KT Uk PDF

Diunggah oleh

ezzularabJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

KT Uk PDF

Diunggah oleh

ezzularabHak Cipta:

Format Tersedia

424.87 Kwikastrip_4:424.

68 HDB Studrail 6/5/10 09:40 Page 9

CI/SfB Xt6

May 2010

HALFEN KWIKASTRIP KT 10-EE

HALFEN KWIKASTRIP

CONCRETE

CONCRETE

424.87 Kwikastrip_4:424.68 HDB Studrail 6/5/10 09:39 Page 2

Halfen Kwikastrip® reinforcement continuity strip

Introduction

The concept of reinforcement

continuity strip has been in

widespread use throughout Europe

for over 20 years and repeatedly

demonstrates itself to be a simple,

time saving and cost effective

method of maintaining reinforcement

continuity across construction joints

in concrete.

The system comprises special

pre-bent reinforcement housed in

a purpose designed carrier casing –

all of which is fabricated off site in

a factory controlled environment.

On site, the entire unit is cast into

the face of the wall. After

the formwork is struck, the lid is

removed to reveal the connection

legs (or starter bars) laying inside

Halfen the casing. These legs are bent out

Halfen Limited is a leading supplier Technical support including: by the contractor, ready for lapping

of building fixings and • Application advice the main reinforcement of the

components, with manufacturing subsequent pour.

• Design guidance

and marketing centres worldwide. The casing remains embedded in

• Software training

For over 75 years Halfen has the wall, providing a rebate into

• Proposal drawings

maintained a position at the which the concrete of the adjoining

• Working drawings member is poured and eliminates

forefront of the construction fixings

market, establishing a reputation • Site visits the need for traditional preparation

for technological innovation, (i.e. scabbling) at the joint.

product reliability and customer Estimating support including:

service.

• Budget quotations

• Priced alternatives

• Product schedules

QA System including:

• BS EN ISO 9001: 2000

• Certificate of Conformity

• Design Warranty

2 Halfen reinforcement helpline: 01582 470300 www.halfen.co.uk

424.87 Kwikastrip_4:424.68 HDB Studrail 6/5/10 09:39 Page 3

Benefits Application

• Simplifies formwork design – Quite simply, any construction joint

bypasses construction joints in concrete has the potential to be

• Accelerates pour schedules – suits formed by this method. Normal

today’s fast track build methods applications include:

• Easy to use – an answer to skills • Walls

shortages of ‘chippies’ and steel • Floor slabs

fixers

• Staircase landings and flights

• No formwork damage or wastage

• Brick support nibs

– no drilled holes in shutters/no

• Corbels

wasted stop ends

• Pile caps

• Enables ‘system formwork’ to be

used – e.g. steel forms/climbing • Underpinning

and slip forms • Gulleys and chambers

• Starter bars remain protected and

clean – they are inside the casing

until needed

• No projecting bars – better working

access in confined areas and

improved site safety

• Improved shear connection –

provides additional formed

joint rebate

Halfen reinforcement helpline: 01582 470300 www.halfen.co.uk 3

424.87 Kwikastrip_4:424.68 HDB Studrail 6/5/10 09:39 Page 4

Installation of Kwikastrip

The Kwikastrip unit is either nailed Anchorage is achieved via the The available straightening tool (see

(through casing) to the shutter face, reinforcement delivered projecting opposite) enables the connection leg

or the projecting anchorage out of the casing. Lap is achieved via to be straightened correctly and

reinforcement is securely wired back the bent out connection legs, which efficiently.

to the main reinforcement cage and are spliced to the main reinforcement

The use of other implements (e.g.

the shutter offered up to it. of the subsequent concrete pour

hammers, scaffold tubes) will result in

(see figure 4).

The Kwikastrip unit is therefore adversely kinked starter bars and

sandwiched in position between the unacceptable work hardening of the

shutter and the main reinforcement Straightening of bars reinforcement that may adversely

cage. The concrete is then poured Reinforcement should only be affect performance of the system.

and the entire unit is cast into the straightened when the temperature The straightening tool is a steel tube

face of the concrete element/wall of the steel is 5ºC or above. Where with a specially shaped end and an

(see figure 1). the temperature of the reinforcement internal diameter only slightly greater

Stripping the shutter reveals the lid is below 5ºC, reinforcement may be than the diameter of the bar to be

on the wall face. The lid is removed indirectly warmed to a temperature straightened. The tube wall thickness

to reveal the connection legs (see not exceeding 100ºC but no form of adequately ensures that the tube will

figure 2), which should be bent out direct heat treatment shall be applied not flex under load.

using the available straightening tool to the reinforcement.

(see figure 3).

Figure 1 Figure 2

4 Halfen reinforcement helpline: 01582 470300 www.halfen.co.uk

424.87 Kwikastrip_4:424.68 HDB Studrail 6/5/10 09:39 Page 5

The length of the tube provides the The straightening operation should Typical counter-bending tool

necessary leverage to eliminate be smooth and progressive and the

undesirable ‘jerky’ movements, tube must be allowed to continuously

otherwise caused as a result of too ‘slip’ around the bend as it becomes

great a physical effort required by the straightened, so in its final ‘rest’

End Side

operative. position, the tube should be in

contact with the interface of the

The tube should be placed over the

embedded case and the bar now

bar and located at the start of the

projecting from it.

bend. The end of the tube is specially

shaped (see right) in order to The tube should then be withdrawn

minimise undesirable point contact of and the bar checked for suitable

the tube on the bar and, more alignment through the joint with due

importantly, to provide continuous consideration to the intended

support to the outside of the bend concrete cover.

during straightening.

Figure 3 Figure 4

Halfen reinforcement helpline: 01582 470300 www.halfen.co.uk 5

424.87 Kwikastrip_4:424.68 HDB Studrail 6/5/10 09:39 Page 6

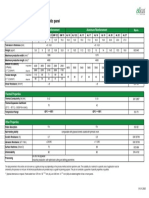

Kwikastrip range and how to order

State only the quantity, Kwikastrip Unit type Dimensions Bar type Bar spacings Lap ‘L’

unit type, bar type and bar centres.

e.g. 50 no. Kwikastrip M8.5S B12 M

B12 C150/C200 500

C150 STD 8.5S

35

The engineer should confirm the

application suitability of all

dimensions.

M

B12 C150/C200 500

Kwikastrip is available off the shelf in 15S

casing lengths of 1200mm. This 35

casing length is significant because

the end distances to the first and last

bars (75mm for 150mm centres and M

B12 C150/C200 500

100mm for 200mm bar centres) 17S 35

ensures that where the cases are

butted to one another, the correct

bar centres are accurately

maintained, as is the cross sectional M

B12 C150/C200 500

area of reinforcement through 19S 35

the construction joint.

200

M

170 B12 C150/C200 500

22S

35

Single leg hook bar 220

M

B12 C150/C200 500

25S 35

M

B16 C150/C200 650

12D

Double leg ‘U’ bar

120

M C150 600

B16

19D C200 650

Bar spacings

200

M

170 B16 C150/C200 650

22D 50

220

C150

M

B16 C150/C200 650

25D

C200

6 Halfen reinforcement helpline: 01582 470300 www.halfen.co.uk

424.87 Kwikastrip_4:424.68 HDB Studrail 6/5/10 09:39 Page 7

Frequently Asked Questions

Can Kwikastrip be cut on site?

Where Kwikastrip needs to be cut to We recommend removing one-bar When a case is shortened the

length, the case material can be cut sections from one or both ends of a remaining pullout bars will project

with a hand-held cut-off saw. Kwikastrip case to reduce the length from the cut ends. These can be

However, extreme care must be of a unit. If more than one unit overlapped into an adjacent unit by

taken not to damage the pullout bars occurs in a run we suggest one-bar removing the polystyrene end seal.

inside the case. sections are removed from a number Please be sure to reseal the cut ends

of units to achieve the required with polystyrene or a strong

reduction in length. formwork tape to prevent the ingress

of cement grout.

Cut point Cut point

N.B Safety

All safety regulations and tool

manufacturer’s instructions

must be observed when

cutting Kwikastrip. Cutting

may leave sharp edges so

suitable personal protection

equipment must be used.

Care must be taken Re-seal cut end Projecting bars Remove polystyrene

not to cut projecting with polystyrene end plug to accommodate

bars unless reduced end plug & tape projecting bars

lap length is acceptable

What are the loading differences If Kwikastrip isn’t feasible for my

between Kwikastrip and traditional application, what can I use instead?

loose/unbent rebar? In these situations, the Halfen HBM

Structural tests (by UK CARES) threaded coupler system forms an

showed that the flexural and shear ideal complement to Kwikastrip.

strength of construction joints formed Please ask for details.

with Kwikastrip are no less than

those of traditionally formed

construction joints.

Halfen reinforcement helpline: 01582 470300 www.halfen.co.uk 7

424.87 Kwikastrip_4:424.68 HDB Studrail 6/5/10 09:40 Page 8

Technical approval

Kwikastrip was the first-ever product Some concern is understandable, as system in its application entirety

to attain Technical Product Approval BS8110 states that high yield (i.e. casing and reinforcement cast

by the UK CARES Certification reinforcement should not be re-bent into concrete construction joints and

Authority for Reinforcing Steels. or straightened without the those joints then subjected to load).

In the UK, due to the absence of any engineer’s approval. The UK CARES Technical Approval

definitive British Standard covering As specialists, Halfen has been active fills this void, and offers

the subject, it has historically been a for many years in regularly testing reinforcement engineers sound data

matter of individual engineer opinion carefully selected reinforcement for by which they can design with

as to product application suitability. its suitability to be rebent, and increased confidence.

Such opinion had been reliant upon defining its subsequent performance

few factors; the manufacturer’s data, once rebent. Whilst this information

elements of relevant British Standards had served engineers well, there had

4449, 8666, and 8110, together with never before been any full-scale UK

individually gained experience. tests for a reinforcement continuity

The most fundamental consideration

had been the aspect of rebending

high yield reinforcement, which is a

prerequisite of the system.

Product testing

A copy of the In all wall/slab specimens the continuity moment. In all cases the samples exceeded

CARES

Technical Technical Approval reinforcement was 16mm diameter the ultimate loads calculated from BS8110.

Approval

Report TA2-5001 Report can be deformed bar, chosen as being the largest

Assessment of the Kwikastrip The structural tests showed that flexural

Product and the Quality System

for Production

downloaded from bar size normally used in the Kwikastrip

strength and shear strength of construction

www.halfen.co.uk system and which imposes the greatest

joints formed with the Kwikastrip system

or from stresses on the surrounding concrete and

are no less than those of equivalent

www.ukcares.co.uk the most severe demands on the

traditionally formed construction joints.

reinforcement in relation to bending and

straightening. The results of the comprehensive test

Several wall/slab joints and column/nib programme, together with the quality of

constructions were formed in reinforced The series of reinforced concrete samples

expert opinion within UK CARES, mean

concrete, incorporating construction joints (some of which were cast in a manner

the approval is virtually equivalent to a

formed with Kwikastrip. These tests were simulating poor compaction) were

British Standard.

full-scale in terms of bar sizes and member subjected to various loading conditions

depths. representing high shear or high bending

Halfen Limited

Humphrys Road Woodside Estate Dunstable LU5 4TP

Tel: +44 (0)1582 470 300 Fax: +44 (0)1582 470 304

Email: reinforcement@halfen.co.uk Web: www.halfen.co.uk

Anda mungkin juga menyukai

- The Post-Frame Advantage HandbookDokumen61 halamanThe Post-Frame Advantage HandbookChuck Achberger100% (1)

- Victorian and Bauhaus ArchitectureDokumen10 halamanVictorian and Bauhaus ArchitectureMars SumatraBelum ada peringkat

- CIV510 - Management of Temporary WorksDokumen14 halamanCIV510 - Management of Temporary Worksezzularab100% (1)

- Technical Drawing StandardsDokumen20 halamanTechnical Drawing StandardsGeorge Maliaris57% (14)

- SGB - Soldiers & Dual PDFDokumen12 halamanSGB - Soldiers & Dual PDFezzularabBelum ada peringkat

- Appendix L Temporary Works Coordinator Training Course Aug19Dokumen14 halamanAppendix L Temporary Works Coordinator Training Course Aug19ezzularabBelum ada peringkat

- 2006-Post-Tensioning Manual - 6th Edition PDFDokumen370 halaman2006-Post-Tensioning Manual - 6th Edition PDFArdiaTiaraR93% (14)

- Mabey Propping and Jacking Brochure WebDokumen27 halamanMabey Propping and Jacking Brochure WebezzularabBelum ada peringkat

- CMOS IC Layout: Concepts, Methodologies, and ToolsDari EverandCMOS IC Layout: Concepts, Methodologies, and ToolsPenilaian: 4.5 dari 5 bintang4.5/5 (3)

- Hilti Webinar HandoutDokumen31 halamanHilti Webinar Handoutmuh2006Belum ada peringkat

- Energy Conservation: Easy Ways To Conserve EnergyDokumen5 halamanEnergy Conservation: Easy Ways To Conserve Energyowais khanBelum ada peringkat

- ArchiCAD Step by Step TutorialDokumen264 halamanArchiCAD Step by Step TutorialAryana Budiman100% (3)

- Exeed Precast-Prequalification PDFDokumen179 halamanExeed Precast-Prequalification PDFDeepu George TBelum ada peringkat

- PEBDokumen17 halamanPEBTanuj Bhardwaj100% (1)

- Section 2: Procedural Control of Temporary Works: 6 ProceduresDokumen38 halamanSection 2: Procedural Control of Temporary Works: 6 Proceduresezzularab100% (3)

- Wilts & Berks Canal Trust Temporary Works ProcedureDokumen21 halamanWilts & Berks Canal Trust Temporary Works ProcedureezzularabBelum ada peringkat

- Construction EstimateDokumen42 halamanConstruction EstimateAngelica GicomBelum ada peringkat

- Pipe Rack Sizing and Loading DataDokumen5 halamanPipe Rack Sizing and Loading DataAnand.5Belum ada peringkat

- SAP HANA Commvault Best PracticesDokumen2 halamanSAP HANA Commvault Best PracticesDevender5194Belum ada peringkat

- CWCT TrainingDokumen51 halamanCWCT TrainingmcbluedBelum ada peringkat

- L1 Intro Well CompletionDokumen27 halamanL1 Intro Well CompletionVG100% (1)

- EN - Allround Technical BrochureDokumen48 halamanEN - Allround Technical BrochuresivanaBelum ada peringkat

- Lafarge Handbook PDFDokumen92 halamanLafarge Handbook PDFezzularabBelum ada peringkat

- TWf2019.03 - Temporary Works Procedure - 8 December 2019 - FINAL1Dokumen22 halamanTWf2019.03 - Temporary Works Procedure - 8 December 2019 - FINAL1ezzularabBelum ada peringkat

- Advanced OutfittingDokumen43 halamanAdvanced OutfittingjishnusajiBelum ada peringkat

- A State-of-the-Art Guide for Post-Installed ReinforcementDari EverandA State-of-the-Art Guide for Post-Installed ReinforcementBelum ada peringkat

- FAQs About Headed Reinf Bars - ETN-M-3-14Dokumen8 halamanFAQs About Headed Reinf Bars - ETN-M-3-14MukarramuddinBelum ada peringkat

- Thesis Hill ResortDokumen8 halamanThesis Hill ResortShahid Afridi43% (7)

- Layher Allround Scaffolding - Technical BrochureDokumen48 halamanLayher Allround Scaffolding - Technical BrochureEmaVanni100% (5)

- Honey Mishra: Prefabricated StructuresDokumen26 halamanHoney Mishra: Prefabricated StructuresC PBelum ada peringkat

- Concrete Bridge Design and Construction SeriesDokumen6 halamanConcrete Bridge Design and Construction SeriesJianhua WuBelum ada peringkat

- Advanced OutfittingDokumen43 halamanAdvanced OutfittingChandan Kumar100% (3)

- Piping Design 5 PDFDokumen9 halamanPiping Design 5 PDFSandra MArrugo100% (1)

- PrefabricationDokumen51 halamanPrefabricationRonald82% (11)

- PPVC Singapore Institute of TechnologyDokumen59 halamanPPVC Singapore Institute of Technologychong pak lim100% (3)

- 01 Soldier SystemDokumen26 halaman01 Soldier SystemezzularabBelum ada peringkat

- Pre-Fabricated Punching Shear ReinfDokumen4 halamanPre-Fabricated Punching Shear ReinfJose ManjooranBelum ada peringkat

- Building Economics (Group 4) FINAL PRINTDokumen34 halamanBuilding Economics (Group 4) FINAL PRINTJasbeer SharmaBelum ada peringkat

- Scaffolding PDFDokumen34 halamanScaffolding PDFezzularabBelum ada peringkat

- Scaffolding PDFDokumen34 halamanScaffolding PDFezzularabBelum ada peringkat

- VSL Catalog PTDokumen44 halamanVSL Catalog PTVu Phi Long100% (1)

- External Tendon DiabolosDokumen2 halamanExternal Tendon DiabolosShishir Kumar Nayak100% (1)

- 5G Testing Training Certification TELCOMA GlobalDokumen199 halaman5G Testing Training Certification TELCOMA GlobalTELCOMA GlobalBelum ada peringkat

- PRS Neoloy BrochureDokumen12 halamanPRS Neoloy BrochureMulsa KTGBelum ada peringkat

- GeoTree Structural Strengthening Brochure 03.17.22 WebDokumen12 halamanGeoTree Structural Strengthening Brochure 03.17.22 WebAmel RBelum ada peringkat

- Aftermarket Services: Trusted Design - Quality Workman-Ship - Proven Experience..Dokumen2 halamanAftermarket Services: Trusted Design - Quality Workman-Ship - Proven Experience..Krishna HartonoBelum ada peringkat

- Volumetric Email VersionDokumen28 halamanVolumetric Email VersionnelsonsainzBelum ada peringkat

- Panelization of Light Gage Steel Framing - From Start To FinishDokumen2 halamanPanelization of Light Gage Steel Framing - From Start To FinishDaveBelum ada peringkat

- Trimapanel® Brochure PDFDokumen36 halamanTrimapanel® Brochure PDFyasserBelum ada peringkat

- Product Catalog: Marine IndustryDokumen32 halamanProduct Catalog: Marine IndustryMohamed AtefBelum ada peringkat

- Common Voss Assembly Station With Poka-YokeDokumen7 halamanCommon Voss Assembly Station With Poka-YokeAnuj Kumar ShrivastavaBelum ada peringkat

- FSAE MonocoqueDokumen1 halamanFSAE MonocoqueShubham PawarBelum ada peringkat

- Brochure - Gas Turbine and Combined Cycle Plants (Small)Dokumen16 halamanBrochure - Gas Turbine and Combined Cycle Plants (Small)danny buiBelum ada peringkat

- VER P Pipe Support Inspection Remediation Package PASS 1Dokumen6 halamanVER P Pipe Support Inspection Remediation Package PASS 1HendyAPBelum ada peringkat

- Provided by Universiti Teknologi Malaysia Institutional RepositoryDokumen8 halamanProvided by Universiti Teknologi Malaysia Institutional RepositoryDyeri FloresBelum ada peringkat

- Engineered For Higher-Quality Installation: Simpler Faster BetterDokumen24 halamanEngineered For Higher-Quality Installation: Simpler Faster BetterMelrose FabianBelum ada peringkat

- Gnthroughbolts PDFDokumen2 halamanGnthroughbolts PDFChandru MohanBelum ada peringkat

- Prefabricated StructuresDokumen81 halamanPrefabricated StructuresrajeshBelum ada peringkat

- Eaton Valve Cavity 2Dokumen64 halamanEaton Valve Cavity 2Drawing TAMHYDBelum ada peringkat

- Subject: Production & Project Management (Ge)Dokumen48 halamanSubject: Production & Project Management (Ge)sheeladeepakBelum ada peringkat

- Compact Taper Roller Bearing Lives Up To Its Name: The CTBU DesignDokumen4 halamanCompact Taper Roller Bearing Lives Up To Its Name: The CTBU DesignedimazorBelum ada peringkat

- Fixed Platforms Products ServicesDokumen14 halamanFixed Platforms Products Services魏永涛Belum ada peringkat

- Manifold Systems: World Proven Compact Valves and PackagesDokumen20 halamanManifold Systems: World Proven Compact Valves and PackagesananBelum ada peringkat

- Structural Repairs and Strengthening of RC ColumnsDokumen8 halamanStructural Repairs and Strengthening of RC ColumnsMyat NoeBelum ada peringkat

- Joint Free Slabs On Grade: Warwick ColefaxDokumen13 halamanJoint Free Slabs On Grade: Warwick Colefaxmohannad eliassBelum ada peringkat

- DM Brochures-2020 Low ResolutionDokumen36 halamanDM Brochures-2020 Low ResolutionThompson LaiBelum ada peringkat

- Cement-Plant-Brochure For - IN - INRDokumen24 halamanCement-Plant-Brochure For - IN - INRIsaiah JohnBelum ada peringkat

- Advanced Fatigue Analysis of Offshore Jacket Tubular Joints: Sesam - 50 Years of SuccessDokumen49 halamanAdvanced Fatigue Analysis of Offshore Jacket Tubular Joints: Sesam - 50 Years of SuccessMuraliBelum ada peringkat

- Lecture 7 - Machining Process and Machining Tools (Part 1)Dokumen24 halamanLecture 7 - Machining Process and Machining Tools (Part 1)sharifah atiqahBelum ada peringkat

- Paper 118 Guidelines For Prequalification and Design of Post-Installed and Cast-In Anchors in AustraliaDokumen11 halamanPaper 118 Guidelines For Prequalification and Design of Post-Installed and Cast-In Anchors in Australiacons2engBelum ada peringkat

- SFT Company ProfileDokumen8 halamanSFT Company ProfileAndy BayuBelum ada peringkat

- Delta BeamDokumen20 halamanDelta BeamHameed_Farah100% (1)

- Corefast Brochure DPS Final Approved 130607Dokumen12 halamanCorefast Brochure DPS Final Approved 130607S.s. LeeBelum ada peringkat

- Masonry RetrofitDokumen12 halamanMasonry RetrofithoustonhimselfBelum ada peringkat

- WaboElastoFlex Park 0408Dokumen4 halamanWaboElastoFlex Park 0408Cristhian Alfonso Mandujano PérezBelum ada peringkat

- L12 FormworkDokumen242 halamanL12 FormworkErnst VenterBelum ada peringkat

- Punching Shear Reinforcement: For The Construction IndustryDokumen12 halamanPunching Shear Reinforcement: For The Construction IndustrySuhail AhamedBelum ada peringkat

- Spe 96655 MSDokumen8 halamanSpe 96655 MSOmar S Al-AbriBelum ada peringkat

- Steel Structures Design Based on Eurocode 3Dari EverandSteel Structures Design Based on Eurocode 3Penilaian: 3 dari 5 bintang3/5 (1)

- TD - Alkus - Load Capacity - Span - GM ProductDokumen3 halamanTD - Alkus - Load Capacity - Span - GM ProductezzularabBelum ada peringkat

- Holland Lift 220 ElectricDokumen3 halamanHolland Lift 220 ElectricezzularabBelum ada peringkat

- Technical Characteristics 2020 ENDokumen1 halamanTechnical Characteristics 2020 ENezzularabBelum ada peringkat

- 5d2dbd383497c-Home Buying Checklist 2019Dokumen1 halaman5d2dbd383497c-Home Buying Checklist 2019ezzularabBelum ada peringkat

- Doka Circular Formwork enDokumen2 halamanDoka Circular Formwork enezzularabBelum ada peringkat

- FDP D Euro PropsDokumen6 halamanFDP D Euro PropsezzularabBelum ada peringkat

- EngiLab Frame.2D User ManualDokumen234 halamanEngiLab Frame.2D User ManualezzularabBelum ada peringkat

- Al Baleed Resort: Case StudyDokumen1 halamanAl Baleed Resort: Case StudyezzularabBelum ada peringkat

- Visa Security Infographic 102314 JC v30Dokumen1 halamanVisa Security Infographic 102314 JC v30ezzularabBelum ada peringkat

- RMD Kwikform India: Formwork ServicesDokumen10 halamanRMD Kwikform India: Formwork ServicesezzularabBelum ada peringkat

- Rapid Column ArmDokumen4 halamanRapid Column ArmezzularabBelum ada peringkat

- Abu Dhabi To Dubai Link Bridges: Case StudyDokumen1 halamanAbu Dhabi To Dubai Link Bridges: Case StudyezzularabBelum ada peringkat

- Al Barari Luxury Residential Complex: Case StudyDokumen1 halamanAl Barari Luxury Residential Complex: Case StudyezzularabBelum ada peringkat

- SGB Taskmaster Aluminium TowerDokumen6 halamanSGB Taskmaster Aluminium TowerezzularabBelum ada peringkat

- Framax CompoDokumen7 halamanFramax CompoezzularabBelum ada peringkat

- Alshor Plus FalseworkDokumen11 halamanAlshor Plus FalseworkezzularabBelum ada peringkat

- A Universal Tool Monolithic Structure Creation Reusable Great Dimensional Precision of The StructuresDokumen2 halamanA Universal Tool Monolithic Structure Creation Reusable Great Dimensional Precision of The StructuresezzularabBelum ada peringkat

- Climbing Systems enDokumen2 halamanClimbing Systems enezzularabBelum ada peringkat

- Framax CompoDokumen7 halamanFramax CompoezzularabBelum ada peringkat

- C.05 SL - SLW Girder Inspection ReportDokumen5 halamanC.05 SL - SLW Girder Inspection ReportSami AjBelum ada peringkat

- Django FileBrowser DocumentationDokumen49 halamanDjango FileBrowser Documentationlara2005Belum ada peringkat

- Sotrafer-Quality Observation Complaince Tracking Record.Dokumen63 halamanSotrafer-Quality Observation Complaince Tracking Record.mitendra singhBelum ada peringkat

- Skid ResistanceDokumen7 halamanSkid Resistanceebinsams007Belum ada peringkat

- Fortigate Transparent Mode 56Dokumen49 halamanFortigate Transparent Mode 56Log BwdBelum ada peringkat

- Cooling Cabinet (6318)Dokumen1 halamanCooling Cabinet (6318)Man MohanBelum ada peringkat

- Inside The Social Network's (Datacenter) NetworkDokumen49 halamanInside The Social Network's (Datacenter) NetworkVamsi Krishna PatchamatlaBelum ada peringkat

- Archi CADDokumen2 halamanArchi CADTheresa CostalesBelum ada peringkat

- Research Methodology Example Thesis ArchitectureDokumen7 halamanResearch Methodology Example Thesis Architecturenicoleyoungaurora100% (3)

- Analysis of Rate For Providing/Fixing of Single Lights: Amount of 44 Pole 3% ContigencyDokumen2 halamanAnalysis of Rate For Providing/Fixing of Single Lights: Amount of 44 Pole 3% Contigencymuhammad iqbalBelum ada peringkat

- ProjectWise IntegrationDokumen11 halamanProjectWise IntegrationFabio MiguelBelum ada peringkat

- GRI 8450-3 Data SheetDokumen4 halamanGRI 8450-3 Data SheetJMAC SupplyBelum ada peringkat

- CS601 Final Term Mega Quiz File With RefrencesDokumen43 halamanCS601 Final Term Mega Quiz File With RefrencesRed FlowerBelum ada peringkat

- 3 Stage and 5 Stage ARMDokumen4 halaman3 Stage and 5 Stage ARMRaj HakaniBelum ada peringkat

- 06 Multiview Projection Drawing Part 1Dokumen46 halaman06 Multiview Projection Drawing Part 1Lakshwanath JaganathBelum ada peringkat

- Irc Gov in 109 1997 PDFDokumen28 halamanIrc Gov in 109 1997 PDFKishore AinavilliBelum ada peringkat

- Ext2 File System PDFDokumen2 halamanExt2 File System PDFLeahBelum ada peringkat

- CTW R Three: Moisture Content of Soil Water ContentDokumen9 halamanCTW R Three: Moisture Content of Soil Water ContentVOJBelum ada peringkat

- DG43NB Product BriefDokumen4 halamanDG43NB Product Briefign_handokoBelum ada peringkat

- Lecture Plan For Even Semester For FCPC (CSE-101-F)Dokumen2 halamanLecture Plan For Even Semester For FCPC (CSE-101-F)EhtashamBelum ada peringkat

- U-Shape Drain (T-6) PU Series: FUJI Precast Concrete SolutionDokumen3 halamanU-Shape Drain (T-6) PU Series: FUJI Precast Concrete SolutiongautamBelum ada peringkat

- Vlan Provisioning Security Guidance At-A-Glance v8r1Dokumen15 halamanVlan Provisioning Security Guidance At-A-Glance v8r1karthikav3Belum ada peringkat