11.4.1 Stringing: LS - "-Ca System

Diunggah oleh

ErolJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

11.4.1 Stringing: LS - "-Ca System

Diunggah oleh

ErolHak Cipta:

Format Tersedia

LS--"-Cable&System 156.147 .226.1 99 /2 0 14 .08 .

25 10:52 / 2008001

IEEE

OVERHEAD TRANSMISSION LINE CONDUCTORS Std 524-2003

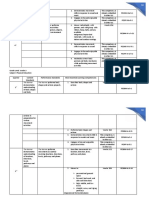

11.4.1 Stringing

Lined blocks are recommended for use with OPGW and the minimum sheave diameter is dependent upon

the cable design. When installing OPGW, the cable manufacturer should be consulted for a recommendation

on the minimum sheave and bullwheel diameters, the specific maximum pulling speed s and the maximum

pulling tension.

Using the correct size sheave is very important to ensure that the optical fibers in an OPGW are not crushed

during the stringing proce ss. If sp.ecifjc sheave recomm~ndations are not available from the manufacturer, a

=

conservative sheave diameter is 40D (i.e ., 40 x D;,.D Cliameter of the OPGW2. On-line angles or pullover

angles greater than 30°, larger sheave diameters may be needed. If sp.ecific bullwheel diameter recommen-

dations are not available, a conservative bullwheel diameter for tensioners is lOD. For OPGW with left-hand

lay, the bull wheel must be reeved from right to left. The opposite reeving direction is appropriat e for OPGW

with right-hand lay . The use of a swivel on the pulling line followed by an anti-rotation device should be

used to minimize the tendenc y of the OPGW to twist during stringing . Some cable design and installation

tension combinations of OPWG may not require an anti-rotation device.

The setup location for the cable reel, the tensioner and the puller should take into consideration the slope of

the cable betwe en the tensioner and the sheave at the first structure. This slopeshould never be steeper than

three to one (3 horizontal and I vertical). If the tensioner cannot be placed.aithe proper distance from the

first structure, the tensioner should be repositioned or the first sheave tempQA iiiy lowered during the pulling

operation, then later raised for final hardware installation. ::'< '~:,~>;.

r:·::~ ..: , ,~.~ -.

Experience has shown that pulling speed, maximum tension ii!ip'Oi> 6'd"on the line during stringing, and the

number of times the line passes through stringing blocks in 9.I1~ 'seCtibn are important factors in achieving a

smooth operation. Typi cal stringing tensions are in the ra [lg'e ~9f' 15% or less of the OPGW ' s rated breaking

strength. The maximum stringing tension should genergllype limited to 20% of the rated breaking strength

and pulling speeds of 2-5 km/h 25 are recommended ~ : :·e " : ·;:: '~ "

I'; . ";::;;.:.~ ..

..:d ."

11.4.2 Sagging " ;~f

l!N:!I.

The method used to sag OPGW is;*$';'" . . i& 'ftio that used for conductors and overhead ground wires . Certain

-1~""j. ~ '

grips used for conductor an£l:wverhe'~2ijiffound wire are normally not acceptable for OPGW becau se they

could crush the fiber tUbe( s)'i;;~?~~k~~ ~'o'6k type comealongs are available , but are typically designed for the

specific OPWG cable . Thes e ~P.~9J$fio o l s are machined to clos ely match the diameter of the OPGW so that

they will not crush the cable. F3f:ined wire grips may sometimes be used , if they are approved by the manu-

facturer. Sag/tension data is normally supplied by the OPGW manufacturer.

11.4.3 Splicing

There is one primary difference between OPGW and conventional overhead groundwires. Convention al

overhead groundwires are often spliced midspan with a compression type connector. OPGW , on the other

hand, is typically spliced at a tower. A 9- 20 meters26 tail is therefore required to make up the connection,

depending on the particular splice box arrangement being used.

11.5 All-dielectric self supporting fiber cable (ADSS)

ADSS cable was devel oped for telecommun ications applications on high-voltage power lines. The cable

contains no metalli c or electrical conducting elements , and yet contains sufficient strength from dielectric

strength members such as aramid or fibergl ass yarns to be suspended between supports without the need to

251.5_3 m.p.h.

26 30_65 feet

Copyright © 2004 IEEE. All rights reserved. 71

LS Cable & System Ltd. User license only. These doc uments are property of LS Cable & System Ltd,

Anda mungkin juga menyukai

- 10 Killer Tips For Transcribing Jazz Solos - Jazz AdviceDokumen21 halaman10 Killer Tips For Transcribing Jazz Solos - Jazz Advicecdmb100% (2)

- The IEE Wiring Regulations Explained and IllustratedDari EverandThe IEE Wiring Regulations Explained and IllustratedPenilaian: 4 dari 5 bintang4/5 (14)

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsDari Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsPenilaian: 4 dari 5 bintang4/5 (1)

- Automatic Gearbox ZF 4HP 20Dokumen40 halamanAutomatic Gearbox ZF 4HP 20Damien Jorgensen100% (3)

- Arduino Uno CNC ShieldDokumen11 halamanArduino Uno CNC ShieldMărian IoanBelum ada peringkat

- Aircraft Electrical SystemsDokumen167 halamanAircraft Electrical SystemspotantonBelum ada peringkat

- Manual For EOT CranesDokumen39 halamanManual For EOT CranesManish Jha67% (12)

- 2016 IT - Sheilding Guide PDFDokumen40 halaman2016 IT - Sheilding Guide PDFlazarosBelum ada peringkat

- Aircraft Electrical SystemsDokumen167 halamanAircraft Electrical SystemsStanislavBelum ada peringkat

- Control CableDokumen65 halamanControl CableDeyoBelum ada peringkat

- Installation Guide For Instrument Cables, Conduits and Cable TraysDokumen35 halamanInstallation Guide For Instrument Cables, Conduits and Cable TraysImran Mohiuddin100% (1)

- Duct Installation of Fiber Optic Cable PDFDokumen9 halamanDuct Installation of Fiber Optic Cable PDFnecmettinsengunBelum ada peringkat

- Segregation in CastingDokumen17 halamanSegregation in CastingAsmaa Smsm Abdallh78% (9)

- Safety For Wiring Methods: By: Komarul FausiyahDokumen16 halamanSafety For Wiring Methods: By: Komarul FausiyahJeffrey ArandiaBelum ada peringkat

- OPGW Installation ManualDokumen23 halamanOPGW Installation Manualspark_187Belum ada peringkat

- HRMDokumen118 halamanHRMKarthic KasiliaBelum ada peringkat

- AC21-99 - Aircraft Wiring and BondingDokumen38 halamanAC21-99 - Aircraft Wiring and Bondingsteve.rodowicz1011100% (2)

- EdisDokumen227 halamanEdisThong Chan100% (1)

- AKTPL Cable Termination GuidelineDokumen15 halamanAKTPL Cable Termination GuidelineDipeshBelum ada peringkat

- Types of OHTL ConductorsDokumen7 halamanTypes of OHTL ConductorsoperahhBelum ada peringkat

- K - Factor EarthingDokumen13 halamanK - Factor EarthingShrikant KajaleBelum ada peringkat

- Exotic DVM 11 3 CompleteDokumen12 halamanExotic DVM 11 3 CompleteLuc CardBelum ada peringkat

- FerrulesDokumen22 halamanFerrulesJogi Oscar Sinaga100% (1)

- Installation Manual For OPGW CableDokumen19 halamanInstallation Manual For OPGW Cablecsudha100% (2)

- Dobbins Opgw PDFDokumen63 halamanDobbins Opgw PDFEdgar Sierra RodriguezBelum ada peringkat

- OPGW Installation in Energized Transmission LineDokumen8 halamanOPGW Installation in Energized Transmission LineUdriste DanielBelum ada peringkat

- Solution Manual for 100 Genesys Design Examples: Second EditionDari EverandSolution Manual for 100 Genesys Design Examples: Second EditionBelum ada peringkat

- Overhead Conductor Installation Guide: Recommended PracticesDokumen20 halamanOverhead Conductor Installation Guide: Recommended Practicesvjs270385Belum ada peringkat

- Transportasi Distribusi MigasDokumen25 halamanTransportasi Distribusi MigasDian Permatasari100% (1)

- OPGW Specifications: GeneralDokumen18 halamanOPGW Specifications: GeneralMubashir HussainBelum ada peringkat

- Mechanical Engineering - Workshop Practice - Laboratory ManualDokumen77 halamanMechanical Engineering - Workshop Practice - Laboratory Manualrajeevranjan_br100% (4)

- Appendix F OPGW Installation Manual: AFL Telecommunications Technical ResponseDokumen15 halamanAppendix F OPGW Installation Manual: AFL Telecommunications Technical ResponseramsesBelum ada peringkat

- OPGWInstallation InstructionsDokumen15 halamanOPGWInstallation InstructionsjorgemachigueBelum ada peringkat

- Inst OAC Steel Tube-GB-05Dokumen7 halamanInst OAC Steel Tube-GB-05kobus8180Belum ada peringkat

- Opgw Installation ManualDokumen12 halamanOpgw Installation ManualSiva PBelum ada peringkat

- Cat 09a en Spring Operated Cable ReelsDokumen40 halamanCat 09a en Spring Operated Cable ReelssonBelum ada peringkat

- Opgw Installation Manual-MegatroDokumen20 halamanOpgw Installation Manual-MegatromanafBelum ada peringkat

- Montaje OpgwDokumen105 halamanMontaje OpgwRicardo PerlaciosBelum ada peringkat

- Carc Buildathon Project: A Tuneable Magnetic Loop Antenna For 7Mhz Made From Coaxial CableDokumen9 halamanCarc Buildathon Project: A Tuneable Magnetic Loop Antenna For 7Mhz Made From Coaxial CableLuca Di ColaBelum ada peringkat

- Transmission Line Construction and Maintenance: Sherman & ReillyDokumen8 halamanTransmission Line Construction and Maintenance: Sherman & ReillyMauricio Mercado VargasBelum ada peringkat

- Telecommodule 5Dokumen40 halamanTelecommodule 5MADRIAGA, CYRILLE MAE RUMABelum ada peringkat

- Spring Operated Cable Reels: Macht Strom MobilDokumen40 halamanSpring Operated Cable Reels: Macht Strom MobilGrumetcomBelum ada peringkat

- OCC-206-3 Installation-Conduit Guidelines Rev A-1Dokumen6 halamanOCC-206-3 Installation-Conduit Guidelines Rev A-1SAMBelum ada peringkat

- Module 6 TelecomDokumen29 halamanModule 6 TelecomMADRIAGA, CYRILLE MAE RUMABelum ada peringkat

- Gradient Control Mat Technical Literature1Dokumen13 halamanGradient Control Mat Technical Literature1Eng Saleem AlshibaniBelum ada peringkat

- 9282Dokumen13 halaman9282Frank StephensBelum ada peringkat

- 1 OpgwDokumen10 halaman1 Opgwpraba13auBelum ada peringkat

- VAHLEDokumen28 halamanVAHLEAdrian M FahriBelum ada peringkat

- IS CableDokumen4 halamanIS Cablewipi12Belum ada peringkat

- Portable Earthing, Line End Clamps, Earth End Clamps PB WeirDokumen40 halamanPortable Earthing, Line End Clamps, Earth End Clamps PB WeirrocketvtBelum ada peringkat

- Auxiliary Cables (Pilot and Telephone)Dokumen4 halamanAuxiliary Cables (Pilot and Telephone)Toni WhiteBelum ada peringkat

- Fiber Optic Cable Handling and InstallationDokumen17 halamanFiber Optic Cable Handling and InstallationJay Flores San JoseBelum ada peringkat

- Guía 2 - Referencias y DiagramasDokumen8 halamanGuía 2 - Referencias y DiagramasSantiago UrrutiaBelum ada peringkat

- Wireline ServicesDokumen21 halamanWireline ServicesweldsvBelum ada peringkat

- 005 038Dokumen11 halaman005 038shaicoBelum ada peringkat

- 14F3001X00 Welding Cable Wire Wisdom US enDokumen2 halaman14F3001X00 Welding Cable Wire Wisdom US enzaphossBelum ada peringkat

- AC 21-99 Sect 2 Chap 4Dokumen38 halamanAC 21-99 Sect 2 Chap 4Christina GrayBelum ada peringkat

- Complete Guide To Cable LacingDokumen83 halamanComplete Guide To Cable LacingfulltrackproductionsBelum ada peringkat

- TS-OPGW 1.4 9feb2017Dokumen18 halamanTS-OPGW 1.4 9feb2017asim204Belum ada peringkat

- Type of GlandDokumen10 halamanType of GlandShrikant KajaleBelum ada peringkat

- Mod 7.13Dokumen36 halamanMod 7.13Sakib Reza SaadBelum ada peringkat

- Rockwell Pf7000 Line/Motor Cable Recommendation.: Power Wiring SelectionDokumen4 halamanRockwell Pf7000 Line/Motor Cable Recommendation.: Power Wiring SelectionIsaac SanchezBelum ada peringkat

- Appendix A-13: CommonDokumen1 halamanAppendix A-13: CommonreacharunkBelum ada peringkat

- Raychem Terminations For GIS and TransformerDokumen1 halamanRaychem Terminations For GIS and Transformerrasheed313Belum ada peringkat

- 3.4 Arc Length: The Distance From The Tip of The WeldingDokumen7 halaman3.4 Arc Length: The Distance From The Tip of The WeldingMohammed IlliasuddinBelum ada peringkat

- Installation PracticeDokumen16 halamanInstallation PracticeramsesiBelum ada peringkat

- Maria - Materials For A2 1Dokumen38 halamanMaria - Materials For A2 1ErolBelum ada peringkat

- Delivered at Frontier: ICC Publication 560 - Copies of The Full Version Are Available From ICC PublishingDokumen2 halamanDelivered at Frontier: ICC Publication 560 - Copies of The Full Version Are Available From ICC PublishingErolBelum ada peringkat

- Carriage Paid To: ICC Publication 560 - Copies of The Full Version Are Available From ICC PublishingDokumen1 halamanCarriage Paid To: ICC Publication 560 - Copies of The Full Version Are Available From ICC PublishingErolBelum ada peringkat

- Delivered Ex Ship: ICC Publication 560 - Copies of The Full Version Are Available From ICC PublishingDokumen1 halamanDelivered Ex Ship: ICC Publication 560 - Copies of The Full Version Are Available From ICC PublishingErolBelum ada peringkat

- Fas PDFDokumen2 halamanFas PDFErolBelum ada peringkat

- Free Carrier: ICC Publication 560 - Copies of The Full Version Are Available From ICC PublishingDokumen1 halamanFree Carrier: ICC Publication 560 - Copies of The Full Version Are Available From ICC PublishingErolBelum ada peringkat

- Free On Board: ICC Publication 560 - Copies of The Full Version Are Available From ICC PublishingDokumen1 halamanFree On Board: ICC Publication 560 - Copies of The Full Version Are Available From ICC PublishingErolBelum ada peringkat

- Blondine in ActionDokumen12 halamanBlondine in ActionErolBelum ada peringkat

- Delivered Duty Unpaid: ICC Publication 560 - Copies of The Full Version Are Available From ICC PublishingDokumen3 halamanDelivered Duty Unpaid: ICC Publication 560 - Copies of The Full Version Are Available From ICC PublishingErolBelum ada peringkat

- OlDokumen66 halamanOlcarlosfilipegomes3994Belum ada peringkat

- BS Index of Aspects National NormeDokumen5 halamanBS Index of Aspects National NormeErolBelum ada peringkat

- EVOM ManualDokumen2 halamanEVOM ManualHouston WhiteBelum ada peringkat

- GE 7 ReportDokumen31 halamanGE 7 ReportMark Anthony FergusonBelum ada peringkat

- Phylogeny Practice ProblemsDokumen3 halamanPhylogeny Practice ProblemsSusan Johnson100% (1)

- Architectural ConcreteDokumen24 halamanArchitectural ConcreteSaud PathiranaBelum ada peringkat

- Codan Rubber Modern Cars Need Modern Hoses WebDokumen2 halamanCodan Rubber Modern Cars Need Modern Hoses WebYadiBelum ada peringkat

- MSC-MEPC.2-Circ.17 - 2019 Guidelines For The Carriage of Blends OfBiofuels and Marpol Annex I Cargoes (Secretariat)Dokumen4 halamanMSC-MEPC.2-Circ.17 - 2019 Guidelines For The Carriage of Blends OfBiofuels and Marpol Annex I Cargoes (Secretariat)DeepakBelum ada peringkat

- ETAP Power Station ErrorDokumen5 halamanETAP Power Station ErroryogacruiseBelum ada peringkat

- Network Fundamentas ITEC90Dokumen5 halamanNetwork Fundamentas ITEC90Psychopomp PomppompBelum ada peringkat

- Dwnload Full Beckers World of The Cell 9th Edition Hardin Solutions Manual PDFDokumen35 halamanDwnload Full Beckers World of The Cell 9th Edition Hardin Solutions Manual PDFgebbielean1237100% (12)

- P 348Dokumen196 halamanP 348a123456978Belum ada peringkat

- Trade MarkDokumen2 halamanTrade MarkRohit ThoratBelum ada peringkat

- Native VLAN and Default VLANDokumen6 halamanNative VLAN and Default VLANAaliyah WinkyBelum ada peringkat

- PE MELCs Grade 3Dokumen4 halamanPE MELCs Grade 3MARISSA BERNALDOBelum ada peringkat

- Derebe TekesteDokumen75 halamanDerebe TekesteAbinet AdemaBelum ada peringkat

- Matka Queen Jaya BhagatDokumen1 halamanMatka Queen Jaya BhagatA.K.A. Haji100% (4)

- Previous Year Questions - Macro Economics - XIIDokumen16 halamanPrevious Year Questions - Macro Economics - XIIRituraj VermaBelum ada peringkat

- Vemu Institute of Technology: Department of Computer Science & EngineeringDokumen79 halamanVemu Institute of Technology: Department of Computer Science & EngineeringSiva SankarBelum ada peringkat

- Kapinga Kamwalye Conservancy ReleaseDokumen5 halamanKapinga Kamwalye Conservancy ReleaseRob ParkerBelum ada peringkat

- Prospekt Puk U5 en Mail 1185Dokumen8 halamanProspekt Puk U5 en Mail 1185sakthivelBelum ada peringkat

- Regional Manager Business Development in Atlanta GA Resume Jay GriffithDokumen2 halamanRegional Manager Business Development in Atlanta GA Resume Jay GriffithJayGriffithBelum ada peringkat