CD6 Prototype Control Plan

Diunggah oleh

mpedraza-1Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

CD6 Prototype Control Plan

Diunggah oleh

mpedraza-1Hak Cipta:

Format Tersedia

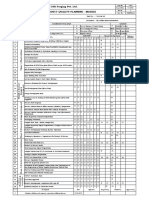

PROTOTYPE PRE-LAUNCH PRODUCTION KEY CONTACT / PHONE: Date (Original): 10/9/2017

CONTROL PLAN NUMBER: Lauren Ritter / 6148705018 Date (Revised):

PART NUMBER / LATEST CHANGE LEVEL: CORE TEAM: CUST. ENG. APPROVAL/DATE (IF REQUIRED):

1056329-002

Lauren Ritter, Steve Mason, Hector Muela, Angelo Caponi, Jim Hubbard, Mark Murfitt

PART NAME / DESCRIPTION: SUPPLIER / PLANT APPROVAL / DATE: CUSTOMER QUALITY APPROVAL/DATE (IF REQUIRED):

Outer Shield

SUPPLIER / PLANT: SUPPLIER CODE: OTHER APPROVAL / DATE (IF REQUIRED): OTHER APPROVAL / DATE (IF REQUIRED):

CMT, Columbus

Characteristics Methods

Part / Process Name / Machine, Special Product / Process Evaluation

Process Operation Device, Jig, Char. Specification / Measurement

Number Description Tools for Mfg. No. Product Process Class Tolerance Technique Sample Control Method Reaction Plan

Size Freq

Heat Shield Molded Parts

10 See SMC Control Plan

20 See SMC Control Plan

Contact Supervisor,

Remove Incorrect

Material

Move Materials to Production Report

30 Boxes 3 Correct SMC FIFO Per Molding P-sheet Visual Each Box 100% Ref. Control of Non

Press: HS3502 Quality Audit Sheet

Conforming Product.

Contain Parts (if

necessary)

Operator Adjust pattern, notify

Hand Tools/ Charge pattern Reference Molding P-

40 Prepare Charge 4 Charge Pattern Visual 100% Shift Process Sheet, supervisor if parts

Cutting Table placement sheet

Template suspect

Adjust weight, notify

Reference Molding P- Operator

5 Charge Weight Calibrated Scale 100% Shift supervisor if parts

sheet Process Sheet

suspect

Adjust settings if needed,

Reference Molding P- Supervisor/Mold Tech

6 Press Set-Up Audit 1 Shift notify supervisor is parts

sheet Audit

suspect.

Ref. Control of Non

100%, Conforming Product.

SC - charge located per P-sheet instructions,

Load Charge Compression Mold 8 HS3502 Location Visual Each Part Contain Parts (if

Core acceptance criteria Mold Tech Audit

necessary), Contact

Supervisor

Ref. Control of Non

Conforming Product.

Reference Molding P-

Close Mold Press 9 Part Molding Visual/ Audit 2 Shift Press Settings Contain Parts (if

sheet

necessary), Contact

Supervisor

Ref. Control of Non

Conforming Product.

Reference Molding P-

Open Mold Press 10 Part Molded Visual/ Audit 2 Shift Press Settings Contain Parts (if

sheet

necessary), Contact

Supervisor

Current Revision: 03/01/2013

Page 1 of 3 Original Revision: 01/12/2006

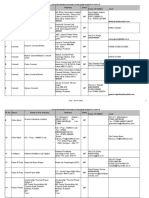

Characteristics Methods

Part / Process Name / Machine, Special Product / Process Evaluation

Process Operation Device, Jig, Char. Specification / Measurement

Number Description Tools for Mfg. No. Product Process Class Tolerance Technique Sample Control Method Reaction Plan

Size Freq

Ref. Control of Non

Conforming Product.

2.0mm +0.5mm / -

11 Part Thickness Micrometers 2 Shift Quality Audit Contain Parts (if

0.25mm

necessary), Contact

Supervisor

Ref. Control of Non

Conforming Product.

Per Acceptance

12 Complete Part SC Visual 2 Shift Quality Audit Contain Parts (if

Criteria

necessary), Contact

Supervisor

Ref. Control of Non

Inspect part Conforming Product.

Ejected mold Per Acceptance

Press 13 meets accepted Visual 3 Shift Quality Audit Contain Parts (if

parts from cavities Criteria

criteria necessary), Contact

Supervisor

Ref. Control of Non

Conforming Product.

Computer and Poke yoke at punch

50 Part Labeling 15 Molded Part Label Application Reference p sheet Visual 2 Shift Contain Parts (if

printer press

necessary), Contact

Supervisor

Ref. Control of Non

Conforming Product.

Check Part check all specified Reference

CMM 16 Molded Part SC Visual 6 Run Quality Audit Contain Parts (if

dimensions dimnsions process/Audit sheet

necessary), Contact

Supervisor

Ref. Control of Non

Holes are within Conforming Product.

Hole Presense,

60 Sand Mold Byes Sander 18 Molded part SC Per design record visual indicators on 100%, Each Part Visual Contain Parts (if

Location

part necessary), Contact

Supervisor

Ref. Control of Non

Conforming Product.

Deflash Free from any flash

70/80 Deflash Fixture 20 Molded part Smooth Edges SC Reference p sheet 1 3001 cycles Training, P-sheet Contain Parts (if

Part/Inspection around part edges

necessary), Contact

Supervisor

Ref. Control of Non

Conforming Product.

21 Part color Per color chart Visual 2 Shift Auditor, audit sheets Contain Parts (if

necessary), Contact

Supervisor

Current Revision: 03/01/2013

Page 2 of 3 Original Revision: 01/12/2006

Characteristics Methods

Part / Process Name / Machine, Special Product / Process Evaluation

Process Operation Device, Jig, Char. Specification / Measurement

Number Description Tools for Mfg. No. Product Process Class Tolerance Technique Sample Control Method Reaction Plan

Size Freq

Ref. Control of Non

Conforming Product.

Per Acceptance

24 Flash on edges safety Attributes Visual 100% Each Part Operator, Quality Audit Contain Parts (if

Criteria

necessary), Contact

Supervisor

Ref. Control of Non

Conforming Product.

Secondary

25 Dust on parts SC As minimum Visual 100% Each Parts/totes Operator, Quality Audit Contain Parts (if

process

necessary), Contact

Supervisor

Ref. Control of Non

Conforming Product.

Secondary

26 Knife in totes SC Not acceptable Visual 100% Each Parts/totes Operator, Quality Audit Contain Parts (if

process

necessary), Contact

Supervisor

Ref. Control of Non

Conforming Product.

Secondary Review per QA/QE review for

Suspect Parts Cardboard Box 27 Defect SC Visual 100% Each Contain Parts (if

processs acceptance criteria contained parts

necessary), Contact

Supervisor

Ref. Control of Non

Operator visual Conforming Product.

safety/Cosmetic Per Acceptance

Scrap Parts Cardboard Box 28 Defect SC Visual 100% Each Part inspection, QA to paint Contain Parts (if

Attributes Criteria

red both sides of shield necessary), Contact

Supervisor

Ref. Control of Non

Properly packed per Conforming Product.

Product Ready to Operator training, P

90 Pack Cardboard Box 29 Outer shield SC P Sheet, excessive Visual 1 Each Tote Contain Parts (if

Ship Sheet

dust not acceptable necessary), Contact

Supervisor

Current Revision: 03/01/2013

Page 3 of 3 Original Revision: 01/12/2006

Anda mungkin juga menyukai

- 6 PFMEA & Control Plan 1 of 7Dokumen8 halaman6 PFMEA & Control Plan 1 of 7P G Suman100% (1)

- 02-Team Feasibility CommittmentDokumen1 halaman02-Team Feasibility CommittmentVinod SaleBelum ada peringkat

- DS-16 Capacity-Analysis (Ford Authorized) CAR-5.6Dokumen12 halamanDS-16 Capacity-Analysis (Ford Authorized) CAR-5.6Ahmet SonerBelum ada peringkat

- AIAG & VDA PFMEA FormatDokumen1 halamanAIAG & VDA PFMEA Formatmahesh KhatalBelum ada peringkat

- 1 ApqpDokumen30 halaman1 ApqpVIPIN YADAVBelum ada peringkat

- CD6 Prototype PFMEADokumen4 halamanCD6 Prototype PFMEAmpedraza-1Belum ada peringkat

- CD6 Prototype PFMEADokumen4 halamanCD6 Prototype PFMEAmpedraza-1Belum ada peringkat

- APQP Timing Plan SampleDokumen3 halamanAPQP Timing Plan SampleDhananjay Patil75% (4)

- QSP-D&D-02 APQP ProcedureDokumen6 halamanQSP-D&D-02 APQP ProcedureDeepak Kumar100% (1)

- Histogram X-Bar Chart: Company NameDokumen1 halamanHistogram X-Bar Chart: Company NameSachin RamdurgBelum ada peringkat

- Action Plan For Red & Yellow Resp TGT Date Implemented / Proof Available Under Progress Not Implemented / Proof Not AvailableDokumen39 halamanAction Plan For Red & Yellow Resp TGT Date Implemented / Proof Available Under Progress Not Implemented / Proof Not AvailableSanjay KumarBelum ada peringkat

- 1 Production Part Approval ProcessDokumen42 halaman1 Production Part Approval ProcessVinod Kaul100% (1)

- MSIL Audit Cheklist 16Dokumen22 halamanMSIL Audit Cheklist 16Pravin Balasaheb GunjalBelum ada peringkat

- Procedure: Measurement System Analysis ExecutionDokumen1 halamanProcedure: Measurement System Analysis Executionaslam100% (1)

- APQP Timing Plan TemplateDokumen9 halamanAPQP Timing Plan TemplatemuthuselvanBelum ada peringkat

- Control PlanDokumen11 halamanControl PlanRadhika GuptaBelum ada peringkat

- Production Part Approval ProcessDokumen6 halamanProduction Part Approval ProcessleonardoBelum ada peringkat

- S ApqpDokumen15 halamanS ApqpIram ChaviraBelum ada peringkat

- Advanced Product Quality Planning Timing Chart: Plan and Define Programme - PP Trial StageDokumen6 halamanAdvanced Product Quality Planning Timing Chart: Plan and Define Programme - PP Trial Stagerajesh sharma100% (2)

- ApqpDokumen72 halamanApqpsaby aroraBelum ada peringkat

- APQP Phases & Elements of APQPDokumen6 halamanAPQP Phases & Elements of APQPSachin Ramdurg100% (1)

- PFMEA SpreadsheetDokumen14 halamanPFMEA SpreadsheetSudhakar Mars ConsultantsBelum ada peringkat

- Control PlanDokumen6 halamanControl PlanFahmy Khoerul HudaBelum ada peringkat

- APQP FormsDokumen23 halamanAPQP FormsJOECOOL670% (1)

- DRBFM WorksheetDokumen1 halamanDRBFM WorksheetHareth MRAIDIBelum ada peringkat

- APQP / PPAP Checklist - Suppliers: Responsiblility StepDokumen8 halamanAPQP / PPAP Checklist - Suppliers: Responsiblility Steprajesh sharmaBelum ada peringkat

- Giriraj Precision Screws PVT - Ltd. Quality Manual Procedure APQP (Advanced Product Quality Planning) 1. PurposeDokumen9 halamanGiriraj Precision Screws PVT - Ltd. Quality Manual Procedure APQP (Advanced Product Quality Planning) 1. PurposeMohit KaushikBelum ada peringkat

- Product Characteristic Matrix (PCM) & Safe Launch Plan - Alignment & AgreementDokumen8 halamanProduct Characteristic Matrix (PCM) & Safe Launch Plan - Alignment & AgreementDavid MorenoBelum ada peringkat

- Paper CraftsDokumen15 halamanPaper CraftsBianca VacunawaBelum ada peringkat

- APQP ENG SiemensDokumen12 halamanAPQP ENG SiemensVikash KumarBelum ada peringkat

- 27 LettersofProtest 000Dokumen52 halaman27 LettersofProtest 000Fredy Golbart100% (3)

- P13-Process For APQPDokumen6 halamanP13-Process For APQPBangali Singh100% (1)

- MsaDokumen7 halamanMsaGobi PSBelum ada peringkat

- Supplier APQP Training SupplementDokumen78 halamanSupplier APQP Training SupplementjcperezBelum ada peringkat

- CSR Matrix For RefDokumen6 halamanCSR Matrix For RefBard Z8Belum ada peringkat

- APQP Phases and ActivitiesDokumen1 halamanAPQP Phases and Activitiesaorto3919Belum ada peringkat

- 9093 w15 QP 22Dokumen4 halaman9093 w15 QP 22omezolBelum ada peringkat

- Product Part Approval Process: Automotive Quality Management SystemDokumen3 halamanProduct Part Approval Process: Automotive Quality Management SystemrajaBelum ada peringkat

- Pfmea - Aiag-VdaDokumen108 halamanPfmea - Aiag-VdaGLAUCIO DOS SANTOS SILVABelum ada peringkat

- Guidelines For Making PFMEA - A PDFDokumen10 halamanGuidelines For Making PFMEA - A PDFKalimuthu PsBelum ada peringkat

- Guidelines For Control PlanDokumen4 halamanGuidelines For Control PlanArjun Rathore100% (1)

- APQPDokumen3 halamanAPQPsam1hi5Belum ada peringkat

- AIAG PPAP Cover SheetDokumen1 halamanAIAG PPAP Cover SheetSCHOPENHAUERBelum ada peringkat

- Gate Check Review FormsDokumen7 halamanGate Check Review FormsKamardeen Nazurudeen100% (1)

- Guideline APQP Workbook Rev DDokumen19 halamanGuideline APQP Workbook Rev Dmpedraza-1100% (1)

- Aiag & Vda Pfmea Form (1st Edition 2019)Dokumen10 halamanAiag & Vda Pfmea Form (1st Edition 2019)Gurcan SayaralBelum ada peringkat

- APQP Chart With Responsibility Matrix: Development Categories Category Details A B C D E F Activity DescriptionDokumen6 halamanAPQP Chart With Responsibility Matrix: Development Categories Category Details A B C D E F Activity DescriptionParveen KumarBelum ada peringkat

- Customer Specific Requirements - PPAP (2014!03!05)Dokumen7 halamanCustomer Specific Requirements - PPAP (2014!03!05)diablo2250Belum ada peringkat

- Production Part Approval Process A Complete Guide - 2019 EditionDari EverandProduction Part Approval Process A Complete Guide - 2019 EditionBelum ada peringkat

- SAMPLE - Process FlowDokumen2 halamanSAMPLE - Process Flowakav123Belum ada peringkat

- Apqp Matrix UpdatedDokumen2 halamanApqp Matrix Updatedabhishek100% (1)

- Apqp Team: Issued Checked ApprovedDokumen1 halamanApqp Team: Issued Checked ApprovedPhannachet RungsrikeawBelum ada peringkat

- What Is Security PaperDokumen3 halamanWhat Is Security PaperRavi Chandra Medisetty100% (1)

- Manual - APQP 20121017 PDFDokumen135 halamanManual - APQP 20121017 PDFBerk NoyanBelum ada peringkat

- Design FMEA (DFMEA) TutorialDokumen18 halamanDesign FMEA (DFMEA) Tutorialpiero_rsBelum ada peringkat

- Corporate Standard CPS0098: 1 ScopeDokumen11 halamanCorporate Standard CPS0098: 1 Scopempedraza-1Belum ada peringkat

- Supplier Performance Management Process A Complete Guide - 2019 EditionDari EverandSupplier Performance Management Process A Complete Guide - 2019 EditionBelum ada peringkat

- PPAP - 4th Edition - Course MaterialDokumen18 halamanPPAP - 4th Edition - Course MaterialMy Dad My WorldBelum ada peringkat

- MadhyaPradesh DCDokumen4 halamanMadhyaPradesh DCAmit SharmaBelum ada peringkat

- 53 MSA PlanDokumen2 halaman53 MSA PlanPk NimiwalBelum ada peringkat

- Training Module Aiag Cqi Licensed Training Partner Topqm Systems Overview enDokumen3 halamanTraining Module Aiag Cqi Licensed Training Partner Topqm Systems Overview enjpaulBelum ada peringkat

- Register Forum Home Page Post Attachment Files All Help Lost PasswordDokumen3 halamanRegister Forum Home Page Post Attachment Files All Help Lost PasswordKirthivasanBelum ada peringkat

- TS-16949 GM Customer-Specific RequirementsDokumen13 halamanTS-16949 GM Customer-Specific Requirementstsllwt100% (1)

- ISO IATF 16949 Gap Tool b70944Dokumen216 halamanISO IATF 16949 Gap Tool b70944SudhagarBelum ada peringkat

- Spec Characteristics GdlnesDokumen2 halamanSpec Characteristics Gdlnessathyabalaraman0% (1)

- Oposite - VE Failure Effect - Ve Failure Mode - Ve Failure CauseDokumen1 halamanOposite - VE Failure Effect - Ve Failure Mode - Ve Failure CauseSethasan SrikochBelum ada peringkat

- Manufacturing Facilities A Complete Guide - 2019 EditionDari EverandManufacturing Facilities A Complete Guide - 2019 EditionBelum ada peringkat

- Mpaps D 7130Dokumen4 halamanMpaps D 7130mpedraza-1Belum ada peringkat

- Mpaps S B 4.101 Gs PLDokumen6 halamanMpaps S B 4.101 Gs PLmpedraza-1Belum ada peringkat

- Qs865atez Data GR&RDokumen2 halamanQs865atez Data GR&Rmpedraza-1Belum ada peringkat

- Bernoulli PDFDokumen19 halamanBernoulli PDFmpedraza-1Belum ada peringkat

- Auditoria Por CapasDokumen23 halamanAuditoria Por Capasmpedraza-1Belum ada peringkat

- CEMS G-5 Part 1ADokumen7 halamanCEMS G-5 Part 1Ampedraza-1Belum ada peringkat

- RequirementsDokumen18 halamanRequirementsmpedraza-1Belum ada peringkat

- E-Coating Process FinalDokumen1 halamanE-Coating Process Finalmpedraza-1Belum ada peringkat

- AtlasDokumen44 halamanAtlasmpedraza-1Belum ada peringkat

- DOE Paint Pops On Seam: CMT Columbus, OHDokumen13 halamanDOE Paint Pops On Seam: CMT Columbus, OHmpedraza-1Belum ada peringkat

- Doe Imc 1 - October 2007Dokumen9 halamanDoe Imc 1 - October 2007mpedraza-1Belum ada peringkat

- Adverbs That Tell Us For How LongDokumen2 halamanAdverbs That Tell Us For How Longmpedraza-1Belum ada peringkat

- English Grammar: Prepositions of TimeDokumen3 halamanEnglish Grammar: Prepositions of Timempedraza-1Belum ada peringkat

- Expressing The Date: For Single Days and Dates We Use OnDokumen2 halamanExpressing The Date: For Single Days and Dates We Use Onmpedraza-1Belum ada peringkat

- 5 Fases Del Apqp (Core)Dokumen5 halaman5 Fases Del Apqp (Core)mpedraza-1Belum ada peringkat

- Prepositions of Place: At, In, On: at For A POINT in For An Enclosed Space On For A SURFACEDokumen4 halamanPrepositions of Place: At, In, On: at For A POINT in For An Enclosed Space On For A SURFACEmpedraza-1Belum ada peringkat

- Pluvial - Galpão Expedição 1Dokumen1 halamanPluvial - Galpão Expedição 1luancassBelum ada peringkat

- Format of Project ReportDokumen28 halamanFormat of Project ReportIrshad AhmadBelum ada peringkat

- Von RudenDokumen4 halamanVon RudenNeeraj SharmaBelum ada peringkat

- How Does A Ball Point Pen WorkDokumen3 halamanHow Does A Ball Point Pen WorkJhuliane RalphBelum ada peringkat

- Design and Technology-Paper-1Dokumen4 halamanDesign and Technology-Paper-1Mudiwa GashupareBelum ada peringkat

- Linocut - WikipediaDokumen14 halamanLinocut - WikipediaLKMs HUBBelum ada peringkat

- Moleskine Spring 2016 CatalogDokumen210 halamanMoleskine Spring 2016 CatalogChronicleBooks100% (2)

- Lesson 3 - Advanced WordDokumen39 halamanLesson 3 - Advanced WordRosa MasigonBelum ada peringkat

- Master Project ReportDokumen97 halamanMaster Project Reportanon_179532672Belum ada peringkat

- Salary For Workcharge StaffDokumen8 halamanSalary For Workcharge StaffRajat SharmaBelum ada peringkat

- Visvesvaraya Technological University Application For Issue of Duplicate Marks Cards / Grade Card (DMC)Dokumen2 halamanVisvesvaraya Technological University Application For Issue of Duplicate Marks Cards / Grade Card (DMC)P.g. SunilkumarBelum ada peringkat

- Essity: Too Closely Associated With The SubjectDokumen7 halamanEssity: Too Closely Associated With The SubjecttokagheruBelum ada peringkat

- BWKDokumen13 halamanBWKan_taniaBelum ada peringkat

- Vendors DetailsDokumen1 halamanVendors DetailsOnkar MannaBelum ada peringkat

- Common Admission Test 2018 Admit Card: Name Registration NumberDokumen1 halamanCommon Admission Test 2018 Admit Card: Name Registration NumberMrunal WaghchaureBelum ada peringkat

- Cracking The Growth Code in ChemicalsDokumen7 halamanCracking The Growth Code in ChemicalsLuca EgidiBelum ada peringkat

- LJN Kyn 2533 17-3-2011 Tanveer BhaiDokumen2 halamanLJN Kyn 2533 17-3-2011 Tanveer BhaizaheerbcBelum ada peringkat

- What Is A Concept PaperDokumen6 halamanWhat Is A Concept Paperkristelle ducayBelum ada peringkat

- How To Recycle Paper - School Recycling ClubDokumen2 halamanHow To Recycle Paper - School Recycling ClubWorm CompostingBelum ada peringkat

- Lucian Costin DumitrescuDokumen2 halamanLucian Costin DumitrescuLucian Costin DumitrescuBelum ada peringkat

- Updates (Company Update)Dokumen3 halamanUpdates (Company Update)Shyam SunderBelum ada peringkat

- BIM ProfileDokumen6 halamanBIM ProfilekurniaBelum ada peringkat

- UntitledDokumen16 halamanUntitledTanmay SuryawanshiBelum ada peringkat

- P 1100 WCDokumen184 halamanP 1100 WCtoanproanhBelum ada peringkat