SF Constructability Lansing Comm College Aug 061

Diunggah oleh

Khilbran MuhammadHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

SF Constructability Lansing Comm College Aug 061

Diunggah oleh

Khilbran MuhammadHak Cipta:

Format Tersedia

g

i l i t y

W i

c

n

tn

ai n

b

rd

r u

®

Awa t

s

The Lansing Community College, Health & Human

on E

Service Career Building project was presented an

Outstanding Project Award (New Buildings Under

R

$10 Million) in the National Council of Structural

C

Engineering Associations (NCSEA) 2005 Excellence

in Structural Engineering Awards program.

Lansing Community College

U

ht

yrig

T

Cop

C

By David I. Ruby, P.E., S.E., SECB

I e

U

n the June 2006 issue of STRUCTURE®, we introduced the To achieve the greatest benefit from Constructability, the Design Team

philosophy of Constructability and presented benefits associated (led by the structural engineer, when appropriate) must understand the

with infusing Constructability into the design process. This second

i n

interdependent nature and uniqueness of each process, consider each

R

article in the series describes the practical application of the principles in developing the project program and then integrate each to create a

of Constructability in the redesign of Lansing Community College,

z

cost-efficient solution for the Owner.

T

Health & Human Service Career Building. Principles discussed in this

article are contained in their entirety in the Constructability Design

g

Guide, which will be published later this year by the American Institute

a The Lansing Community College (LCC) Project

S

At LCC, Constructability was introduced at the stage of bidding,

of Steel Construction (AISC).

a

fabrication and installation; the project schedule and the architectural

envelope had been established at this point. As designed for bidding,

What is Constructability?

m

the structure was a three-story building with a fourth floor expansion

Constructability has been defined by the Construction Industry planned in the future, but the three-story building excessed the original

Institute as the optimum use of construction knowledge and experience budget by approximately $200,000.

in planning, design, procurement and field operations to achieve overall Ruby+Associates was presented with the opportunity to partner

project objectives. Constructability does not only relate to the ease with Douglas Steel and provide a cost effective redesign in an at-

of construction and/or erection of structural steel; Constructability tempt to deliver the steel structure of the building within budget.

concepts engage all aspects, materials and elements of construction and Although Ruby+Associates was not involved in the early concept-

therefore can greatly reduce the overall cost of construction as well as ual stages of the design, the firm was able to apply Constructability

the cost of structural steel by facilitating: principles — the integration of construction knowledge and expe-

• construction friendly designs rience — during the bid-

• reduction or elimination of special installation conditions ding stage and completely

• accurate and cost-effective proposals from fabricators/erectors redesign the major struc-

• coordination of structural and non-structural items tural steel components of

• trades and related construction activities the building. This rede-

• economic material procurement sign saved enough money

• timely and inexpensive shop drawing preparation to enable LCC to procure

• standard fabrication processes, and and Douglas Steel to con-

• architecturally exposed structural steel requirements. struct the fourth floor, and

still complete the project

Stages of Constructability $100,000 under budget

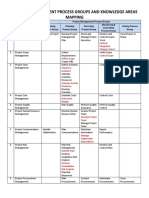

In general, the Constructability process should include the and ahead of schedule!

following activities: In the original design, the

• Design team formation floor beams were spaced at about 3-feet on center, with a light metal deck

• Testing of options

• Data gathering and a reasonably thin slab. The lateral-load resisting system consisted

• Final design process

• Constraints recognition of a combination of labor intensive full capacity moment connections,

• Bid package development

• Evaluation of constraints “ornamental” X-bracing and inefficient knee braces throughout the

• Bidding process

• Program development corridors. The framing system also included concrete filled columns.

• Fabrication process

• Framing options evaluation By analyzing several lateral-load resisting systems, the Ruby design

• Installation process

• Preliminary design development eliminated the inefficient bracing, reduced pieces to receive, handle,

fabricate and erect, and reduced the field labor required to handle and

install the structural steel.

STRUCTURE magazine 20 August 2006

Framing

The initial design decisions made by the Structural Engineer, the

choice of construction materials and the determination of the appro-

priate framing system establish the lower boundary of the economics

and the effectiveness that can be realized through Constructability as

the design progresses. Structures should be designed to provide suffi-

cient structural capacity to safely resist and sustain all loads and effects ®

E

of loads that may reasonably be expected, with adequate consideration

given to industry standards, ease of fabrication and installation, con-

struction procedures, serviceability and the anticipated service life of

R

the structure.

Decisions such as building grid or bay spacing, lateral-load resisting

framing options, floor systems and roof systems will impact cost and

U

without Constructability input can be irreversible.

The floor framing follows. The options available to the engineerhare t

rig

T

numerous. Each, with the variety of elements and materials, p

o y

magnifies

Alternate design

the options and amplifies the importance of inserting C construction

knowledge into the design process.

C

Member Selection

The impact of framing design on the LCC project was huge. The

original flooring system for the project was typical for construction Member selection includes columns, beams, horizontal bracing,

vertical bracing, trusses and sway frames. Often, structural engineering

e

U

of single story structures. In fact, it is commonly used in school

construction. However, application of this system for the LCC project decisions for member selections are driven by computer-based analyses

n

that do not contain critical or realistic parameters:

i

was not an economical solution. Ruby increased the 2-inch metal deck

R

to 3-inch, which allowed the floor beam spacing to be increased to 10- • What architectural constraints exist? Are there options?

z

feet, reducing the number of floor beams by 78 percent, reducing the • What is the cost or schedule impact?

• What is the relationship of each member to the others?

T a

shear studs by 11,000 and reducing the steel tonnage by 300 tons.

Further, the original LCC design called for use of “ornamental” X- • What is the availability of the member or material?

• What opportunities exist to increase uniformity of

g

bracing and knee braces for part of the lateral system. Both the “orna-

S

mental” X-braces and knee braces required an additional level of detail shapes and sizes?

a

preparation, generated many pieces to handle, fabricate and install, • How will the members impact the ease of construction?

were shop labor intensive, were relatively inefficient, provided varying • Were the members needed? Were there options?

m

levels of stiffness and were not compatible with the original moment During the redesign of LCC, the Ruby/Douglas team considered

frames. Therefore these braces were disproportionately expensive when these and other Constructability issues as they developed alternatives

viewed as benefits versus cost. for the cantilevered framing along the perimeter of the structure, the

Ruby replaced the inefficient “ornamental” X-braces and knee braces “ornamental” X-bracing, the inefficient knee bracing, the concrete-

with field-bolted moment frames in both directions. This lateral load- filled columns, the original column orientation, the cantilever

resisting system was developed to suit the structural requirements, while girder/columns details, the floor system design and the inability

the field bolted moment connections were designed utilizing the ac- to insert vertical bracing within the building due to schedule and

tual moments and stiffness required. This concept simplified detailing, architectural constraints.

reduced beam/girder fabrication to drilling and punching and elimi-

Connection Development

nated pieces which eased erection, shortened the schedule and reduced

costs, while providing a lateral-load resisting system that was stiffer than Connections are a major contributor to the final cost of the struc-

the original with fewer pieces and less field labor. ture. Initial structural design decisions directly impact the difficulty

of the connections in structures. An understanding of the mechanics

of connectors and the process of fabrication and erection constraints

builds a unique understanding of the Constructability concept. An

initial effort to plan, conceive and design an efficient framing system

pays big dividends when developing the connections. Designing con-

nections that perform and are constructible delivers a structure that

is simpler to detail, fabricate and erect. Initial framing considerations

and the subsequent connection developments are the keys to provid-

ing contractor-friendly structures, without sacrificing the integrity of

the structure.

When the lateral load-resisting system was redesigned on the LCC

project, connection design was an important design aspect to re-

evaluate as well. The original beam to beam connections were to be

double angles designed to support 75 percent of the beams uniform

load capacity. Lateral-load resisting connections were required to

develop the beam’s full moment capacity, and (as noted previously)

the knee braces and the “ornamental” X-braces were detail intensive

Original design

STRUCTURE magazine 21 August 2006

The impact of construction process decisions was first illustrated

on the LCC project by the concrete-filled column for the structure.

These columns were a construction concern due to site constraints,

temporary heating or blankets during curing, sequencing of trades,

schedule delays due to the cure time and, finally, stability after con-

crete placement. While these Constructability items are of concern

and would impact the project schedule, several other factors made

their use impractical on this project.

First, the concrete-filled columns were among the heaviest ® construc-

E

tion components on the project, increasing the crane capacity require-

ment and/or decreasing the operating radius necessary for the crane’s

Orginal design operation. Secondly, due to the limited number of such columns, the

R

and inefficient. The Ruby/Douglas team developed completely field- cost associated with their procurement and installation was a premium.

bolted moment connections using the actual moments and stiffness Finally, the columns could cause major scheduling issues. If the columns

were installed as hollow HSS members, then filled with concrete in the

U

required, eliminated the bracing elements and utilized single plate shear

connections, thus simplifying shop fabrication and installation and field, the required concrete curing time could limit flexibility and the

t out of sequence concrete placement would disrupt the installation of the

subsequently reducing shop and field labor. righ

T

y remaining structural steel. Further, connection options to these columns

Cop were limited due to AESS constraints and concrete-fill requirements.

Fabrication Process

C

The Ruby redesign eliminated the concrete-fill from these HSS

Partnered with Douglas Steel, Ruby pursued economies in the fabrica-

columns in several ways:

tion process in every aspect of the structural design for the LCC proj-

• utilizing higher strength material,

ect. The fabrication of structural steel requires custom detailing, cutting,

e

U

• utilizing a thicker HSS shape,

punching, drilling, welding, grinding and painting of structural shapes

• modifying the connections details and in the extreme case, and

n

of various sizes, weights and material grades. The concept of standard,

i

• designing a built-up column shaft. The built-up shaft consisted

R

off the shelf details is a myth. Therefore, the designer must consider if

of a 10-inch HSS shape inserted into a 12-inch HSS shape column,

z

the degree of difficulty of the structural system proposed is warranted

detailing the base and cap plates in a doughnut configuration

T

for the project structure. Degree of difficulty can refer to number of

a

to allow each of the HSS members to be adequately attached to the

pieces, field welding requirements, length of span, exaggerated connec-

supporting elements.

g

tion forces, inappropriate framing requirements, excessive bracing details

S

These alternatives reduced the cost of the materials, simplified

or requirements, column web stiffeners or web doubler plates, and inap-

fabrication, expedited the construction schedule, eliminated the impact

a

propriate use of material or shapes, among other factors.

on the size of the crane required and simplified the design of connections

The Ruby/Douglas team reviewed each aspect of the structural framing

to these columns.

m

system and related detail requirements, changed the floor system which

reduced the number of floor beams, eliminated the doubled angles and

substituted single plate shear connections, modified the concrete-filled

columns, eliminated the time consuming “ornamental” and knee brac-

ing details and designed the moment connections for the actual forces.

Construction Process

By understanding the nuances inherent to the construction industry,

the structural engineer can simplify the overall construction process by

understanding the various construction industry standards, by utiliz-

ing this knowledge during the design process and by accommodating Alternate design

the standards within the project construction plan; thus reducing costs,

improving schedules, and minimizing conflict between the design and The original floor system, as previously noted, consisted of floor beams

construction teams. at 3-feet on center. The number of beams and related field-installed

To do this, several key construction considerations should drive shear studs demanded an excessive amount of field hours to install.

structural design decisions. The essential five S’s are as follows: Ruby revised the floor system with floor beams at 10-foot spacing. This

• Site – Constraints such as access, staging areas, operating area reduced the number of floor beams by about 360 pieces and eliminated

and storage space? 11,000 shear studs.

• Season – What regulations or weather conditions must Single plate shear connections were substituted for the originally

be accommodated? specified double angle connections. This substitute reduced field labor

• Sequence – Is the project to be sequenced? How can material and eliminated the common bolts through the girder beams webs (a

handling be minimized? How can “comeback work” be avoided? potential erection safety issue).

• Scheduling – When should various materials arrive? How will the

structural steel be integrated with the other trades? When will Lost Opportunities

the lateral-load resisting system non-structural steel elements The traditional design begins with the prime design professional

arrive at the site? presenting the concept in a graphic form, which generally establishes the

• Stability – The erector is responsible for stability of the building grid and basic architectural constraints. The structural engineer

structure during installation. This task has a cost associated takes the building grid, reviews the architectural constraints, digests the

with it that is closely tied to the need for temporary bracing code and project requirements, develops possible lateral load-resisting

and the impact of non-structural steel elements in the systems and selects the framing and lateral-load resisting system to suit

lateral load system. How can this be simplified? the prime design professional’s concept.

STRUCTURE magazine 24 August 2006

As stated earlier, Constructability is not just related to installation,

but engages all aspects, material and elements of construction to provide

maximum benefit to the owner. The best solution for the facility may

not be the least cost structure. Each project has a personality and each

personality demands a unique solution.

Understanding the anatomy of Constructability, and inserting it into

a project during the initial concept stage is similar to the value of preven-

tative medicine: problems are avoided and risks are reduced. The true

value of introducing the philosophy of Constructability into®a project

E

can be measured in what does not happen: time is not lost, money is not

wasted, claims are not made and budgets are not exceeded.▪

yrig

ht

U R

T

Cop

C

Original design 2nd floor

e

U

The Constructability design begins with the design team review-

ing the owner’s program and the prime design professional’s concept,

brain-storming options and alternatives, jointly establishing the build-

i n

R

ing’s requirements, allocating space for the lateral-load resisting, rec-

ognizing any code restrictions and preparing the project requirements

z

T

accordingly. The design then proceeds with all of the team members

understanding the concept, the focus and the constraints.

The Ruby redesign at LCC eliminated over 700 members, beams and

g a

S

braces, as well as 11,000 shear studs from the floor system, eliminated Alternate design 2nd floor

a

cantilever perimeter framing, substituted steel columns for concrete-

filled columns and moved to a completely field bolted structure. The

m

David I. Ruby, P.E., S.E., SECB, F.ASCE, is a Principal with

resulting floor system (including a thicker slab) added minimal dead

Ruby + Associates PC, in Farmington Hills, Michigan. Mr. Ruby

load to the structure, but increased the strength of the composite floor

specializes in steel designs that speed and ease constructability.

system. This redesigned structure was easier to build, stiffer and much

David can be reached via email at druby@rubyusa.com.

more economical — over 300 tons of structural steel were eliminated!

However, the impact of the redesign was limited because Construc-

tability was inserted during the bidding stage instead of at the planning

stage. The foundations for the structure were already in place, and they For Constructability Part 1 visit STRUCTURE’s on-line

were designed to accommodate the building’s original lateral-load re- archives at www.structuremag.org, June 2006

sisting system. If Constructability had been inserted during the initial

concept stage of the project, the opportunity existed to eliminate the

moment frame requirements in favor of a more economical chevron or Lansing Community College

full story X-bracing scheme. The AESS perimeter columns could have Health & Human Service

been more economical as 12- or 14-inch HSS shapes in lieu of the Career Building

original 8- and 12-inch HSS. The redesign was the most

cost-effective solution based on the architectural

constraints and the project schedule

constraints that existed at the

time of bidding.

STRUCTURE magazine August 2006

Anda mungkin juga menyukai

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Chapter13 Income TaxesDokumen17 halamanChapter13 Income TaxesKhilbran MuhammadBelum ada peringkat

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- 7-Gaikindo Import Data Jandec2011-RevDokumen1 halaman7-Gaikindo Import Data Jandec2011-RevKhilbran MuhammadBelum ada peringkat

- Chevrolet Indonesia Trax My17 Leaflet Premier Campaign 02marchDokumen2 halamanChevrolet Indonesia Trax My17 Leaflet Premier Campaign 02marchKhilbran MuhammadBelum ada peringkat

- 7 Gaikindo Import Data Janoct2017Dokumen2 halaman7 Gaikindo Import Data Janoct2017Khilbran MuhammadBelum ada peringkat

- Key Concept of Project ManagementDokumen1 halamanKey Concept of Project ManagementKhilbran MuhammadBelum ada peringkat

- Project Management Process Groups and Knowledge Areas MappingDokumen1 halamanProject Management Process Groups and Knowledge Areas MappingKhilbran Muhammad100% (1)

- Affinity DiagramDokumen21 halamanAffinity DiagramMarco Bernabe JumaquioBelum ada peringkat

- 14 Project Risk ManagementDokumen72 halaman14 Project Risk ManagementKhilbran MuhammadBelum ada peringkat

- All New Kijang Innova 2015 LeafletDokumen6 halamanAll New Kijang Innova 2015 LeafletKhilbran MuhammadBelum ada peringkat

- 01 Brainstorming - Production PDFDokumen8 halaman01 Brainstorming - Production PDFKhilbran MuhammadBelum ada peringkat

- BAUER (Piling & Earth Retaining Structure)Dokumen16 halamanBAUER (Piling & Earth Retaining Structure)Khilbran MuhammadBelum ada peringkat

- All Excell FunctionsDokumen3 halamanAll Excell Functionsrajesh_jeyachandranBelum ada peringkat

- Education During The Ancient Period Primitive EducationDokumen5 halamanEducation During The Ancient Period Primitive EducationEn CyBelum ada peringkat

- Manual Diagrama Detector de MetalesDokumen18 halamanManual Diagrama Detector de MetalesEdmundo Cisneros0% (1)

- Senarai Harta Modal Makmal KomputerDokumen20 halamanSenarai Harta Modal Makmal Komputerapi-19878848100% (1)

- Mcs Text BookDokumen309 halamanMcs Text Bookkancha_basu2447100% (1)

- Fret Position CalculatorDokumen1 halamanFret Position CalculatorRay RamirezBelum ada peringkat

- 63-9378 - Rev-F - Ultra Puck - Datasheet - Web - 63-9378 - Rev-F - Ultra-Puck - Datasheet - WebDokumen2 halaman63-9378 - Rev-F - Ultra Puck - Datasheet - Web - 63-9378 - Rev-F - Ultra-Puck - Datasheet - WebAradhana AradhanaBelum ada peringkat

- CSR of Pidilite PDFDokumen2 halamanCSR of Pidilite PDFtarang keraiBelum ada peringkat

- QuestionnaireDokumen5 halamanQuestionnairePrisca FolorunsoBelum ada peringkat

- Virtual Screening of Natural Products DatabaseDokumen71 halamanVirtual Screening of Natural Products DatabaseBarbara Arevalo Ramos100% (1)

- Pdpa CraDokumen3 halamanPdpa CraAdyrah RahmanBelum ada peringkat

- Dakshin Dinajpur TP ListDokumen5 halamanDakshin Dinajpur TP ListDeb D Creative StudioBelum ada peringkat

- 20-12-11 Ericsson V, Samsung EDTX ComplaintDokumen22 halaman20-12-11 Ericsson V, Samsung EDTX ComplaintFlorian MuellerBelum ada peringkat

- SOS Children's Village: by Bekim RamkuDokumen21 halamanSOS Children's Village: by Bekim RamkuAbdulKerim AyubBelum ada peringkat

- Resume MullinsDokumen4 halamanResume Mullinsapi-236735643Belum ada peringkat

- AquaMapPublic v202Dokumen26 halamanAquaMapPublic v202engfeupBelum ada peringkat

- 6.4L - Power Stroke EngineDokumen16 halaman6.4L - Power Stroke EngineRuben Michel100% (2)

- Kids 2: INSTITUTO CAMBRIDGE de Cultura Inglesa - EXÁMENES 2019Dokumen2 halamanKids 2: INSTITUTO CAMBRIDGE de Cultura Inglesa - EXÁMENES 2019Evaluna MoidalBelum ada peringkat

- Thing in Itself Kantian: AnstoßDokumen1 halamanThing in Itself Kantian: Anstoßwhynotbequiet23Belum ada peringkat

- Acceptance To An Offer Is What A Lighted Matchstick Is To A Train of GunpowderDokumen2 halamanAcceptance To An Offer Is What A Lighted Matchstick Is To A Train of GunpowderAnushka SharmaBelum ada peringkat

- PMP Itto GuideDokumen11 halamanPMP Itto GuideSocrates XavierBelum ada peringkat

- Antennas L01Dokumen15 halamanAntennas L01Domenico RizzoBelum ada peringkat

- 4363 112 Heat TransferDokumen6 halaman4363 112 Heat Transferyogesh_b_kBelum ada peringkat

- BCO120Dokumen3 halamanBCO120erwin_simsensohnBelum ada peringkat

- CBSE Class 6 - MCQ Separation of SubstancesDokumen4 halamanCBSE Class 6 - MCQ Separation of Substancesvinod1577100% (1)

- Advanced Numerical Modelling of Geogrids and Steel Wire Meshes - Daniele TubertiniDokumen94 halamanAdvanced Numerical Modelling of Geogrids and Steel Wire Meshes - Daniele TubertiniSze Mian KuehBelum ada peringkat

- A-W and A-F Oil SeparatorsDokumen1 halamanA-W and A-F Oil SeparatorstribleprinceBelum ada peringkat

- Product Management PRELIM EXAMDokumen24 halamanProduct Management PRELIM EXAMAlyssa marieBelum ada peringkat

- UT Dallas Syllabus For Math3303.501.10f Taught by Phillip Kisunzu (pxk091000)Dokumen7 halamanUT Dallas Syllabus For Math3303.501.10f Taught by Phillip Kisunzu (pxk091000)UT Dallas Provost's Technology GroupBelum ada peringkat

- Pakistan Wapda - Power Wing: Standard Operating ProceduresDokumen8 halamanPakistan Wapda - Power Wing: Standard Operating Procedureszahra batoolBelum ada peringkat