Jsa Removal Fixing Insulation

Diunggah oleh

Aprilia Rizki Ardila63%(8)63% menganggap dokumen ini bermanfaat (8 suara)

2K tayangan2 halamanJOB SAFETY ANALYSIS

Hak Cipta

© © All Rights Reserved

Format Tersedia

DOC, PDF, TXT atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniJOB SAFETY ANALYSIS

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai DOC, PDF, TXT atau baca online dari Scribd

63%(8)63% menganggap dokumen ini bermanfaat (8 suara)

2K tayangan2 halamanJsa Removal Fixing Insulation

Diunggah oleh

Aprilia Rizki ArdilaJOB SAFETY ANALYSIS

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai DOC, PDF, TXT atau baca online dari Scribd

Anda di halaman 1dari 2

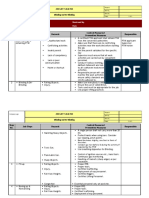

Project:

Company Logo JOB SAFET ANALYSIS

Ref No.:

Rev No.:

Removal & Fixing of Insulation

Page: 1 of 2

Prepared by: Reviewed by:

Approved by: Date:

Step Control Measures/ Responsible

Description of Task Step Hazard

No. Preventive Measures Person

1 Insulation Removal & Fixing. Glass wool. Proper PPE as per MSDS.

Sharp Objects. Proper Tools.

Dust. Housekeeping.

Skin Irritation. Agreed Lay down area for storage.

Fall. Secure all loose insulation at storage area

from high wind.

Flammable gasses Gas testing to be done at the start of

removing insulation on any line containing

hydrocarbons: Note especially at flange

and valve locations.

Inadequate access Make sure that adequate access is

available.

If scaffold is used for access it should be

inspected by a certified scaffold inspector

& scaff-tag should be installed

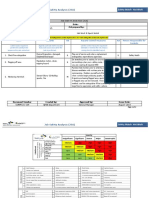

2 Using Foam spray for Glass wool Proper Gun maintenance

insulation application with Air-conditioned storage of Chemicals at

Aluminium foil on site

one side Compressor / Generator certification

Fire Extinguisher

Chemical (Polyol + Wear proper PPE as per the MSDS

Iso-cyanide = (material Safety Data Sheet)

Polyurethane) Workers should not play around with the

Pressurised Injection tools

Project:

Company Logo JOB SAFET ANALYSIS

Ref No.:

Rev No.:

Removal & Fixing of Insulation

Page: 2 of 2

Step Control Measures/ Responsible

Description of Task Step Hazard

No. Preventive Measures Person

gun Only competent workers are allowed to

Foaming machine use the pressurized injection gun

Breathing trouble Operators must read the manufacturers

for using the foaming machine

Anda mungkin juga menyukai

- Jsa Heat Exchanger Inspection Water Cleaning 2Dokumen5 halamanJsa Heat Exchanger Inspection Water Cleaning 2halfy safitri100% (2)

- JSA Blinding and de Blinding PDF FreeDokumen3 halamanJSA Blinding and de Blinding PDF Free최승원Belum ada peringkat

- JSA For Insulation of VesselDokumen6 halamanJSA For Insulation of Vesselyc safetyBelum ada peringkat

- JSA No. 9 - Safe Use of Pneumatic and Power ToolsDokumen2 halamanJSA No. 9 - Safe Use of Pneumatic and Power ToolsAshok Suresh100% (1)

- JSA For Painting Works-Hazards ControlDokumen4 halamanJSA For Painting Works-Hazards Controlkaleem0% (2)

- Job Safety Analysis - Clinker StorageDokumen4 halamanJob Safety Analysis - Clinker StorageMohammed MinhajBelum ada peringkat

- Form JSA Lifting CraneDokumen6 halamanForm JSA Lifting CraneYeti Srinurhayati100% (1)

- EF 1931-STCC-JSA-33 Fire Proofing of The Steel Structure and Vessel Foun...Dokumen5 halamanEF 1931-STCC-JSA-33 Fire Proofing of The Steel Structure and Vessel Foun...Anis Uddin100% (2)

- JSA-020-Safety Watch-Hot WorkDokumen2 halamanJSA-020-Safety Watch-Hot WorkNishad MuhammedBelum ada peringkat

- Confined Spaces: Job Safety AnalysisDokumen2 halamanConfined Spaces: Job Safety Analysismalimsaidi_160040895Belum ada peringkat

- Jsa PaintDokumen2 halamanJsa PaintKhalid NaseemBelum ada peringkat

- JSA - Fire Proofing WorksDokumen5 halamanJSA - Fire Proofing WorksAnis Uddin100% (3)

- Job Safety Analysis (Jsa) : Title of Activity / Work: Hot Work ActivityDokumen2 halamanJob Safety Analysis (Jsa) : Title of Activity / Work: Hot Work ActivityJayendra PatelBelum ada peringkat

- JSA For HVAC WorkDokumen8 halamanJSA For HVAC Worksathakathulla100% (3)

- Job Safety Analysis: Night Work at SiteDokumen2 halamanJob Safety Analysis: Night Work at SiteSaiyad RiyazaliBelum ada peringkat

- Jsa Pipe Cutting at Fire PumpDokumen5 halamanJsa Pipe Cutting at Fire PumpHow Chin Engineering Sdn BhdBelum ada peringkat

- Jsa forOperatingAForkliftDokumen2 halamanJsa forOperatingAForkliftsupahing supahingBelum ada peringkat

- Copy of JSA For Cathodic Protection For Oily Water LineDokumen6 halamanCopy of JSA For Cathodic Protection For Oily Water LineMohammed Minhaj80% (5)

- jesa-INSTALLATION OF Toilet Cubicle PartitionDokumen5 halamanjesa-INSTALLATION OF Toilet Cubicle PartitionLeo PascualBelum ada peringkat

- Hot Work: Job Hazard Analysis PT Technic (M)Dokumen4 halamanHot Work: Job Hazard Analysis PT Technic (M)ShahrizatSmailKassim100% (1)

- JHA-011 (Power Brush & Touch-Up Painting Activities 1)Dokumen1 halamanJHA-011 (Power Brush & Touch-Up Painting Activities 1)shaiful annuar50% (2)

- Tie in Hot Work JHADokumen4 halamanTie in Hot Work JHAmalik jahan100% (2)

- Gas Cutting JsaDokumen4 halamanGas Cutting JsaMohammed Minhaj100% (1)

- Jsa Radiographic Test RTDokumen1 halamanJsa Radiographic Test RTHussein Adnan Fneish100% (1)

- JSA of Pipe Unloading.Dokumen2 halamanJSA of Pipe Unloading.vijay kumar singh100% (1)

- Jsa Cable TerminationDokumen4 halamanJsa Cable TerminationSyed Yousuf Ali100% (1)

- JSA For DuctDokumen14 halamanJSA For DuctRakeshkasarla100% (3)

- Jsa For Pipe Fabrication ErrectionDokumen8 halamanJsa For Pipe Fabrication Errectionjithin shankarBelum ada peringkat

- Manual Tig Welding (RRC) - Job ProcedureDokumen3 halamanManual Tig Welding (RRC) - Job Proceduretitto84886100% (1)

- Jsa-Jha For Using of Hand ToolsDokumen2 halamanJsa-Jha For Using of Hand ToolsKamran Khan50% (2)

- JSA For Hydro Test Activites (Generic)Dokumen4 halamanJSA For Hydro Test Activites (Generic)Khaled Ismail88% (25)

- Jsa For Cutting, Grinding and Welding For GulfconDokumen3 halamanJsa For Cutting, Grinding and Welding For GulfconOgunwa Emmanuel100% (1)

- JSA Excavation PDFDokumen6 halamanJSA Excavation PDFmohamedamine.zemouriBelum ada peringkat

- JSA Erection of Gathering TentDokumen12 halamanJSA Erection of Gathering TentMuhammad Tariq100% (2)

- Kaztec Fabrication Yard, Snake Island: Job Safety Analysis (JSA)Dokumen3 halamanKaztec Fabrication Yard, Snake Island: Job Safety Analysis (JSA)Ogunwa EmmanuelBelum ada peringkat

- Jsa For RadiographyDokumen3 halamanJsa For Radiographyjithin shankarBelum ada peringkat

- Refueling JSA 4 08 2019 Rev.03 Near WaterDokumen9 halamanRefueling JSA 4 08 2019 Rev.03 Near Waterrisky indra antariBelum ada peringkat

- 003-JSA Pipe Loading and OffloadingDokumen8 halaman003-JSA Pipe Loading and OffloadingMoaatazz NouisriBelum ada peringkat

- JSA Hydrant Pipe LineDokumen7 halamanJSA Hydrant Pipe Lineakshay pradeepBelum ada peringkat

- JSA For Coating and Raping Activity in TankDokumen7 halamanJSA For Coating and Raping Activity in TankEslam lotfy- Eslam elsadatBelum ada peringkat

- JSA E&I 10.electrical Instrument Panels RemovalDokumen3 halamanJSA E&I 10.electrical Instrument Panels RemovalAmyBelum ada peringkat

- Safe Working Procedure: Thermoplastic Road MarkingsDokumen1 halamanSafe Working Procedure: Thermoplastic Road MarkingsABHINAV MISHAL100% (2)

- Jsa Insulation WorkDokumen19 halamanJsa Insulation WorkM M PRADHAN100% (2)

- JSA ScaffoldingDokumen2 halamanJSA ScaffoldingHrishikesh UnnikrishnanBelum ada peringkat

- JSA-055 Hydro-TestDokumen24 halamanJSA-055 Hydro-TestOmar Dhieb100% (7)

- Area Hard Barrication JsaDokumen7 halamanArea Hard Barrication JsaJanakiramanBelum ada peringkat

- JSA Confined Sapce EntryDokumen1 halamanJSA Confined Sapce EntryprasongBelum ada peringkat

- JHA LiftingDokumen4 halamanJHA Liftingsyamimi balkhisBelum ada peringkat

- JSA For Dismantalling of PVC Pipe (5cm) by Acetylene Gas CuttingDokumen4 halamanJSA For Dismantalling of PVC Pipe (5cm) by Acetylene Gas CuttingMohammed Minhaj100% (1)

- JSA For Flange AlignmentDokumen5 halamanJSA For Flange AlignmentHưởng Phạm100% (1)

- JSA Hot WorkDokumen3 halamanJSA Hot WorkNasir Mehmood Aryani100% (1)

- Job Safety Analysis: Organization: JSA Number: Work Type: Work Activity: Specific SiteDokumen5 halamanJob Safety Analysis: Organization: JSA Number: Work Type: Work Activity: Specific SiteM M PRADHANBelum ada peringkat

- JHA PlumberDokumen3 halamanJHA PlumberEko Susanto100% (1)

- Job Safety Analysis Sheet: FacilityDokumen1 halamanJob Safety Analysis Sheet: Facilitywahyu nugrohoBelum ada peringkat

- Blinding and De-BlindingDokumen3 halamanBlinding and De-Blindingkaremkoko33% (3)

- JHA # 009 - Hot WorkDokumen7 halamanJHA # 009 - Hot WorkkumarBelum ada peringkat

- Job Safety Analysis - Cone ErectionDokumen7 halamanJob Safety Analysis - Cone ErectionMohammed MinhajBelum ada peringkat

- Work Permit Request For HydrotestingDokumen3 halamanWork Permit Request For HydrotestingZeyad Rezk50% (2)

- ომარ ხაიამი - რობაიები (პარალელური ტექსტები)Dokumen31 halamanომარ ხაიამი - რობაიები (პარალელური ტექსტები)გენო მუმლაძეBelum ada peringkat

- Overall Summary:: SAP MM Certified Associate & SAP Certification ID: 0019350978Dokumen6 halamanOverall Summary:: SAP MM Certified Associate & SAP Certification ID: 0019350978Ganapathi RajBelum ada peringkat

- A Review On Bioactive Compounds of Beet Beta Vulgaris L Subsp Vulgaris With Special Emphasis On Their Beneficial Effects On Gut Microbiota and Gastrointestinal HealthDokumen13 halamanA Review On Bioactive Compounds of Beet Beta Vulgaris L Subsp Vulgaris With Special Emphasis On Their Beneficial Effects On Gut Microbiota and Gastrointestinal HealthWinda KhosasiBelum ada peringkat

- Unit Weight of Soil in Quezon CityDokumen2 halamanUnit Weight of Soil in Quezon CityClarence Noel CorpuzBelum ada peringkat

- Unknown Facts About Physicians Email List - AverickMediaDokumen13 halamanUnknown Facts About Physicians Email List - AverickMediaJames AndersonBelum ada peringkat

- Water Quality Index Determination of Malathalli LakeDokumen16 halamanWater Quality Index Determination of Malathalli Lakeajay kumar hrBelum ada peringkat

- COT RPMS Rating Sheet For MT I IV For SY 2021 2022 in The Time of COVID 19Dokumen2 halamanCOT RPMS Rating Sheet For MT I IV For SY 2021 2022 in The Time of COVID 19Don Mariano Marcos Elementary SchoolBelum ada peringkat

- A6V10424583 - 2 - and 3-Port Valves With - BR - Flanged Connections - enDokumen14 halamanA6V10424583 - 2 - and 3-Port Valves With - BR - Flanged Connections - enAjdin BuljubasicBelum ada peringkat

- Variance AnalysisDokumen22 halamanVariance AnalysisFrederick GbliBelum ada peringkat

- White Vaseline: Safety Data SheetDokumen9 halamanWhite Vaseline: Safety Data SheetHilmi FauziBelum ada peringkat

- Probni Test 1. Godina - Ina KlipaDokumen4 halamanProbni Test 1. Godina - Ina KlipaMickoBelum ada peringkat

- Schedule NDokumen3 halamanSchedule Nmittal kelaBelum ada peringkat

- Intentions and Results ASFA and Incarcerated ParentsDokumen10 halamanIntentions and Results ASFA and Incarcerated Parentsaflee123Belum ada peringkat

- Blood DonationDokumen19 halamanBlood DonationsuruthiBelum ada peringkat

- Case StudyDokumen7 halamanCase StudyLeighvan PapasinBelum ada peringkat

- Formulation and Evaluation of Mefenamic Acid Ointment Using Penetration EnhancersDokumen5 halamanFormulation and Evaluation of Mefenamic Acid Ointment Using Penetration EnhancersIndradewiBelum ada peringkat

- Borelog CP.101Dokumen1 halamanBorelog CP.101radixkusumaBelum ada peringkat

- MAOH600 Ropu 48 Presentation Script and ReferencesDokumen10 halamanMAOH600 Ropu 48 Presentation Script and ReferencesFano AsiataBelum ada peringkat

- Tuyet W3 Unit 2 Tenses Adverbial Clause of Time Zalo HSDokumen16 halamanTuyet W3 Unit 2 Tenses Adverbial Clause of Time Zalo HSVũ Thanh GiangBelum ada peringkat

- Geology Harn v1 2Dokumen17 halamanGeology Harn v1 2vze100% (1)

- Đề ANH chuyên 5Dokumen7 halamanĐề ANH chuyên 5Phạm Ngô Hiền MaiBelum ada peringkat

- Tackling Food Inflation: Ashwinkumar Kokku - 67 Malcolm Pinto - 89 Samir Vele - Nitin JadhavDokumen9 halamanTackling Food Inflation: Ashwinkumar Kokku - 67 Malcolm Pinto - 89 Samir Vele - Nitin JadhavMalcolm PintoBelum ada peringkat

- 7 Fuel Failure in Water Reactors - Causes and MitigationDokumen165 halaman7 Fuel Failure in Water Reactors - Causes and MitigationLauri RubertiBelum ada peringkat

- Pressure Vessels SHO ProgrammeDokumen42 halamanPressure Vessels SHO Programmehew ka yeeBelum ada peringkat

- Dryer Regenerative Blower Purge DBP 02250195 405 R00 PDFDokumen84 halamanDryer Regenerative Blower Purge DBP 02250195 405 R00 PDFjennyBelum ada peringkat

- SSP 465 12l 3 Cylinder Tdi Engine With Common Rail Fuel Injection SystemDokumen56 halamanSSP 465 12l 3 Cylinder Tdi Engine With Common Rail Fuel Injection SystemJose Ramón Orenes ClementeBelum ada peringkat

- 10.1.polendo (Additional Patent)Dokumen11 halaman10.1.polendo (Additional Patent)Rima AmaliaBelum ada peringkat

- Vaccination Schedule in Dogs and CatsDokumen3 halamanVaccination Schedule in Dogs and CatsAKASH ANANDBelum ada peringkat

- Emission Estimation Technique Manual: For Mining and Processing of Non-Metallic MineralsDokumen84 halamanEmission Estimation Technique Manual: For Mining and Processing of Non-Metallic MineralsAbdelaziem mahmoud abdelaalBelum ada peringkat

- What Has The Government and The Department of Health Done To Address To The Issues of Reproductive and Sexual Health?Dokumen5 halamanWhat Has The Government and The Department of Health Done To Address To The Issues of Reproductive and Sexual Health?Rica machells DaydaBelum ada peringkat