WPS Creation Sample ISO

Diunggah oleh

musheerHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

WPS Creation Sample ISO

Diunggah oleh

musheerHak Cipta:

Format Tersedia

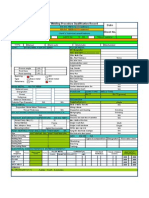

WELDING PROCEDURE SPECIFICATION

Sample WPS (ISO)

CLIENT: PROJECT:

BASIC INFORMATION

PQR no: STANDARD: ISO 15614-1 PRODUCT TYPE: Pipe

WELD TYPE: BW WELDING PROCESSES: ROOT: 141 FILL: 135

BASE MATERIAL DETAILS

BASE MATERIALS: SA 312 TP316L & SA 312 TP316L THICKNESS (mm): 3 - 24 DIAMETER (mm): 44,45 -

PD,H-L045,

GROUP: 8.1 - 8.1 WELDING POSITIONS ROOT: FILL: PD,H-L045,PA,PH,PB,PE,PF,PC

PA,PH,PB,PE,PF,PC

FILLER MATERIAL DETAILS

ROOT FILL ROOT FILL

Gas Gas

SPECIFICATION SFA 5.9 SFA 5.9 SHIELDING

I1 M21

CLASSIFICATION ER316L ER316L FLOW RATE 11-18 15-20

COMMERCIAL

COMMERCIAL NAME / / / /

NAME

GROUP FM5 FM5

BACKING & Gas - 5 l/min (Root) + 0 l/min (Fill)

FLOW RATE

DIAMETER 2 1,2 I1

JOINT DETAILS

PREPARATION METHODS: WELD DETAILS: ml,ss nb

GROOVE DESIGN WELD LAYER CONFIGURATION

ROOT GAP (R): 0,5 - 1,5 ROOT FACE (F): 1 - 2 GROOVE ANGLE (A): 30 - 35

WELDING PARAMETER

WIRE FEED TRANSF.

PASS # PROCESS F.M. DIAMETER (mm) CURRENT (A) VOLTAGE (V) POLARITY (mm/s)

TRAVEL SPEED (mm/s) HEAT INPUT

MODE

1 141 ER316L 2 80 - 150 11 - 14 DC- / 80 - 140 / 1 - 1,5 (KJ/mm)

2 135 ER316L 1,2 120 - 200 14 - 20 DC+ 300 - 400 120 - 180 Spray 1 - 1,8 (KJ/mm)

3-N 135 ER316L 1,2 150 - 230 14 - 23 DC+ 300 - 400 120 - 180 Spray 1,2 - 1,8 (KJ/mm)

/ / / / / / / / / /

/ / / / / / / / / /

/ / / / / / / / / /

/ / / / / / / / / /

/ / / / / / / / / /

/ / / / / / / / / /

/ / / / / / / / / /

ADDITIONAL DETAILS

1 - WT20 + Metal Cored

ELECTRODE TYPE AND NUMBER: OSCILLATION:

Wire

CONTACT TIP TO WORK DISTANCE / STICK OUT: 15mm + 20mm PULSE WELD DETAILS:

DETAILS OF BACK GOUGING: TORCH ANGLE:

THERMAL PARAMETERS

PREHEAT TEMPERATURE: INTERPASS TEMPERATURE: POSTHEAT TEMPERATURE:

POST WELD HEAT TREATMENT

TIME: TEMPERATURE: METHOD: HEAT/COOL RATE:

ADDITIONAL INFORMATION

NOTES:

REVISION WRITTEN BY VERIFIED BY APPROVED BY CLIENT APPROVAL STATUS

A DATE: DATE: DATE: DATE:

Anda mungkin juga menyukai

- Welder Qualification Test Certificate BS EN ISO 9606-1: 2017Dokumen2 halamanWelder Qualification Test Certificate BS EN ISO 9606-1: 2017idthdrayahbdnhauniBelum ada peringkat

- WPS ISO 15614-1 WeldNote MetricDokumen1 halamanWPS ISO 15614-1 WeldNote MetricVirgil SorcaruBelum ada peringkat

- WPQR Welding Procedure Qualification RecordsDokumen3 halamanWPQR Welding Procedure Qualification Recordsramesh rajaBelum ada peringkat

- Welding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test CertificateDokumen3 halamanWelding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test Certificateramesh rajaBelum ada peringkat

- Welding Procedure Qualification Record (WPQR) (ISO 15614-1-2017)Dokumen3 halamanWelding Procedure Qualification Record (WPQR) (ISO 15614-1-2017)ramesh rajaBelum ada peringkat

- WPQ Process As Per ISO-9606-1 2013Dokumen4 halamanWPQ Process As Per ISO-9606-1 2013Md Anamul Hoque0% (1)

- Welding Procedure Qualification Certificate EN ISO 15614-1: 2017Dokumen3 halamanWelding Procedure Qualification Certificate EN ISO 15614-1: 2017dcsamaraweera100% (1)

- Aws 001Dokumen1 halamanAws 001akshay sarfareBelum ada peringkat

- WPS Format For ISO 15614-1 PWPSDokumen1 halamanWPS Format For ISO 15614-1 PWPSThe Welding Inspections CommunityBelum ada peringkat

- Weld Checklist PQRDokumen2 halamanWeld Checklist PQRScott Trainor100% (1)

- P-WPS 135 - MAG (GR 316)Dokumen9 halamanP-WPS 135 - MAG (GR 316)Tarun PatelBelum ada peringkat

- Preliminary Welding Procedure Specification: Code: EN ISO 15609-1Dokumen2 halamanPreliminary Welding Procedure Specification: Code: EN ISO 15609-1wentropremBelum ada peringkat

- (Applicable Code: ASME Section IX Edition 2019) : Page 1 of 2Dokumen2 halaman(Applicable Code: ASME Section IX Edition 2019) : Page 1 of 2amit singh100% (2)

- Fcaw 16 THKDokumen5 halamanFcaw 16 THKparesh2387Belum ada peringkat

- En Iso 9606 1 GDokumen2 halamanEn Iso 9606 1 GAnonymous dziHEjc7Y100% (1)

- Poster Welding Positions Asme Vs enDokumen1 halamanPoster Welding Positions Asme Vs enalan100% (1)

- Welder Qualification CertificateDokumen2 halamanWelder Qualification CertificateNguyen Thanh BinhBelum ada peringkat

- Radiographic Inspection Report SheetDokumen1 halamanRadiographic Inspection Report SheetMike BoyesBelum ada peringkat

- Welding Procedure Specification (WPS) (As Per EN / ISO 15609-1)Dokumen1 halamanWelding Procedure Specification (WPS) (As Per EN / ISO 15609-1)ramesh rajaBelum ada peringkat

- Welding procedure specification guideDokumen3 halamanWelding procedure specification guideAnilBelum ada peringkat

- PWPS - ISO EN 15614-1 - DNV-GLDokumen1 halamanPWPS - ISO EN 15614-1 - DNV-GLvinoth100% (1)

- WPQR SMAW EN-2 - 30mm (Under Modification)Dokumen2 halamanWPQR SMAW EN-2 - 30mm (Under Modification)Mohamed Reda HusseinBelum ada peringkat

- Model WopqDokumen2 halamanModel WopqAnilkumarGopinathanNairBelum ada peringkat

- Welding Procedure Specification (WPS) According To DIN EN ISO 15614-1Dokumen2 halamanWelding Procedure Specification (WPS) According To DIN EN ISO 15614-1Vijay OfficialBelum ada peringkat

- VP16 PDFDokumen13 halamanVP16 PDFKara WhiteBelum ada peringkat

- Gta+sma PQRDokumen3 halamanGta+sma PQRRahul MoottolikandyBelum ada peringkat

- Iso 15614-13Dokumen24 halamanIso 15614-13Marija IvanovskaBelum ada peringkat

- Welding Procedure Specifications (WPS) : NMDC Nagarnar 2 MTPA Pellet Plant, Jagdalpur - 494001Dokumen2 halamanWelding Procedure Specifications (WPS) : NMDC Nagarnar 2 MTPA Pellet Plant, Jagdalpur - 494001neerajBelum ada peringkat

- Guidance To Prepare Wps PQR For WeldingDokumen1 halamanGuidance To Prepare Wps PQR For WeldingHamid MansouriBelum ada peringkat

- WPS 304L &316LDokumen2 halamanWPS 304L &316LShakeel Memon100% (1)

- A Comparison of ISO 15614 Part 1 and ASME IXDokumen3 halamanA Comparison of ISO 15614 Part 1 and ASME IXsusanwebBelum ada peringkat

- Welding Procedure Specifications (Wps - 6G) : 2mm (Max)Dokumen2 halamanWelding Procedure Specifications (Wps - 6G) : 2mm (Max)Gbenga Mobolade100% (1)

- WPS & WPQR (Asme Section IX)Dokumen7 halamanWPS & WPQR (Asme Section IX)Rizaldy PhoenksBelum ada peringkat

- WPS-6 Doc Rev00 On 17 Sept 2018 Final FormatDokumen3 halamanWPS-6 Doc Rev00 On 17 Sept 2018 Final FormatSWARUP CHUGUGLEBelum ada peringkat

- WPS Format For ISO 15614-1 WPSDokumen1 halamanWPS Format For ISO 15614-1 WPSThe Welding Inspections CommunityBelum ada peringkat

- WPS Welding Procedure SpecificationDokumen1 halamanWPS Welding Procedure SpecificationburakBelum ada peringkat

- WPQ Sample PrintoutDokumen1 halamanWPQ Sample PrintoutKannan VelBelum ada peringkat

- Aws D1.1 - WPS - Smaw-Fcaw PDFDokumen1 halamanAws D1.1 - WPS - Smaw-Fcaw PDFThe Welding Inspections CommunityBelum ada peringkat

- 004 Gtaw P5aDokumen16 halaman004 Gtaw P5aMuhammad Fitransyah Syamsuar Putra100% (1)

- Welding Procedure Qualification Record (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test CertificateDokumen11 halamanWelding Procedure Qualification Record (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test Certificateramesh raja100% (1)

- Welding Procedure Specification for Vertical Storage TanksDokumen6 halamanWelding Procedure Specification for Vertical Storage TanksYASH BARDHAN SinghBelum ada peringkat

- QW-484A (WPQ) GTAW 4MM FilletDokumen2 halamanQW-484A (WPQ) GTAW 4MM FilletBalkishan Dyavanapelly100% (1)

- Report on Welding Procedure Specifications for Single V-Groove JointsDokumen15 halamanReport on Welding Procedure Specifications for Single V-Groove JointsAvishek Gupta100% (1)

- WPS Format For ISO 9606-1 WelderDokumen2 halamanWPS Format For ISO 9606-1 WelderThe Welding Inspections Community100% (1)

- WPQR6Dokumen3 halamanWPQR6Dimitris NikouBelum ada peringkat

- Welding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weigh Systems Pvt. LTDDokumen5 halamanWelding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weigh Systems Pvt. LTDHussein MohamedBelum ada peringkat

- Welder Qualification CertificateDokumen2 halamanWelder Qualification CertificatevitharvanBelum ada peringkat

- Tasks and Responsibilities of RWCDokumen1 halamanTasks and Responsibilities of RWCKDT100% (1)

- Welder Visual Inspection ReportsDokumen24 halamanWelder Visual Inspection ReportsKyBelum ada peringkat

- What's New in ISO 15614-12017Dokumen13 halamanWhat's New in ISO 15614-12017alevent100% (1)

- WPS Format For ISO 15614-1 PQRDokumen3 halamanWPS Format For ISO 15614-1 PQRThe Welding Inspections Community100% (2)

- Welding Procedure Specification (WPS) ASME CODE: BPVC Section IX, Edition 2015/ B31.3, Edition 2014 & ABS 2016 PART 2Dokumen3 halamanWelding Procedure Specification (WPS) ASME CODE: BPVC Section IX, Edition 2015/ B31.3, Edition 2014 & ABS 2016 PART 2Ahmad DanielBelum ada peringkat

- Iso 15609-1-2019Dokumen19 halamanIso 15609-1-2019HarikeshRana100% (2)

- P-WPS 135 - Mag (S355JR)Dokumen9 halamanP-WPS 135 - Mag (S355JR)Tarun PatelBelum ada peringkat

- WPS MatrixDokumen4 halamanWPS MatrixHarshaVeeragandham50% (2)

- WPS Creation Sample ISODokumen1 halamanWPS Creation Sample ISOAlex HummelBelum ada peringkat

- WPS ASME IX WeldNote MetricDokumen1 halamanWPS ASME IX WeldNote MetricGoutham RathinamBelum ada peringkat

- WPS AWS D1.1 WeldNote MetricDokumen1 halamanWPS AWS D1.1 WeldNote MetricGoutham RathinamBelum ada peringkat

- Welding Procedure Specification: JOINTS (QW-402)Dokumen3 halamanWelding Procedure Specification: JOINTS (QW-402)Nitin KurupBelum ada peringkat

- FA-For ReferenceDokumen1 halamanFA-For ReferenceUmer KhanBelum ada peringkat

- Sleeve CoatingDokumen30 halamanSleeve Coatingmusheer100% (1)

- 1 Yield Strength Should Be The Lower Yield Point R. If It Is Not Distinct Then Choose The 0.2 % - Yield Strength RDokumen3 halaman1 Yield Strength Should Be The Lower Yield Point R. If It Is Not Distinct Then Choose The 0.2 % - Yield Strength RmusheerBelum ada peringkat

- BS EN ISO 15609-5 2004 Resistance WeldingDokumen19 halamanBS EN ISO 15609-5 2004 Resistance WeldingNguyen Quang TienBelum ada peringkat

- Steel Grouping System by TR/ISO 15608Dokumen5 halamanSteel Grouping System by TR/ISO 15608musheerBelum ada peringkat

- Iso 15608Dokumen7 halamanIso 15608korhankarakayaBelum ada peringkat

- Iso 15608Dokumen7 halamanIso 15608korhankarakayaBelum ada peringkat

- Welding Parameters Control PipelineDokumen1 halamanWelding Parameters Control PipelinemusheerBelum ada peringkat

- Welding - DIN EN ISO 6947-1997 Welds-Working Positions Definitions of Angles of Slope and Rotation PDFDokumen12 halamanWelding - DIN EN ISO 6947-1997 Welds-Working Positions Definitions of Angles of Slope and Rotation PDFEswaranBelum ada peringkat

- Iso 15608Dokumen7 halamanIso 15608korhankarakayaBelum ada peringkat

- BS en 288-2-92Dokumen12 halamanBS en 288-2-92vuthuy94Belum ada peringkat

- BS en 288-2-92Dokumen12 halamanBS en 288-2-92vuthuy94Belum ada peringkat

- (Iso/tr 17671-5) (Iso/tr 17671-6) (Iso/tr 17671-7) (Iso/tr 17671-8)Dokumen1 halaman(Iso/tr 17671-5) (Iso/tr 17671-6) (Iso/tr 17671-7) (Iso/tr 17671-8)Ivan Briscoe100% (7)

- Gaussian Pulsed Current Waveform Welding For Aluminum AlloysDokumen8 halamanGaussian Pulsed Current Waveform Welding For Aluminum AlloysmeleileiwangBelum ada peringkat

- European Steel and Alloy Grades: About Us EN 10248-1Dokumen2 halamanEuropean Steel and Alloy Grades: About Us EN 10248-1farshid KarpasandBelum ada peringkat

- Friction Stir Welding PPT On FSP Using Twin ToolDokumen58 halamanFriction Stir Welding PPT On FSP Using Twin ToolrobertalhaBelum ada peringkat

- Variasi Arus Terhadap Kekuatan Tarik Dan Bending Pada Hasil Pengelasan Sm490Dokumen11 halamanVariasi Arus Terhadap Kekuatan Tarik Dan Bending Pada Hasil Pengelasan Sm490Chio HahaBelum ada peringkat

- SANDVIK Priročnik Za VarjenjeDokumen354 halamanSANDVIK Priročnik Za Varjenjerisbo12Belum ada peringkat

- Welder SyllabusDokumen52 halamanWelder Syllabussantosh0% (1)

- 2 67 1587472886 2.ijmperdjun20202Dokumen12 halaman2 67 1587472886 2.ijmperdjun20202TJPRC PublicationsBelum ada peringkat

- Quite Interesting Facts About GoldDokumen2 halamanQuite Interesting Facts About GoldSamscribdingBelum ada peringkat

- ASTM Grade 70-50-05 (ISO 500-7, En-JS 1050) Ductile Cast IronDokumen8 halamanASTM Grade 70-50-05 (ISO 500-7, En-JS 1050) Ductile Cast IronNagarjun ReddyBelum ada peringkat

- Lab 3 Material Science - G4Dokumen35 halamanLab 3 Material Science - G4Syafiq Fauzi100% (1)

- PART 100 What Is GMAW - STTDokumen5 halamanPART 100 What Is GMAW - STTravindra_jivaniBelum ada peringkat

- 7040Dokumen89 halaman7040ScrbertoBelum ada peringkat

- Process: Chrome PlatingDokumen2 halamanProcess: Chrome PlatingRizky PratamaBelum ada peringkat

- Sae 147626610-Astm-A-576 PDFDokumen5 halamanSae 147626610-Astm-A-576 PDFNina LazuardiBelum ada peringkat

- Low-cost aluminum MMC production via rapid mixing processDokumen4 halamanLow-cost aluminum MMC production via rapid mixing processxharpreetxBelum ada peringkat

- Evaluating Cu-W Composite Powder Metallurgy ProcessesDokumen24 halamanEvaluating Cu-W Composite Powder Metallurgy Processesmuthu kumarBelum ada peringkat

- Minerals and Metals in Ancient IndiaDokumen2 halamanMinerals and Metals in Ancient IndiaSuneel KotteBelum ada peringkat

- Thesis - Ebe - 2020 - Dlamini Reuben MkhulekoDokumen120 halamanThesis - Ebe - 2020 - Dlamini Reuben Mkhulekorsrizwan2392Belum ada peringkat

- High-Strength Low-Alloy Steel Shapes of Structural Quality, Produced by Quenching and Self-Tempering Process (QST)Dokumen4 halamanHigh-Strength Low-Alloy Steel Shapes of Structural Quality, Produced by Quenching and Self-Tempering Process (QST)indityoBelum ada peringkat

- Manufacturing and supply of steel products for infrastructure, mining, cement, petrochemical and agroindustry sectorsDokumen21 halamanManufacturing and supply of steel products for infrastructure, mining, cement, petrochemical and agroindustry sectorsJUAN CBelum ada peringkat

- Cutting Data For Boring With Big KaiserDokumen17 halamanCutting Data For Boring With Big KaiserRajasekaran MuruganBelum ada peringkat

- Haynes: Hastelloy W AlloyDokumen4 halamanHaynes: Hastelloy W AlloyLuiz FernandoBelum ada peringkat

- Aalco Metals LTD - Aluminium Alloy 6063 T6 Extrusions - 158 PDFDokumen3 halamanAalco Metals LTD - Aluminium Alloy 6063 T6 Extrusions - 158 PDFganmosesBelum ada peringkat

- Bolt Depot - Bolt Grade Markings and Strength ChartDokumen3 halamanBolt Depot - Bolt Grade Markings and Strength ChartfrancisBelum ada peringkat

- Floor Drains and Accessories: Adjustable Floor Drain For Non-Membrane Floors, Series 210 200 SeriesDokumen1 halamanFloor Drains and Accessories: Adjustable Floor Drain For Non-Membrane Floors, Series 210 200 SeriesRajBelum ada peringkat

- ASTM A193-A193M-04cDokumen12 halamanASTM A193-A193M-04cNadhiraBelum ada peringkat

- Propiedades AISI 410Dokumen25 halamanPropiedades AISI 410alvaroyepezBelum ada peringkat

- Astm A 703 A 703M-07 PDFDokumen15 halamanAstm A 703 A 703M-07 PDFFranciele Kaezala100% (2)

- Sltp-Standard Inch Pins UsDokumen2 halamanSltp-Standard Inch Pins UsErick Frank Dueñas CudeñaBelum ada peringkat

- Presentation of SP Global PlattsDokumen33 halamanPresentation of SP Global PlattsBinod Kumar PadhiBelum ada peringkat