Plan 1124 A 13205 Welded Steel T

Diunggah oleh

neoJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Plan 1124 A 13205 Welded Steel T

Diunggah oleh

neoHak Cipta:

Format Tersedia

SECTION 13205 - WELDED STEEL WATER STORAGE TANK

PART 1 GENERAL

1.01 SCOPE

A. This section covers the construction of steel water storage ground tank in conformance

with AWWA D-100 “Welded Steel Tanks for Water Storage”, latest edition, including

Section 13 for seismic design. All components shall comply with NSF/NSF61, Drinking

Water System Components – Health Effects in addition to Safe Drinking Water Act.

B. The tank site is not accessible by rail. The access to the site is provided by a private

road owned by the City. The construction of the tank will require re-alignment of an

existing road as shown in the drawings. The Contractor shall complete the construction

of the road re-alignment work before start of construction of the tank.

C. The Owner will not provide electricity or compressed air for the construction of the

reservoir. The Contractor may be able to use the water from the site at the prevailing

rate to be paid to the City. The Contractor will be responsible for installation of the water

meter and temporary piping for the purpose of metering the water used during

construction.

D. This work shall be performed on a design-build basis by an independent tank fabricator /

erector (Contractor). The Contractor shall provide the foundation, steel tank, pipe

connections, man ways, ladders, hatches, vents, water level indicator, and other

appurtenances shown on the drawings and/or included in the specifications. The work to

be performed under these specifications includes, but is not limited to, the design,

fabrication, construction, cleaning, coating, painting, disinfection, and testing of welded

steel ground water storage tanks, including the foundation and all accessories as shown

and specified in the Contract Documents.

E. The tank lining and coating systems are specified in Section 13217. The hydro test and

disinfection of the tank shall conform to Section 13206.

F. The Contractor shall provide all labor, materials, equipment, tools, supervision, and

incidentals necessary to construct the water storage tanks as shown and specified in the

Contract Documents.

G. The tank shall be vertical, cylindrical, flat-bottom type of all-welded steel construction,

supported on a poured-in-place reinforced-concrete ring foundation. Height of the tank,

steel tank plate thicknesses, foundation details shown on the drawings is the minimum

requirement. The Contractor will re-evaluate the height of the tank to accommodate the

freeboard predicted by the formula in AWWA D100 latest edition using the appropriate

seismic use group as required by the soils report. Should the calculations performed by

the Contractor indicate lower tank height, lower plate thicknesses, or smaller concrete

ring foundation, the Contractor shall supply the tank with the height, plate thicknesses,

and concrete foundation as indicated in the contract documents.

H. All materials used for tank construction shall be new, previously unused and shall comply

with all the requirements of this standard. Copies of the mill test reports shall be

furnished.

1.02 PRE-QUALIFICATION OF CONTRACTOR:

A. Bids will only be accepted from experienced Contractors who have successfully

completed at least 5 (five) tanks of equal or greater capacity in the last five (5) years.

Rev.10/13/15 13205-1 Country Club Reservoir

WELDED STEEL WATER STORAGE TANK

SECTION 13205 - WELDED STEEL WATER STORAGE TANK

Each bidder shall provide a list of at least 5 (five) such projects stating location,

completion date, contact names and telephone numbers. If a contact name and

telephone number listed cannot be reached, this project will not count as one of the five

minimum projects.

1.03 REFERENCED STANDARDS

A. The materials, design, fabrication, erection and inspection of the welded steel tank and

foundation, shall conform to the latest editions of: ACI 301 Specifications for Structural

Concrete for Buildings; ACI 318 Building Code Requirements for Structural Concrete;

ASCE 7 Minimum Design Loads for Buildings and Other Structures; AWWA C652

Standard for Disinfection of Water Storage Facilities; AWWA D100 Standard for Welded

Steel Tanks for Water Storage; AWWA D102 Standard for Painting Steel Water Storage

Tanks; NSF 61 Drinking Water System Components; OSHA Occupational Safety and

Health Standards; SSPC-PAS Steel Structures Painting Council: Paint Application

Specification.

1.04 GEOTECHNICAL REPORT

A. The soils investigation report furnished by a qualified Geotechnical Engineer dated

February 3, 2015 is included in Appendix A of the Project Specifications.

1.05 SUBMITTALS

A. Each Bidder shall submit with its proposal a sketch of the tank showing major dimensions

and plate thickness, nozzles and nozzle orientation, manholes, together with details of

the reinforced concrete foundation. The latter shall show preliminary dimensions and

approximate quantities of concrete and reinforcing steel.

B. Manufacturer’s qualification submittal.

C. After award and prior to construction, the successful bidder shall furnish detailed

drawings of the tank and foundation sealed by a Professional Engineer licensed in the

State of California. The successful bidder shall include a specification sheet for seismic

data per AWWA D 100 – Welded Steel Tanks for Water Storage.

D. The successful bidder shall provide details of welded joints, including the sequence and

methods for welding 3 plate intersections for floors and roofs. Mill test reports shall be

submitted for all steel materials prior to shop fabrication of plates. Steel supplied for the

tanks shall be all new.

E. The Contractor shall provide certified copies of radiography reports at the end of erection

of tanks before start of painting and coating work. The Owner will provide the services of

an independent radiograph inspector to evaluate the quality of the welding. If any weld

defect is established, the Contractor will correct the defective welding and re-radiograph

the welds to the satisfaction of the independent radiograph inspector. No additional

compensation will be provided to the Contractor for the repair of defective welding. The

cost for the independent radiograph inspector shall be by the Owner. The submitted

radiography reports shall become property of the City Engineer.

F. Welder’s certifications shall be submitted in accordance with AWWA D100 upon request.

G. Design calculations certified by a Professional Engineer proving compliance with all

requirements herein, shall be furnished by the Contractor to the Engineer.

Rev.10/13/15 13205-2 Country Club Reservoir

WELDED STEEL WATER STORAGE TANK

SECTION 13205 - WELDED STEEL WATER STORAGE TANK

H. Submittals shall conform to the requirements of Section 01300 – Contractor Submittals.

I. After conclusion of the Work of this Section, the Contractor shall submit a written

compliance certification report per AWWA D 100, paragraph 11. The report shall include

the following:

Copy of the welder performance qualifications

Summary of inspection radiographs and inspection by air carbon arc gauging

Identification of unacceptable radiographs and inspections by arc gauging and

statement of the action taken to rectify unsatisfactory welds

Record of welders employed on each joint

Certified record of welders.

Radiographs and inspection records.

PART 2 PRODUCTS

2.01 GENERAL

A. Provide one ground storage tank as shown on the Plans and as specified in this section

and located as shown on the Plans. The approximate dimensions of the tank shall be as

follows:

Diameter: 72 feet

Sidewall Height: 22.6 feet plus the required freeboard per AWWA D100

2.02 DESIGN CRITERIA

A. The roof shall be of “witches hat” design with a minimum slope of 1 inch in 12 inches.

B. Dead load shall be the estimated weight of all permanent construction and fittings. The

unit weight of steel shall be considered as 490 pounds per cubic foot and the unit weight

of concrete shall be taken as 144 pounds per cubic foot.

C. Live load shall be the weight of all of the liquid when the tank is filled to the overflow. The

unit weight of water shall be considered as 62.4 pounds per cubic foot.

D. The specified snow load shall not be less than that required by AWWA D100 Section

3.1.3.

E. Wind load shall be 115 miles-per-hour

F. Seismic design shall be in accordance with AWWA D100 Section 3.1.5 for the zoning

indicated by AWWA D100 Figure 7.

G. The design for all sections of the steel tank (cylinders, conical and double curved) shall

be per the classes of materials and unit tension/compression stresses mentioned in the

latest edition of AWWA D100.

H. The tank details shall be designed to eliminate un-welded joints that will promote

corrosion, pockets that will accumulate rain water, and attachments to the shell which

result in excessive localized stresses due to welding or imposed loads. The exceptions

to this requirement are the roof rafters and internal roof plate lap joints. The contact

Rev.10/13/15 13205-3 Country Club Reservoir

WELDED STEEL WATER STORAGE TANK

SECTION 13205 - WELDED STEEL WATER STORAGE TANK

surfaces between the roof rafters and roof plates and the interior roof plate lap joints shall

be primed before erection in accordance with Section 09800 - Painting and Coating.

I. Welds joining shell plates and wetted roof plates shall have complete joint penetration

and fusion and shall be double-welded from both sides. The use of low-hydrogen

electrodes is mandatory for manual welding of shell plates, for permanent attachments to

the shell plates, for fittings, and for welds joining the shell plates to the bottom plates.

Shell plates shall be rolled, regardless of material thickness.

J. The roof shall be designed for the minimum live load and shall have a pitch as indicated.

Lateral bracing of rafter compression flanges shall not be assumed to be provided by

friction between roof sheets and rafters. Rafters and bridging between rafters shall be

designed of standard structural steel shapes. The minimum roof plate thickness shall be

3/16-inch.

K. Columns shall be fabricated from steel pipe sealed at both ends. Column bases shall be

fabricated from steel plate and provided with the necessary gusset plates to distribute the

load uniformly. The base plates shall be designed for a maximum foundation loading of

2,000 pounds per square foot, exclusive of the weight of water. The column bases shall

not be welded to the bottom plates but shall be prevented from lateral movement by

angle clips welded to the bottom plates. Where column base plates are placed over lap

joints, filler plates shall be used to provide full bearing under the base. Structural steel

shapes shall not be used for column bases.

L. Nuts and bolts used for erection purposes shall be hot-dip galvanized after fabrication.

Bolts inside the reservoir that support permanent loads, ladders, or appurtenances shall

be Type 304 stainless steel.

M. The tank bottom, including sketch and annular plates, shall be fabricated from steel plate

not less than 1/4-inch thick. Annular bottom plates shall be provided per Section 13 of

AWWA D100, except that the butt-welded joints shall be double-welded from both sides.

The minimum annular plate width shall be determined by AWWA D100, Section 13.

N. The design, materials, fabrication, construction, and inspection of the steel tank shall

conform to AWWA D100, except as modified herein.

O. No corrosion allowance is required.

2.03 APPURTENANCES

A. One vent of adequate size to handle a pressure differential caused by water entering or

leaving the tank at a maximum rate shall be provided. The maximum inlet rate is 2,000

gpm, the maximum withdrawal rate is 2,000 gpm. The open area of the overflow shall

not be considered as a venting area. The vent shall have stainless steel insect screens

and shall be designed to relieve any pressure or vacuum in the event the screen frosts

over or is otherwise clogged and shall be easily dismantled for cleaning. Center roof vent

shall be 48 inch minimum.

B. Ladders, safety devices and safety cages shall be as required by state and federal

regulations. All ladders shall be furnished with "Saf-T-Climb” or equal, fall prevention

devices and shall meet OSHA standards. The City shall be supplied with 2 sleeves and 2

belts.

Rev.10/13/15 13205-4 Country Club Reservoir

WELDED STEEL WATER STORAGE TANK

SECTION 13205 - WELDED STEEL WATER STORAGE TANK

C. One 36-inch by 36-inch steel rainproof, flanged roof hatch shall be supplied, with hinges

and hasps for locking and one 36-inch by 36-inch steel rainproof, flanged roof hatch with

removable cover, so constructed that an exhaust fan may be connected for ventilation

during painting.

D. One 36-inch diameter shell manhole shall be supplied, equipped with hinges, centered

four feet above the base of the tank. This manhole shall have a bolting flange suitable for

connecting an exhaust fan for ventilation and a suitable blind flange and gasket.

E. All welded joints on the tank in contact with the tank contents shall be seal welded as a

minimum.

F. A 12-inch diameter steel inlet pipe shall be provided with the following configuration as

shown on the plans: Steel inlet pipe welded to the tank wall and flange-bolted to ductile

iron inlet pipe.

G. One 12” diameter steel outlet pipe welded to the tank wall and flange-bolted to ductile

iron outlet pipe.

H. A 16-inch diameter overflow equipped with an anti-vortex entrance shall be provided.

Overflow shall extend down the outside of the tank and shall terminate a minimum of 32

inches above grade.

I. Inlet shall be equipped with a removable silt stop extending four inches above the bottom

of the tank floor.

J. One fixed ladder shall be supplied on the exterior of the tank, and one fixed ladder shall

be supplied in the interior of the tank. Each ladder shall begin at a point even with the

tank bottom. Access to roof hatches and vents shall be provided according to the

minimum requirements versus roof slope as described in Section 5.4.3 of AWWA D100.

J. One 36” x 48” Cleanout Door as shown on the Plans.

K. The minimum roof plate thickness shall be 3/16 – inch

L. The tank bottom, including sketch and annular plates shall be fabricated from steel plate

not less than ¼ - inch thick.

M. Submerged bolts inside the tank shall be Type 304 stainless steel.

N. Design of the access manhole in the lowest ring of the shell shall conform to API 650-

Welded Steel Tanks for Oil Storage, and shall be hinged as indicated.

O. The fall protection system shall comply with OSHA.

P. Welds joining the bottom plates shall be vacuum tested using solution film. Any

detectable leaks shall be marked and repaired by welding. Sealing shall not be

accomplished by peening. One spot radiograph shall be taken on 10 percent of the butt-

welded annular plates. The inside shell-to-bottom fillet welds shall be vacuum tested

using solution film before the outside welds is made.

Q. All seismic anchor bolts and nuts shall be Type 304 stainless steel.

Rev.10/13/15 13205-5 Country Club Reservoir

WELDED STEEL WATER STORAGE TANK

SECTION 13205 - WELDED STEEL WATER STORAGE TANK

PART 3 EXECUTION

Safety and Health Requirements: In accordance with the requirements set forth by regulatory

agencies applicable to the construction industry and in accordance with the manufacturer’s

printed instructions and appropriate technical bulletins and manual, the Contractor shall provide

and require use of personal lifesaving equipment for persons working on or about the site.

As a minimum, personal lifesaving equipment shall properly address protection of these persons

in the following categories:

(a) Head and Face Protection

(b) Respiratory Devices

(c) Ventilation

(d) Sound Levels

(e) Illumination

(f) Temporary Ladders and Scaffolding.

3.01 INSPECTION

A. Mill or shop inspection reports shall be supplied in accordance with Section 11.1 of

AWWA D100.

B. At the completion of the work a written report shall be supplied in accordance with

Section 11.2.1 of AWWA D100.

3.02 CONCRETE FOUNDATION

A. The concrete foundation shall be constructed per the details shown on the project plans.

Concrete work shall conform to the requirements of ACI 301 “Specifications for Structural

Concrete for Buildings.”

3.03 WELDING

A. All welders shall be qualified by ASME Section IX for the processes and positions

utilized.

B. The Contractor shall employ the services of a welding supervisor independent of the tank

erection foreman’s jurisdiction. Performing and paying for inspection and testing of welds

shall be by the Contractor and shall be completed before the application of coating and

painting.

C. Horizontal welding shall be inspected and tested by radiographic testing consistent with

the requirements of Section 11 of AWWA D100. Sectional segments will not be allowed.

D. The edges or surfaces of the pieces to be joined by welding shall be prepared by flame

cutting, plasma arc cutting, arc gouging, machining, shearing, grinding or chipping and

shall be cleaned of detrimental oil, grease, scale and rust. The edges of the pieces may

have a protective coating applied to them which need not be removed before they are

welded unless specifically prohibited by the WPS.

E. Welding procedures and welding operators shall be qualified in accordance with ASME

Section IX. All field welding may be done by the shielded metal-arc welding process, the

gas metal-arc welding process, the flux-core arc-welding process and/or the submerged

arc welding process. Shop welding may be done by the shielded metal-arc process,

Rev.10/13/15 13205-6 Country Club Reservoir

WELDED STEEL WATER STORAGE TANK

SECTION 13205 - WELDED STEEL WATER STORAGE TANK

submerged-arc welding process, gas metal-arc welding process, and/or flux-core metal-

arc welding process. Plates and component members of the tank shall be assembled

and welded following erection methods which result in a minimum of distortion from weld

shrinkage. The weld metal shall meet or exceed the minimum requirements for visual

inspection in AWWA D100 Section 11.4 and as set forth in the radiographic acceptance

standards of AWWA D100 Section 11.6.10. Surfaces to be welded shall be free from

loose scale, slag, heavy rust, grease, paint and all other foreign material.

F. The Contractor shall not use an automatic welding machine for vertical welds. Vertical

welds shall be radiographed for 100 percent of their length. Welds not meeting the

acceptance criteria in AWWA D100 shall be repaired and radiographed until

requirements are met.

G. Automatic Welding Machine: If the Contractor uses an automatic welding machine for the

horizontal welds in the tank shell, the following startup procedure shall be used. After the

first 10-feet of the first pass is welded, the Contractor shall air carbon arc gouge into the

root of the weld to allow the Engineer to visually confirm that full penetration and fusion is

attained. If full penetration and fusion have not been attained, the machine shall be

immediately corrected. The procedure shall be repeated until satisfactory welding is

achieved. Defective welding in the startup area shall be repaired.

H. Roof Welds: Welds in contact with the reservoir contents shall be spot radiographed per

AWWA D100

I. After reinforcing plate is fitted to the shell, but before the pipe or neck fitting is inserted,

the reinforcing plate shall be seal welded to the shell at the inner and outer edges. Air

pressure shall then be applied to the space between the reinforcing plate and the shell,

and the seal welds tested with solution film.

J. The Contractor shall use a written procedure for fitting and welding the bottom plates.

Out-of-plane distortion shall not exceed 0.75 percent of the tank radius.

K. Local deviations, such as flat spots, peaked joints, and welding distortion shall be limited

as follows for the shell plates:

(a) Using a horizontal sweep board 36-inches long, the distance from the sweep

board to the shell shall not be greater than 1/2-inch. Flat spots shall be

measured with an external sweep board. Peaked spots shall be measured

with an internal sweep board.

(b) Using a vertical sweep board 36-inches long, banding of horizontal joints

shall not exceed 1/2-inch.

(c) Measurements shall be taken beginning with the first joints that are welded.

Corrections to the fitting and welding procedure shall immediately be made if

the joints are not within the distortion criteria. The Contractor shall submit

corrective procedures for joints that have been welded but are not within the

criteria for distortion.

---END OF SECTION--

Rev.10/13/15 13205-7 Country Club Reservoir

WELDED STEEL WATER STORAGE TANK

Anda mungkin juga menyukai

- Contractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerDari EverandContractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerPenilaian: 5 dari 5 bintang5/5 (1)

- Material Submittal HANDRAILDokumen6 halamanMaterial Submittal HANDRAILManu Mohan0% (1)

- Water Tank SpecificationDokumen28 halamanWater Tank Specificationdan20000Belum ada peringkat

- Aerospace Structural Metals HandbookDokumen74 halamanAerospace Structural Metals HandbookBrian Pinto50% (2)

- 331615-Water Storage Steel TanksDokumen14 halaman331615-Water Storage Steel TanksinstrengBelum ada peringkat

- Astm 1011Dokumen9 halamanAstm 1011calidad campana100% (1)

- PFI ES 42 1996 Standard For PositiveDokumen7 halamanPFI ES 42 1996 Standard For Positiveahmad effendiBelum ada peringkat

- A Guide to Ship Repair Estimates in Man-hoursDari EverandA Guide to Ship Repair Estimates in Man-hoursPenilaian: 4.5 dari 5 bintang4.5/5 (5)

- Thermal Energy Storage TankDokumen24 halamanThermal Energy Storage Tankfahimafroz0% (1)

- AWWA C 204 Mortar Lined MS PipeDokumen19 halamanAWWA C 204 Mortar Lined MS PipeAnonymous D66WHl100% (1)

- Technical Specification For PlumbingDokumen4 halamanTechnical Specification For PlumbingJoeven JagocoyBelum ada peringkat

- 22 11 13 - Facility Water Distribution Piping PDFDokumen11 halaman22 11 13 - Facility Water Distribution Piping PDFmasoodaeBelum ada peringkat

- Saph 440Dokumen1 halamanSaph 440rinkumax2003100% (1)

- TDS For Repair Process For Galvanized ItemsDokumen4 halamanTDS For Repair Process For Galvanized ItemsPappu Kishore Kumar100% (2)

- 33 16 13 - Ground Storage TanksDokumen5 halaman33 16 13 - Ground Storage TanksHizbar ArsjadBelum ada peringkat

- MS 50002 Parte 1Dokumen22 halamanMS 50002 Parte 1urias9050% (2)

- AWWA D100 Guide Specification PDFDokumen8 halamanAWWA D100 Guide Specification PDFDaniel Marín100% (1)

- Chance Helical Pier Specification - Standard-3Dokumen8 halamanChance Helical Pier Specification - Standard-3Sen HuBelum ada peringkat

- Awwa d103 PotableDokumen9 halamanAwwa d103 PotableAnonymous UArnIExBelum ada peringkat

- ASTM A573 SteelDokumen2 halamanASTM A573 SteelneoBelum ada peringkat

- Volume 8: Water Works 8.1: Part 2 Particular Specifications: Relating ToDokumen11 halamanVolume 8: Water Works 8.1: Part 2 Particular Specifications: Relating Tobuddy1971Belum ada peringkat

- Types of Cranes ComparisonDokumen7 halamanTypes of Cranes Comparisonneo0% (1)

- ST52-3 (PLATE) Mechanical PropertiesDokumen1 halamanST52-3 (PLATE) Mechanical Propertiesistasyonbaykusu100% (1)

- Precast Post Tentioned TanksDokumen20 halamanPrecast Post Tentioned TanksMarcel SteoleaBelum ada peringkat

- Plumbing - Technical Specifications PDFDokumen18 halamanPlumbing - Technical Specifications PDFEdzon LacayBelum ada peringkat

- General Requirements For Water Storage TanksDokumen8 halamanGeneral Requirements For Water Storage TanksAnonymous DJrec2100% (1)

- Section - Multi-Column Elevated Water Storage TankDokumen6 halamanSection - Multi-Column Elevated Water Storage Tankali gholiaBelum ada peringkat

- 067 S 13200 Elevated Water Storage TankDokumen7 halaman067 S 13200 Elevated Water Storage TankAsep SuhermanBelum ada peringkat

- Awwa d100 PotableDokumen8 halamanAwwa d100 PotableOnatBelum ada peringkat

- Section 13210 Spheroid Elevated Water Storage Tank: Spec Note - Add Sections As RequiredDokumen12 halamanSection 13210 Spheroid Elevated Water Storage Tank: Spec Note - Add Sections As RequiredHitanshuBelum ada peringkat

- SECTION 15061 Steel Pipe Specification - Transmission MainDokumen9 halamanSECTION 15061 Steel Pipe Specification - Transmission MainMohammad AlizadehBelum ada peringkat

- Section 13210 Composite Elevated WaterDokumen22 halamanSection 13210 Composite Elevated Waterhasen kushlafBelum ada peringkat

- 2015 11 24 20121231 Composite Elevated Tank - SpecificationDokumen21 halaman2015 11 24 20121231 Composite Elevated Tank - SpecificationOladunni AfolabiBelum ada peringkat

- Composite Elevated Water Storage Tank SpecificationsDokumen9 halamanComposite Elevated Water Storage Tank SpecificationsArputharaj Maria LouisBelum ada peringkat

- WTSPECSDokumen6 halamanWTSPECSFawwaz KhanBelum ada peringkat

- (0018) 2.3 - SteelWaterPipe - Aug2011Dokumen14 halaman(0018) 2.3 - SteelWaterPipe - Aug2011Sixto Gerardo Oña AnaguanoBelum ada peringkat

- Multi-Column Water Tank Construction Specifications Tank Contractor: Phoenix Fabricators and Erectors, LLCDokumen8 halamanMulti-Column Water Tank Construction Specifications Tank Contractor: Phoenix Fabricators and Erectors, LLCJorge León IllanesBelum ada peringkat

- 2688 Water MainDokumen10 halaman2688 Water MainAnonymous NR3qZ30Belum ada peringkat

- Tanques de AguaDokumen9 halamanTanques de Aguargb0906Belum ada peringkat

- Tank DesignDokumen7 halamanTank Designbektiwidi1060Belum ada peringkat

- Aquastore Glass-Fused-To-Steel Tank Specifications (Revised)Dokumen14 halamanAquastore Glass-Fused-To-Steel Tank Specifications (Revised)Juan Carlos Ortiz AlzateBelum ada peringkat

- Material Specification in TenderDokumen3 halamanMaterial Specification in TenderenggmohanBelum ada peringkat

- Section 02651 - Steel Pipe, Lined and Coated City of San Diego, CWP GuidelinesDokumen23 halamanSection 02651 - Steel Pipe, Lined and Coated City of San Diego, CWP GuidelinesMohammed HarrisBelum ada peringkat

- Elevated SpecsDokumen14 halamanElevated SpecsSure ConsultancyBelum ada peringkat

- Swimming Pool Plumbing SystemsDokumen6 halamanSwimming Pool Plumbing SystemschampionaquaticBelum ada peringkat

- Steel Pipe, CMLC - Rev 3-17Dokumen18 halamanSteel Pipe, CMLC - Rev 3-17A T AlhershBelum ada peringkat

- 33 16 13 - Ground Storage TankDokumen6 halaman33 16 13 - Ground Storage TankBelford AbuhBelum ada peringkat

- Ductile Iron Pipe For Sewers 012221Dokumen9 halamanDuctile Iron Pipe For Sewers 012221สุภรัตน์ จันทร์คุณาภาสBelum ada peringkat

- Bolted Tank Specifications Final 11-5-15Dokumen6 halamanBolted Tank Specifications Final 11-5-15Rodrigo ZapataBelum ada peringkat

- SECTION 13121 Fountains Part 1 - General 1.1Dokumen6 halamanSECTION 13121 Fountains Part 1 - General 1.1garych72Belum ada peringkat

- FGV Bulkers SDN BHDDokumen46 halamanFGV Bulkers SDN BHDBoluya FDBelum ada peringkat

- Modifications/Changes in This UpdateDokumen19 halamanModifications/Changes in This UpdateAdea CarolBelum ada peringkat

- 23 21 14 Hydronic SpecialtiesDokumen7 halaman23 21 14 Hydronic SpecialtiesSoumojit SamantaBelum ada peringkat

- SECTION 03300 Concrete: Hilltown Township Water and Sewer AuthorityDokumen9 halamanSECTION 03300 Concrete: Hilltown Township Water and Sewer AuthoritybrentosjBelum ada peringkat

- Section 21 11 00Dokumen10 halamanSection 21 11 00Ismail MohammadBelum ada peringkat

- Specification Plumbing SystemDokumen16 halamanSpecification Plumbing SystemGhiovani DayananBelum ada peringkat

- Domestic Water SystemsDokumen20 halamanDomestic Water Systemsabdullah sahibBelum ada peringkat

- 23 21 13 Hydronic PipingDokumen15 halaman23 21 13 Hydronic PipingSoumojit SamantaBelum ada peringkat

- Awwa d103 PotableDokumen9 halamanAwwa d103 PotableAnonymous UArnIExBelum ada peringkat

- 334100Dokumen5 halaman334100jia wangBelum ada peringkat

- Seismic Requirements - MSTDokumen4 halamanSeismic Requirements - MSTwafikmh4Belum ada peringkat

- Chapter 5Dokumen18 halamanChapter 5arsiajanBelum ada peringkat

- Project Specifications PDFDokumen8 halamanProject Specifications PDFAlexis DiololaBelum ada peringkat

- Elevated TanksDokumen8 halamanElevated TanksChâu TúBelum ada peringkat

- Water Distribution System - 2Dokumen6 halamanWater Distribution System - 2kkkhattabbbBelum ada peringkat

- Precast Reinforced Concrete Vaults - MSTDokumen9 halamanPrecast Reinforced Concrete Vaults - MSTwafikmh4Belum ada peringkat

- Cement Coated Pipe PDFDokumen29 halamanCement Coated Pipe PDFArjed Ali ShaikhBelum ada peringkat

- Viking Serie 4197 Sec - 164!12!06screenDokumen5 halamanViking Serie 4197 Sec - 164!12!06screenneoBelum ada peringkat

- ContractDokumen98 halamanContractneoBelum ada peringkat

- BVA300 Series Pneumatic Actuators For Use With Spirax Sarco Ball ValveDokumen8 halamanBVA300 Series Pneumatic Actuators For Use With Spirax Sarco Ball ValveneoBelum ada peringkat

- Tank Level Indicator: KING-GAGE Marine SystemsDokumen4 halamanTank Level Indicator: KING-GAGE Marine SystemsneoBelum ada peringkat

- Flow Meters, Flow Switches and Flow Transmitters: A Piston Design For Low Flows of LiquidsDokumen6 halamanFlow Meters, Flow Switches and Flow Transmitters: A Piston Design For Low Flows of LiquidsneoBelum ada peringkat

- New Asce 7-16 Requirements and Limitations of For Site-Specific Ground MotionsDokumen34 halamanNew Asce 7-16 Requirements and Limitations of For Site-Specific Ground MotionsneoBelum ada peringkat

- Mobile Offshore Drilling Units 2016: Rules For Building and ClassingDokumen9 halamanMobile Offshore Drilling Units 2016: Rules For Building and ClassingneoBelum ada peringkat

- Mobile Offshore Drilling Units 2016: Rules For Building and ClassingDokumen6 halamanMobile Offshore Drilling Units 2016: Rules For Building and ClassingneoBelum ada peringkat

- Part 1 Ships E-Jan17Dokumen60 halamanPart 1 Ships E-Jan17neoBelum ada peringkat

- SVR Nandgi E-Jan17Dokumen28 halamanSVR Nandgi E-Jan17neoBelum ada peringkat

- S235JR DIN EN 10025-2number: 1.0037 ST37-2 E24-2 SS400 A283CDokumen1 halamanS235JR DIN EN 10025-2number: 1.0037 ST37-2 E24-2 SS400 A283CneoBelum ada peringkat

- I JR Et 20170601003Dokumen7 halamanI JR Et 20170601003neoBelum ada peringkat

- ICC-ES Report: Roof Tech, IncDokumen3 halamanICC-ES Report: Roof Tech, IncneoBelum ada peringkat

- Cn72-1 - Allowable Thickness Diminution PDFDokumen23 halamanCn72-1 - Allowable Thickness Diminution PDFneoBelum ada peringkat

- Structure Steel DesignDokumen62 halamanStructure Steel Designneo100% (1)

- C45Dokumen2 halamanC45neoBelum ada peringkat

- Draft Select BeamDokumen1 halamanDraft Select BeamneoBelum ada peringkat

- Oil and Gas - VillaresDokumen12 halamanOil and Gas - VillaresBruno PereiraBelum ada peringkat

- 2 Bijih Besi Dan AglomerisasiDokumen56 halaman2 Bijih Besi Dan AglomerisasiJon SanBelum ada peringkat

- Alloy904L SpecSheet PDFDokumen2 halamanAlloy904L SpecSheet PDFPieter BrodeouxBelum ada peringkat

- Welding 304HDokumen29 halamanWelding 304Hclaude.bouillot3566Belum ada peringkat

- 30Cr2Ni4MoV MaterialDokumen12 halaman30Cr2Ni4MoV Materiallacoste11111Belum ada peringkat

- Is 13212 1991 PDFDokumen9 halamanIs 13212 1991 PDFJegadeeshBelum ada peringkat

- Corrosion: Introduction - Definitions and TypesDokumen13 halamanCorrosion: Introduction - Definitions and TypesGuru PrasadBelum ada peringkat

- Assignment: Chapter 3: Metal Forming and Shaping ProcessesDokumen22 halamanAssignment: Chapter 3: Metal Forming and Shaping ProcessesIrfanBelum ada peringkat

- Tentative Calendar of Events INDOCOR 2017Dokumen2 halamanTentative Calendar of Events INDOCOR 2017Firlan MaulanaBelum ada peringkat

- Effect of Feed Rate On Surface Roughness in Abrasive Waterjet Cutting Applications.Dokumen7 halamanEffect of Feed Rate On Surface Roughness in Abrasive Waterjet Cutting Applications.ronBelum ada peringkat

- Stainless Lifting Bolts - Male: MetricDokumen3 halamanStainless Lifting Bolts - Male: MetricShreenidhiBelum ada peringkat

- Experiment 2: Brinell Hardness TestDokumen5 halamanExperiment 2: Brinell Hardness TestseifBelum ada peringkat

- Aluminium Alloy U Channel - : Astm B221 / Astm B557Dokumen2 halamanAluminium Alloy U Channel - : Astm B221 / Astm B557fery indrawanBelum ada peringkat

- Prevent From Deterioration Due To The Formation: Efflorescence, Stalling, Leaching, StainingDokumen30 halamanPrevent From Deterioration Due To The Formation: Efflorescence, Stalling, Leaching, StainingAsish BarailiBelum ada peringkat

- Answers To End-Of-Chapter Questions For Chapter 7, Metals and StructuresDokumen2 halamanAnswers To End-Of-Chapter Questions For Chapter 7, Metals and StructuresAliBelum ada peringkat

- Flamefast crm700 Crucible Furnace - Axminster Tools EuropeDokumen2 halamanFlamefast crm700 Crucible Furnace - Axminster Tools EuropeshahinBelum ada peringkat

- Optimization of Industrial Processes ForDokumen202 halamanOptimization of Industrial Processes ForArne BeningBelum ada peringkat

- Plate Steel CatalogueDokumen73 halamanPlate Steel CatalogueMelele MuBelum ada peringkat

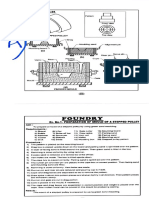

- Foundry: Ex. Mo.1. Preparation of Mould of A Stepped PulleyDokumen4 halamanFoundry: Ex. Mo.1. Preparation of Mould of A Stepped PulleyAtshayaBelum ada peringkat

- Panasonic SwitchesDokumen16 halamanPanasonic SwitchesMohamed MostafaBelum ada peringkat

- EndexDokumen25 halamanEndexbelacheweshetu222Belum ada peringkat

- Ions ChargeDokumen1 halamanIons Chargeshashankshukla676100% (1)