Fewfweefw

Diunggah oleh

anthony christian yangDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Fewfweefw

Diunggah oleh

anthony christian yangHak Cipta:

Format Tersedia

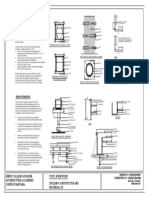

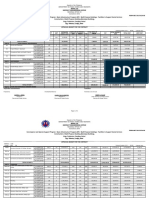

SAW-CUT GROOVE 8MM WIDE

SAW-CUT GROOVE 8MM 65MM DEEP TO BE FILLED WITH

WIDE TO BE FILLED WITH POLYURETHANE SEALANT

RET. WALL/CHB WALL POLYURETHANE SEALANT

SLAB REINF.

SLAB REINF.

SPACED @ 400MM O.C.

POLYURETHANE SEALANT FLR. LVL. SLAB ON GRADE

20MM MIN.

SLAB

FLR. LVL.

20MM MIN.

"t"

SLAB

CONC. COVER

100

"t"

SLAB REINF. CONC. COVER

100

FLR. LVL.

VARIES

100

CONSTRUCTION JOINT GRAVEL BED

DOWEL LENGTH

250

VARIES

150MM THICK

EXTERIOR CHB WALL

COMPACTED GRAVEL SUBGRADE COMPACTED

COMPACTED GRAVEL SUBGRADE COMPACTED BEDDING (TYP.) TO 95% OF MAXIMUM

400 BEDDING (TYP.) TO 95% OF MAXIMUM

200

VAPOR BARRIER DRY DENSITY @ OPTIMUM

VAPOR BARRIER DRY DENSITY @ OPTIMUM MOISTURE CONTENT (MAX.

WHEN REQUIRED

WHEN REQUIRED MOISTURE CONTENT (MAX. DEPTH OF COMPRESSED

COMPACTED GRAVEL SUBGRADE COMPACTED DEPTH OF COMPRESSED

BEDDING (TYP.) TO 95% OF MAXIMUM FILL = (200mm PER LAYER).

FILL = (200mm PER LAYER). FOOTING TIE BEAM

VAPOR BARRIER DRY DENSITY @ OPTIMUM

WHEN REQUIRED MOISTURE CONTENT (MAX.

DEPTH OF COMPRESSED

FILL = (200mm PER LAYER).

SLAB-ON-GRADE CONSTRUCTION SLAB-ON-GRADE CONTRACTION

JOINT DETAIL JOINT DETAIL TYPICAL WALL TO TIE BEAM DETAILS

SLAB-ON-GRADE EXPANSION

JOINT DETAIL

2D (NO PIPE SLEEVE PROPOSED PIPE SLEEVE LOCATIONS

SHALL BE ALLOWED W/IN

THIS ZONE (TYP.)) SCH. 40 G.I. PIPE SLEEVE

CHB "t" 2 - EXTRA STIR. EA. SIDE

A PIPE SLEEVE

OF SLEEVE

2 EXTRA STIRRUPS

2D 0 2D

REQUIRED 50 .) EACH SIDE OF SLEEVE

MAIN REINFORCEMENTS TO BE YP B

CONTINUOUS (TOP & BOT. BARS) TOP BARS (T FACE OF TOP BARS

A

SUPPORT

CONCRETE FILLER

40

DEPRESSION

PIPE E.F. (DIAGONALS)

50

D=FOR BEAM

t=FOR SLAB

VERIFY

D

(MIN.) (MIN.) PIPE SLEEVE

D/5

D/5

CONCRETE

40

FILLER

WELDED TO SLEEVE

D/2

BOT. BARS A (TYPICAL)

FACE OF BOTTOM BARS

STIR. AS SCHED.

SLOPE 1:2 V:H SUPPORT 4d (MIN.) SECTION A - A

12mm GAP

MASTIC SEALANT

D/2

EACH SIDE

(MIN.)

PIPE SLEEVE L/4 L/2 L/4 NOTES:

REQUIRED PIPE SLEEVE

LIMIT LOCATION OF PIPE SLEEVE 1. SEEK STRUCT'L ENGINEER'S

D=FOR BEAM COMPRESSIBLE APPROVAL FOR PIPE SLEEVES

MATERIALS L PIPE SLEEVE MAXIMUM DIAMETER

SIDE IF BEAM CONSTRUCTION JOINT 2t=FOR SLAB W/ DIAMETERS BIGGER THAN

IS NOT WITHIN THE MIDDLE THIRD CHB WALL IS : (LEAST GOVERNS) THE MAXIMUM STIPULATED.

OF THE SPAN. LEGEND:

A) 1/5 OF BEAM DEPTH 2. PIPE SLEEVES SHALL BE

BEAM/SLAB CHANGE SOFFIT SECTION A-A 1. D = DEPTH OF BEAM/GIRDER

BEAM CONSTRUCTION 2. d = PIPE SLEEVE DIAMETER B) 100 MM LOCATED WITHIN TENSION

ZONES OF BEAM.

JOINT DETAIL DETAIL

PIPE SLEEVE THRU WALL 3. NO PIPE SLEEVE SHALL BE

ALLOWED AT TWICE THE

PIPE SLEEVE THRU BEAM DETAIL BEAM DEPTH (2D) FROM

THE SUPPORT.

SEE WALL

SCHEDULE

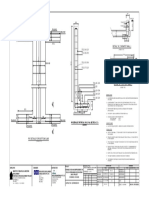

TABLE OF LAP SPLICE

W = 1.20m (max) PARAMETERS

550

200 W = 1.20m (max) 200 200 200

WALLS LESS THAN

MATERIAL psi MPa ACI 318-05

200 mm THK.

f'c 5000 34.5 DEV'T & SPLICE LENGTH

fy 60000 414 16mm & HIGHER

fyh 40000 276 12mm & LOWER

550 10 10

(TYP.) fyt 40000 fyt 40000

& BOTTOM BARS & BOTTOM BARS

WINDOW

AT INTERSECTION ANCHORAGE

Ldh(mm)

STANDARD HOOK (mm)

BEAM COMP.

TENSION LAP SPLICE (mm)

UNIT WT.

(mm) LENGTH (mm) SPLICE (mm) BEAM COLUMN

OPENING LAP CLASS (kg/m)

CHB WALL CHB WALL TOP BAR BOTTOM BAR TIED SPIRAL

WALLS LESS THAN A 300 300

200 mm THK. 10 600 150 160 110 120~120 300 300 300 0.616

B 390 390

DOOR A 530 410

H

H

OPENING SEE WALL 12 600 200 200 120 130~130 350 410 410 0.888

B 690 530

SCHEDULE

A 700 540

16 740 270 260 130 160~160 460 540 540 1.579

B 910 700

A 880 680

550

20 920 340 320 160 200~320 580 680 680 2.466

BARS B 1140 880

(TYP.)

BARS

550

A 1370 1060

25 1150 430 400 200 250~400 720 1060 1060 3.854

B 1780 1380

A 1540 1180

28 1300 480 480 260 810 1180 1180 4.833

B 2000 1530

550 A 1760 1350

32 1700 540 550 290 930 1350 1350 6.313

(TYP.) B 2290 1760

A 1980 1520

36 2150 610 650 360 1040 1520 1520 7.991

AT CORNER B 2570 1980

TYPICAL DOOR OPENING TYPICAL WINDOW OPENING NOTES:

1. DEVELOPMENT LENGTH OF INDIVIDUAL BARS WITHIN A BUNDLE, IN TENSION OR COMPRESSION, SHALL BE THAT FOR INDIVIDUAL BARS,

WITH LINTEL BEAM WITH LINTEL BEAM RC WALL CONNECTION AT INCREASED 20% FOR THREE-BUNDLED AND 33% FOR FOUR-BUNDLED BARS.

2. FOR COLUMNS AT ANY LEVEL, NO MORE THAN ALTERNATE BARS SHOULD BE SPLICED, NOTMORE THAN 33% OF THE BARS SHALL BE SPLICED WITHIN

THE REQUIRED LAP LENGTH, MINIMUM DISTANCE BETWEEN TWO ADJACENT SPLICED SHALL BE 600mm.

INTERSECTION 3. TOP BARS ARE HORIZONTAL BARS WITH MORE THAN 300mm DEPTH OF CONCRETE CAST BELOW REINFORCEMENT.

4. LAP SPLICE SHALL BE "CLASS B" TENSION LAP SPLICE IF MORE THAN ONE HALF OF THE BARS WERE SPLICED AT ANY SECTION, WHILE "CLASS A"

TENSION LAP SPLICE IF HALF OR FEWER THAN HALF OF BARS WERE SPLICED.

JEMAR ENGINEERING

SERVICES

ENGINEERING DESIGNS & CONSTRUCTION MANAGEMENT

JBM UNITS 201 & 202 GARNET PLACE, M.L. QUEZON ST., CABANCALAN, MANDAUE CITY

Telefax No. (032) 420-5176 Mobile No's: 0917-7204480 / 0922-7243999

E-mail Address: jemar.engineering@yahoo.com

Anda mungkin juga menyukai

- Typical Reinforced Concrete Details and Construction Notes - 2Dokumen1 halamanTypical Reinforced Concrete Details and Construction Notes - 2Aly Arquillano JrBelum ada peringkat

- (R4) Details of Mother Slab PDFDokumen1 halaman(R4) Details of Mother Slab PDFsurya prakashBelum ada peringkat

- Page 2 - Perimeter FenceDokumen1 halamanPage 2 - Perimeter FenceJet ToledoBelum ada peringkat

- Scaffold Designs - Chadworth House Elevation PDFDokumen1 halamanScaffold Designs - Chadworth House Elevation PDFsabeerBelum ada peringkat

- GEO Updated-CheatsheetDokumen3 halamanGEO Updated-CheatsheetGiovanni LinBelum ada peringkat

- General Notes 2Dokumen1 halamanGeneral Notes 2Wilbert ReuyanBelum ada peringkat

- Muthiga Apartments Structural Plans 5 Floors-Model5Dokumen1 halamanMuthiga Apartments Structural Plans 5 Floors-Model5Daniel OkereBelum ada peringkat

- Dev and Lap Splice Lengths - ETN-D-1-15 PDFDokumen9 halamanDev and Lap Splice Lengths - ETN-D-1-15 PDFsathiyaprasathBelum ada peringkat

- cp1 2011Dokumen1 halamancp1 2011rameshkaaBelum ada peringkat

- Typical Fence DetailDokumen1 halamanTypical Fence DetailGelbert SilotBelum ada peringkat

- RMD Shoring PDFDokumen2 halamanRMD Shoring PDFBalaji SubramanianBelum ada peringkat

- Composite Slab DesignDokumen8 halamanComposite Slab DesignOladunni AfolabiBelum ada peringkat

- 1stability AnalysisDokumen93 halaman1stability AnalysisSatha IyathuraiBelum ada peringkat

- MS-Type VI-Modified GirderDokumen26 halamanMS-Type VI-Modified GirderJeff AlinayaBelum ada peringkat

- Micropile Drawing - FinalDokumen1 halamanMicropile Drawing - Finalrao shoaibBelum ada peringkat

- Foundations High MastDokumen6 halamanFoundations High MastPriya Ranjan SinghBelum ada peringkat

- Backstay EffectDokumen2 halamanBackstay EffectCHarlesghylonBelum ada peringkat

- Form - Work: Column FormworkDokumen1 halamanForm - Work: Column FormworkAshish SharmaBelum ada peringkat

- Foundation Wall Formwork Detailed DrawingsDokumen1 halamanFoundation Wall Formwork Detailed DrawingsanilBelum ada peringkat

- Design and Installation Guide: FLEX-LOK®400Dokumen6 halamanDesign and Installation Guide: FLEX-LOK®400PRAVEENKUMAR GBelum ada peringkat

- Detail "A" (Parapet Wall) : R/F Details For Typical Wing Wall Section (C-C)Dokumen1 halamanDetail "A" (Parapet Wall) : R/F Details For Typical Wing Wall Section (C-C)sathiyanBelum ada peringkat

- ST 100 Stacking Tower: ShoringDokumen32 halamanST 100 Stacking Tower: ShoringPrimelift Safety Resources LimitedBelum ada peringkat

- Opening in Slab and BeamDokumen13 halamanOpening in Slab and BeamYohan LimBelum ada peringkat

- Technical Data Sheet For Hilti HIT HY 200 Injectable Mortar in Concrete Technical Information ASSET DOC 8258686 PDFDokumen41 halamanTechnical Data Sheet For Hilti HIT HY 200 Injectable Mortar in Concrete Technical Information ASSET DOC 8258686 PDFiabdillahBelum ada peringkat

- FormworkDokumen62 halamanFormworkFahad AnisBelum ada peringkat

- Code Commentary: 12.14 - Splices of Reinforcement - General R12.14 - Splices of Reinforcement - GeneralDokumen1 halamanCode Commentary: 12.14 - Splices of Reinforcement - General R12.14 - Splices of Reinforcement - GeneralSriram KiranBelum ada peringkat

- Sheet 01Dokumen1 halamanSheet 01Ashish GBelum ada peringkat

- Genset Concrete Pad Detail-SignedDokumen1 halamanGenset Concrete Pad Detail-SignedJOSEPH ANTHONY VINCE MOICOBelum ada peringkat

- Plinth ProtectionDokumen3 halamanPlinth ProtectionSanjeev kumarBelum ada peringkat

- Form - Work: Slab FormworkDokumen1 halamanForm - Work: Slab FormworkAshish SharmaBelum ada peringkat

- Box CulvertDokumen4 halamanBox CulvertDen OghangsombanBelum ada peringkat

- Calculation Sheet of Slab Scaffolding: Middle East Scaffolding TR. L.L.CDokumen8 halamanCalculation Sheet of Slab Scaffolding: Middle East Scaffolding TR. L.L.CissaBelum ada peringkat

- StructuralDokumen15 halamanStructuralMark James MateoBelum ada peringkat

- Couplers PaperDokumen6 halamanCouplers PaperPiyush BhardwajBelum ada peringkat

- Brief Schedules - (Building Designers' Manual)Dokumen39 halamanBrief Schedules - (Building Designers' Manual)nivram75100% (2)

- 00-Event Level - Prefunction - Demo Structural Demolition NotesDokumen1 halaman00-Event Level - Prefunction - Demo Structural Demolition NoteshuyxpkissBelum ada peringkat

- Scaffolding DetailsDokumen8 halamanScaffolding DetailsGopal Sudhir100% (1)

- Mass-10 14 1 - May-2016Dokumen14 halamanMass-10 14 1 - May-2016ianfldBelum ada peringkat

- Deep Beam As A CantileverDokumen2 halamanDeep Beam As A CantileverSagar SakoreBelum ada peringkat

- Labourer Histograms GraphDokumen1 halamanLabourer Histograms Graphcrk document JayanathBelum ada peringkat

- Plandoc 22 3465Dokumen1 halamanPlandoc 22 3465mohdnazirBelum ada peringkat

- False Form WKDokumen12 halamanFalse Form WKRonald Cario SeguinBelum ada peringkat

- Ask The Engineer Proper Bedding For PVC Pressure PipeDokumen5 halamanAsk The Engineer Proper Bedding For PVC Pressure PipeUnibellBelum ada peringkat

- Slab On GradeDokumen2 halamanSlab On GradeVistash Buhary100% (1)

- RMDK Product Brochure April 2018 Rev B PDFDokumen122 halamanRMDK Product Brochure April 2018 Rev B PDFJojo Samaco0% (1)

- Core Drilling ProcedureDokumen7 halamanCore Drilling ProcedureEngineeri TadiyosBelum ada peringkat

- WRN STD 002aDokumen1 halamanWRN STD 002ahenryLYDBelum ada peringkat

- Detailed Specification For Steel ReinforcementDokumen6 halamanDetailed Specification For Steel ReinforcementYoga ArchBelum ada peringkat

- S 1 Structural NotesDokumen1 halamanS 1 Structural NotesJBFPBelum ada peringkat

- Shop Drawings of Column and Wall FormworkDokumen1 halamanShop Drawings of Column and Wall FormworkPrakash Singh RawalBelum ada peringkat

- Post-Installed Rebar Guide Technical Information ASSET DOC LOC 7210535Dokumen69 halamanPost-Installed Rebar Guide Technical Information ASSET DOC LOC 7210535kyleBelum ada peringkat

- Combine Eccentric Pile Cap - FardhahDokumen8 halamanCombine Eccentric Pile Cap - FardhahMongkol JirawacharadetBelum ada peringkat

- Elastic ShorteningDokumen12 halamanElastic Shorteningo100% (1)

- Sachpazis - Raft Foundation Design For Typical 2 Storey House Example - BS8110 - PART 1 - 1997Dokumen5 halamanSachpazis - Raft Foundation Design For Typical 2 Storey House Example - BS8110 - PART 1 - 1997mushroom0320Belum ada peringkat

- Ch4 Settlement of Buildings (1-34) - 2016Dokumen36 halamanCh4 Settlement of Buildings (1-34) - 2016Rafi SulaimanBelum ada peringkat

- Proposed New Cebu City Medical Center: Table of Lap SpliceDokumen1 halamanProposed New Cebu City Medical Center: Table of Lap SpliceclarenceBelum ada peringkat

- Box Culvert 1+825-1Dokumen1 halamanBox Culvert 1+825-1ANKESH SHRIVASTAVABelum ada peringkat

- Concrete Slabs: Typical SectionDokumen1 halamanConcrete Slabs: Typical SectionKsooBaekby ByebyeBelum ada peringkat

- WRN STD 005aDokumen1 halamanWRN STD 005afekeceh343Belum ada peringkat

- ARCHITECTURAL DETAILS 2.1-ModelDokumen1 halamanARCHITECTURAL DETAILS 2.1-ModelRitesh LoharBelum ada peringkat

- Pert CPMDokumen1 halamanPert CPManthony christian yangBelum ada peringkat

- PWPWOPWOWDokumen5 halamanPWPWOPWOWanthony christian yangBelum ada peringkat

- Cabantan - TudtudDokumen3 halamanCabantan - Tudtudanthony christian yangBelum ada peringkat

- TimelineasdDokumen1 halamanTimelineasdanthony christian yangBelum ada peringkat

- I QWOEREWRJOE222 DDDokumen4 halamanI QWOEREWRJOE222 DDanthony christian yangBelum ada peringkat

- Portland Cement Concrete Pavement (0.230m THK., 3500 Psi)Dokumen1 halamanPortland Cement Concrete Pavement (0.230m THK., 3500 Psi)anthony christian yangBelum ada peringkat

- WAHAHA32412Dokumen1 halamanWAHAHA32412anthony christian yangBelum ada peringkat

- Mounting Heights:: LegendDokumen1 halamanMounting Heights:: Legendanthony christian yangBelum ada peringkat

- BILLING NO.2 - Daanlungsod-Calangahan DetailedDokumen1 halamanBILLING NO.2 - Daanlungsod-Calangahan Detailedanthony christian yangBelum ada peringkat

- DPWH Candijay Municipal Building - Mitsubishi ElevatorDokumen6 halamanDPWH Candijay Municipal Building - Mitsubishi Elevatoranthony christian yangBelum ada peringkat

- BILLING NO. 4-Daanlungsod-Calangahan (Draft 1)Dokumen61 halamanBILLING NO. 4-Daanlungsod-Calangahan (Draft 1)anthony christian yangBelum ada peringkat

- E8 XertDokumen1 halamanE8 Xertanthony christian yangBelum ada peringkat

- S-10 Footing Section DetailsDokumen1 halamanS-10 Footing Section Detailsanthony christian yangBelum ada peringkat

- Site Development Plan: C E F A G H J K L H'Dokumen1 halamanSite Development Plan: C E F A G H J K L H'anthony christian yangBelum ada peringkat

- Fast Fast FastDokumen1 halamanFast Fast Fastanthony christian yangBelum ada peringkat

- Ground Floor Lighting System Lay-Out PlanDokumen1 halamanGround Floor Lighting System Lay-Out Plananthony christian yangBelum ada peringkat

- AfasdadffffffDokumen1 halamanAfasdadffffffanthony christian yangBelum ada peringkat

- A Proposed 09-Storey Residential CondominiumDokumen1 halamanA Proposed 09-Storey Residential Condominiumanthony christian yangBelum ada peringkat

- AvxcvxxcvxcvDokumen1 halamanAvxcvxxcvxcvanthony christian yangBelum ada peringkat

- S-02 Miscellaneous DetailsDokumen1 halamanS-02 Miscellaneous Detailsanthony christian yangBelum ada peringkat

- Elevator Pit: Design Consultancy Pablo R. Antonio, Jr. IncDokumen1 halamanElevator Pit: Design Consultancy Pablo R. Antonio, Jr. Incanthony christian yangBelum ada peringkat

- S-08 5f Framing PlanDokumen1 halamanS-08 5f Framing Plananthony christian yangBelum ada peringkat

- S-07 4f Framing PlanDokumen1 halamanS-07 4f Framing Plananthony christian yangBelum ada peringkat

- Lista Preturi Linhai 300 2014 PDFDokumen25 halamanLista Preturi Linhai 300 2014 PDFSimonaVătafuBelum ada peringkat

- 2019 02 01 Racecar EngineeringDokumen100 halaman2019 02 01 Racecar EngineeringGregory Aguilera LopesBelum ada peringkat

- Color Code - Canadian Standard - ABES - PROD.PW - MC.B017.E24806.ATTA003Dokumen14 halamanColor Code - Canadian Standard - ABES - PROD.PW - MC.B017.E24806.ATTA003Adam Michael GreenBelum ada peringkat

- CMVR ProcedureDokumen14 halamanCMVR ProcedureSoumil GuptabhayaBelum ada peringkat

- Step-By-Step Guide - Sensors Alarms1Dokumen14 halamanStep-By-Step Guide - Sensors Alarms1Andy_kokoBelum ada peringkat

- Workstation-Sub Micro Space PlanDokumen21 halamanWorkstation-Sub Micro Space Planarnella_hBelum ada peringkat

- GE Proficy Machine Edition Getting StartedDokumen124 halamanGE Proficy Machine Edition Getting StartedIrfan AshrafBelum ada peringkat

- Online Bank SynopsisDokumen7 halamanOnline Bank SynopsisPrashant VermaBelum ada peringkat

- Arun Et al-2019-ChemistrySelectDokumen8 halamanArun Et al-2019-ChemistrySelectRavi Kumar ARunBelum ada peringkat

- Direct Current Generator ReviewerDokumen16 halamanDirect Current Generator ReviewerCaitriona AngeletteBelum ada peringkat

- Cs9152 DBT Unit IV NotesDokumen61 halamanCs9152 DBT Unit IV NotesNivithaBelum ada peringkat

- Hitman Contracts PC ManualDokumen14 halamanHitman Contracts PC ManualChernoll MendoncaBelum ada peringkat

- Patrick C Hall@yahoo - com-TruthfinderReportDokumen13 halamanPatrick C Hall@yahoo - com-TruthfinderReportsmithsmithsmithsmithsmithBelum ada peringkat

- Molded Case Circuit Breakers Section 6: Spectra RMSDokumen1 halamanMolded Case Circuit Breakers Section 6: Spectra RMSArslan LashariBelum ada peringkat

- Commercial Vehicles BrochureDokumen20 halamanCommercial Vehicles Brochurebinhtb14Belum ada peringkat

- About Some Important Items of Composite Insulators Design: February 1999Dokumen6 halamanAbout Some Important Items of Composite Insulators Design: February 1999ipraoBelum ada peringkat

- Lab - 17-WAN ConfigurationDokumen12 halamanLab - 17-WAN ConfigurationMuhammad Asghar Khan100% (1)

- Weatherford Artificial Lifts Reciprocating Rod Lift OverviewDokumen7 halamanWeatherford Artificial Lifts Reciprocating Rod Lift OverviewKentodalBelum ada peringkat

- CVDokumen2 halamanCVAkash JainBelum ada peringkat

- DE GUZMAN - Module 2 Activity No. 2Dokumen4 halamanDE GUZMAN - Module 2 Activity No. 2Alvin De GuzmanBelum ada peringkat

- Oem Sale Sheet RenaultDokumen4 halamanOem Sale Sheet RenaultDarmawan PutrantoBelum ada peringkat

- Guide To Apparel/Textile Care Symbols: Machine Wash CyclesDokumen1 halamanGuide To Apparel/Textile Care Symbols: Machine Wash Cyclesnilhan1Belum ada peringkat

- PHP Practicals With SolutionDokumen31 halamanPHP Practicals With SolutionBharti100% (3)

- Lab Manual No 13Dokumen3 halamanLab Manual No 13Hammad JawadBelum ada peringkat

- ABB Wireless Communications For Mining OperationsDokumen38 halamanABB Wireless Communications For Mining OperationsAymanBelum ada peringkat

- Basic ProbabilityDokumen53 halamanBasic ProbabilityGhada SheashaBelum ada peringkat

- Case Study #3 ThermodynamicsDokumen6 halamanCase Study #3 ThermodynamicsColeene Forteza100% (1)

- Session Plan CarpentryDokumen8 halamanSession Plan Carpentrymark abayonBelum ada peringkat

- Introduction To R: Shanti.S.Chauhan, PH.D Business Studies ShuatsDokumen53 halamanIntroduction To R: Shanti.S.Chauhan, PH.D Business Studies ShuatsShanti Swaroop ChauhanBelum ada peringkat

- Sikafloor Morritex Self-Levelling Broadcast SystemDokumen4 halamanSikafloor Morritex Self-Levelling Broadcast SystemTPBelum ada peringkat