00000-JDS-014 (Pressure Safety Valve) Rev 0

Diunggah oleh

sithulibraHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

00000-JDS-014 (Pressure Safety Valve) Rev 0

Diunggah oleh

sithulibraHak Cipta:

Format Tersedia

Engineering

Standard

Instrument Datasheets - Pressure Safety Valve

Template Rev. No.: 0 Template No. : ENG-STD-JDS-GLR-014 Temp. Rev. Date : Feb 17, 2009

Instrument Datasheet - Pressure Safety Valve

Project Details :

Client : CLIENT NAME

Project Name : PROJ. NAME

Location : LOCATION

Project Ref. Number: : 00-000

GLR Document No. : 00000-JDS-014

Revision No. : 0

Date : 17-Feb-2009

Rev. No. Date Remarks Prepared Reviewed Approved

Engineering

Standard

Instrument Datasheets - Pressure Safety Valve

Template Rev. No.: 0 Template No. : ENG-STD-JDS-GLR-014 Temp. Rev. Date : Feb 1

Document No. : 00000-JDS-014 Rev. No.: 0

Revision History :

Revison No. Date :

Revison No. Date :

Revison No. Date :

Revison No. Date :

Revison No. Date :

afety Valve

Temp. Rev. Date : Feb 17, 2009

Date : 17-Feb-2009

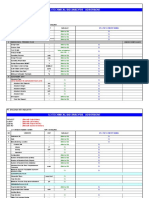

Pressure Safety Valve Datasheet

Client: CLIENT NAME Rev. Date Revision By Chk App Specification:

Project Name / Location: PROJ. NAME / LOCATION 27-Feb-2010 Requisition:

Project Ref. Number: 00-000 Doc. Revision: 0

Document Number: 00000-JDS-014 Page: 1 of 1

SPECIFICATION & TECHNICAL DATA

1 TAG NUMBER PSV-XXX

2 SERVICE

GENERAL

3 REFERENCE P&ID

4 LINE NO./VESSEL NO.

5 Full Nozzle / Semi Nozzle

6 Safety or Relief Safety Relief

7 Valve Type (Conventional, bellow, pilot op. Conventional

8 Bonnet Type Closed

9 Size: Inlet Outlet TBD TBD

CONN

10 Flange rating / Screwed ANSI 150# ANSI 150#

.

11 Flange Facing RF RF

12 Body / Base A216 Gr. WCB

13 Bonnet / Cylinder A216 Gr. WCB

MATERIALS

14 Seat and Disc 316 SS

15 Resilient Seat Seal

16 Guide and Rings

17 Spring

18 Bellows

19

20 Cap: Screwed or Bilted N/A

OPTION

21 Level: Plain or Packed N/A

S

22 Test Gag N/A

23

24 Code Accum. Section VIII 21%

BASIS

25 Sizing Basis Fire

26

27 Fluid Name Water vapor+blanket gas

FLUID DATA

28 Fluid State Vapor

29 Molecular Wt. Comp. (Z) 18.02 0.9939

30 k (Cp/Cv) C 1.3

31 Kb Flow Factor

32 API Effective K

33

34 Operating Set

PRESSURE DATA

35 Constant N/A

36 Back Pressure Variable N/A

(psi)

37 Total 0

38 Barometric Pressure 14.5

39 % Allowable Overpressure 20

40 Overpressure Factor 1.2

41

Temp. (ºC) 42 Operating Relative Design

Capacity 43 Required Calculated

(Kg/hr) 44

Flow Area 45 Calculated API Effective

(in2) 46 API Orifice Designaion

47 Manufacturer

Valve

48 Model Number

F1 Liquid Height

F2 Latent Heat of Vaporization (BTU/lb)

F3 Environmental Factor

Calculations

Fire Vessel

F4 Tank

F5 Orientation

F6 Ground Clearance (ft)

F7 Height / Length

F8 Diameter (ft)

F9 Vessel Heads

F10 Vessel Area (ft2)

NOTES:

Anda mungkin juga menyukai

- Pressure Transmitter Specification Sheet: GeneralDokumen1 halamanPressure Transmitter Specification Sheet: GeneralFranklin J Talero BBelum ada peringkat

- Control Valve Technical Specification Sheet Globe Service: GasDokumen1 halamanControl Valve Technical Specification Sheet Globe Service: Gassiddhesh_guessBelum ada peringkat

- TBA - AdsorbentDokumen4 halamanTBA - AdsorbentTifano KhristiyantoBelum ada peringkat

- R2B-P3-206-02-P-HD-00002 - Rev.1 - Datasheets For Oxygen Analyzer U-21000 - EngDokumen6 halamanR2B-P3-206-02-P-HD-00002 - Rev.1 - Datasheets For Oxygen Analyzer U-21000 - EngDiana Paula Echartea Molina0% (1)

- Motorised Valve: Instrument Datasheet Tag NoDokumen1 halamanMotorised Valve: Instrument Datasheet Tag Nokrishna kumarBelum ada peringkat

- Valve Sizing Calculation8Dokumen2 halamanValve Sizing Calculation8PIDBelum ada peringkat

- Orifice Plate DatasheetDokumen29 halamanOrifice Plate DatasheetshayabajBelum ada peringkat

- 1.2 ประมาณราคาศูนย์เด็ก ใส่ ประตู หน้าต่าง อิฐแก้ว แล้วDokumen18 halaman1.2 ประมาณราคาศูนย์เด็ก ใส่ ประตู หน้าต่าง อิฐแก้ว แล้วsarafan leewan0% (1)

- National Oil Corporation: Rev Date Description Checked ApprovedDokumen21 halamanNational Oil Corporation: Rev Date Description Checked ApprovedYousab JacobBelum ada peringkat

- 6261 - 4803 - 029 - Attachment-20 - Mandatory Spare Part List - XX PDFDokumen34 halaman6261 - 4803 - 029 - Attachment-20 - Mandatory Spare Part List - XX PDFharmlesdragon100% (1)

- Heat Exchanger Specification Sheet SI 2 Units: D:/HE/PLN/SHE - HtriDokumen1 halamanHeat Exchanger Specification Sheet SI 2 Units: D:/HE/PLN/SHE - HtrivikzefgBelum ada peringkat

- APNEA-J-DSH-0002 Rev. 1Dokumen3 halamanAPNEA-J-DSH-0002 Rev. 1Michelle MartinezBelum ada peringkat

- BE-WI-248-01-F12 Datasheet Level Instrument Displacer or FloatDokumen3 halamanBE-WI-248-01-F12 Datasheet Level Instrument Displacer or Floatmika cabelloBelum ada peringkat

- BE-WI-248-01-F07 Datasheet Turbine FlowmeterDokumen3 halamanBE-WI-248-01-F07 Datasheet Turbine Flowmetermika cabelloBelum ada peringkat

- Tie in Point (TP) 08 ADokumen19 halamanTie in Point (TP) 08 At_i_f_anoBelum ada peringkat

- Positioner SpecsDokumen1 halamanPositioner Specsbiswasdipankar05Belum ada peringkat

- Appendix 5 - Control and Alarm SetpointsDokumen20 halamanAppendix 5 - Control and Alarm SetpointsCù Xuân HuyBelum ada peringkat

- Pumps Final TeDokumen48 halamanPumps Final Tegharsallah mounaBelum ada peringkat

- Pump CalcDokumen5 halamanPump CalcpavanBelum ada peringkat

- Hook Ups PDFDokumen8 halamanHook Ups PDFAnonymous d7Jde8Belum ada peringkat

- Stack Gas Specification: Project Name Client Location GeneralDokumen6 halamanStack Gas Specification: Project Name Client Location Generalbudi utomoBelum ada peringkat

- Engineering Units ConverterDokumen19 halamanEngineering Units Convertertitou_d8638Belum ada peringkat

- BFW Cooler Datasheet Rev-2Dokumen3 halamanBFW Cooler Datasheet Rev-2Anonymous iCFJ73OMpDBelum ada peringkat

- Actuator Data SheetDokumen3 halamanActuator Data SheetPratik Ray ChaudhuryBelum ada peringkat

- 2922-GAC-STA-DAS-000-1038 - B Preheater XH4001 - TR-59Dokumen6 halaman2922-GAC-STA-DAS-000-1038 - B Preheater XH4001 - TR-59RonggolaweBelum ada peringkat

- A11627SE-08 - CVDS Rev B Technical Specification 840GDokumen2 halamanA11627SE-08 - CVDS Rev B Technical Specification 840GMichael Adu-boahenBelum ada peringkat

- IPA HeaterDokumen14 halamanIPA HeaterNitin KurupBelum ada peringkat

- IPS-MBD21907-In-529 - Datasheet of PH Transmitter - ADokumen3 halamanIPS-MBD21907-In-529 - Datasheet of PH Transmitter - ANikhil KarkeraBelum ada peringkat

- PMS Rev 0Dokumen36 halamanPMS Rev 0rami ghorbelBelum ada peringkat

- 20G12-MF-0010 - RA Heat & Mass Balance Diagram-2 PDFDokumen7 halaman20G12-MF-0010 - RA Heat & Mass Balance Diagram-2 PDFahmedBelum ada peringkat

- 1117 Ed 00 PL SP 013 A1 PDFDokumen5 halaman1117 Ed 00 PL SP 013 A1 PDFamini_mohiBelum ada peringkat

- Cvts - Tag No. Mpt-tv-4161Dokumen2 halamanCvts - Tag No. Mpt-tv-4161biswasdipankar05Belum ada peringkat

- Syn CompressorDokumen23 halamanSyn CompressorManish GautamBelum ada peringkat

- Superheated Steam SeparatorDokumen4 halamanSuperheated Steam SeparatorGanesh BhardwajBelum ada peringkat

- Yazd-System Description For Start Up & Blow Down SystemDokumen6 halamanYazd-System Description For Start Up & Blow Down Systemandri.motoGBelum ada peringkat

- Tank Datasheet - CS-8000KL - RADokumen1 halamanTank Datasheet - CS-8000KL - RASumantrra ChattopadhyayBelum ada peringkat

- SVDN CPP I 0023 D01 0002 Rev.04 General Arrangement Drawing in Signaler ReplaceDokumen8 halamanSVDN CPP I 0023 D01 0002 Rev.04 General Arrangement Drawing in Signaler ReplacejfdlksaBelum ada peringkat

- Hydraulic Cal - Tanks Vent To FlareDokumen1 halamanHydraulic Cal - Tanks Vent To FlareRexx Mexx0% (1)

- Project No. P12513 Feed For New Flow Suction Tank On Bu Hasa CdsDokumen6 halamanProject No. P12513 Feed For New Flow Suction Tank On Bu Hasa CdssarathBelum ada peringkat

- Rho v2Dokumen1 halamanRho v2Myung Ho SynBelum ada peringkat

- 528 - Tank Weighing System - 0Dokumen4 halaman528 - Tank Weighing System - 0Nikhil KarkeraBelum ada peringkat

- 7 Natural Gas Transmission Pipelines and City Gas Distribution NetworksDokumen2 halaman7 Natural Gas Transmission Pipelines and City Gas Distribution NetworksJatin Vadhera VCSPBelum ada peringkat

- LPG Amine Cooler-SummaryDokumen15 halamanLPG Amine Cooler-SummaryJEEVITHABelum ada peringkat

- Mucog 1910502 Mec DS 055Dokumen12 halamanMucog 1910502 Mec DS 055vinodBelum ada peringkat

- IPS-MBD21907-In-516B-Data Sheet of On Off Valve-Flush Bottom (Y Type) - ADokumen3 halamanIPS-MBD21907-In-516B-Data Sheet of On Off Valve-Flush Bottom (Y Type) - ANikhil KarkeraBelum ada peringkat

- Aspen Exchanger Design and Rating Shell & Tube V8.8Dokumen3 halamanAspen Exchanger Design and Rating Shell & Tube V8.8Camila Florencia ScarlatoBelum ada peringkat

- Process Calculation For FREYLIT CPI Oil SeparatorDokumen4 halamanProcess Calculation For FREYLIT CPI Oil SeparatorRajdeepsinhBelum ada peringkat

- Design of Incinerator Plant For Vasai-Virar RegionDokumen4 halamanDesign of Incinerator Plant For Vasai-Virar RegionVIVA-TECH IJRIBelum ada peringkat

- R2B-P3-206-02-P-HD-00205 - DATASHEETS FOR CONTROL VALVE, SLIDE, U-21000 - Rev.1Dokumen21 halamanR2B-P3-206-02-P-HD-00205 - DATASHEETS FOR CONTROL VALVE, SLIDE, U-21000 - Rev.1Diana Paula Echartea MolinaBelum ada peringkat

- ACFrOgALH7tI4bGAHoY RBTNzPHzMIyHy7FK3 - NLfBCnaIFG6 NJq3Ec8m HIQzGzsRrhL - EaKBKBfiHbz8J4GJN6MjbtxKXVhWqDR 2HbQRcF HAQ5 - xgrqTpvP2io PDFDokumen6 halamanACFrOgALH7tI4bGAHoY RBTNzPHzMIyHy7FK3 - NLfBCnaIFG6 NJq3Ec8m HIQzGzsRrhL - EaKBKBfiHbz8J4GJN6MjbtxKXVhWqDR 2HbQRcF HAQ5 - xgrqTpvP2io PDFMurali MuthuBelum ada peringkat

- 541-PC-1002 Utility Consumption Summary1Dokumen3 halaman541-PC-1002 Utility Consumption Summary1svnaik14Belum ada peringkat

- National Oil Corporation: Rev Date Description Checked ApprovedDokumen20 halamanNational Oil Corporation: Rev Date Description Checked ApprovedALI BEN AMORBelum ada peringkat

- Volume3A MechDokumen321 halamanVolume3A MechAdeel JamilBelum ada peringkat

- PFD Unit 2000 - ReferenceDokumen2 halamanPFD Unit 2000 - ReferenceAgravante JakeBelum ada peringkat

- GA GAS HOLDER - 120MLD-Layout2Dokumen1 halamanGA GAS HOLDER - 120MLD-Layout2epe civil1Belum ada peringkat

- Pig Receiver Data Sheet 91303 - 8 InchDokumen4 halamanPig Receiver Data Sheet 91303 - 8 InchSinaBelum ada peringkat

- M M M M M M M M: Product Condenser 101-A-0001-A / C / E / G / B / D / F / HDokumen1 halamanM M M M M M M M: Product Condenser 101-A-0001-A / C / E / G / B / D / F / Hahm3d16nBelum ada peringkat

- Al-Khobar Seawater Reverse Osmosis 2 Desalination PlantDokumen4 halamanAl-Khobar Seawater Reverse Osmosis 2 Desalination PlantABAID ULLAHBelum ada peringkat

- Venting Due To External Firing-12500 LTRS-R0Dokumen5 halamanVenting Due To External Firing-12500 LTRS-R0Dinesh VaghelaBelum ada peringkat

- 00000-JDS-015 (ERV Manhole) Rev 0Dokumen10 halaman00000-JDS-015 (ERV Manhole) Rev 0sithulibraBelum ada peringkat

- MB Tickets ReceiptsDokumen9 halamanMB Tickets ReceiptssithulibraBelum ada peringkat

- s7300 Cp341 Manual en en-USDokumen248 halamans7300 Cp341 Manual en en-USdavidpornBelum ada peringkat

- 11 Jul 2019 14:10 PM 1A: You Are Eligible For Scoot To GateDokumen3 halaman11 Jul 2019 14:10 PM 1A: You Are Eligible For Scoot To GatesithulibraBelum ada peringkat

- Itinerary - C37UPIDokumen2 halamanItinerary - C37UPIsithulibraBelum ada peringkat

- Seraya Energy Static Fact Sheet - Get It Fixed 24 (30 June 2019)Dokumen3 halamanSeraya Energy Static Fact Sheet - Get It Fixed 24 (30 June 2019)sithulibraBelum ada peringkat

- Manual de Bolsillo FM MantenimientoDokumen94 halamanManual de Bolsillo FM MantenimientoCristhian D CaicedoBelum ada peringkat

- Chubb - Travel-Claim-Form - DL20171130 PDFDokumen10 halamanChubb - Travel-Claim-Form - DL20171130 PDFsithulibraBelum ada peringkat

- LGs Way of Life Flyer PDFDokumen4 halamanLGs Way of Life Flyer PDFsithulibraBelum ada peringkat

- J2XJE2 MB Tickets ReceiptsDokumen9 halamanJ2XJE2 MB Tickets ReceiptssithulibraBelum ada peringkat

- Chubb - Travel-Claim-Form - DL20171130 PDFDokumen10 halamanChubb - Travel-Claim-Form - DL20171130 PDFsithulibraBelum ada peringkat

- Fact Sheet For Standard Price Plan: A: General InformationDokumen3 halamanFact Sheet For Standard Price Plan: A: General InformationsithulibraBelum ada peringkat

- Season One BrochureDokumen67 halamanSeason One BrochuresithulibraBelum ada peringkat

- Fact Sheet For Standard Price Plan: A: General InformationDokumen3 halamanFact Sheet For Standard Price Plan: A: General InformationsithulibraBelum ada peringkat

- (5IJO24QFBLFS: Now With The Google AssistantDokumen6 halaman(5IJO24QFBLFS: Now With The Google AssistantsithulibraBelum ada peringkat

- Ariel Training Hoerbiger Valves 2012Dokumen100 halamanAriel Training Hoerbiger Valves 2012sithulibra100% (7)

- LGs Way of Life Flyer PDFDokumen4 halamanLGs Way of Life Flyer PDFsithulibraBelum ada peringkat

- Fact Sheet For Standard Price Plan: A: General InformationDokumen3 halamanFact Sheet For Standard Price Plan: A: General InformationsithulibraBelum ada peringkat

- Guide For Preparation of NEMA Standards PublicationsDokumen38 halamanGuide For Preparation of NEMA Standards PublicationssithulibraBelum ada peringkat

- Flanges Price List - 2018 - PDFDokumen3 halamanFlanges Price List - 2018 - PDFsithulibraBelum ada peringkat

- 0003-MI20-60S1-0001-1-0 (E&I Cable)Dokumen16 halaman0003-MI20-60S1-0001-1-0 (E&I Cable)sithulibraBelum ada peringkat

- Campbell BundledDokumen24 halamanCampbell BundledsithulibraBelum ada peringkat

- Electronic Instrument Trades Worker (General) - 342314Dokumen3 halamanElectronic Instrument Trades Worker (General) - 342314sithulibraBelum ada peringkat

- Iecex Certificate of ConformityDokumen3 halamanIecex Certificate of ConformitysithulibraBelum ada peringkat

- (5IJO24QFBLFS: Now With The Google AssistantDokumen6 halaman(5IJO24QFBLFS: Now With The Google AssistantsithulibraBelum ada peringkat

- Travel Reservation August 20 For THNGDokumen2 halamanTravel Reservation August 20 For THNGsithulibraBelum ada peringkat

- Overspeed TestDokumen1 halamanOverspeed TestsithulibraBelum ada peringkat

- Annex To IECEx ITS 14.0025X Issue 0Dokumen4 halamanAnnex To IECEx ITS 14.0025X Issue 0sithulibraBelum ada peringkat

- DOC001Dokumen1 halamanDOC001sithulibraBelum ada peringkat

- Sithu Zaw CVDokumen8 halamanSithu Zaw CVsithulibraBelum ada peringkat

- FSE LV&HV CourseCertificateDokumen1 halamanFSE LV&HV CourseCertificatesithulibraBelum ada peringkat

- 06 SAP PM Level 1 Role Matrix Template SampleDokumen5 halaman06 SAP PM Level 1 Role Matrix Template SampleRiteshSinhmar100% (1)

- RH-A Catalog PDFDokumen1 halamanRH-A Catalog PDFAchmad KBelum ada peringkat

- Man Bni PNT XXX 105 Z015 I17 Dok 886160 03 000Dokumen36 halamanMan Bni PNT XXX 105 Z015 I17 Dok 886160 03 000Eozz JaorBelum ada peringkat

- Community Profile and Baseline DataDokumen7 halamanCommunity Profile and Baseline DataEJ RaveloBelum ada peringkat

- Marking Scheme For Term 2 Trial Exam, STPM 2019 (Gbs Melaka) Section A (45 Marks)Dokumen7 halamanMarking Scheme For Term 2 Trial Exam, STPM 2019 (Gbs Melaka) Section A (45 Marks)Michelles JimBelum ada peringkat

- 28 TerminalsDokumen42 halaman28 TerminalsAlin FazacasBelum ada peringkat

- Pam8610 PDFDokumen15 halamanPam8610 PDFRaka Satria PradanaBelum ada peringkat

- .CLP Delta - DVP-ES2 - EX2 - SS2 - SA2 - SX2 - SE&TP-Program - O - EN - 20130222 EDITADODokumen782 halaman.CLP Delta - DVP-ES2 - EX2 - SS2 - SA2 - SX2 - SE&TP-Program - O - EN - 20130222 EDITADOMarcelo JesusBelum ada peringkat

- Problem Solving No. 123Dokumen5 halamanProblem Solving No. 123Christy Joy BarboBelum ada peringkat

- Cap1 - Engineering in TimeDokumen12 halamanCap1 - Engineering in TimeHair Lopez100% (1)

- Life and Works of Jose Rizal Modified ModuleDokumen96 halamanLife and Works of Jose Rizal Modified ModuleRamos, Queencie R.Belum ada peringkat

- VOTOL EMController Manual V2.0Dokumen18 halamanVOTOL EMController Manual V2.0Nandi F. ReyhanBelum ada peringkat

- Course Outline ENTR401 - Second Sem 2022 - 2023Dokumen6 halamanCourse Outline ENTR401 - Second Sem 2022 - 2023mahdi khunaiziBelum ada peringkat

- Transfert de Chaleur AngDokumen10 halamanTransfert de Chaleur Angsouhir gritliBelum ada peringkat

- Principled Instructions Are All You Need For Questioning LLaMA-1/2, GPT-3.5/4Dokumen24 halamanPrincipled Instructions Are All You Need For Questioning LLaMA-1/2, GPT-3.5/4Jeremias GordonBelum ada peringkat

- E7d61 139.new Directions in Race Ethnicity and CrimeDokumen208 halamanE7d61 139.new Directions in Race Ethnicity and CrimeFlia Rincon Garcia SoyGabyBelum ada peringkat

- Prediction of Compressive Strength of Research PaperDokumen9 halamanPrediction of Compressive Strength of Research PaperTaufik SheikhBelum ada peringkat

- 1994 Manual de Taller Bronco, Econoline, F-Series PDFDokumen208 halaman1994 Manual de Taller Bronco, Econoline, F-Series PDFOscar Cruz100% (1)

- A Project Report ON Strategic Purchasing Procedure, Systems and Policies (Hospital Industry)Dokumen20 halamanA Project Report ON Strategic Purchasing Procedure, Systems and Policies (Hospital Industry)amitwin1983Belum ada peringkat

- Third Party Risk Management Solution - WebDokumen16 halamanThird Party Risk Management Solution - Webpreenk8Belum ada peringkat

- Control ValvesDokumen95 halamanControl ValvesHardik Acharya100% (1)

- Sim Uge1Dokumen62 halamanSim Uge1ALLIAH NICHOLE SEPADABelum ada peringkat

- For Accuracy and Safety: Globally ApprovedDokumen4 halamanFor Accuracy and Safety: Globally ApprovedPedro LopesBelum ada peringkat

- Test On Real NumberaDokumen1 halamanTest On Real Numberaer.manalirathiBelum ada peringkat

- Approvals Management Responsibilities and Setups in AME.B PDFDokumen20 halamanApprovals Management Responsibilities and Setups in AME.B PDFAli LoganBelum ada peringkat

- 23 Ray Optics Formula Sheets Getmarks AppDokumen10 halaman23 Ray Optics Formula Sheets Getmarks AppSiddhant KaushikBelum ada peringkat

- Keeping Track of Your Time: Keep Track Challenge Welcome GuideDokumen1 halamanKeeping Track of Your Time: Keep Track Challenge Welcome GuideRizky NurdiansyahBelum ada peringkat

- Consecration of TalismansDokumen5 halamanConsecration of Talismansdancinggoat23100% (1)

- Resume - James MathewsDokumen2 halamanResume - James Mathewsapi-610738092Belum ada peringkat

- My BaboogDokumen1 halamanMy BaboogMaral Habeshian VieiraBelum ada peringkat