Siemens Turns Focus To Gasoline Injection: Automotive Is One of The Leaders in This

Diunggah oleh

sinasayedanaJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Siemens Turns Focus To Gasoline Injection: Automotive Is One of The Leaders in This

Diunggah oleh

sinasayedanaHak Cipta:

Format Tersedia

Siemens turns focus

to gasoline injection

Though diesel engines have been getting One key enabling technology is

the lions share of automotive press gasoline injection, and Siemens VDO

recently, two-thirds of the worlds Automotive is one of the leaders in this

automobiles are still powered by area. Its global engineering network is

gasoline engines. Recent gasoline engine developing the latest injection systems

engineering and development efforts by for gasoline engines by focusing both on

many OEMs and suppliers have focused conventional and direct-injection

on closing the efficiency gap with diesel technology.

while enabling further improvements in The heart of Siemens VDO

efficiency and emissions. Automotives European gasoline injector

production lies in Pisa, Italy. The San

Piero and Fauglia facilities, which

produce approximately 15 million fuel

injectors annually, have helped the

company secure close to 30% of the

European market. The companys newest

product for indirect injection, called the

DEKA VII, has been in production in Italy

since November of last year, and by 2006

Siemens VDO Automotive expects that

more than half of its global 16-million-

injector-a-year production to be made at

its Italian facilities.

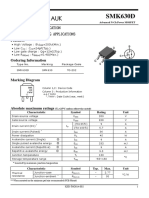

The new line of DEKA VII fuel injectors

give spark-injection engine developers

Siemens VDO Automotives new DEKA VII injector for port injection gasoline more freedom by offering a modular

engines comes in five variants. design and the ability to combine

standardized injector components. Given

the high performance of even the

shortest body length, a single injector size

can work for an entire family of engines.

One injector in the line can have the

capability of delivering minimal fuel

quantities for small engines, yet its

maximum flow could meet the demands

of larger-displacement engines. Engine

developers can integrate the injectors into

both compact and complex engine

geometries with less effort while simulta-

neously ensuring very fine fuel atomiza-

tion for reduced untreated exhaust

emissions. The same nozzle needle

actuator is used for 34.5-, 48.4-, and

60.4-mm (1.36-, 1.91-, and 2.38-in)

injector lengths. The modular approach

allows each basic body length to be

combined with each nozzle length.

And the DEKA VIIs performance charac-

teristics enable engine developers to

The assembly of DEKA injection valves is combine the shortest body length with

completely automated in Siemens Pisa plant. the longest nozzle without a drop in

52 JULY 2004 aei

Briefs

Gentex Corp. has begun shipping

interior rear-view mirrors for Volvo Car

Corp.s new V50 sports wagon. Gentex

auto-dimming mirrors automatically

darken to reduce glare from the

headlamps of vehicles approaching from

the rear. V50 vehicles sold in the U.S. will

be equipped with a Gentex auto-

dimming interior mirror that features a

built-in electronic compass display using

Johnson Controls PathPoint digital

compass system. Gentex will supply a

similar mirror for the Hyundai Tucson

compact SUV.

ArvinMeritor, Inc., has announced a

new contract for a large roof-opening

module with a European OEM. The rail-

to-rail module features a full-glass

appearance, and uses the ArvinMeritor

long-fiber-injected process. A large,

integrated spoiler sunroof is included,

with a tubeless water management

The key components of Siemens piezo gasoline injection system are the engine control unit,

system. A separate contract for a three- high-pressure pump, and injector (shown in cutaway).

panel sunroof, also with an unidentified

European OEM, has been awarded.

performancean advantage when manufactured components, one of the

Magna International, Inc., has signed installation space between the fuel rail and most important of which is the orifice disk.

an agreement with DaimlerChrysler intake manifold is small and the jet origin Its 0.1-0.5 mm (0.004-0.020 in) wide fuel

Corp. to acquire the worldwide opera- is required to extend far into the intake multichannels are delivered just-in-time to

tions of New Venture Gear, Inc., a manifold. The design flexibility reduces the the six assembly lines. A new injector is

supplier of transfer cases and other risk of fuel wetting on the intake manifold produced about every 1.5 s, which equates

drivetrain products. U.S. operations will wall after a cold start, which increases to more than 40 fuel injectors per minute,

be taken over by a joint venture named unburned hydrocarbon emissions. or 2500 per hour. Siemens VDO Automo-

New Process Gear, Inc., which will One of the injectors performance tive has satisfied the demand for 15,000

initially be owed 80% by Magna and features is optimized jet preparation, four-cylinder engines per day by

20% by DaimlerChrysler. The European with options running from single jets producing 60,000 units.

operation will be acquired directly by with cone angles of 10-30 to double To improve the quality and efficiency

Magna. Closing of the transaction is jets with a spread angle of 15 to 30 in of the DEKA injector, engineers substan-

subject to various conditions. between, or a combination of both tially reduced the number of compo-

geometries with an additional bent angle nents and changed the injectors design

Calty Design Research, Inc., has between 5 and 25. Sophisticated dual- to eliminate interior seals. Clean-room

opened a design studio adjacent to the cone jet and bent angle solutions also assembly ensures that contaminants do

headquarters of the Toyota Technical help reduce intake manifold wall not hinder fuel flow through the seal-

Center in Ann Arbor, MI. Caltys first wetting. To keep untreated exhaust less design, which ensures long-lasting

project at the new location will be to emissions low and satisfy stricter reliability since there are no rubber seals

collaborate with the Technical Center emissions standards such as Euro V, the and plastic washers to age and wear.

on Toyotas next-generation Tundra DEKA VII injects finely atomized fuel with Although quality control inspection

pickup truck. average particle sizes of less than 70 m occurs after each assembly step,

(0.003 in), depending on injection employees perform additional quality

Delphi has announced nine new pressure and other conditions, and checks at the end of production and test

contracts for steering columns. The typical operating pressure of 3 to 5 bar each injector on an automated bench

contracts feature Delphis standard, rake, (44 to 73 psi). before it is packaged and delivered to a

tilt, and telescopic columns in both floor- The Pisa operations manufacturing customers engine manufacturing plant.

and column-shift models. Each of the process is a high-speed exercise produc- Further injection research will be

columns incorporates Delphis energy- ing nearly one injector every three required so that European Automobile

absorbing technology. seconds. DEKA injectors are assembled in Manufacturers Association (ACEA)

clean rooms using mostly in-house members can fulfill their commitment

54 JULY 2004 aei

to lower their vehicle fleets CO2 the range of stratified operation. How- Clean combustion is ensured by an

emissions to a maximum average of ever, the spray-guided combustion extremely fine atomization of fuel. At a

140 g/km by 2008. Although the processes place much greater demands high gasoline injection pressure of

growing market share of increasingly on injection pressure, dynamics, jet about 200 bar (2.9 ksi), average fuel-

efficient next-generation diesel engines preparation, and feed precision, hence droplet diameter is only 15 m (590

will help, the ACEA target can be the need for further development. in). Together with injector nozzles

reached only by lowering gasoline The core components of the PDI that open into the cylinder, the

engine fuel consumption, with one system are the innovative piezo-injector, atomization results in an optimally

solution being direct injection. However, newly developed high-pressure fuel prepared mixture cloud at the spark

the promise of direct fuel injections pump, and a new engine control unit. plug under nearly all conditions. The

fuel-saving benefits has yet to be fully Fitting a piezo-actuator directly on high injection pressure is enabled by a

realized, according to Siemens VDO the nozzle needle improves injector new axial piston pump with extremely

Automotive, primarily due to the dynamics, allowing a nozzle needle to efficient dose control. Pump friction is

technologys current air- and wall- complete its full stroke in only 0.2 ms. reduced by thorough lubrication and

guided combustion processes. In Piezo injectors allow multiple injections bearing technology to ensure low

addition, stratified-charge can only be in the light and medium load range to pump drive power requirements and

employed in certain driving situations. ensure stable combustion with little high overall drive efficiency.

San Piero is a part of the development fluctuation. In stratified operation, fuel The 32-bit engine control unit (ECU)

network working on the next generation feed precision is enhanced by the piezo that manages the overall system has

of direct gasoline injection, including elements ability to partially or com- among its expanded functions a freely

injectors that will enable the reduction of pletely open and close the injector. definable needle stroke length and

fuel consumption by up to 20% starting Precision is improved even with short speed and multiple-injection control

around 2006. The Piezo Direct Injection injection pulses, the maximum deviation with up to three injection pulses per

(PDI) system is based on piezoelectric between individual injected quantities of cylinder and working cycle. If an engine

actuation technology and enables the fuel being just 2%. The combination of is equipped with appropriate sensors,

first-ever spray-guided combustion injector switching speed and precision is the ECU can individually adjust the

procedure. Fuel can be injected directly in the key to improved control of injection injectors needle for each cylinder.

front of the spark plug more of the time and enables late ignition timing in Kevin Jost

with the new system, greatly expanding stratified-charge mode without misfiring.

Sound design from Boysen

It used to be that sound was merely a In an ideal case, the acoustics of a exhaust system has to be tuned to

by-product of engine and vehicle car are just as unmistakable as its various frequency bands.

development. Car makers and exhaust appearance, said Bjrn Koch, Acoustic The target specification for the BMW

system suppliers confined themselves to Engineer at Boysen, a German exhaust 645Ci was to create a completely new

meeting the legal noise limits and system specialist. Sound design sound image that matches the character

eliminating undesired noise. Those days includes all those measures that modify of the luxury sports coupe, said Koch.

are over. For todays luxury and sports the sound of a vehicle in a targeted There was to be a conscious effort to

cars, a sound that is typical of the brand manner by emphasizing the desired disregard the engine sound of the old

and the model is now an essential part frequency ranges and suppressing the 6-Series and vehicles of other brands.

of the cars character. The sound of the undesired frequencies, he added. Since The aim was to achieve a subjectively

BMW 645Ci is the result of a systematic engine noise frequencies change their pleasant, sporty, V8 sound that is also

design process. composition with the engine speed, the clearly audible inside the car.

The exhaust system of the BMW 645Ci, with twin asymmetrical rear Boysen engineers measured the BMW 645Ci tailpipe noise on an

silencers, was tuned by Boysen to create a desired sound image. acoustic rolling test stand.

56 JULY 2004 aei

two front silencers, one middle silencer, designing source noises in such a way

and two rear silencers. For the sound that the driver has appropriate acoustic

design, the acoustic engineers concen- feedback without the noise becoming

trated on the middle silencer and the irritating for the other vehicle occu-

two rear silencers. The front part from pants, said Koch.

the manifold to the front silencers is To give the sound of the BMW 645Ci

identical to the system in the 545i the desired sporty quality, the acoustic

and 745i vehicles. engineers from Boysen raised the sound

The firing order and ignition timing level compared to the luxury models. The

determine the low-frequency composi- separation of the exhaust flows from the

tion of the tailpipe noise, and the left- and right-hand cylinder banks, the

manifold and catalytic converters have reduction of the middle silencer volume,

only a minor influence, said Koch. The and the expansion of the pipe cross

two front silencers also function sections, particularly for the internal

primarily as pipe interruptions to pipes in the rear silencers, all contributed

prevent resonances. to making the coupe noticeably louder.

Acoustic engineers at Boysen use a Throughout the development project, The developers tuned the characteris-

dummy head to make realistic

recordings for subjective evaluation

two different front silencers and around tic sound image of the V8 engine by

of the noise inside a vehicle. ten different middle silencers were giving each of the two parallel rear

designed, built, and tested. For the rear silencers a slightly different interior

The raw noise is provided by a 4.4-L silencers alone, about two dozen structure. This asymmetrical design results

V8 engine, the same power unit installed variants were tested. In this project, in a targeted phase displacement of the

in the BMW 545i and 745i models. But more than half of the variants were built noise from each tailpipe. Due to their

it doesnt sound anywhere near as on the basis of subjective fine-tuning. An firing order, the two cylinder banks1 to

powerful in those cars, said Koch. In important role was played by effects that 4 and 5 to 8sometimes produce noise

keeping with the specifications at the we are not yet able to measure on the in antiphase, said Koch. So our aim in

time, we tuned the exhaust systems for computer, said Koch. designing the rear silencers was to

those two cars with the emphasis more The acoustic engineers measured the emphasize the differences without

on comfort than on sportiness. exterior noise, composed of tailpipe and reinforcing the undesirable side effects.

Kochs colleagues from the computa- surface-borne sound, at precisely defined Koch is convinced that sound design

tion department used computer tailpipe positions behind the vehicle. To measure will become increasingly important in the

simulations to develop the concept for interior noise, the engineers used what is future, and he is sure that the subject of

the exhaust system of the coupe. The called dummy head measuring sound design still has a long way to go.

system has a dual-line design, consisting technology. Realistic recordings with the People will hear about it much more in

of two air-gap-insulated steel manifolds, dummy head allow a subjective evalua- the future, he said.

two close-coupled catalytic converters, tion of the interior noise. The skill lies in David Alexander

New Hyundai tech center to support growth

Up to now, we have been concentrat- technical support. At the moment,

ing on EPA certification testing and we are thinking vehicle development,

vehicle validation, but this is not said Cho.

enough for us to increase our sales in An additional 85 people will be

the United States, said Won Suk Cho, hired when the new technical center

President of the Hyundai Kia America opens. And the 125-person staff for

Technical Center, during ground- 2005 is projected to more than triple

breaking ceremonies for a new by decades end. In 2010, we are

technical center that will be more going to have 400 people, primarily

than five times the size of the design and test engineers, said Cho,

existing facility. who noted that one of the reasons for

The current 33,000-ft2 (3000-m2) remaining in Michigan is the availability

Michigan technical center will be of very well experienced engineers. Superior Township becomes the new

Michigan home to the Hyundai technical

replaced in June 2005 by a 190,000-ft2 The two-stage, $117 million project center in 2005 as a replacement for an

(18,000-m2) center in a nearby commu- will facilitate the company reaching its existing facility in nearby Pittsfield

nity to support the development goal of selling one million units in the Township.

namely competitive analysis, emissions, U.S. by 2010. Hyundai Motor Com-

and durability testingof current and pany has high aspirations for the U.S. for this country, said S.K. Kim,

new Hyundai and Kia vehicles for the market, and this facility will play a vital President of Research and Develop-

U.S. market. But the long-term vision role in supporting the development, ment for Hyundai Motor Co.

may mean powertrain and platform design, and manufacture of vehicles Kami Buchholz

58 JULY 2004 aei

Keeping it clean and smooth

The rear-screen wiper is an essential

feature on many types of vehicle. The

wiper must function in all weather

conditions and with any number of

materials that might be thrown onto

the glass, including liquids, dirt, and

ice. Smooth, quiet operation is

also desirable.

The typical rear-wiper system is a

device consisting of a unidirectional

electric motor with a shaft-mounted

worm gear, a mating helical gear, and a

mechanical crank mechanism. The crank

mechanism creates reciprocating motion The second-generation rear wiper system

at the balance link, which translates into from Johnson Electric has electronic control

a bidirectional, limited-angle rotation of and was developed for a passenger vehicle

the output shaft. This electromechanical scheduled for 2004 production.

design has many limitations, with its

high mechanical complexity, multiple

wear points, and inflexible performance: design provides additional flexibility in

wipe angles and park positions are fixed program timing with the ability to

by the linkage design. simultaneously adjust to system design

Johnson Electric began develop- A typical current rear wiper is a complicated changes and market trends. The

ment of a rear wiper without a me- device consisting of an electric motor with a advanced electronic control system

shaft-mounted worm gear, a mating helical

chanical mechanism in 1990, and the makes it possible to offer changeable

gear, and a mechanical crank mechanism.

first-generation product was launched systems to enhance customer value and

on a 1994 production vehicle. This adjust to environmental and vehicle

design proved the technical feasibility of conditions. The performance and

an electronic wiper system, and resulted motion profile. However, the sinusoidal reliability of the technology has been

in a 15% reduction in mass over the motion profile required a more proven through rigorous testing.

traditional mechanical system. The sophisticated sensing system. To meet The new wiper system is completely

microprocessor electronic control unit this need for the second-generation programmable for optimum perfor-

directed four power MOSFETs (metal- system, new sensing technology was mance on different vehicles and for

oxide-semiconductor field-effect- designed using a 16-pole magnet different customer requirements.

transistors) controlling power to the attached to the motor shaft, and two Disruptions on the wipe surface, or at

gear motor. Ramping up the voltage to Hall sensors that send rotor position the end of the wipe angle, are auto-

the motor at the start of a wipe cycle signals to a microprocessor. matically handled. The motor starts

and down at the end of the cycle The final development step was the softly with smoothly increasing speed

provided soft start/stop capability. The integration of the electronics into the and reaches peak speed at the glass

general operation relied on the micro- gear motor assembly. In order to mid position. The motor then deceler-

processor to optimize the system accomplish this, the electronics package ates smoothly until it reaches the end

motion by precisely controlling the size had to be drastically reduced. The of travel, where motor reversal occurs.

motor. Bidirectional wiping action was final design reduced the part count to The advanced sensing system allows

achieved without linkages by electrically just 14six active and eight passivea absolute precision during wiping

reversing the direct-drive gear motor. reduction of 80% from the original 68. of 0.2.

The first-generation system used a Reliability was also enhanced with the In addition to improved perfor-

control method that resulted in sudden integration of 52 components into the mance, the second-generation rear

speed and direction changes at each mixed signal (analog/digital) ASIC wiper gives a 40% reduction in mass

end of the wiper travel. Analysis (application-specific integrated circuit). and a 20% reduction in size over the

showed that substantial improvements The ability to use one motor for old mechanical system.

in noise and end-of-travel position many vehicle platforms and still provide David Alexander

accuracy could be achieved by using a vehicle-specific performance features

sinusoidal, rather than trapezoidal, provides real cost advantages. The new

60 JULY 2004 aei

>>Concept to Reality

CAN oe Independence for pickup trucks

For CAN, LIN

MOST, FlexRay

TM Historically, the leaf-sprung solid axle has

been the untouchable symbol of

ruggedness and load-carrying ability for

working trucks. However, a small

Ne

Versionw engineering team at Dana Automotive

5.0!

Systems Group has developed a full-

perimeter rear frame section with an

independent axle, double A-arms, and

coil springs. The objective: provide an

assembly-line exchange independent

rear suspension (IRS) option that would

give a smoother ride and better han-

dling, such as for those pickups that will

be mainly for personal use.

As developed, the IRS module has

the Dana Model 44 independent axle,

said Aaron Stange, the engineering

Enterprise Wide leader, who worked with six engineers

part-time and finished the job in under a

Solution from year. The module is not limited to light-

The Dana IRS module uses tubular aluminum

duty operation. If necessary, a larger axle

OEM thru Supplier could be installed to increase towing

crossmembers over the rear differential,

which are joined to the steel frame rails by

capacity, and changes in shocks, springs, magnetic-pulse welding.

Model and Simulate and sway-bar bushings could be made to

Network Behavior increase load capacity, he added. The An additional potential application

module was designed to adapt to would be those SUVs built on pickup

Verify the Module locking differentials and even four- truck frames. Although such models as

Performance (In- wheel-steering. the Ford Explorer and Expedition,

the-Loop) Against originally built on pickup frames, now

have frames and IRS, other SUVs do not.

the Model The Ford IRS is built up on the assembly

line, not installed as a bolt-in module.

Specific module and network For SUVs built on the same assembly line

behavior problems are identified, as pickup trucks, a bolt-in IRS module as

without question, and with ease in an alternative would provide great

the early build stages. Reduces cost flexibility to the manufacturer.

and time delays at 'crunch time'! The Dana module is a lightweight

design, using aluminum for upper and

lower control arms, knuckles, differential

housing, and two crossmembers. The

aluminum crossmembers are joined to

the steel frame rails with Danas mag-

netic-pulse welding, a cold-welding

process that uses an electromagnetic

USED BY field to force one metal into another. The

THOUSANDS amperage used is very high, but because

WORLDWIDE! the process is instantaneous, there is no

temperature buildup. Magnetic-pulse

welding lends itself to tubular parts, and

The Dana IRS module for pickup trucks and this process for aluminum-to-steel is also

truck-based SUVs has the Dana Axle Model used by Dana for aluminum-tube/steel-

44 independent axle, and includes vented-

rotor disc brakes, aluminum control arms, end driveshafts.

www.vector-cantech.com and knuckles. Paul Weissler

Vector CANtech, Inc.

39500 Orchard Hill Pl. Ste 550

Novi, MI 48375 USA

(248) 449-9290

Circle 262

62 JULY 2004 aei

Optis gets the LEDs out

The Audi Le Mans quattro concept car LEDs, and the simulated results had to be with the companys CAD software CATIA

was first shown at the 2003 Frankfurt presented so as to correspond to the V5, from Dassault Systemes.

Auto Show. A showcase for new technol- automotive industry lighting standards in The Speos software from the French

ogy, one of the features was the use of force, thereby ensuring the immediate company Optis was chosen. The

LED (light-emitting diode) headlamps. LEDs validity of the headlight. The software training carried out in Optiss

have been around for some time, but not needed to be easy to learn and integrated consultancy offices in Stuttgart lasted

used in production for automotive lighting.

Known for long life, robust construction,

and low power consumption, the design

issue has traditionally been brightness.

Audi turned to Ruetz, an engineering

company specializing in the design and

building of prototypes. We got a

development request from Audi concern-

ing the feasibility of a low-beam headlamp

in LED technology using the design space

of an A6 headlight, said Clemens Stberl,

Project Engineer at Ruetz.

The Le Mans quattro concept car was

to be designed with the traditional front

headlight bulb replaced by a series of LEDs

for improved driver visibility. The new

headlight design had to meet European

standards in order to be approved. Given

the timeframe and the limited number of

cars to be produced, the manufacturer

wouldnt have either the time or the

budget necessary to make multiple

prototypes before approval. Use of a

virtual prototype and simulation software

therefore was essential.

The choice of software was guided by

several criteria. It had to include a library of

At Akebono, world-class brake NVH engineering results in innovative,

The Audi Le Mans quattro concept car dependable friction materials and foundation brakes of superior quality

features the use of LED headlamps

developed by Ruetz with the help of SPEOS and performance. Call us to see how our engineers are working to

software from OPTIS.

solve your next braking challenge.

Quiet. Dependable. Braking Solutions.

Satisfied Customers. The Essence of Braking.

For the concept car, the low-beam has nine akebonobrakes.com

and the high-beam eight LED modules in the

design space of an Audi A6 headlight.

See our Capabilities pg 116-153 Circle 263 aei JULY 2004 63

We can help you

flow faster.

three days and was followed by a two- few possibilities in assembling and

day practical session during which work arranging the lighting modules. We tested

EnkaFusion was started on the project. this with Speos.

Flow Medium With Speos we tested a variety of The first test prototype of the headlight

optical principles for one lighting mod- used 24 LED modules, and had only low-

ulereflector, lenses, and different beam functionality. For the concept car the

arrangements of the LED, said Stberl. low-beam used nine and the high-beam

The preliminary studies were the base for eight modules, thereby eliminating

further development. We decided to numerous problems linked to mounting

continue with a lens-based solution. Optis and space restrictions, and also reduced

supported the LED-coding and re- purchasing costs. Approval was obtained

engineering of the FRAEN-Lens. In the next after building a single prototype.

step we created an illumination for the David Alexander

complete headlight. Here again we had a

Promotes complete wet Red Dot keeps cool

out by creating an open A new air conditioning (A/C) refrigerant rugged environment, and the applica-

channel to flow resins will begin to replace R-134a by the start tions offer good test conditions,

and foams. of the next decade, as part of efforts to explained James Shevlin of AGO. Up to

reduce global-warming emissions, but 50 rooftop units will be installed on

which one? The U.S. EPA and the logging and mining vehicles, according

Acts as a spring and Australian Greenhouse Office (AGO) to Rachel Clarke of AGO.

pushes fiberglass to outer want to give advocates of R-152a the Off-road equipment operates at low

chance to demonstrate that it should be speed, which reduces ram airflow and

edges of mold walls.

the choice. places a premium on efficient system

The system supplier is Red Dot, U.S. operation. For the test, the Red Dot 9727,

Low cost solution for manufacturer of systems and parts for a rooftop unit, was selected and is being

increased productivity. off-road equipment and heavy-duty modified to resolve R-152a safety issues,

trucks, and the AGO is lining up Austra- which arent severe but cant be ignored.

lian fleet operators to equip the demon- R-152a offers some inherent effi-

Ensures a repeatable,

stration vehicles for testing this year. The ciency advantages over R-134a thanks to

high-quality part. U.S. and Australia, although not signato- its much lower molecular weight, but is

ries to the Kyoto Protocol on global very mildly flammable (it will burn with a

Fastest flow medium on warming, promote voluntary projects in flame but not with a spark). In fact, its

their countries and have forged an active rated as non-flammable when used in

the market today. aerosols and as a computer dust-off

partnership. Stephen Andersen of EPA,

Ward Atkinson, chair of the SAE Interior product. The Red Dot 9727 needs only

Climate Control Committee, and Gary 10 oz (280 g) of R-152a, vs. 16 oz

Hansen, Engineering Vice President of (450 g) of R-134a.

Red Dot, developed the program. However, EPA is cautious, so Red

Andersen brought the proposal to the Dots rooftop unit uses an intelligent

U.S.-Australian partnership. temperature-sensing system to evacuate

Australia was chosen because, for all refrigerant from the evaporator (the

openers, it has a hot climate and only part in the passenger cabin) to

provide a safe system shutdown in case

of a major leak.

Were The Thin Line Between Theres a superheat temperature

sensor in the evaporator outletlow-

Comfort and Catastrophe pressureline to the compressor. If the

sensor measures high refrigerant tempera-

tures for the operating conditions,

indicating a leak, it signals a control

module to turn on a low-refrigerant

indicator. If the temperatures go still

1.800.365.7391 higher, indicating a severe leak, the system

www.colbond-usa.com Red Dots Gary Hansen shows Rachel logs a trouble code and goes into the safe

Clarke of the Australian Greenhouse

Office the rooftop unit developed for shutdown. The A/C wont come on until

testing of off-road Australian vehicles. the code is cleared.

Circle 264

64 JULY 2004 aei

Red Dot No. 9727 rooftop unit,

converted to run on R-152a, has an

electronic thermostatic expansion

valve and a check valve in the

discharge line to trap refrigerant in

the condenser and receiver-dryer for a

safe system shutdown. An intelligent

superheat sensor used to determine

refrigerant charge level also enables a

control module to determine when the

evaporator has been emptied on

shutdown.

The system has an electronic thermo-

static expansion valve in the refrigerant

liquid line and a check valve in the discharge

line between compressor and condenser. So

all refrigerant (including what is drawn out

of the evaporator) is trapped on shutdown

between those two points (primarily in the

condenser and receiver-dryer).

The safe shutdown also is used for

normal system turnoff, so no refrigerant

remains in the evaporator in case a leak

develops later. If the condition of the system

remains normal, it turns on again.

Red Dot and AGO also plan to install

secondary-loop R-152a systems in heavy-

duty trucks. The refrigerant loop (the

primary) chills liquid coolant (anti-freeze and

water) in a secondary loop, within a dual

heat exchanger. Because that dual heat

exchangerand the rest of the refrigerant

loopis outside the passenger cabin, no

safety systems are needed in case of a leak.

The chilled coolant is circulated by a

pump to in-cabin heater core-like cooling

coils. Aside from the in-cabin cooling coils

and underhood compressor (and possibly an

accumulator), the Red Dot system is in a

single box.

Although the secondary loop has a slight

operating lag and some efficiency loss

through the dual heat exchanger, it permits

multiple cooling points in the cabin without

additional refrigerant lines. The over-the-

road trucks with sleeper units will be the

ones to use the feature.

Paul Weissler

aei JULY 2004 65

TI pumps it up

The industrys first dual-channel, (48 gal/h) with an

single-stage (DCSS) fuel pump employs operation efficiency rate

two rows of turbine blades to provide of about 20%. What

two parallel pumping paths, compared were going to is a 150 to 250

to a conventional single-stage pump liter per hour flow rate at four to

with an impeller and a single row of six bar of pressure at an efficiency of

outer edge blades. That difference 25 to 30%. This combination is a

essentially makes the product line an quantum leap for a turbine pump, said

on-target match for the high fuel Manouchehr Kambakhsh, Vice President

pressure needs of advanced direct- of Global Advanced Engineering at the

injection gasoline engines. TI Automotive Technology Center

TI Automotive currently produces GmbH in Germany.

about seven million gasoline fuel With parallel pumping paths and an

pumps annually, but the companys The use of two parallel pumping channels in impeller with unique curved-leaning

executive responsible for worldwide the new fuel pump from TI Automotive blades, the DCSS fuel pump helps

improves pumping efficiency by 50% over a

commercial activity believes that DCSS single-channel turbine pump. reduce fuel turbulence and increase

fuel pumpsentering production in pump output. We worked with

2005 for 2006 vehicle model year computational fluid dynamics models to

applicationswill shake up the status TI Automotive. Lindsay thinks the DCSS find geometry that creates the least

quo. We expect this product line to family of fuel pumps will claim that amount of flow disturbances as the fluid

replace our existing gasoline fuel feat by 2010. particles are accelerated through the

pumps 100%, said Brian Lindsay, A typical single-stage turbine provides high-pressure flow channels,

Managing Director, Commercial and a maximum pressure of approximately Kambakhsh said, referencing more than

Purchasing, Global Fuel Systems Group, 5 bar (72 psi) and flow rates of 180 L/h nine months of development time spent

addressing that issue.

Use of a 39-mm motor, which also

LOW PROFILE, FATIGUE RATED, S-BEAM, ROD, & SPECIALTY STYLES powers the companys single-stage

family of pumps, gave the two-year

Load Cells.

program a time advantage. We already

had a reliable pump motor, so we were

able to shave development time right

there, said David Ford, Director of

Advanced Fuel Delivery and Application

Engineering. The pump motor is mated

High accuracy and stiffness

to a 50-mm inlet housing.

Capacities from 25 to 100,000 pounds In hot fuel testing, the DCSS showed

an 8% flow loss, compared to single-

Fatigue-rated models guaranteed for stage turbine pumps that typically show

100 million fully-reversed cycles flow losses ranging from 12 to 32%.

Not only do we need to deliver a cooler

NIST traceable calibration; fuel, but engine-mounted, direct-injection

A2LA accredited to ISO 17025 pumps hold high tolerances, and if they

are exposed to high temperatures, the

New low cost signal conditioners varying coefficients of thermal expansion

in the pump material can create lockup,

Call for information on our strain, said Ford. In a durability payback, the

torque, and dynamic force sensors! pump runs at lower speedsmeaning

less motor brush wearbecause the new

design provides increased fuel flow.

Production of the DCSS pump will

take place in the U.S. and Germany. The

company is investing $16 million for

automated assembly lines and equip-

ment. Initial users of the new product,

Satisfaction Guaranteed or Your Money Refunded according to TI Automotive, include

Toll Free 888-684-0004 24-hour SensorLineSM 716-684-0001 DaimlerChrysler, Nissan, and BMW.

E-mail force@pcb.com Web site www.pcb.com Kami Buchholz

66 JULY 2004 aei

Circle 266

Anda mungkin juga menyukai

- SSP403 2.0 TDI Engine With Common Rail PDFDokumen68 halamanSSP403 2.0 TDI Engine With Common Rail PDFChengdong WuBelum ada peringkat

- CIM Handbook: The Opportunities for Rationalisation Opened up by the Acquisition and Integration of Computer AutomationDari EverandCIM Handbook: The Opportunities for Rationalisation Opened up by the Acquisition and Integration of Computer AutomationM. MesinaBelum ada peringkat

- John Deere Powersource - Tier 4 Engines On Godwin Pumps PDFDokumen2 halamanJohn Deere Powersource - Tier 4 Engines On Godwin Pumps PDFAlvaro TreviñoBelum ada peringkat

- Injection Technology For Marine Diesel Engines MechanicalDokumen8 halamanInjection Technology For Marine Diesel Engines Mechanicalvijendra_1893100% (1)

- Valvetronic Engine Technology PDF FreeDokumen15 halamanValvetronic Engine Technology PDF FreeAnexmechBelum ada peringkat

- GM Dexos Engine Oil Increases Engine Efficiency: New Acdelco Tiered Branding StrategyDokumen8 halamanGM Dexos Engine Oil Increases Engine Efficiency: New Acdelco Tiered Branding StrategyBBNBGHBelum ada peringkat

- Diesel Progress - November 2022-19Dokumen2 halamanDiesel Progress - November 2022-19ovz07333nezid.comBelum ada peringkat

- Inner CleanlinessDokumen8 halamanInner CleanlinessGustavo FelipeBelum ada peringkat

- MTZ Beitrag Die Neuen Ottomotoren en EN PDFDokumen8 halamanMTZ Beitrag Die Neuen Ottomotoren en EN PDFmhafizanBelum ada peringkat

- Fuel Injection System For Opposed-Piston Gasoline Compression-Ignited (OP-GCI) EnginesDokumen15 halamanFuel Injection System For Opposed-Piston Gasoline Compression-Ignited (OP-GCI) EnginesErick RodriguesBelum ada peringkat

- Bosch Paper On Fuel Injection 2005 PDFDokumen9 halamanBosch Paper On Fuel Injection 2005 PDFiocsachinBelum ada peringkat

- MTZ Worldwide. October 2010Dokumen68 halamanMTZ Worldwide. October 2010michele.texaeduBelum ada peringkat

- Diesel Progress - November 2022-14Dokumen2 halamanDiesel Progress - November 2022-14Matias121212Belum ada peringkat

- SSP 351 Common Rail Fuel Injection System Fitted in The 30l v6 Tdi EngineDokumen56 halamanSSP 351 Common Rail Fuel Injection System Fitted in The 30l v6 Tdi EngineNhuong Hoang DinhBelum ada peringkat

- Cummins l9Dokumen12 halamanCummins l9Fodil ZouBelum ada peringkat

- Pump Engineer Cover Story ArticleDokumen3 halamanPump Engineer Cover Story ArticleJosé Bayonas MartínezBelum ada peringkat

- Diesel Progress - November 2022-13Dokumen2 halamanDiesel Progress - November 2022-13Matias121212Belum ada peringkat

- General: CatalogueDokumen21 halamanGeneral: CatalogueTewodros GetachewBelum ada peringkat

- Folha de Dados COMAP Intelidrive LiteDokumen4 halamanFolha de Dados COMAP Intelidrive LiteAdriano lopes da silvaBelum ada peringkat

- Volkswagen Service Training The 30l v6 Tdi EngineDokumen4 halamanVolkswagen Service Training The 30l v6 Tdi Engineterrie100% (36)

- The Diesel Engine As A Sign of The Times and On Its Way To New HorizonsDokumen9 halamanThe Diesel Engine As A Sign of The Times and On Its Way To New HorizonsTamer MoustafaBelum ada peringkat

- 320D FMDokumen20 halaman320D FMlesantiago67% (3)

- 2014-32-0040 - An Advanced Fuel Supply Unit For Single Cylinder Gas EnginesDokumen6 halaman2014-32-0040 - An Advanced Fuel Supply Unit For Single Cylinder Gas EnginesCaio PaimBelum ada peringkat

- A DaimlerChrysler CompanyDokumen19 halamanA DaimlerChrysler Companycmarqcs100% (1)

- Liquid Fuel Medium Speed Generator Sets: Sustainable and Affordable Power SystemsDokumen5 halamanLiquid Fuel Medium Speed Generator Sets: Sustainable and Affordable Power Systemsthomas1313Belum ada peringkat

- Good. Better. Bosch.: Fit For The Future. Fit For Diesel SuccessDokumen8 halamanGood. Better. Bosch.: Fit For The Future. Fit For Diesel SuccessAdrian Evangelist SantificBelum ada peringkat

- Bosch Automotive Battery: Works Any Time, Every Time, All The TimeDokumen28 halamanBosch Automotive Battery: Works Any Time, Every Time, All The TimeSA khBelum ada peringkat

- BorgWarner - Delphi Technologies Aftermarket - Fuel Brochure - 2020Dokumen12 halamanBorgWarner - Delphi Technologies Aftermarket - Fuel Brochure - 2020Wai MinBelum ada peringkat

- Intelidrive Dcu Industrial: Modular Engine Controller For Industrial ApplicationsDokumen2 halamanIntelidrive Dcu Industrial: Modular Engine Controller For Industrial ApplicationsJVV ENGENHARIABelum ada peringkat

- Innovative Valve Train Systems: Technology Highlights and R&D Activities at FEVDokumen8 halamanInnovative Valve Train Systems: Technology Highlights and R&D Activities at FEVAsrar AhmedBelum ada peringkat

- The New BMW Motorrad Boxer Engine With Shiftcam Technology: Valve Ge ArDokumen8 halamanThe New BMW Motorrad Boxer Engine With Shiftcam Technology: Valve Ge Armasanta11Belum ada peringkat

- OM 654 - Launch of A NewDokumen8 halamanOM 654 - Launch of A Newkammy4love9888100% (3)

- From A Single Source: Diagnostics and Spare PartsDokumen27 halamanFrom A Single Source: Diagnostics and Spare PartsГеворг АлексанянBelum ada peringkat

- Brochure Bergen C - EngineDokumen16 halamanBrochure Bergen C - EngineMaxim ShchukinBelum ada peringkat

- B2B Purchase March 2020 PDFDokumen3 halamanB2B Purchase March 2020 PDFLokesh GowdaBelum ada peringkat

- Mohamad Omar MohamadDokumen44 halamanMohamad Omar MohamadVictor GarciaBelum ada peringkat

- Engine Exhaust System Development Optimization For FSAE VehicleDokumen19 halamanEngine Exhaust System Development Optimization For FSAE VehicleNaveen SubramanyamBelum ada peringkat

- Use of CRDi MPFi Technology in AutomobilesDokumen3 halamanUse of CRDi MPFi Technology in AutomobilesSreehari MBelum ada peringkat

- d16 Power Gen EngDokumen8 halamand16 Power Gen EngAzilan AriaBelum ada peringkat

- DocumentDokumen11 halamanDocumentthanhhai31Belum ada peringkat

- Oem Sale Sheet ManDokumen4 halamanOem Sale Sheet ManSanogo YayaBelum ada peringkat

- Combustion Chamber Design Effect On The Rotary Engine Performance - A ReviewDokumen13 halamanCombustion Chamber Design Effect On The Rotary Engine Performance - A Review임학진Belum ada peringkat

- Frank Atzler PDFDokumen11 halamanFrank Atzler PDFlongtrandang5867Belum ada peringkat

- Common Rail System 1Dokumen6 halamanCommon Rail System 1Minh Nhat Phan100% (2)

- Inresol Data Sheet Catalogue July2015 PDFDokumen15 halamanInresol Data Sheet Catalogue July2015 PDFedm1Belum ada peringkat

- Up Above: Back at Base Come To LightDokumen5 halamanUp Above: Back at Base Come To LightjohnjoviedoBelum ada peringkat

- Sage Oil Vac - Lube Truck Literature - September 2019Dokumen7 halamanSage Oil Vac - Lube Truck Literature - September 2019winexonlineBelum ada peringkat

- 1206e-E70tta Iopu PN1962Dokumen4 halaman1206e-E70tta Iopu PN1962dmitryiBelum ada peringkat

- Three Cylinder Gasoline EngineDokumen6 halamanThree Cylinder Gasoline EngineHuyBelum ada peringkat

- Hatz Brochure E1 en 70255616Dokumen12 halamanHatz Brochure E1 en 70255616ColdbloodedbikerBelum ada peringkat

- Electronic Fuel Injection Systems For Heavy-Duty EnginesDokumen4 halamanElectronic Fuel Injection Systems For Heavy-Duty EnginesMohammadO.BarqBelum ada peringkat

- 1.6 Turbo Gdi Hyundai Kim eDokumen24 halaman1.6 Turbo Gdi Hyundai Kim egiampaoloBelum ada peringkat

- Automotive Engineering CRDI TechnologyDokumen14 halamanAutomotive Engineering CRDI TechnologyShaurya GuptaBelum ada peringkat

- Duel Fuel Engine ReportDokumen17 halamanDuel Fuel Engine ReportABHISHEK V GOWDA100% (1)

- Hitec 9490 PDFDokumen2 halamanHitec 9490 PDFPranit More Arabian Petroleum LimitedBelum ada peringkat

- Emmission Reduktion at VWDokumen8 halamanEmmission Reduktion at VWAlin DanielBelum ada peringkat

- Shell Lubricants ck4 and Fa4 Technical BrochureDokumen20 halamanShell Lubricants ck4 and Fa4 Technical BrochureRaden ArdyBelum ada peringkat

- Delphi's Diesel Unit Pump Common Rail System 2012Dokumen6 halamanDelphi's Diesel Unit Pump Common Rail System 2012qingcaohe100% (1)

- Pdf-To-Word Om SRIDokumen18 halamanPdf-To-Word Om SRIDixith NagarajanBelum ada peringkat

- Meraki Datasheet Auto RFDokumen1 halamanMeraki Datasheet Auto RFsinasayedanaBelum ada peringkat

- Car Hacker'S Handbook Reversing The Can Bus Craig Smith @opengaragesDokumen30 halamanCar Hacker'S Handbook Reversing The Can Bus Craig Smith @opengaragessinasayedana0% (1)

- 8bae50fc-ffaf-4e7e-af42-06b1b81e7f9fDokumen52 halaman8bae50fc-ffaf-4e7e-af42-06b1b81e7f9fsinasayedanaBelum ada peringkat

- Collapsed Radiator Hose ECT Sensors Import Insights: February 2015Dokumen60 halamanCollapsed Radiator Hose ECT Sensors Import Insights: February 2015sinasayedanaBelum ada peringkat

- Pdfeetedec 2014Dokumen52 halamanPdfeetedec 2014sinasayedanaBelum ada peringkat

- Pdfeetedec 2014Dokumen52 halamanPdfeetedec 2014sinasayedanaBelum ada peringkat

- SSP 222 Electronically Mapped Cooling SystemDokumen28 halamanSSP 222 Electronically Mapped Cooling Systemภูเก็ต เป็นเกาะBelum ada peringkat

- Ubicaci N Can Bus7Dokumen32 halamanUbicaci N Can Bus7masquimuchiBelum ada peringkat

- 1nzfe9Dokumen11 halaman1nzfe9sinasayedanaBelum ada peringkat

- Cpre 458/558: Real-Time Systems: Controller Area NetworkDokumen27 halamanCpre 458/558: Real-Time Systems: Controller Area NetworksinasayedanaBelum ada peringkat

- Shijo.T.Daniel S5 Mechanical Roll No: 859 REG NO: 11020125Dokumen28 halamanShijo.T.Daniel S5 Mechanical Roll No: 859 REG NO: 11020125sinasayedanaBelum ada peringkat

- ISS Platt Final For Web MedDokumen22 halamanISS Platt Final For Web MeddadaBelum ada peringkat

- Canbus 150328105928 Conversion Gate01Dokumen45 halamanCanbus 150328105928 Conversion Gate01sinasayedanaBelum ada peringkat

- Shijo.T.Daniel S5 Mechanical Roll No: 859 REG NO: 11020125Dokumen28 halamanShijo.T.Daniel S5 Mechanical Roll No: 859 REG NO: 11020125sinasayedanaBelum ada peringkat

- Canbus 150328105928 Conversion Gate01Dokumen45 halamanCanbus 150328105928 Conversion Gate01sinasayedanaBelum ada peringkat

- CAN Bus Signal Monitoring Using The DL850V: Yokogawa Meters & Instruments CorporationDokumen27 halamanCAN Bus Signal Monitoring Using The DL850V: Yokogawa Meters & Instruments CorporationsinasayedanaBelum ada peringkat

- Adaptive Cruise Control Sys OverviewDokumen7 halamanAdaptive Cruise Control Sys OverviewMuhammad FarhanBelum ada peringkat

- Hybrid Air Conditioning Systems OverviewDokumen68 halamanHybrid Air Conditioning Systems OverviewsinasayedanaBelum ada peringkat

- CAN Troubleshooting GuideDokumen8 halamanCAN Troubleshooting GuideJukka SoinilaBelum ada peringkat

- Optimization of A McPherson Suspension System Using The Design of Experiments MethodDokumen10 halamanOptimization of A McPherson Suspension System Using The Design of Experiments MethodsinasayedanaBelum ada peringkat

- 1nzfe9Dokumen11 halaman1nzfe9sinasayedanaBelum ada peringkat

- Ths 2Dokumen24 halamanThs 2gabi18051991Belum ada peringkat

- Judgment Basis Definitions: If Author Claims First Use of Technology, Is Claim Valid?Dokumen2 halamanJudgment Basis Definitions: If Author Claims First Use of Technology, Is Claim Valid?sinasayedanaBelum ada peringkat

- Judgment Basis Definitions: If Author Claims First Use of Technology, Is Claim Valid?Dokumen2 halamanJudgment Basis Definitions: If Author Claims First Use of Technology, Is Claim Valid?sinasayedanaBelum ada peringkat

- 5cWAVga An Top Oem Suppliers 20140616Dokumen16 halaman5cWAVga An Top Oem Suppliers 20140616sinasayedanaBelum ada peringkat

- TB2 Incorrect Method SensorsDokumen2 halamanTB2 Incorrect Method SensorsKandy KnBelum ada peringkat

- Car Talk Winter Driving Tips: 1. If Your Car Needs Regular Service, Get It Done Now. Nothing's A Big Deal in The SummerDokumen6 halamanCar Talk Winter Driving Tips: 1. If Your Car Needs Regular Service, Get It Done Now. Nothing's A Big Deal in The SummersinasayedanaBelum ada peringkat

- How - To Engine Tune-Up BasicsDokumen6 halamanHow - To Engine Tune-Up Basicsimplode32Belum ada peringkat

- Peu 0046Dokumen12 halamanPeu 0046sinasayedanaBelum ada peringkat

- Al Kindi Research Complex / Saad 16 Sa'ad General Establishment Mosul 36 ??'N 43 ??'EDokumen4 halamanAl Kindi Research Complex / Saad 16 Sa'ad General Establishment Mosul 36 ??'N 43 ??'EMoltaz AwdBelum ada peringkat

- 5 Feeder Protection & Relay CoordinationDokumen51 halaman5 Feeder Protection & Relay CoordinationSatya VasuBelum ada peringkat

- Design and Simulation of A Sine Wave Inverter With PID Control For Nonlinear Load ApplicationsDokumen12 halamanDesign and Simulation of A Sine Wave Inverter With PID Control For Nonlinear Load ApplicationsReno ReoBelum ada peringkat

- SMK 630 DDokumen8 halamanSMK 630 DMuhammad Chaidir FhadlyBelum ada peringkat

- Filmwise and Dropwise ExperimentDokumen16 halamanFilmwise and Dropwise ExperimentGoodMarissa100% (5)

- New Energy Technologies Issue 17Dokumen100 halamanNew Energy Technologies Issue 17blameitontherain9877100% (1)

- Digital BangladeshDokumen5 halamanDigital Bangladeshhimelhimel34Belum ada peringkat

- Distillation Column ModellingDokumen1 halamanDistillation Column ModellingChem.EnggBelum ada peringkat

- Lab3E8 - Series and Parallel PumpDokumen8 halamanLab3E8 - Series and Parallel PumpRaied Basam0% (1)

- NACHI Full Catalog Small RevDokumen468 halamanNACHI Full Catalog Small RevSombat MahamadBelum ada peringkat

- 100% NATEF Task Coverage: Automotive TechnologyDokumen88 halaman100% NATEF Task Coverage: Automotive TechnologynhathoaBelum ada peringkat

- Refrig - Samsung RF23J9011SR - v2 - User ManualDokumen108 halamanRefrig - Samsung RF23J9011SR - v2 - User ManualadamsusaBelum ada peringkat

- Instrumentation AssignmentDokumen5 halamanInstrumentation AssignmentShreyee PalBelum ada peringkat

- Steam Leak CalculationDokumen3 halamanSteam Leak Calculationvazzoleralex6884Belum ada peringkat

- EC303Dokumen25 halamanEC303api-3853441100% (1)

- DNV Maritime Forecast 2050 2021-WebDokumen82 halamanDNV Maritime Forecast 2050 2021-WebДмитрий Ганжа100% (1)

- Self Cleaning Hydro ScreensDokumen4 halamanSelf Cleaning Hydro ScreenssavuBelum ada peringkat

- The Bearing Capacity Evaluations of A Spread Footing On Single Thick Stratum or Two-Layered Cohesive SoilsDokumen19 halamanThe Bearing Capacity Evaluations of A Spread Footing On Single Thick Stratum or Two-Layered Cohesive SoilsJohnclaude ChamandiBelum ada peringkat

- Miller 652 and 812 Owners Manualo278aj - MilDokumen44 halamanMiller 652 and 812 Owners Manualo278aj - MilrobertoarellanocastiBelum ada peringkat

- 1 s2.0 S002236972200364X MainDokumen16 halaman1 s2.0 S002236972200364X MainFatima NBelum ada peringkat

- Quantum Phase Transitions: Alexander DanielsDokumen12 halamanQuantum Phase Transitions: Alexander Danielsapi-288833495Belum ada peringkat

- Isv5 0-Web PDFDokumen2 halamanIsv5 0-Web PDFperulapiaBelum ada peringkat

- Test Format Light & WaveDokumen7 halamanTest Format Light & WaveDewan Olin ChotepadaeBelum ada peringkat

- Xmt350cccvauto Line (Le073174)Dokumen150 halamanXmt350cccvauto Line (Le073174)Jose Arcesio Betancourt Trujillo100% (1)

- Saudi Arabian Oil Company: NotesDokumen1 halamanSaudi Arabian Oil Company: Noteshany mohamedBelum ada peringkat

- SMES Challenges 2022Dokumen14 halamanSMES Challenges 2022Marcelo Gustavo MolinaBelum ada peringkat

- FILE 51 Use of Grinder or Angle GrinderDokumen1 halamanFILE 51 Use of Grinder or Angle GrinderJonathan BobadillaBelum ada peringkat

- FULLTEXT01Dokumen246 halamanFULLTEXT01rayzo2182Belum ada peringkat

- Part Cat-Soil Compactor BW 212Dokumen218 halamanPart Cat-Soil Compactor BW 212Dhru Ti100% (7)

- Homopolar MachinesDokumen9 halamanHomopolar MachinesCarlosAugustoDaSilveiraDeJesusBelum ada peringkat

- Hyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionDari EverandHyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionPenilaian: 4.5 dari 5 bintang4.5/5 (3)

- Faster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestDari EverandFaster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestPenilaian: 4 dari 5 bintang4/5 (28)

- How to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerDari EverandHow to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerPenilaian: 4.5 dari 5 bintang4.5/5 (54)

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisDari EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisPenilaian: 4 dari 5 bintang4/5 (2)

- Automotive Wiring and Electrical SystemsDari EverandAutomotive Wiring and Electrical SystemsPenilaian: 4.5 dari 5 bintang4.5/5 (3)

- Allison Transmissions: How to Rebuild & Modify: How to Rebuild & ModifyDari EverandAllison Transmissions: How to Rebuild & Modify: How to Rebuild & ModifyPenilaian: 5 dari 5 bintang5/5 (1)

- Chasing the Demon: A Secret History of the Quest for the Sound Barrier, and the Band of American Aces Who Conquered ItDari EverandChasing the Demon: A Secret History of the Quest for the Sound Barrier, and the Band of American Aces Who Conquered ItPenilaian: 4 dari 5 bintang4/5 (25)

- How to Fabricate Automotive Fiberglass & Carbon Fiber PartsDari EverandHow to Fabricate Automotive Fiberglass & Carbon Fiber PartsPenilaian: 5 dari 5 bintang5/5 (4)

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsDari EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsPenilaian: 3.5 dari 5 bintang3.5/5 (3)

- Pressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedDari EverandPressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedPenilaian: 5 dari 5 bintang5/5 (1)

- Einstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseDari EverandEinstein's Fridge: How the Difference Between Hot and Cold Explains the UniversePenilaian: 4.5 dari 5 bintang4.5/5 (51)

- The Laws of Thermodynamics: A Very Short IntroductionDari EverandThe Laws of Thermodynamics: A Very Short IntroductionPenilaian: 4.5 dari 5 bintang4.5/5 (10)

- CDL Study Guide 2024-2025: Everything You Need to Know to Pass the Commercial Driver’s License Exam on your First Attempt, with the Most Complete and Up-to-Date Practice Tests - New VersionDari EverandCDL Study Guide 2024-2025: Everything You Need to Know to Pass the Commercial Driver’s License Exam on your First Attempt, with the Most Complete and Up-to-Date Practice Tests - New VersionPenilaian: 5 dari 5 bintang5/5 (2)

- Modern Engine Blueprinting Techniques: A Practical Guide to Precision Engine BlueprintingDari EverandModern Engine Blueprinting Techniques: A Practical Guide to Precision Engine BlueprintingPenilaian: 4.5 dari 5 bintang4.5/5 (9)

- Pilot's Handbook of Aeronautical Knowledge (2024): FAA-H-8083-25CDari EverandPilot's Handbook of Aeronautical Knowledge (2024): FAA-H-8083-25CBelum ada peringkat

- Small Engines and Outdoor Power Equipment: A Care & Repair Guide for: Lawn Mowers, Snowblowers & Small Gas-Powered ImplementsDari EverandSmall Engines and Outdoor Power Equipment: A Care & Repair Guide for: Lawn Mowers, Snowblowers & Small Gas-Powered ImplementsBelum ada peringkat

- Automotive Electronic Diagnostics (Course 1)Dari EverandAutomotive Electronic Diagnostics (Course 1)Penilaian: 5 dari 5 bintang5/5 (6)

- Powder Coating: A How-to Guide for Automotive, Motorcycle, and Bicycle PartsDari EverandPowder Coating: A How-to Guide for Automotive, Motorcycle, and Bicycle PartsPenilaian: 4.5 dari 5 bintang4.5/5 (17)

- Aerodynamics for Engineering StudentsDari EverandAerodynamics for Engineering StudentsPenilaian: 5 dari 5 bintang5/5 (5)