Shell Turbo: Premium Based Industrial Steam, Gas and Combined Cycle Turbine Lubricant

Diunggah oleh

faisalnadimJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Shell Turbo: Premium Based Industrial Steam, Gas and Combined Cycle Turbine Lubricant

Diunggah oleh

faisalnadimHak Cipta:

Format Tersedia

Technical Data Sheet

Shell Turbo S4 X 32 • Extra Long Oil Life

• Extra efficiency

Premium based industrial steam, gas and combined cycle turbine lubricant •

Shell Turbo S4 X 32 is based on Gas-to-Liquid (GTL) technology and has been developed to meet the demands

of the latest high efficiency turbine systems. Designed to offer outstanding, long term performance under the

most severe operating conditions Shell Turbo S4 X 32 will minimise deposit and sludge formation even under

cyclic peak loading conditions.

Performance, Features & Benefits

· Note that some applications with highly loaded gearboxes

· Extended oil life

require a lubricant with enhanced anti-wear performance -

for these applications use Shell Turbo S4 GX.

Shell Turbo S4 X 32 delivers exceptional resistance to

oxidation even under conditions of high oxidative and

thermal stress. Excellent results in both the ASTM dry

· Further industrial applications

Shell Turbo S4 X 32 may also be used for other industrial

TOST and the TOST life test (ASTM D943) demonstrate applications requiring a high performance gas turbine oil,

the potential for Shell Turbo S4 X 32 to offer extended such as the lubrication of turbo compressors.

service life and reduced maintenance costs when

compared to conventional mineral oil technology. Specifications, Approvals & Recommendations

· Enhanced Equipment protection

The greater resistance against varnish and sludge

Shell Turbo S4 X 32 meets & exceeds international

specification and requirements of the major turbine

formation provided by Shell Turbo S4 X 32 allows turbine

systems to operate reliably even during severe peak load manufacturers including:

operation. Minimising the formation of sludge and bearing

deposits not only reduces the wear of critical system · ASTM 4304-13 Type I & III

components, but can also reduce the risk of an unplanned

turbine shutdown. · GB (China) 11120-2011, L-TGA, L-TSA, L-TGSB

· Enhanced System Efficiency · DIN 51515 Part 1 L-TD & Part 2 L-TG

Demulsibility, air release and resistance to foaming are · ISO 8068, L-TGB and L-TGSB

critical performance factors for oil in the latest turbine

designs (especially turbines which have shorter oil

residence times). Shell Turbo S4 X 32 offers excellent

· Shell Turbo S4 X 32 is approved by Siemens Power

Generation, spec TLV 9013 04 and TLV 9013 05

performance in all three areas, ensuring that optimum

operating conditions are maintained.

Main Applications

· General Electric GEK 32568j, 46506e, 28143b, 107395a and

120498

· Alstom HTGD 90 117 V0001 Y

· Dresser Rand 003-406-001 type I & III

· Power and industrial steam, gas & combined cycle turbines

· Westinghouse 21 TO591 and 55125Z3 and Eng

Spec_DP21T-00000443

Shell Turbo S4 X 32 is used as the lubricating oil of choice

in modern steam, gas and combined cycle turbines. · Solar ES 9-224Y Class II

· MAN D&T SE TED 10000494596

· Shell Turbo S4 X 32 meets the specification of Elliott Turbo-

machinery X-18-0004

For a full listing of equipment approvals and

recommendations, please consult your local Shell Technical

Helpdesk.

Page 1 of 2 Shell Turbo S4 X 32, v 6.5

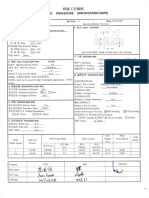

Typical Physical Characteristics

Properties Method Shell Turbo S4 X 32

ISO Viscosity Grade ISO 3448 32

Kinematic Viscosity @400C mm2/s ASTM D445 32.0

Kiematic Viscosity @1000C mm2/s ASTM D445 6.10

Viscosity Index ASTM D2270 141

Density @150C g/cm3 IP 365 0.827

0

Flash Point (COC) C ASTM D92 230

0

Pour Point C ASTM D97 -42

Neutralisation Number mg KOH/g ASTM D974 0.10

Air Release @500C Minutes ASTM D3427 1

Copper Corrosion 3hr/1000C ASTM D130 1b

Rust Preventing Properties ASTM D665 A & B No Rust

Water Separability minutes to 3 mL Minutes ASTM D1401 15

emulsion

Steam Demulsibility Seconds IP 19 80

Foaming Characteristics tendency, mL/mL ASTM D892

stability

Sequence I 0/0

Sequence II 0/0

Sequence III 0/0

Load Carrying - FZG - failure load stage DIN 51354 7

Oxidation Stability

RPVOT Minutes ASTM D2272 1400

Modified RPVOT % of RPVOT 95%

TOST lifetime hr ASTM D943 10 000+

TOST 1000hr sludge mg/kg ASTM D4310 20

Dry TOST @1200C ASTM D7873

Sludge Content at 25% RPVOT mg/kg 69

Hours 25% RPVOT mins 1322

These characteristics are typical of current production. Whilst future production will conform to Shell's specification,

variations in these characteristics may occur.

Health, Safety & Environment

· Health and Safety

Shell Turbo S4 X 32 is unlikely to present any significant health or safety hazard when properly used in the recommended

application and good standards of personal hygiene are maintained.

Avoid contact with skin. Use impervious gloves with used oil. After skin contact, wash immediately with soap and water.

Guidance on Health and Safety is available on the appropriate Material Safety Data Sheet (MSDS), which can be obtained

from www.epc.shell.com

· Protect the Environment

Take used oil to an authorized collection point. Do not discharge into drains, soil or water.

Additional Information

· Advice

Advice on applications not covered here may be obtained from your Shell representative.

Page 2 of 2 Shell Turbo S4 X 32, v 6.5

Anda mungkin juga menyukai

- Shell Turbo S4 X 32Dokumen3 halamanShell Turbo S4 X 32Muhammad SaputraBelum ada peringkat

- Shell Turbo S4 GX 46: Performance, Features & BenefitsDokumen3 halamanShell Turbo S4 GX 46: Performance, Features & BenefitsHEENA SHAIKHBelum ada peringkat

- Shell GT32 1451468381Dokumen2 halamanShell GT32 1451468381Pramod SokhariyaBelum ada peringkat

- Technical Data Sheet for High Performance Industrial Gas Turbine Lubricant Shell Turbo GT 32Dokumen2 halamanTechnical Data Sheet for High Performance Industrial Gas Turbine Lubricant Shell Turbo GT 32Raden ArdyBelum ada peringkat

- Shell Turbo Oil T32: Performance, Features & BenefitsDokumen2 halamanShell Turbo Oil T32: Performance, Features & BenefitsHANIF AKBARBelum ada peringkat

- Shell Turbo T32: Performance, Features & Benefits Main ApplicationsDokumen3 halamanShell Turbo T32: Performance, Features & Benefits Main ApplicationsPandu SatrioBelum ada peringkat

- Shell Turbo T 32 PDFDokumen2 halamanShell Turbo T 32 PDFaqas_khanBelum ada peringkat

- Shell Turbo Oil T32: Performance, Features & BenefitsDokumen2 halamanShell Turbo Oil T32: Performance, Features & BenefitsElias GabrielBelum ada peringkat

- Shell Turbo Oil T 32 Technical Data SheetDokumen2 halamanShell Turbo Oil T 32 Technical Data SheetMuhammad SaputraBelum ada peringkat

- Shell Turbo Oil T32: Performance, Features & BenefitsDokumen2 halamanShell Turbo Oil T32: Performance, Features & BenefitsCertified Rabbits LoverBelum ada peringkat

- Shell Turbo Oil T46: Performance, Features & Benefits Main ApplicationsDokumen4 halamanShell Turbo Oil T46: Performance, Features & Benefits Main Applicationshaider100% (1)

- Shell Turbo T 68Dokumen2 halamanShell Turbo T 68Eid EeidBelum ada peringkat

- Shell Turbo Oil T 68 Technical Data SheetDokumen2 halamanShell Turbo Oil T 68 Technical Data SheetMuhammad SaputraBelum ada peringkat

- Shell Turbo Oil T 68 Technical Data SheetDokumen2 halamanShell Turbo Oil T 68 Technical Data SheetAntonio CardosoBelum ada peringkat

- Gpcdoc Local Tds Iraq Shell Turbo T 68 (Ar-Iq) TdsDokumen2 halamanGpcdoc Local Tds Iraq Shell Turbo T 68 (Ar-Iq) TdsBar AvaitBelum ada peringkat

- Shell Turbo Oil T 32 TDSDokumen2 halamanShell Turbo Oil T 32 TDSBahim BahimanBelum ada peringkat

- GPCDOC Local TDS Pakistan Shell Turbo Oil T 46 (ur-PK) TDS PDFDokumen2 halamanGPCDOC Local TDS Pakistan Shell Turbo Oil T 46 (ur-PK) TDS PDFSefa yıldızBelum ada peringkat

- Shell Turbo Oil T46: Performance, Features & Benefits Main ApplicationsDokumen2 halamanShell Turbo Oil T46: Performance, Features & Benefits Main ApplicationsMOHAMED GamalBelum ada peringkat

- Gpcdoc Local Tds Iraq Shell Turbo T 32 (Ar-Iq) TdsDokumen3 halamanGpcdoc Local Tds Iraq Shell Turbo T 32 (Ar-Iq) Tds100impianBelum ada peringkat

- CC 46 - Premium Quality Industrial Gas, Steam &combined Cycle Turbine OilDokumen2 halamanCC 46 - Premium Quality Industrial Gas, Steam &combined Cycle Turbine OilRaden ArdyBelum ada peringkat

- J 32 - Premium Industrial Turbine OilDokumen2 halamanJ 32 - Premium Industrial Turbine OilRaden ArdyBelum ada peringkat

- Shell Rimula R4 L 15W-40: Performance, Features & Benefits Specifications, Approvals & RecommendationsDokumen2 halamanShell Rimula R4 L 15W-40: Performance, Features & Benefits Specifications, Approvals & RecommendationsAMITBelum ada peringkat

- Shell Turbo Oil J 32Dokumen2 halamanShell Turbo Oil J 32Muhammad SaputraBelum ada peringkat

- Turbo Oil T 46Dokumen2 halamanTurbo Oil T 46Parthiban SowndararajanBelum ada peringkat

- UAE Shell Turbo Oil T 46Dokumen3 halamanUAE Shell Turbo Oil T 46diego lizaldes valarezoBelum ada peringkat

- Shell Turbo Oil T 46 Technical Data SheetDokumen2 halamanShell Turbo Oil T 46 Technical Data SheetwasayBelum ada peringkat

- Shell Rimula R3 X 15W-40 (CH-4/228.3) : Performance, Features & Benefits Specifications, Approvals & RecommendationsDokumen2 halamanShell Rimula R3 X 15W-40 (CH-4/228.3) : Performance, Features & Benefits Specifications, Approvals & RecommendationsSounak SasmalBelum ada peringkat

- Shell Turbo Oil T 46Dokumen2 halamanShell Turbo Oil T 46Muhammad SaputraBelum ada peringkat

- Shell Turbo T 46Dokumen2 halamanShell Turbo T 46Salem IereebiBelum ada peringkat

- FT Grease 22Dokumen2 halamanFT Grease 22Edgar Leonel CortésBelum ada peringkat

- Shell Rimula R3 Turbo 15W-40Dokumen2 halamanShell Rimula R3 Turbo 15W-40HUM CIREBON DFLTSBelum ada peringkat

- Shell Turbo Oil J 32Dokumen2 halamanShell Turbo Oil J 32Agus F RahmanBelum ada peringkat

- Shell Rimula R3 X 20W-50 (CH-4/228.3) : Performance, Features & BenefitsDokumen2 halamanShell Rimula R3 X 20W-50 (CH-4/228.3) : Performance, Features & Benefitssamsoon80Belum ada peringkat

- Triple Protection Heavy Duty Diesel Engine OilDokumen2 halamanTriple Protection Heavy Duty Diesel Engine OilAbel Carhuapoma100% (1)

- Rimula R4 L 15W-40 - TDS - enDokumen2 halamanRimula R4 L 15W-40 - TDS - enviktor chervonenkoBelum ada peringkat

- Helix Ultra Professional AG 5W-30 (Dexos 2)Dokumen2 halamanHelix Ultra Professional AG 5W-30 (Dexos 2)rstec pyBelum ada peringkat

- Shell Rimula R3 X 15W 40 TDSDokumen2 halamanShell Rimula R3 X 15W 40 TDSUmair AbbasBelum ada peringkat

- Shell Rimula R3 X 15W-40: Performance, Features & BenefitsDokumen2 halamanShell Rimula R3 X 15W-40: Performance, Features & Benefitsمحمد إحسنBelum ada peringkat

- Shell Rimula R4L 15W-40 DatasheetDokumen2 halamanShell Rimula R4L 15W-40 Datasheetphankhoa83-1Belum ada peringkat

- Shell Turbo Oil T 100Dokumen2 halamanShell Turbo Oil T 100Muhammad SaputraBelum ada peringkat

- Techinical Data-Proton X70 DCT FluidDokumen2 halamanTechinical Data-Proton X70 DCT Fluidjasonccw.pqholdingsBelum ada peringkat

- Shell Rimula R4 15W-40 (CI-4 Plus) : Performance, Features & Benefits Specifications, Approvals & RecommendationsDokumen2 halamanShell Rimula R4 15W-40 (CI-4 Plus) : Performance, Features & Benefits Specifications, Approvals & RecommendationsVimal GopalakrishnanBelum ada peringkat

- Aeroshell Grease 22: Main Applications Specifications, Approvals & RecommendationsDokumen2 halamanAeroshell Grease 22: Main Applications Specifications, Approvals & RecommendationsyierbBelum ada peringkat

- GPCDOC Local TDS Oman Shell Rimula R3+ 40 CF 228.0 en TDS v1Dokumen2 halamanGPCDOC Local TDS Oman Shell Rimula R3+ 40 CF 228.0 en TDS v1Nokiabhre WijayaBelum ada peringkat

- Shell Turbo Oilj32: Performance, Features & Benefits Main ApplicationsDokumen2 halamanShell Turbo Oilj32: Performance, Features & Benefits Main ApplicationsBahim BahimanBelum ada peringkat

- Shell Helix Ultra Professional AF 5W-30: Performance, Features & BenefitsDokumen2 halamanShell Helix Ultra Professional AF 5W-30: Performance, Features & BenefitsCristiBvBelum ada peringkat

- Shell AgDokumen2 halamanShell AgAndrei30Belum ada peringkat

- EfekDokumen2 halamanEfekGasa RafliBelum ada peringkat

- Sirius X 40 TdsDokumen2 halamanSirius X 40 TdsNikolas LarenBelum ada peringkat

- Shell Spirax S5 DCT 11: Performance, Features & Benefits Main ApplicationsDokumen2 halamanShell Spirax S5 DCT 11: Performance, Features & Benefits Main ApplicationsFernando Yupa SalazarBelum ada peringkat

- Aeroshell Fluid 31Dokumen2 halamanAeroshell Fluid 31mertaktayBelum ada peringkat

- Shell Morlina s2 BL 10 France TdsDokumen2 halamanShell Morlina s2 BL 10 France TdsRolando GuijarroBelum ada peringkat

- Shell Rimula Light Duty LD4 Extra 15W-40Dokumen2 halamanShell Rimula Light Duty LD4 Extra 15W-40Muhammad SaputraBelum ada peringkat

- Gpcdoc Local Tds Oman Shell Rimula r4 15w-40 (Ci-4) (En) Tds v1Dokumen2 halamanGpcdoc Local Tds Oman Shell Rimula r4 15w-40 (Ci-4) (En) Tds v1Anonymous zTFaHayRdBelum ada peringkat

- GPCDOC Local TDS Canada Shell Turbo T 68 (en-CA) TDS v1Dokumen2 halamanGPCDOC Local TDS Canada Shell Turbo T 68 (en-CA) TDS v1abid azizBelum ada peringkat

- Shell Turbo T46 PDFDokumen2 halamanShell Turbo T46 PDFdionisio emilio reyes jimenezBelum ada peringkat

- Mobil Type 8000 Turbine OilDokumen4 halamanMobil Type 8000 Turbine OilJJBelum ada peringkat

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsDari EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsPenilaian: 5 dari 5 bintang5/5 (1)

- Thermo-hydrodynamic Lubrication in Hydrodynamic BearingsDari EverandThermo-hydrodynamic Lubrication in Hydrodynamic BearingsBelum ada peringkat

- ATT03 Pages From HTGD693025V9019 Disassembly of The Intermediate Bearing PedestalDokumen16 halamanATT03 Pages From HTGD693025V9019 Disassembly of The Intermediate Bearing PedestalfaisalnadimBelum ada peringkat

- M26831 - NEW - (For IGV N VSV) - 5 - 18Dokumen36 halamanM26831 - NEW - (For IGV N VSV) - 5 - 18faisalnadimBelum ada peringkat

- How To Search Product HuntingDokumen5 halamanHow To Search Product HuntingShadab FaysalBelum ada peringkat

- Goat Fattening Farm 450 Animals Rs. 7.35 Million Mar-2018Dokumen25 halamanGoat Fattening Farm 450 Animals Rs. 7.35 Million Mar-2018Ashat Ul Haq100% (1)

- Divertor DamperDokumen53 halamanDivertor DamperfaisalnadimBelum ada peringkat

- Sourcing Secerets Ali-BabaDokumen5 halamanSourcing Secerets Ali-BabafaisalnadimBelum ada peringkat

- Rdlo / Rdlo V: Axially Split Volute Casing PumpDokumen24 halamanRdlo / Rdlo V: Axially Split Volute Casing PumpfaisalnadimBelum ada peringkat

- Operating Manual: BHIKKI 1180MW CCPP Project Serve OnlyDokumen62 halamanOperating Manual: BHIKKI 1180MW CCPP Project Serve OnlyfaisalnadimBelum ada peringkat

- p92 & t23 - Esope France, 2004Dokumen1 halamanp92 & t23 - Esope France, 2004faisalnadimBelum ada peringkat

- General Overhead Crane Maintenance GuideDokumen18 halamanGeneral Overhead Crane Maintenance GuidefaisalnadimBelum ada peringkat

- Exercise 3: Problem StatementDokumen2 halamanExercise 3: Problem StatementfaisalnadimBelum ada peringkat

- Symbols PDFDokumen2 halamanSymbols PDFKuttappa I GBelum ada peringkat

- Heatexchangers 140603082139 Phpapp01Dokumen67 halamanHeatexchangers 140603082139 Phpapp01esamhamadBelum ada peringkat

- How To Create Store On FacebookDokumen20 halamanHow To Create Store On FacebookfaisalnadimBelum ada peringkat

- WPS P008Dokumen1 halamanWPS P008faisalnadimBelum ada peringkat

- Performance Monitoring Guidelines For Power PlantsDokumen1 halamanPerformance Monitoring Guidelines For Power PlantsKeyur Patel0% (1)

- ALLWEIR NTT40 PumpDokumen12 halamanALLWEIR NTT40 PumpfaisalnadimBelum ada peringkat

- p92 & t23 - Esope France, 2004Dokumen13 halamanp92 & t23 - Esope France, 2004adityadhBelum ada peringkat

- 5 ImpactsDokumen60 halaman5 ImpactsfaisalnadimBelum ada peringkat

- Weekly preventive maintenance scheduleDokumen2 halamanWeekly preventive maintenance schedulefaisalnadimBelum ada peringkat

- Biomass Pretreatment: Mats Galbe Dept. Chemical Engineering Lund UniversityDokumen57 halamanBiomass Pretreatment: Mats Galbe Dept. Chemical Engineering Lund UniversityfaisalnadimBelum ada peringkat

- 5 ImpactsDokumen8 halaman5 ImpactsfaisalnadimBelum ada peringkat

- 4 Types of Heat Exchanger Failures ArticleDokumen6 halaman4 Types of Heat Exchanger Failures ArticleAamir KhanBelum ada peringkat

- Fuel Oil System DescriptionDokumen11 halamanFuel Oil System DescriptionfaisalnadimBelum ada peringkat

- Calculation of Thermal Stress and Fatigue Life of 1000 MW Steam Turbine RotorDokumen6 halamanCalculation of Thermal Stress and Fatigue Life of 1000 MW Steam Turbine RotorLe Anh TuanBelum ada peringkat

- I.G.V Openning and Closing CurveDokumen3 halamanI.G.V Openning and Closing CurveHussam Baiee100% (3)

- Guidelines 0n Pump Vibration First Edition Final July 2013Dokumen17 halamanGuidelines 0n Pump Vibration First Edition Final July 2013ridzim4638Belum ada peringkat

- Real Time Water Wash System of Gas Turbine in Power PlantDokumen4 halamanReal Time Water Wash System of Gas Turbine in Power PlantfaisalnadimBelum ada peringkat

- Guidelines 0n Pump Vibration First Edition Final July 2013Dokumen17 halamanGuidelines 0n Pump Vibration First Edition Final July 2013ridzim4638Belum ada peringkat

- 2006 j6Dokumen12 halaman2006 j6faisalnadimBelum ada peringkat

- Manual de Servicio Ventilador Bear Cub 750psvDokumen64 halamanManual de Servicio Ventilador Bear Cub 750psvVladimir BorjaBelum ada peringkat

- End Indifference - Pope: Stray Bullet Cases Hit 36 Firecrackers Injure 459Dokumen56 halamanEnd Indifference - Pope: Stray Bullet Cases Hit 36 Firecrackers Injure 459Art JasmeBelum ada peringkat

- SelectionList R1 WebDokumen586 halamanSelectionList R1 WebVishakha SutarBelum ada peringkat

- Plano FarmasiDokumen44 halamanPlano FarmasiAna Cristina MachadoBelum ada peringkat

- Posterior Open Bite CausesDokumen30 halamanPosterior Open Bite CauseschaitreeBelum ada peringkat

- Interpretation: L23 - FPSC Malviya Nagar1 A-88 Shivanand Marg, Malviyanagar JaipurDokumen4 halamanInterpretation: L23 - FPSC Malviya Nagar1 A-88 Shivanand Marg, Malviyanagar Jaipurmahima goyalBelum ada peringkat

- Ruhs College of Nursing Sciences, Jaipur: Assignment ON Sampling TechniquesDokumen13 halamanRuhs College of Nursing Sciences, Jaipur: Assignment ON Sampling TechniquesDr-Sanjay SinghaniaBelum ada peringkat

- Hematology Sample QuestionsDokumen5 halamanHematology Sample QuestionsEarleen Del Rosario100% (1)

- Paediatric Dermatology: by EmilyDokumen42 halamanPaediatric Dermatology: by EmilySilviuBelum ada peringkat

- Marriage Equality, It's Just RightDokumen1 halamanMarriage Equality, It's Just RightAlphonse L. Williams IIIBelum ada peringkat

- WHO - Ammonia Chemical FactsheetDokumen4 halamanWHO - Ammonia Chemical FactsheetMark Joseph AbelleraBelum ada peringkat

- Infectious DiseasesDokumen4 halamanInfectious Diseasesapi-484776271Belum ada peringkat

- Bakteri Anaerob: Morfologi, Fisiologi, Epidemiologi, Diagnosis, Pemeriksaan Sy. Miftahul El J.TDokumen46 halamanBakteri Anaerob: Morfologi, Fisiologi, Epidemiologi, Diagnosis, Pemeriksaan Sy. Miftahul El J.TAlif NakyukoBelum ada peringkat

- Incident Report PortfolioDokumen2 halamanIncident Report Portfolioapi-397923551Belum ada peringkat

- Stretching - Anderson, Bob PDFDokumen194 halamanStretching - Anderson, Bob PDFxehupatl100% (6)

- Masonry QuizDokumen12 halamanMasonry QuizJoanne Jose Castro0% (1)

- Rhetorical Analysis Revision Final ProjectDokumen13 halamanRhetorical Analysis Revision Final Projectapi-371084574100% (1)

- Good Will Hunting Report AnalysisDokumen8 halamanGood Will Hunting Report AnalysislylavanesBelum ada peringkat

- Margie Roselle G. Opay Grade 11 STEM: (Monroe's Motivated Sequence Attention)Dokumen2 halamanMargie Roselle G. Opay Grade 11 STEM: (Monroe's Motivated Sequence Attention)Margie OpayBelum ada peringkat

- Planning Design and Analysis of G+1 Hospital Building For Iiit Srikakulam CampusDokumen1 halamanPlanning Design and Analysis of G+1 Hospital Building For Iiit Srikakulam CampusSaritha TejavathBelum ada peringkat

- Brochure Men - Ingrid Auer - Angel Essences To Help MenDokumen4 halamanBrochure Men - Ingrid Auer - Angel Essences To Help MenJoanne JacksonBelum ada peringkat

- Hyperglycemic Hyperosmolar State - A Diabetic EmergencyDokumen2 halamanHyperglycemic Hyperosmolar State - A Diabetic EmergencyNiken AninditaBelum ada peringkat

- Flora-Focus® Lactobacillus Reuteri LR-G100 200billionDokumen2 halamanFlora-Focus® Lactobacillus Reuteri LR-G100 200billionUmar AliBelum ada peringkat

- S.No. Block Name of The Vaccination Centre CategoryDokumen2 halamanS.No. Block Name of The Vaccination Centre CategoryRajesh RawatBelum ada peringkat

- Timetable Theory-August 2023Dokumen22 halamanTimetable Theory-August 2023SueBelum ada peringkat

- TG 6 Refractive ErrorDokumen11 halamanTG 6 Refractive ErrorNovi AdriBelum ada peringkat

- Narrative Report: Intro To GMP, Hand Washing and Personal HygieneDokumen6 halamanNarrative Report: Intro To GMP, Hand Washing and Personal HygieneKrystelle Mae Salas AbuyogBelum ada peringkat

- Mita Das (Universityof CalcuttaDokumen52 halamanMita Das (Universityof CalcuttaBishal Roy100% (1)

- Cultural Differences in Travel Risk PerceptionDokumen20 halamanCultural Differences in Travel Risk PerceptionEsther Charlotte Williams100% (2)

- Career Path PDFFFFDokumen2 halamanCareer Path PDFFFFapi-410567922Belum ada peringkat