JSA PCI-Upgrading Altronic Panel Waukesha F3521-Booster

Diunggah oleh

Muhammad Reza GadranHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

JSA PCI-Upgrading Altronic Panel Waukesha F3521-Booster

Diunggah oleh

Muhammad Reza GadranHak Cipta:

Format Tersedia

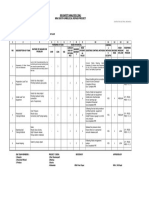

PetroChina International Jabung Date :

Ltd. Job Safety Analysis

Job: Title of person Analyzed by Area Supt / supv

who does the job:,

Upgrading Control Panel Gas Compressor CP-5000

Name: Sign

Department / Company : Section: Prepared by: Reviewed by: Approved by Work Supt

Work Supv HSE Supt/Supv

PT. Sigma Kreasi Instrument

Name &Sign Name & Sign Name & Sign Name: Sign

Write down correct specifications of personal protective

Personal protective equipment (PPE) : Put on PPE required for a safe job. equipment required (Consult HSE Dept) :

1. Safety hat / helmet 6. Face shield 11. SCBA 16. Safety shoes / boots

2. Safety glasses 7. Ear plugs / muffs 12. Gloves – Ordinary 17. Rubber boots

3. Goggles – ordinary 8. Dust mask 13. Gloves - Chemicals 18. Prot. Clothing / Apron

4. Goggles – tinted lenses 9. Air-purifying respirator 14. Gloves – Thermal 19. Body harnesses, L-line

5. Goggles – Chemicals 10. Air-line respirator 15. Rubber gloves 20. Life vest

Sequence of Basic Job Steps Protective Equipment Potential Hazard Safe Procedures

Misscommunication,

Make Work Permit and discuss about Have good communication per-section.

Wrong tools and equipment may cause

scope of work with NGF- OPS , E/I & Standard PPE as required / Correct Tools

personnel injury and equipment

Mechanic CPS Correct tools and PPE

damage.

Prepare all equiptment to be use Standard PPE as required / Correct Tools Personal injuries,

Pre-job meeting

exposed to heat temperature

Communication and report with

Engine shutdown operator

Using complete PPE required for a

safe job.

Installing protective for bottle discharge

compressor

remove the recyle handle valve so

smooth work process

make sure the power cord in a safe

state machines

Use air pressure and drill bit according

to the specifications of the drilling

machine

Make sure the hose is installed

correctly

Prepare fire extinguisher ( make hole

for vibration and reset pin )

Using complete PPE required for a

safe job.

make sure the power cord in a safe

state machines.

Position of the pipe should be fitted, do

Remove Instrument Device and not move during the process

Standard PPE as required / Correct Tools Personal Injuries, damage machines

Existing Local Control Panel.

The tools and materials are put in a

safe place.

Attention to the effects on the

environment in every do the job.

Using complete PPE required for a

safe job.

Position of the tubing pipe should be

fitted, do not move during the process

The tools and materials are put in a

Set Up Tubing Pipe for Pressure safe place

Standard PPE as required / Correct Tools Personal Injuries

devices

Attention to the effects on the

environment in every do the job

Make the process of cutting tubing

pipe in according with the working

steps

Make hole for Vibration Transmitter Standard PPE as required / Correct Tools Personal Injuries, damage machines

and Detonation Sensor Using complete PPE required for a

safe job.

The tools and materials are put in a

safe place

Operators need to find the safest, most

effective position for themselves and

the machine.

if possible, consider moving materials

so that drills can be operated from

such a position to allow the driller to

maintain good footing and posture.

If necessary, a spotter, or an additional

operator can help support give the oil

at drill bit

Make the process of drilling according

with the working steps

Attention to the effects on the

environment in every do the job

Using complete PPE required for a

safe job.

Attention to the effects on the

environment in every do the job.

Pulling Instrument cable for device Standard PPE as required

Personal Injuries

(Level Switch,Vibration) Hand Tools Position of the pipe should be fitted put

in a safe place.

Stop activities when compressor

shutdown.

Using complete PPE required for a

safe job.

Attention to the effects on the

environment in every do the job

Installation Tubing Pipe at Engine Standard PPE as required

Personal Injuries

F3521 Hand Tools

Position of the pipe should be fitted put

in a safe place.

Stop activities when compressor

shutdown.

Electrical installation & maintenance

shall only be performed by Certified

Electricians.

Lockout and Tagout electrical

equipment prior to exposing

personnel.

All Electrical equipment shall have

ground fault circuit interrupters or

assured equipment grounding

Working around electrical : Power Standard PPE as required Personal injuries, damage machines Avoid lifting long dimensional

poles, conduit , panel Hand Tools conductor (duct or pipe ) over or

around live electrical.

All receptacle must be mounted and

secure prior to use

Panel boxs must be covered to prevent

accidental contact with live part.

Conductive item or jewelry or clothing

shall not be worn unless they are

rendered non conductive by covering,

wrapping or other insulating means.

Function Test & Commisoning Standard PPE as required Personal injuries, damage machines

Hand Tools All non essential personnel must stay

clear of the test location for the

duration of the commissioning

procedure

All commisioning personnel must wear

standart protective equipment

All the participant shall be aware of

potential environmental hazards during

all phase ecountered

Any member of the test team may stop

the testing at any point should

dangers to personnel, the

environment, equipment exist

Verify all work is clear of any debris

and tools before powering up

Ensure that the engine over speed ,

emergency stop and any other

mechanical protectiion system have

been verified and are fully

operational.

Verify all out going feeder breaker and

isolator are open status before

applying power to the main.

All personnel must follow the

appropriate lock out/tag out

procedures.

Close Work Permit after job complete

or expire

Anda mungkin juga menyukai

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- Main Schedule Callout Service PetrochinaDokumen2 halamanMain Schedule Callout Service PetrochinaMuhammad Reza GadranBelum ada peringkat

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Company Profile TPIDokumen9 halamanCompany Profile TPIMuhammad Reza GadranBelum ada peringkat

- Pengertian SurgingDokumen23 halamanPengertian SurgingMuhammad Reza GadranBelum ada peringkat

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Form2-01-01Process FMEA WorksheetDokumen1 halamanForm2-01-01Process FMEA WorksheetMuhammad Reza GadranBelum ada peringkat

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- Pengertian SurgingDokumen23 halamanPengertian SurgingMuhammad Reza GadranBelum ada peringkat

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Surat LamaranDokumen1 halamanSurat LamaranMuhammad Reza GadranBelum ada peringkat

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- BOM - Altronic 1 For Arrow C-96Dokumen3 halamanBOM - Altronic 1 For Arrow C-96Muhammad Reza GadranBelum ada peringkat

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- Work Report Callout Ilovepdf CompressedDokumen10 halamanWork Report Callout Ilovepdf CompressedMuhammad Reza GadranBelum ada peringkat

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Work Procedure Fuel Upgrade & Detonation SystemDokumen9 halamanWork Procedure Fuel Upgrade & Detonation SystemMuhammad Reza GadranBelum ada peringkat

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- SPPB AssemblingDokumen83 halamanSPPB AssemblingMuhammad Reza GadranBelum ada peringkat

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Form2!01!01Process FMEA Worksheet (RCL SMALL)Dokumen1 halamanForm2!01!01Process FMEA Worksheet (RCL SMALL)Muhammad Reza GadranBelum ada peringkat

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Komponen Dan Summaries Parameter Rev.3Dokumen2 halamanKomponen Dan Summaries Parameter Rev.3Muhammad Reza GadranBelum ada peringkat

- Steper Valve Instalasi PlanDokumen1 halamanSteper Valve Instalasi PlanMuhammad Reza GadranBelum ada peringkat

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- List Aplicator Crimping Proses Wiring Harness: NO Part No Part Name Proses Model Tahun M/C Metode Crimping KeteranganDokumen1 halamanList Aplicator Crimping Proses Wiring Harness: NO Part No Part Name Proses Model Tahun M/C Metode Crimping KeteranganMuhammad Reza GadranBelum ada peringkat

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Sahala Pressure GaugeDokumen2 halamanSahala Pressure GaugeMuhammad Reza GadranBelum ada peringkat

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Rekarma Seviye GostergesiDokumen2 halamanRekarma Seviye GostergesibrsgnBelum ada peringkat

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- Cylinder Block 8sgtDokumen4 halamanCylinder Block 8sgtMuhammad Reza GadranBelum ada peringkat

- JSA Tubing Leak TestDokumen1 halamanJSA Tubing Leak TestMuhammad Reza Gadran67% (3)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- Control Air Pressure Regulator 400Dokumen2 halamanControl Air Pressure Regulator 400Muhammad Reza GadranBelum ada peringkat

- Operating InstructionDokumen77 halamanOperating InstructionMuhammad Reza GadranBelum ada peringkat

- Work Schedule Upgrading Panel GC 'CP-5000Dokumen6 halamanWork Schedule Upgrading Panel GC 'CP-5000Muhammad Reza GadranBelum ada peringkat

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- IO List Dengan DSM 6 Board Exacta 21 - PetrochinaDokumen5 halamanIO List Dengan DSM 6 Board Exacta 21 - PetrochinaMuhammad Reza GadranBelum ada peringkat

- Contoh Membuat Daftar Komponen Quotation Temperature GaugeDokumen3 halamanContoh Membuat Daftar Komponen Quotation Temperature GaugeMuhammad Reza Gadran100% (1)

- Expense Petrochina-WB - 13112017Dokumen1 halamanExpense Petrochina-WB - 13112017Muhammad Reza GadranBelum ada peringkat

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Komponen Dan Summaries Parameter Rev.3Dokumen2 halamanKomponen Dan Summaries Parameter Rev.3Muhammad Reza GadranBelum ada peringkat

- C&e PetrochinaDokumen66 halamanC&e PetrochinaMuhammad Reza GadranBelum ada peringkat

- Risk Assessment TSDokumen5 halamanRisk Assessment TSMuhammad Reza GadranBelum ada peringkat

- Non-Contact Infrared Thermometers: Tel-Tru Manufacturing CompanyDokumen2 halamanNon-Contact Infrared Thermometers: Tel-Tru Manufacturing CompanyMuhammad Reza GadranBelum ada peringkat

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (120)

- Catalog For Pahala BahariDokumen4 halamanCatalog For Pahala BahariMuhammad Reza GadranBelum ada peringkat

- HR Q and ADokumen87 halamanHR Q and Asanjeeb88Belum ada peringkat

- BP Azspu Driver Fatigue & Tiredness Management ProcedureDokumen11 halamanBP Azspu Driver Fatigue & Tiredness Management ProcedureEl Khan100% (1)

- Pfmar SampleDokumen15 halamanPfmar SampleJustin Briggs86% (7)

- Power Dense and Robust Traction Power Inverter For The Second Generation Chevrolet Volt Extended Range EDokumen8 halamanPower Dense and Robust Traction Power Inverter For The Second Generation Chevrolet Volt Extended Range Ejrz000Belum ada peringkat

- Grant Miller Resume-ColliersDokumen3 halamanGrant Miller Resume-ColliersDeven GriffinBelum ada peringkat

- HyderabadDokumen3 halamanHyderabadChristoBelum ada peringkat

- Eastern Bank Limited: Name: ID: American International University of Bangladesh Course Name: Faculty Name: Due DateDokumen6 halamanEastern Bank Limited: Name: ID: American International University of Bangladesh Course Name: Faculty Name: Due DateTasheen MahabubBelum ada peringkat

- Note 2958296 Pre-Implementation Steps: Create Table TypeDokumen3 halamanNote 2958296 Pre-Implementation Steps: Create Table Typevishnu900890Belum ada peringkat

- Step Recovery DiodesDokumen3 halamanStep Recovery DiodesfahkingmoronBelum ada peringkat

- Inductive Grammar Chart (Unit 2, Page 16)Dokumen2 halamanInductive Grammar Chart (Unit 2, Page 16)Michael ZavalaBelum ada peringkat

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- 1610-2311-Executive Summary-EnDokumen15 halaman1610-2311-Executive Summary-EnKayzha Shafira Ramadhani460 105Belum ada peringkat

- Far160 Pyq Feb2023Dokumen8 halamanFar160 Pyq Feb2023nazzyusoffBelum ada peringkat

- OMS - Kangaroo Mother CareDokumen54 halamanOMS - Kangaroo Mother CareocrissBelum ada peringkat

- DMP 2021 TPJ SRDokumen275 halamanDMP 2021 TPJ SRishu sBelum ada peringkat

- Statics: Vector Mechanics For EngineersDokumen25 halamanStatics: Vector Mechanics For EngineersProkopyo BalagbagBelum ada peringkat

- Legal Environment of Business 7th Edition Kubasek Solutions Manual Full Chapter PDFDokumen34 halamanLegal Environment of Business 7th Edition Kubasek Solutions Manual Full Chapter PDFlongchadudz100% (12)

- Sample Pilots ChecklistDokumen2 halamanSample Pilots ChecklistKin kei MannBelum ada peringkat

- Cyber Law: Submitted byDokumen8 halamanCyber Law: Submitted bySonu MishraBelum ada peringkat

- Evaluating The Policy Outcomes For Urban Resiliency in Informal Settlements Since Independence in Dhaka, Bangladesh: A ReviewDokumen14 halamanEvaluating The Policy Outcomes For Urban Resiliency in Informal Settlements Since Independence in Dhaka, Bangladesh: A ReviewJaber AbdullahBelum ada peringkat

- NGOs in Satkhira PresentationDokumen17 halamanNGOs in Satkhira PresentationRubayet KhundokerBelum ada peringkat

- Solar Power Plant in Iit HyderabadDokumen9 halamanSolar Power Plant in Iit HyderabadHimanshu VermaBelum ada peringkat

- 7MWTW1710YM0Dokumen8 halaman7MWTW1710YM0Izack-Dy JimZitBelum ada peringkat

- Mercantile Law Zaragoza Vs Tan GR. No. 225544Dokumen3 halamanMercantile Law Zaragoza Vs Tan GR. No. 225544Ceasar Antonio100% (1)

- Student Application Form BCIS - 2077Dokumen2 halamanStudent Application Form BCIS - 2077Raaz Key Run ChhatkuliBelum ada peringkat

- Add New Question (Download - PHP? SC Mecon&id 50911)Dokumen9 halamanAdd New Question (Download - PHP? SC Mecon&id 50911)AnbarasanBelum ada peringkat

- MIami Beach City Attorney's DenialDokumen7 halamanMIami Beach City Attorney's DenialDavid Arthur WaltersBelum ada peringkat

- Unit 8 - Week 7: Assignment 7Dokumen3 halamanUnit 8 - Week 7: Assignment 7Nitin MoreBelum ada peringkat

- Cam 12 Test 2 ReadingDokumen7 halamanCam 12 Test 2 ReadingLê Nguyễn Ái DuyênBelum ada peringkat

- PraxiarDokumen8 halamanPraxiara_roy003Belum ada peringkat

- SHPXXX 20 IS XX 13Dokumen240 halamanSHPXXX 20 IS XX 13Geyciane PinheiroBelum ada peringkat