Executive Summary of The Repaort

Diunggah oleh

MansoorJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Executive Summary of The Repaort

Diunggah oleh

MansoorHak Cipta:

Format Tersedia

Table of Contents

Executive Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Background. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

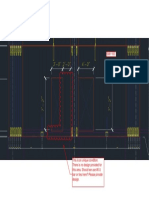

Diaphragm response . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Shear Wall response . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Frame response . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Foundation response . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . 3

Seismic force resisting systems in the Precast . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

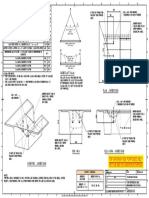

Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Shear Wall to Foundation and Floor to floor connections. . . . . . . . . . . . . . . . . . . . . . 4

Shear Wall to Foundation Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Floor to Floor Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Wall to Wall connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Ductile Connectors for Precast Moment Frames . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Buckling-restrained braces in Precast concrete Frames . . . . . . . . . . . . . . . . . . . . . . . 11

Beam to Column connections in precast concrete moment resisting frames . . . . . . . 15

More Steel Framing Connections used with Precast . . . . . . . . . . . . . . . . . . . . . . . . . 18

Executive Summary

Precast or reinforcing concrete with steel improves strength and durability. Rebar is the

most common form of concrete reinforcement. It is typically made from steel, manufactured with

ribbing to bond with concrete as it cures. There are different yield strength rebar. Most common

rebar is ASTM 615 fy=60ksi. Concrete has no ductile/tension capacity and is brittle in nature

whereas rebar have a well-defined yield point before they fracture. In order to make the fracture

mechanism ductile in nature, we use rebar in the concrete. During seismic loading we have

horizontal motion in the building. This motion creates forces in the floor diaphragm that is

resisted by floor to floor connection. These floor to floor connections take these forces to the

seismic resisting elements where they take the forces to the foundation. For high seismic areas,

designs are based on heavy reinforcement. Reason for heavy reinforcement is so they can resist

seismic forces. Instead of structure failing instantly, we have considerable amount of time and

deflection so that people can evacuate at the time of seismic event. We have precast frames and

moment resisting frames that are reinforced in a special way prescribed in the building code to

resist these seismic forces. In this report, different types of seismic resisting system and their

connection are discussed.

Precast concrete with its amazing compressive strength has shaped the structures in the

new direction. The use of steel rods in precast or concrete is the oldest technology of mankind.

Embedding steel bars into concrete increases the materials tensile strength, allowing concrete to

cure to be used in the applications like precast frames or beams. This works well because of the

steel inherent tensile strength. For effective steel reinforcement in any application, the size or

area, strength and precise placement of bars must all be carefully considered. Fortunately, this is

a well-studied area, and precast manufacturers have access to comprehensive specifications

and well-developed codes and tools when designing new elements.

Anda mungkin juga menyukai

- Column AnalysisDokumen2 halamanColumn AnalysisMansoorBelum ada peringkat

- Angle EmbedDokumen1 halamanAngle EmbedMansoorBelum ada peringkat

- Structural Engineering Practice ProblemsDokumen2 halamanStructural Engineering Practice ProblemsMansoorBelum ada peringkat

- 0506 001Dokumen1 halaman0506 001MansoorBelum ada peringkat

- Changes To ACIDokumen4 halamanChanges To ACIMansoorBelum ada peringkat

- Condo QuestionnaireDokumen5 halamanCondo QuestionnaireMansoorBelum ada peringkat

- Technical Information ASSET DOC LOC 1555609Dokumen2 halamanTechnical Information ASSET DOC LOC 1555609MansoorBelum ada peringkat

- Engr600 Quiz - 3Dokumen4 halamanEngr600 Quiz - 3MansoorBelum ada peringkat

- For Example of One of The IntegralsDokumen3 halamanFor Example of One of The IntegralsMansoorBelum ada peringkat

- Executive Summary of The RepaortDokumen1 halamanExecutive Summary of The RepaortMansoorBelum ada peringkat

- 0416 001Dokumen5 halaman0416 001MansoorBelum ada peringkat

- CE 631 Advanced Steel Design Homework 5Dokumen2 halamanCE 631 Advanced Steel Design Homework 5MansoorBelum ada peringkat

- Novel Use of Buckling-Restrained Braces in Precast Concrete Frames, PCI Journal Sep-Oct 2017Dokumen1 halamanNovel Use of Buckling-Restrained Braces in Precast Concrete Frames, PCI Journal Sep-Oct 2017MansoorBelum ada peringkat

- 10Dokumen1 halaman10MansoorBelum ada peringkat

- Standard Girder PDFDokumen1 halamanStandard Girder PDFMansoorBelum ada peringkat

- ENGR 636 Tuesday 3/14: 1. Review HW 3 SolutionDokumen3 halamanENGR 636 Tuesday 3/14: 1. Review HW 3 SolutionMansoorBelum ada peringkat

- OLS - Report - Certification of 10T Obelix Lifting Clutch PDFDokumen2 halamanOLS - Report - Certification of 10T Obelix Lifting Clutch PDFMansoorBelum ada peringkat

- Engr 636-3 PDFDokumen3 halamanEngr 636-3 PDFMansoorBelum ada peringkat

- Movie LetterDokumen2 halamanMovie LetterMansoorBelum ada peringkat

- SWI 100 QueryDokumen1 halamanSWI 100 QueryMansoorBelum ada peringkat

- 2881 001Dokumen1 halaman2881 001MansoorBelum ada peringkat

- Direct and Min Total PE FormulationDokumen12 halamanDirect and Min Total PE FormulationMansoorBelum ada peringkat

- HW4 Problem 1Dokumen12 halamanHW4 Problem 1MansoorBelum ada peringkat

- Summary of 2D Constant Strain ElementDokumen3 halamanSummary of 2D Constant Strain ElementMansoorBelum ada peringkat

- 3517 001Dokumen1 halaman3517 001MansoorBelum ada peringkat

- 3531 001Dokumen1 halaman3531 001MansoorBelum ada peringkat

- Quiz 3 - Finite ElementDokumen1 halamanQuiz 3 - Finite ElementMansoorBelum ada peringkat

- Homework 4, EnGR 636Dokumen1 halamanHomework 4, EnGR 636MansoorBelum ada peringkat

- 2762 001Dokumen12 halaman2762 001MansoorBelum ada peringkat

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Letter Advocating For Hazard PayDokumen2 halamanLetter Advocating For Hazard PayQueens PostBelum ada peringkat

- Costs-Concepts and ClassificationsDokumen12 halamanCosts-Concepts and ClassificationsLune NoireBelum ada peringkat

- Efectele Crizei Economice Asupra Politicilor Pietei Muncii Din RomaniaDokumen24 halamanEfectele Crizei Economice Asupra Politicilor Pietei Muncii Din Romaniacristian_incaltarauBelum ada peringkat

- In Gov cbse-SSCER-191298202020 PDFDokumen1 halamanIn Gov cbse-SSCER-191298202020 PDFrishichauhan25Belum ada peringkat

- EasementDokumen10 halamanEasementEik Ren OngBelum ada peringkat

- Rohini 43569840920Dokumen4 halamanRohini 43569840920SowmyaBelum ada peringkat

- PartlowControllerCatalog PDFDokumen98 halamanPartlowControllerCatalog PDFvinh nguyen theBelum ada peringkat

- Oyo Summer Internship ReportDokumen31 halamanOyo Summer Internship ReportJayasree S RBelum ada peringkat

- Different Aids For TeachingDokumen19 halamanDifferent Aids For TeachingPrecious CabarseBelum ada peringkat

- SCM NotesDokumen29 halamanSCM NotesNisha Pradeepa100% (2)

- LL Baby Carrier Corner Drool Pads TutorialDokumen9 halamanLL Baby Carrier Corner Drool Pads TutorialBryan DerryBelum ada peringkat

- Paper 19 Revised PDFDokumen520 halamanPaper 19 Revised PDFAmey Mehta100% (1)

- Schoology App Login DirectionsDokumen5 halamanSchoology App Login Directionsapi-234989244Belum ada peringkat

- Regulations 2020: Mechanical Engineering CurriculumDokumen162 halamanRegulations 2020: Mechanical Engineering CurriculumdsathiyaBelum ada peringkat

- Poka Yoke BDokumen31 halamanPoka Yoke BjaymuscatBelum ada peringkat

- ReportDokumen4 halamanReportapi-463513182Belum ada peringkat

- Dep 32.32.00.11-Custody Transfer Measurement Systems For LiquidDokumen69 halamanDep 32.32.00.11-Custody Transfer Measurement Systems For LiquidDAYOBelum ada peringkat

- An - APX18 206516L CT0Dokumen2 halamanAn - APX18 206516L CT0Maria MartinsBelum ada peringkat

- Less Than a Decade to Avoid Catastrophic Climate ChangeDokumen1 halamanLess Than a Decade to Avoid Catastrophic Climate ChangeXie YuJiaBelum ada peringkat

- SC upholds invalid donation of land shareDokumen3 halamanSC upholds invalid donation of land shareAizza JopsonBelum ada peringkat

- Cough: by Dr. Meghana Patil (Intern Batch 2016)Dokumen24 halamanCough: by Dr. Meghana Patil (Intern Batch 2016)Meghana PatilBelum ada peringkat

- Cost Analysis Format-Exhaust DyeingDokumen1 halamanCost Analysis Format-Exhaust DyeingRezaul Karim TutulBelum ada peringkat

- Pumping Station Modification PDFDokumen15 halamanPumping Station Modification PDFcarlosnavalmaster100% (1)

- Tối Ưu Hóa Cho Khoa Học Dữ LiệuDokumen64 halamanTối Ưu Hóa Cho Khoa Học Dữ Liệuminhpc2911Belum ada peringkat

- Loan Agreement with Chattel Mortgage SecuredDokumen6 halamanLoan Agreement with Chattel Mortgage SecuredManny DerainBelum ada peringkat

- Real-Time Java and ATCDokumen44 halamanReal-Time Java and ATCdnk_victon6248Belum ada peringkat

- Wizard's App Pitch Deck by SlidesgoDokumen52 halamanWizard's App Pitch Deck by SlidesgoandreaBelum ada peringkat

- Elegant Tranquil Blue Agency by SlidesgoDokumen41 halamanElegant Tranquil Blue Agency by SlidesgoJoana TavaresBelum ada peringkat

- CJCuny Talmor PE TurnaroundsDokumen18 halamanCJCuny Talmor PE TurnaroundsMayank Shankar SinghBelum ada peringkat

- Manual de Motores Vol 4Dokumen75 halamanManual de Motores Vol 4Gabriel Piñon Conde100% (1)