Workshop Inspection Checklist: Safe@Work

Diunggah oleh

ChickenChick070 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

23 tayangan4 halamansdsad

Judul Asli

uow016946

Hak Cipta

© © All Rights Reserved

Format Tersedia

PDF, TXT atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen Inisdsad

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

23 tayangan4 halamanWorkshop Inspection Checklist: Safe@Work

Diunggah oleh

ChickenChick07sdsad

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

Anda di halaman 1dari 4

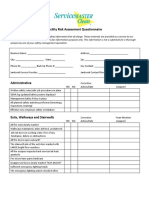

SAFE@WORK

WORKSHOP INSPECTION CHECKLIST

Inspection Team Members:

Workshop Room No: Workshop Supervisor: Inspection Date:

Instructions:

Boxes to be marked ticked () as items are sighted or with a cross(x) if not present. Otherwise NA indicates the

item is not applicable to this laboratory. Any question marked with a cross requires a corrective action.

Any corrective actions which cannot be immediately resolved are to be entered into the SafetyNet Hazard-Incident

Report Form at the completion of the inspection to assess the risk and determine appropriate controls,

responsibilities and time frames.

If the corrective action is immediately completed please write “Completed” in the column with the heading

“SAFETYNET REF.NO”.

If a maintenance number has been identified please enter the BEIMS number in the column with the heading

“SAFETYNET REF.NO”.

SafetyNet

Criteria X NA Corrective Action

Ref. No.

Work Environment

The general area is tidy and free of obstruction and mess.

Spaces between and under benches, cabinets and equipment

are accessible for cleaning.

Walkways/floor areas are clear of obstructions and trip

hazards (e.g. electrical cords).

Floor surfaces/coverings are even, not slippery and are in

good condition.

Stair treads are in good condition (no worn or broken treads).

Handrails present, secure, and in good condition.

Landings are clear of obstruction.

Lighting adequate and operational

Temperature is comfortable

Area is free from odours

Noise level is acceptable or controlled to an adequate level

Ventilation is adequate

Hand basin or alternative means of decontaminating hands is

available within the area.

Facilities for the storage of outer garments and personal items

are available outside the room.

Walkways/forklift areas are clearly marked

Signage

First aid signage is visible and contains details of first aid

officers for the area.

An Emergency Evacuation Diagram (from FMD) is located in

the near vicinity and is clearly displayed.

Exit signs are in place and illuminated.

Building warden signage is visible and contains details of

building wardens for the area.

HRD-WHS-FRM-034.14 Workshop Inspection Checklist 2017 March Page 1 of 4

SafetyNet

Criteria X NA Corrective Action

Ref. No.

Hazard/safety signage on entrance/s clearly visible and

contains information including:

• Authorized access only

• No food or drink

• Type of chemicals

• Lab supervisor details

Emergency Requirements

Exit doors are marked, clearly visible and can be opened from

inside (no pad-locks).

Exit corridors are clear of obstructions (including outside of

the building).

A first aid kit is located in the near vicinity.

Fire equipment (fire blanket, extinguisher, hose reel) is

accessible and clear of obstruction.

Fire equipment (fire blanket, extinguisher, hose reel) have

been inspected/tagged within the last 6 months.

Overhead sprinklers and detectors are clear of obstruction.

Safety shower and emergency eye wash station is functional

and easily accessible.

‘Experiments in Progress’ are labeled with procedures

outlining response in case of emergency.

Electrical

Electrical equipment tested, tagged and in date.

All power leads, outlets and switches are in good condition

(not broken).

Extension leads / power boards are used as designed (no

temporary or makeshift leads/power boards, double adaptors,

overloading).

Hazardous Manual Tasks

Frequently used items within easy reach between knee and

shoulder height, heavy items stored at waist height.

Step ladders or stools are accessible to access items stored on

high shelves if required and are in good condition.

Materials handling equipment available for heavy or awkward

items and loads

Personal Protective Equipment

PPE is available and in good condition.

PPE is stored appropriately.

Signage of PPE requirements displayed.

Chemical

Chemicals stored in appropriate containers.

Containers are labelled correctly (e.g. not handwritten, label

contains minimum chemical name and GHS pictogram).

Chemicals are stored according to compatibility.

Compatibility chart is readily available.

Dangerous goods cabinets are used and maintained in

accordance with the relevant Australian Standard including:

• Self-closing and close fitting doors

• Locking automatically (flammable)

• Locking mechanism in 2 or more places

(flammable/corrosive)

• Self-releasing locking mechanism (oxidizing agents

and organic peroxides)

• Clearance from ignition/heat sources (flammable,

oxidizing agents, organic peroxides)

• Bunding

• Ventilation

HRD-WHS-FRM-034.14 Workshop Inspection Checklist 2017 March Page 2 of 4

SafetyNet

Criteria X NA Corrective Action

Ref. No.

• Other specific requirements

Maximum volumes of chemicals in laboratory inventory has

been checked (and recorded) against ChemAlert stock

holdings in the past 12 months

There is bunding or spill trays for the storage of hazardous

liquids.

Spill kits are available and maintained.

Refrigerators used to store flammable materials are

intrinsically safe.

Refrigerators are suitably labeled (e.g. no food, no drink, no

flammables, biohazard).

Segregated waste disposable containers are available and

labelled correctly.

Materials that are subject to spontaneous combustion, such as

oily rags and paint rags, placed in approved oily waste cans

that are emptied daily.

Compressed Gas

Compressed gas cylinder contents are appropriately identified.

Cylinders are secured appropriately by bracket or chain.

All cylinders are at least 3m away from ignition sources,

combustible material and are stored according to dangerous

goods class with compatible gases.

Empty cylinders are separated from full cylinders and clearly

labelled.

Appropriate resources (eg. cylinder trolley) are available for

transporting gas cylinders.

The regulator is appropriate for the gas being used (e.g.

stainless steel for corrosive gases, brass for non-corrosive

gases).

Gas lines are labelled and free of leaks, kinks, signs of wear &

tear.

Gas use is confined to areas with good local exhaust

ventilation.

Cylinders, pipes and valves are protected from mechanical

damage.

Cryogenics

Dewars < 25 L have handles and loose fitting lids.

Dewars > 25 L have wheels and pressure release valves.

Cryogen storage areas are appropriately ventilated.

Wet Areas

Floor/area free from water and being wet

Drains (floors and sink ) clear and free flowing

Taps free from drips

Plant & Equipment

Area around plant clean

Plant and equipment maintained and in good condition

Plant cannot be operated/accessed when unattended

Emergency stops are working.

Guarding on plant and equipment is in good condition.

Log book maintained for use

Warning labels/procedures on equipment

Welding screens maintained and in good condition

HRD-WHS-FRM-034.14 Workshop Inspection Checklist 2017 March Page 3 of 4

SafetyNet

Criteria X NA Corrective Action

Ref. No.

Other Comments:

HRD-WHS-FRM-034.14 Workshop Inspection Checklist 2017 March Page 4 of 4

Anda mungkin juga menyukai

- 5S: A Practical Guide to Visualizing and Organizing Workplaces to Improve ProductivityDari Everand5S: A Practical Guide to Visualizing and Organizing Workplaces to Improve ProductivityPenilaian: 5 dari 5 bintang5/5 (3)

- Accommodation Inspection Checklist: Safe@WorkDokumen4 halamanAccommodation Inspection Checklist: Safe@WorkMontadhar HaithamBelum ada peringkat

- The Concise Calibration & Test Equipment Management Guide: The Concise Collection, #1Dari EverandThe Concise Calibration & Test Equipment Management Guide: The Concise Collection, #1Penilaian: 4.5 dari 5 bintang4.5/5 (2)

- Laboratory Inspection Checklist: Safe@WorkDokumen5 halamanLaboratory Inspection Checklist: Safe@WorkAlpha Excellence consultingBelum ada peringkat

- The Safety Relief Valve Handbook: Design and Use of Process Safety Valves to ASME and International Codes and StandardsDari EverandThe Safety Relief Valve Handbook: Design and Use of Process Safety Valves to ASME and International Codes and StandardsPenilaian: 3.5 dari 5 bintang3.5/5 (14)

- Accommodation Inspection Checklist: Safe@WorkDokumen4 halamanAccommodation Inspection Checklist: Safe@WorkAccrescenet hseBelum ada peringkat

- Labour Camp InspectionDokumen4 halamanLabour Camp InspectionChandirprakash KrishnamoorthyBelum ada peringkat

- Inspection ChecklistDokumen4 halamanInspection ChecklistAli haiderBelum ada peringkat

- General Areas Inspection ListDokumen4 halamanGeneral Areas Inspection ListbkgboqdraftsmanBelum ada peringkat

- Check List: Managing Industrial Technology & Design WorkspacesDokumen5 halamanCheck List: Managing Industrial Technology & Design Workspacesmohammed sameeullahBelum ada peringkat

- Surface Exploration Drilling ChecklistDokumen5 halamanSurface Exploration Drilling ChecklistZulfiqar HyderBelum ada peringkat

- 22-SAFETY Inspection Checklists: Hsseworld Com Health, Safety, Security and EnvironmentDokumen30 halaman22-SAFETY Inspection Checklists: Hsseworld Com Health, Safety, Security and EnvironmentMohammed Hasnain Saleem/KSA/EMD100% (1)

- MHI - Safety Audit Inspection ChecklistDokumen4 halamanMHI - Safety Audit Inspection ChecklistDominic John Armada0% (1)

- 22 Safety ChecklistsDokumen30 halaman22 Safety ChecklistsIrvys G. Juarez Dordi100% (2)

- Facility safety checklist SEODokumen5 halamanFacility safety checklist SEOAnuj Kjoy67% (3)

- Construction Industry Inspection Checklist (Long Version)Dokumen6 halamanConstruction Industry Inspection Checklist (Long Version)Usman ShahidBelum ada peringkat

- (F-L3-MR-188) Workplace Inspection SheetDokumen1 halaman(F-L3-MR-188) Workplace Inspection SheetAbdul MueedBelum ada peringkat

- All Safety Inspection ChecklistsDokumen30 halamanAll Safety Inspection ChecklistsSagar Sharma50% (2)

- ISBN Health and Safety Self Assessment Checklist For Small Businesses 2021 08Dokumen7 halamanISBN Health and Safety Self Assessment Checklist For Small Businesses 2021 08Essam El-DesokeyBelum ada peringkat

- HSE Inspection - ChecklistDokumen30 halamanHSE Inspection - ChecklistMutaman EldirdiriBelum ada peringkat

- Process Safety Check List 2Dokumen2 halamanProcess Safety Check List 2renjithv_4Belum ada peringkat

- Workplace Inspection Checklist - Workshop EnvironmentDokumen2 halamanWorkplace Inspection Checklist - Workshop Environmentjustine84480% (1)

- Offsite Storage Location AuditDokumen3 halamanOffsite Storage Location AuditnoorulatharBelum ada peringkat

- Facility Inspection ChecklistDokumen9 halamanFacility Inspection ChecklistdesignselvaBelum ada peringkat

- Gas CheklistDokumen1 halamanGas CheklistSoledayo Tom OsuntuyiBelum ada peringkat

- Compressed Gas Inspection ChecklistDokumen2 halamanCompressed Gas Inspection ChecklistlawsonchichoniBelum ada peringkat

- HS ChecklistDokumen8 halamanHS ChecklistVepxvia NadiradzeBelum ada peringkat

- Hazard CheckListDokumen6 halamanHazard CheckListbmkallarackalBelum ada peringkat

- PSSR ChecklistDokumen5 halamanPSSR ChecklistzhangjieBelum ada peringkat

- # Monthly Inspection Check List-PDDokumen7 halaman# Monthly Inspection Check List-PDArjun KoiralaBelum ada peringkat

- Intro Summary Main Findings and ConclusionDokumen4 halamanIntro Summary Main Findings and Conclusionjimento0% (1)

- ACCOMMODATION INSPECTION CHECKLIST - StaffDokumen2 halamanACCOMMODATION INSPECTION CHECKLIST - StaffAnvesh BondugulaBelum ada peringkat

- Planned Inspection & MaintenanceDokumen44 halamanPlanned Inspection & MaintenanceSn CarbonelBelum ada peringkat

- Hazop StudyDokumen49 halamanHazop Studychempraveen4u100% (1)

- Safety Industrial Safety Inspection ChecklistDokumen2 halamanSafety Industrial Safety Inspection ChecklistAhmadi HasanBelum ada peringkat

- Warehouse Audit ChecklistDokumen2 halamanWarehouse Audit ChecklistNada GHAZOUANI100% (1)

- Complete Internal Audit Checklist (HSE)Dokumen59 halamanComplete Internal Audit Checklist (HSE)Meer Jan89% (18)

- Guidance Checklist WebDokumen5 halamanGuidance Checklist WebmeidiansyahBelum ada peringkat

- Fire Safety AuditDokumen13 halamanFire Safety AuditRabhBelum ada peringkat

- Checklist for Auto Shop ComplianceDokumen2 halamanChecklist for Auto Shop CompliancelinteringBelum ada peringkat

- Audit ChecklistDokumen3 halamanAudit Checklistlbss22008Belum ada peringkat

- Checklist For Preparation of Visits by The Competent Inspection AuthoritiesDokumen18 halamanChecklist For Preparation of Visits by The Competent Inspection AuthoritiesSrinivas Polikepati100% (1)

- Workshop Inspection Checklist January 2012Dokumen12 halamanWorkshop Inspection Checklist January 2012Sundara MoorthyBelum ada peringkat

- Welding Checklist 9195Dokumen3 halamanWelding Checklist 9195Michael PenaBelum ada peringkat

- Laboratory Inspection Checklist Form Hsse World: SN Observations Recommendation (S) By: StatusDokumen4 halamanLaboratory Inspection Checklist Form Hsse World: SN Observations Recommendation (S) By: StatusMyolwinooBelum ada peringkat

- SOPs: Standard safety guidelinesDokumen3 halamanSOPs: Standard safety guidelinesMarella surendraBelum ada peringkat

- Standard Lab SOPDokumen6 halamanStandard Lab SOPrm101520271Belum ada peringkat

- Warehouse Audit ChecklistDokumen2 halamanWarehouse Audit ChecklistWalid Sonji82% (11)

- Hazard Identification - MethodDokumen12 halamanHazard Identification - Methodrnp2007123Belum ada peringkat

- Facility Risk Assessment QuestionnaireDokumen5 halamanFacility Risk Assessment QuestionnaireGrayBelum ada peringkat

- Facilities Inspection FormDokumen7 halamanFacilities Inspection FormMonching AdecerBelum ada peringkat

- Inspection ChecklistsDokumen6 halamanInspection Checklistsmegaspice0% (1)

- Chemical Handling StorageDokumen19 halamanChemical Handling StorageHartz Indharta100% (2)

- Lab Audit FormDokumen6 halamanLab Audit Formmahesh90600Belum ada peringkat

- CanteenDokumen4 halamanCanteenRydel CuachonBelum ada peringkat

- 5s ChecklistDokumen4 halaman5s ChecklistkalpeshankitaBelum ada peringkat

- Fire Risk AssessmentDokumen13 halamanFire Risk AssessmentAnand ChinnappanBelum ada peringkat

- Home Economics ChecklistDokumen3 halamanHome Economics ChecklistDawnBelum ada peringkat

- Porter Abs PDFDokumen6 halamanPorter Abs PDFSANJEEV KUMARBelum ada peringkat

- Product Bulletin Hazardous Area Classifications Protections en 123358Dokumen8 halamanProduct Bulletin Hazardous Area Classifications Protections en 123358mohamed abourayaBelum ada peringkat

- Q Q Q Q: Units Listed Numbers Checked Sources Referenced Inputs ListedDokumen2 halamanQ Q Q Q: Units Listed Numbers Checked Sources Referenced Inputs ListedChickenChick07Belum ada peringkat

- Mesh To Micron ConverterDokumen1 halamanMesh To Micron ConverterAniket royBelum ada peringkat

- Stainless Steel Fitting Specifications GuideDokumen2 halamanStainless Steel Fitting Specifications GuideChickenChick07Belum ada peringkat

- Ductile Iron Pipe Installation Guide 05 2015Dokumen134 halamanDuctile Iron Pipe Installation Guide 05 2015Anonymous R7EKGEDBelum ada peringkat

- Conditioning Orifice Plates Reduce Piping Requirements by Up to 96Dokumen8 halamanConditioning Orifice Plates Reduce Piping Requirements by Up to 96Uber_KonstruktorBelum ada peringkat

- STAHL Poster Safety RealityDokumen1 halamanSTAHL Poster Safety Realityedwardesjr100% (1)

- Q Q Q Q: Units Listed Numbers Checked Sources Referenced Inputs ListedDokumen2 halamanQ Q Q Q: Units Listed Numbers Checked Sources Referenced Inputs ListedChickenChick07Belum ada peringkat

- TEP10 Natural Gas Liquefaction - 2008Dokumen28 halamanTEP10 Natural Gas Liquefaction - 2008viknesh100% (1)

- Steel BracingsDokumen6 halamanSteel BracingsLleiLlei100% (1)

- SM4NS 4ar T V91a PDFDokumen1 halamanSM4NS 4ar T V91a PDFChickenChick07Belum ada peringkat

- ASME B31.3 InterpretationsDokumen44 halamanASME B31.3 InterpretationsChickenChick07Belum ada peringkat

- DEA Skirt With Fixation PDFDokumen1 halamanDEA Skirt With Fixation PDFChickenChick07Belum ada peringkat

- AUGI - Creating 2D Drawings From 3D AutoCAD ModelsDokumen23 halamanAUGI - Creating 2D Drawings From 3D AutoCAD ModelsMohan ShanmugamBelum ada peringkat

- DEA Skirt With Fixation PDFDokumen1 halamanDEA Skirt With Fixation PDFChickenChick07Belum ada peringkat

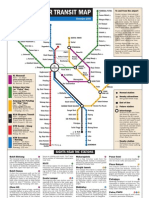

- KL Transit MapDokumen1 halamanKL Transit MapWong PfBelum ada peringkat

- ASME B31.3 InterpretationsDokumen44 halamanASME B31.3 InterpretationsChickenChick07Belum ada peringkat

- Support Bracket KitDokumen1 halamanSupport Bracket KitChickenChick07Belum ada peringkat

- SM4NS 4ar T V91aDokumen1 halamanSM4NS 4ar T V91aChickenChick07Belum ada peringkat

- Support Bracket KitDokumen1 halamanSupport Bracket KitChickenChick07Belum ada peringkat

- P07023 Oshiro Et AlDokumen15 halamanP07023 Oshiro Et AlChickenChick07Belum ada peringkat

- KL Transit MapDokumen1 halamanKL Transit MapWong PfBelum ada peringkat

- Stainless Steel Fitting Specifications GuideDokumen2 halamanStainless Steel Fitting Specifications GuideChickenChick07Belum ada peringkat

- Stainless Steel Fitting Specifications GuideDokumen2 halamanStainless Steel Fitting Specifications GuideChickenChick07Belum ada peringkat

- Support Bracket KitDokumen1 halamanSupport Bracket KitChickenChick07Belum ada peringkat

- KL Transit MapDokumen1 halamanKL Transit MapWong PfBelum ada peringkat

- Conditioning Orifice Plates Reduce Piping Requirements by Up to 96Dokumen8 halamanConditioning Orifice Plates Reduce Piping Requirements by Up to 96Uber_KonstruktorBelum ada peringkat

- Conditioning Orifice Plates Reduce Piping Requirements by Up to 96Dokumen8 halamanConditioning Orifice Plates Reduce Piping Requirements by Up to 96Uber_KonstruktorBelum ada peringkat

- KL Transit MapDokumen1 halamanKL Transit MapWong PfBelum ada peringkat

- Hydraulic Accumulator (High Pressure) - Test and Charge: Pruebas y AjustesDokumen16 halamanHydraulic Accumulator (High Pressure) - Test and Charge: Pruebas y AjustesBrayan Sánchez ParedesBelum ada peringkat

- Hydraulic Cylinder Overhaul Instructions Rev. 2.0 - LowDokumen56 halamanHydraulic Cylinder Overhaul Instructions Rev. 2.0 - Lowab hadi hafizin ab kaharBelum ada peringkat

- Penlon Prima SP2 Anaesthetic Machine - User Manual PDFDokumen44 halamanPenlon Prima SP2 Anaesthetic Machine - User Manual PDFjeison cardenasBelum ada peringkat

- Arc WelderDokumen13 halamanArc WelderNamdeo YengadeBelum ada peringkat

- Welding ProcedureDokumen14 halamanWelding Procedureamirhazwan100% (2)

- Cylinder LP Switch (POPREN50)Dokumen1 halamanCylinder LP Switch (POPREN50)nastyn-1Belum ada peringkat

- HTM 2022-2Dokumen96 halamanHTM 2022-2Arvish RamseebaluckBelum ada peringkat

- NFPA58 2011EditionvsProposed2020EditionafterEditingDokumen17 halamanNFPA58 2011EditionvsProposed2020EditionafterEditingcarry pamungkasBelum ada peringkat

- ISQ SparePartsGuideDokumen108 halamanISQ SparePartsGuideWimbi KalistaBelum ada peringkat

- Compressed Gas Cylinder Safety ProgramDokumen7 halamanCompressed Gas Cylinder Safety ProgramsafetyjasonBelum ada peringkat

- Catalogo Western Medica Reguladores y BalonesDokumen13 halamanCatalogo Western Medica Reguladores y BalonesSONDAN MEDICALBelum ada peringkat

- PSI Tier 3 Mobile Engine Fuel System Service Manual-I-1 PDFDokumen351 halamanPSI Tier 3 Mobile Engine Fuel System Service Manual-I-1 PDFRenato Sanchez100% (2)

- Cat 740 BDokumen13 halamanCat 740 BTom Souza100% (4)

- Safety Slide V2 PDFDokumen9 halamanSafety Slide V2 PDFSyukri Abd RahmanBelum ada peringkat

- Compressed Gas Cylinder SafetyDokumen3 halamanCompressed Gas Cylinder SafetyrishibarathiBelum ada peringkat

- Masterbuilt Mps 330G User ManualDokumen36 halamanMasterbuilt Mps 330G User ManualJoel AlvarezBelum ada peringkat

- Sans 9809-1:2010 Iso 9809-1:2010Dokumen5 halamanSans 9809-1:2010 Iso 9809-1:2010milouman01Belum ada peringkat

- Safety Data Sheet for ALUMAXX PLUS Gas MixtureDokumen13 halamanSafety Data Sheet for ALUMAXX PLUS Gas MixtureRichard StanleyBelum ada peringkat

- Idealarc SP-250Dokumen113 halamanIdealarc SP-250Manuel IzaguirreBelum ada peringkat

- DL079Dokumen43 halamanDL079Annie HawkinsBelum ada peringkat

- First211 Manual CompletDokumen30 halamanFirst211 Manual CompletpepeBelum ada peringkat

- Etil Chloride MsdsDokumen5 halamanEtil Chloride MsdsMank WidhieBelum ada peringkat

- Ford Mondeo 2001 10.2000-02.2007 Workshop Manual ( (10.2000-02.2007) ) PDFDokumen506 halamanFord Mondeo 2001 10.2000-02.2007 Workshop Manual ( (10.2000-02.2007) ) PDFAdel hodzicBelum ada peringkat

- Safety Officer Job Interview QuestionsDokumen8 halamanSafety Officer Job Interview QuestionsMhel DemabogteBelum ada peringkat

- Brochure Siex-Hc 227 Eng Web PDFDokumen12 halamanBrochure Siex-Hc 227 Eng Web PDFAhmed SalamaBelum ada peringkat

- Aircraft EM EquipmentsDokumen5 halamanAircraft EM EquipmentsLiridon ShalaBelum ada peringkat

- 7.1 Safety Precautions - Aircraft and WorkshopDokumen76 halaman7.1 Safety Precautions - Aircraft and WorkshopSeanRiniFernando33% (3)

- Multimatic 200Dokumen68 halamanMultimatic 200Darren PalmBelum ada peringkat

- V Range 502, 652, 802 Maintenance 7063773 Rev ADokumen220 halamanV Range 502, 652, 802 Maintenance 7063773 Rev AWilfer PimientoBelum ada peringkat

- GCR 2016 English PDFDokumen89 halamanGCR 2016 English PDFRanjana MadabushiBelum ada peringkat