for Grade S275 steel;

2. Electrodes class E70xx to AWS A5.1 or class ER70xx to AWS A5.18 with minimum elongation

22% are also acceptable for Grade S275 steel;

3. Class 42 electrodes to BS EN 440 or BS EN 499 for grade S355 steel; and

4. Class 50 electrodes to BS EN 440 or BS EN 449 for grade S460 steel.

Design strength of fillet welds shall be in accordance with Table 37 of BS 5950 Part 1.

Standard simple beam connections, unless otherwise noted, shall be designed and detailed by the

fabricator for the beam capacity load as shown in Part 3 of BCSA Structural Steelwork Handbook. For

member sizes not covered in Part 3 of the BCSA handbook the design load shall be equal to the

calculated reaction for the beam loaded with the maximum allowable uniform load assuming full lateral

supports.

18.2.6.4 Grating, Stairs Treads and Solid Plate Flooring

Grating shall conform to BS 4592 or equal and be galvanised to a coating weight of 610 g/m2, in

accordance with BS EN ISO 1461. Grating steel shall conform to grade S275 JR in accordance with

BS EN 10025 and shall be fixed with spring washers.

New Port Project

NPP/0085: Strategic Food Security Facilities

15 June 2016 Page 81

Load bearing bars: minimum 30mm x 5mm, with serrated top, at 30mm pitch.

Transverse bars: minimum 6mm x 6mm twisted square bars at 100mm pitch.

Stair treads shall have load bearing bars and transverse bars similar to Gratings. Treads shall be

supplied with end plate and a slip resistant nosing.

Solid chequer plate flooring shall be 6mm thick and galvanised to 610 g/m2, in accordance with BS

EN ISO 1461 or equal.

Where floor plates or grating are removable, the weight of a single plate or section of grating should

not be more than 45 kg.

Solid plate flooring shall be secured to supporting members by 10mm diameter countersunk bolts at

not more than 300mm centres.

Solid plate flooring shall have 12mm drainage holes at 600mm centres each way.

18.2.7 Walls and Claddings

18.2.7.1 Thermal Insulation

All buildings where air-conditioning is to be provided shall have sufficient thermal insulation. The

thermal properties of the building elements shall meet the following minimum standards:

The heat transmission (U) value for roofs : 0.570 watts/m2C

The heat transmission (U) value for external walls : 0.741 watts/m2C

All external windows shall be double-glazed with solar reflecting glass, 6mm thick minimum.

18.2.7.2 Concrete Blockwork

Blockwork shall be designed to BS 5628 and shall comply with BS 6073 Part 1 and QCS Section 13.

External walls shall be cavity type comprising of 100mm thick solid concrete block external skin,

150mm thick hollow concrete block internal skin and a 75mm cavity with 50mm thick insulation in

between the two skins.

Walls dividing storage areas from office areas and walls surrounding electrical rooms shall be

minimum 200mm solid concrete block. Other internal block work walls shall be minimum 150mm

concrete blocks.

Blockwork walls shall be tied to structural columns and beams using proprietary stainless steel system

that complies with the requirements of BS 5628. Cavity wall ties shall also be stainless steel.

Where joints are required, stainless steel plaster stops shall be used either side of each joint for all

external joints. Internal wall joints in office areas shall be finished flush with plaster on stainless steel

expanded metal.

Wall joints formed using plaster stops shall be filled using an approved two-part polysulphide sealant.

All blockwork up to the ground level shall be of solid blocks and of sulphate resisting cement and shall

2

have minimum compressive strength of 15 N/mm .

2

Minimum compressive strength of hollow block work shall be 7 N/mm .

Blockwork walls shall not be used as a structural load carrying member.

New Port Project

NPP/0085: Strategic Food Security Facilities

15 June 2016 Page 82

Anda mungkin juga menyukai

- Dimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyDari EverandDimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyBelum ada peringkat

- A Short Guide to the Types and Details of Constructing a Suspension Bridge - Including Various Arrangements of Suspension Spans, Methods of Vertical Stiffening and Wire Cables Versus Eyebar ChainsDari EverandA Short Guide to the Types and Details of Constructing a Suspension Bridge - Including Various Arrangements of Suspension Spans, Methods of Vertical Stiffening and Wire Cables Versus Eyebar ChainsBelum ada peringkat

- Stop LogsDokumen7 halamanStop LogsDangol RupeshBelum ada peringkat

- Weicco India HangersDokumen4 halamanWeicco India HangersDnyaneshwarBelum ada peringkat

- Checklist For BPI Structure Design & DrawingDokumen4 halamanChecklist For BPI Structure Design & DrawingRupesh KhandekarBelum ada peringkat

- Checklist For Fabrication of Beam Structure Design & DrawingDokumen4 halamanChecklist For Fabrication of Beam Structure Design & DrawingRupesh KhandekarBelum ada peringkat

- Expansion Compensation For PlumbingDokumen6 halamanExpansion Compensation For Plumbingabdullah sahibBelum ada peringkat

- H-Beam, Channel Sleeper FabricationDokumen64 halamanH-Beam, Channel Sleeper FabricationVipin Dhanwaliya100% (5)

- Technical Specification - 2023 04 12 13 58 37Dokumen14 halamanTechnical Specification - 2023 04 12 13 58 37Structures ProductionBelum ada peringkat

- Hanger CatalogueDokumen4 halamanHanger CatalogueDnyaneshwar100% (1)

- Checklist For Lighting Mast Structure Design & DrawingDokumen4 halamanChecklist For Lighting Mast Structure Design & DrawingRupesh KhandekarBelum ada peringkat

- Checklist For Wave Trap Structure Design & DrawingDokumen4 halamanChecklist For Wave Trap Structure Design & DrawingRupesh KhandekarBelum ada peringkat

- Technical Specification: Section - C1Dokumen5 halamanTechnical Specification: Section - C1Anonymous EVFw59Belum ada peringkat

- Checklist For 33kV DP Structure Design & DrawingDokumen4 halamanChecklist For 33kV DP Structure Design & DrawingRupesh KhandekarBelum ada peringkat

- Checklist For 33kV HG Fuse Structure Design & DrawingDokumen4 halamanChecklist For 33kV HG Fuse Structure Design & DrawingRupesh KhandekarBelum ada peringkat

- Technical Specifications CanopyDokumen5 halamanTechnical Specifications CanopyNaman SharmaBelum ada peringkat

- SLL Glideloc Ladder Systems Emeauk Amp Aus PDFDokumen17 halamanSLL Glideloc Ladder Systems Emeauk Amp Aus PDFRaduBelum ada peringkat

- 2012MBSM DeflectionsDokumen8 halaman2012MBSM DeflectionsmaheshbandhamBelum ada peringkat

- Checklist For Isolator With or Without One or Two Earth Switch Structure Design & DrawingDokumen4 halamanChecklist For Isolator With or Without One or Two Earth Switch Structure Design & DrawingRupesh KhandekarBelum ada peringkat

- Sluice Gate ValveDokumen15 halamanSluice Gate ValveRinia DurrsakeBelum ada peringkat

- Checklist For 33kV Bus Duct Structure Design & DrawingDokumen4 halamanChecklist For 33kV Bus Duct Structure Design & DrawingRupesh KhandekarBelum ada peringkat

- Standard Specification For Corrugated Aluminum Pipe For Sewers and DrainsDokumen15 halamanStandard Specification For Corrugated Aluminum Pipe For Sewers and Drainsjun floresBelum ada peringkat

- Hanger & Support - SpecificationDokumen6 halamanHanger & Support - SpecificationParwez KhanBelum ada peringkat

- Seminar On Pre-Engineered Metal Buildings BY Kavitha Maharaj M.Tech. (P.T.P.G) 5 SemesterDokumen38 halamanSeminar On Pre-Engineered Metal Buildings BY Kavitha Maharaj M.Tech. (P.T.P.G) 5 SemestermaheshbandhamBelum ada peringkat

- Obo Specification - Metal 1.5mm Raceways + JBM + Gesx + Service PoleDokumen2 halamanObo Specification - Metal 1.5mm Raceways + JBM + Gesx + Service PolepmyilsamyBelum ada peringkat

- Early Works Package - Specification B (Section 317210) - Tunnel Primary Support - Ground ReinforcementDokumen3 halamanEarly Works Package - Specification B (Section 317210) - Tunnel Primary Support - Ground ReinforcementZain AbidiBelum ada peringkat

- SECTION 161xx Cable Trays: D. ASTM A1011 - Specification For Steel, Sheet and Strip, Hot-Rolled, CarbonDokumen6 halamanSECTION 161xx Cable Trays: D. ASTM A1011 - Specification For Steel, Sheet and Strip, Hot-Rolled, CarbonMontu KangriwalaBelum ada peringkat

- TS-03 Air Distribution WorksDokumen14 halamanTS-03 Air Distribution WorksPraveen KumarBelum ada peringkat

- 19.sec.1900 (Structural Steel)Dokumen31 halaman19.sec.1900 (Structural Steel)aalignup arc & const. pvt ltdBelum ada peringkat

- Furring For Gypsum Board CeilingsDokumen4 halamanFurring For Gypsum Board Ceilingsjack.simpson.changBelum ada peringkat

- TP 08 LGSS SmallDokumen8 halamanTP 08 LGSS SmallJnanjit ChalihaBelum ada peringkat

- Fire Fighting Specs - 20181228155441Dokumen25 halamanFire Fighting Specs - 20181228155441Sudipto KumarBelum ada peringkat

- Metal StairsDokumen6 halamanMetal Stairssks_242Belum ada peringkat

- STD 15080Dokumen4 halamanSTD 15080dineshinnaci123Belum ada peringkat

- Cold-Formed Steel in ConstructionDokumen33 halamanCold-Formed Steel in ConstructionVijender JainBelum ada peringkat

- PLP Solar PanelDokumen8 halamanPLP Solar PanelCarlos SolerBelum ada peringkat

- Technical Specifications 45990Dokumen4 halamanTechnical Specifications 45990Ravi RajBelum ada peringkat

- SECTION 22 05 29 Hangers and Supports For Plumbing Piping and EquipmentDokumen6 halamanSECTION 22 05 29 Hangers and Supports For Plumbing Piping and Equipmentmichael_george291616Belum ada peringkat

- Specification Ss-20/5 Steel Structures For Substation and Switching Station MaterialDokumen5 halamanSpecification Ss-20/5 Steel Structures For Substation and Switching Station MaterialharrisvasBelum ada peringkat

- Canales UNISTRUTDokumen44 halamanCanales UNISTRUTMarkBelum ada peringkat

- Cement-Mortar Lined & Coated Steel PipeDokumen5 halamanCement-Mortar Lined & Coated Steel Pipenay denBelum ada peringkat

- Specification - Reinforcement BarsDokumen23 halamanSpecification - Reinforcement BarsShishupal SinghBelum ada peringkat

- B. AASHTO - American Association of State Highway and Transport Officials. Aashto 181 Chain Link FenceDokumen6 halamanB. AASHTO - American Association of State Highway and Transport Officials. Aashto 181 Chain Link FenceuddinnadeemBelum ada peringkat

- Technical Specification Section: StructureDokumen10 halamanTechnical Specification Section: StructurePremBhushanBelum ada peringkat

- 76 Vol II SEC - STR - 04 PDFDokumen10 halaman76 Vol II SEC - STR - 04 PDFPremBhushanBelum ada peringkat

- 10 - Chapter10Dokumen4 halaman10 - Chapter10HundeejireenyaBelum ada peringkat

- Section VII. Technical SpecificationDokumen10 halamanSection VII. Technical SpecificationBalkrishna PangeniBelum ada peringkat

- MBMA 2012 Deflection LimitDokumen1 halamanMBMA 2012 Deflection LimitHoang Duc LocBelum ada peringkat

- ITCC in Riyadh Residential Complex J10-13300 10200-1 Louvers and VentsDokumen6 halamanITCC in Riyadh Residential Complex J10-13300 10200-1 Louvers and VentsuddinnadeemBelum ada peringkat

- Icbo Es Report-Er2078pDokumen65 halamanIcbo Es Report-Er2078peltorro-tBelum ada peringkat

- CraneDokumen19 halamanCranedeua2004Belum ada peringkat

- Piping Systems and AccessoriesDokumen16 halamanPiping Systems and AccessoriesYoussef100% (1)

- Dhofar Power Company Saog: Moil MacdonaldDokumen1 halamanDhofar Power Company Saog: Moil Macdonald54045114Belum ada peringkat

- Material Compliance Sheet ValvesDokumen10 halamanMaterial Compliance Sheet ValvesindikumaBelum ada peringkat

- Standard Specification For Corrugated Steel Structural Plate, Zinc-Coated, For Field-Bolted Pipe, Pipe-Arches, and ArchesDokumen17 halamanStandard Specification For Corrugated Steel Structural Plate, Zinc-Coated, For Field-Bolted Pipe, Pipe-Arches, and Archesjun floresBelum ada peringkat

- Civil SpecificationDokumen111 halamanCivil SpecificationAmit Kundu DVCBelum ada peringkat

- Adea Company BroucherDokumen15 halamanAdea Company BroucherVelu SamyBelum ada peringkat

- Section - 05520 - Handrails and RailingsDokumen3 halamanSection - 05520 - Handrails and RailingsNana DelgadoBelum ada peringkat

- Specification For Support and HangerDokumen6 halamanSpecification For Support and Hangerdee1985Belum ada peringkat

- A Practical Workshop Companion for Tin, Sheet Iron, and Copper Plate Workers: Containing Rules for Describing Various Kinds of Patterns used by Tin, Sheet Iron, and Copper Plate Workers, Practical Geometry, Mensuration of Surfaces and Solids, Tables of the Weights of Metals, Lead Pipe, Tables of Areas and CircumferencesDari EverandA Practical Workshop Companion for Tin, Sheet Iron, and Copper Plate Workers: Containing Rules for Describing Various Kinds of Patterns used by Tin, Sheet Iron, and Copper Plate Workers, Practical Geometry, Mensuration of Surfaces and Solids, Tables of the Weights of Metals, Lead Pipe, Tables of Areas and CircumferencesBelum ada peringkat

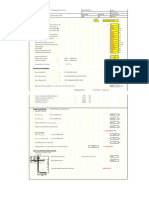

- Purlin Data:-: 10-Sep-2014 1 OF 2 VGC SMA Design of Intermediate Purlin 0 IS: 801Dokumen2 halamanPurlin Data:-: 10-Sep-2014 1 OF 2 VGC SMA Design of Intermediate Purlin 0 IS: 801keerthivasan_mrvBelum ada peringkat

- Purlin Data:-: 26-Apr-2022 1 OF 2 Port RK SSK Design of Int Girt 0 SSK Vizag IS: 801Dokumen2 halamanPurlin Data:-: 26-Apr-2022 1 OF 2 Port RK SSK Design of Int Girt 0 SSK Vizag IS: 801keerthivasan_mrvBelum ada peringkat

- Project: Document No Date 21-05-2022 Designed Checked Description Visakhapatnam Port TrustDokumen1 halamanProject: Document No Date 21-05-2022 Designed Checked Description Visakhapatnam Port Trustkeerthivasan_mrvBelum ada peringkat

- Purlin Data:-: 26-Apr-2022 1 OF 2 Port RK SSK Design of End Purlin 0 SSK Vizag IS: 801Dokumen2 halamanPurlin Data:-: 26-Apr-2022 1 OF 2 Port RK SSK Design of End Purlin 0 SSK Vizag IS: 801keerthivasan_mrvBelum ada peringkat

- Check For Tension: TF TDF: MF m1 M MWDokumen4 halamanCheck For Tension: TF TDF: MF m1 M MWkeerthivasan_mrvBelum ada peringkat

- Defects - Lamellar TearingDokumen5 halamanDefects - Lamellar Tearingkeerthivasan_mrvBelum ada peringkat

- InputsDokumen6 halamanInputskeerthivasan_mrvBelum ada peringkat

- Chain Link ManualDokumen34 halamanChain Link Manualkeerthivasan_mrv100% (2)

- Defects/imperfections in Welds - Slag Inclusions: ! " # # $ # % # # # # & Type of Flux Coating Welder Technique ! # &Dokumen3 halamanDefects/imperfections in Welds - Slag Inclusions: ! " # # $ # % # # # # & Type of Flux Coating Welder Technique ! # &keerthivasan_mrvBelum ada peringkat

- PJR Projects Construction PVT.: Design Basis ReportDokumen96 halamanPJR Projects Construction PVT.: Design Basis Reportkeerthivasan_mrvBelum ada peringkat

- AESS Finish PDFDokumen32 halamanAESS Finish PDFkeerthivasan_mrvBelum ada peringkat

- Shear Stud WeldingDokumen1 halamanShear Stud Weldingkeerthivasan_mrvBelum ada peringkat

- Load CombinationsDokumen2 halamanLoad Combinationskeerthivasan_mrvBelum ada peringkat

- Design of Splicing of RafterDokumen3 halamanDesign of Splicing of Rafterkeerthivasan_mrvBelum ada peringkat

- Locktite 2701Dokumen3 halamanLocktite 2701keerthivasan_mrvBelum ada peringkat

- SDBDokumen5 halamanSDBkeerthivasan_mrvBelum ada peringkat

- Tension: Unity Check For Bolt in Tension 87.28/112 0.77 Hence SafeDokumen2 halamanTension: Unity Check For Bolt in Tension 87.28/112 0.77 Hence Safekeerthivasan_mrvBelum ada peringkat

- Datta ResumeDokumen3 halamanDatta ResumeGnanaSai DattatreyaBelum ada peringkat

- Simplifying Current Sensing: How To Design With Current Sense AmplifiersDokumen58 halamanSimplifying Current Sensing: How To Design With Current Sense AmplifiersAgfagf212Belum ada peringkat

- CD4007Dokumen8 halamanCD4007renegonzalesvasquezBelum ada peringkat

- Manual StereoDokumen29 halamanManual StereoPeter Mac RedBelum ada peringkat

- Online Ethernet 10Base-Fl Module Installation and Operation GuideDokumen100 halamanOnline Ethernet 10Base-Fl Module Installation and Operation Guidesol9159Belum ada peringkat

- RANE SL 1 ManualDokumen40 halamanRANE SL 1 Manualmohamad_moza0% (1)

- Minas A DriverDokumen14 halamanMinas A DriverPham Long100% (1)

- Manual NVT - Configuraciones e InstalaciónDokumen25 halamanManual NVT - Configuraciones e InstalaciónChristian CristãoBelum ada peringkat

- Necessary But Not SufficientDokumen215 halamanNecessary But Not Sufficientvipin13794Belum ada peringkat

- Names, Bindings, Type Checking, and Scopes: Chapter 5 TopicsDokumen20 halamanNames, Bindings, Type Checking, and Scopes: Chapter 5 TopicsAdvait KaleBelum ada peringkat

- Lenovo V110 14IAP Platform SpecificationsDokumen1 halamanLenovo V110 14IAP Platform Specificationskhamida nur faizahBelum ada peringkat

- Session 3Dokumen20 halamanSession 3Hiệu Nguyễn CôngBelum ada peringkat

- IntroductionDokumen18 halamanIntroductionCường TrầnBelum ada peringkat

- YaRrr BookDokumen247 halamanYaRrr BookBaalaji RavichandranBelum ada peringkat

- Heart Beat Monitoring and Wireless Data Logging Using Arm Cortex A8Dokumen5 halamanHeart Beat Monitoring and Wireless Data Logging Using Arm Cortex A8Kb NguyễnBelum ada peringkat

- OpenMax OverViewDokumen45 halamanOpenMax OverViewRajat JindalBelum ada peringkat

- Operating Systems: Suad AlaofiDokumen13 halamanOperating Systems: Suad AlaofiAmal FahadBelum ada peringkat

- Cybertek - Issue #8Dokumen17 halamanCybertek - Issue #8GBPPR100% (1)

- Lan Cabling: BY: Sharee Lei U. UmosoDokumen33 halamanLan Cabling: BY: Sharee Lei U. UmosoShar LeiBelum ada peringkat

- Mach-O Hooking & Dynamic Linking AnalysesDokumen6 halamanMach-O Hooking & Dynamic Linking AnalysesntdetourBelum ada peringkat

- LiftDokumen8 halamanLiftpooja modia100% (1)

- Esite Scanclimber SC1300 - 0Dokumen1 halamanEsite Scanclimber SC1300 - 0Boruida MachineryBelum ada peringkat

- Computer - Hardware: Arithmetic and Logic Unit Micro ProcessorDokumen25 halamanComputer - Hardware: Arithmetic and Logic Unit Micro ProcessorHarsha NaiduBelum ada peringkat

- Java 7 FundamentalsDokumen158 halamanJava 7 Fundamentalscristian_masterBelum ada peringkat

- Au Aix San Switch Firmware PDFDokumen6 halamanAu Aix San Switch Firmware PDFSunieetBelum ada peringkat

- DX DiagDokumen14 halamanDX DiagMelissa MorganBelum ada peringkat

- Using Cadence NC-Verilog or Verilog-XL Simulator: Electronic Design Automation (EDA) Tools at NPUDokumen6 halamanUsing Cadence NC-Verilog or Verilog-XL Simulator: Electronic Design Automation (EDA) Tools at NPUApoorva BhattBelum ada peringkat

- ECS307R1 EmergencyLEDDriver PIBDokumen4 halamanECS307R1 EmergencyLEDDriver PIBJuanBelum ada peringkat

- Extended ToolkitDokumen2 halamanExtended ToolkitJaskaran SinghBelum ada peringkat

- Nidirokorabozep Cemu 1.11.1 Ultimate Setup Guide Zelda Breath of The Wild Retavuzugogaf PDFDokumen4 halamanNidirokorabozep Cemu 1.11.1 Ultimate Setup Guide Zelda Breath of The Wild Retavuzugogaf PDFPriandi MUkhlisBelum ada peringkat