OMAE2017-62118: Effects in Free Water Knockout Separator Caused by Fpso Motions in Ocean Waves

Diunggah oleh

thlim19078656Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

OMAE2017-62118: Effects in Free Water Knockout Separator Caused by Fpso Motions in Ocean Waves

Diunggah oleh

thlim19078656Hak Cipta:

Format Tersedia

Proceedings of the ASME 2017 36th International Conference on Ocean, Offshore and Arctic Engineering

OMAE2017

June 25-30, 2017, Trondheim, Norway

OMAE2017-62118

EFFECTS IN FREE WATER KNOCKOUT SEPARATOR CAUSED BY FPSO MOTIONS IN

OCEAN WAVES

Catharine Fernandez Martins Celso Kazuyuki Morooka

Graduate Program Faculty of Mechanical Engineering &

Petroleum Science & Engineering Center for Petroleum Studies

University of Campinas University of Campinas

Campinas-SP, Brazil Campinas-SP, Brazil

ABSTRACT Response Amplitude Operator (RAO)

In offshore operations, wind, waves and currents cause Significant wave height (m)

motions on Floating Production Storage and Offloading

(FPSO) platforms that can induce effects on equipment at the Initial emulsion thickness (m)

topside processing plant, such as on an oilfield separator. The Initial free water thickness (m)

purpose of this work is to propose a procedure to evaluate the Final emulsion thickness (m)

quality of the emulsion separated in a horizontal Free Water

Knockout separator (FWKO) under the influence of the FPSO Final free water thickness (m)

motions in ocean waves. In this paper, a software named Emulsion quality indicator

WAMIT© was used to obtain FPSO motions. Time series of roll Seam to seam length (m)

and pitch motions are calculated considering regular and Vessel effective length (m)

irregular waves and through these results the emulsion quality

indicator is obtained to evaluate the separator performance. Terminal velocity (m/s)

The main contribution from the present study is the estimation Motion response in time domain

of the quality of the emulsion separated on the FWKO, which

Oil retention time (min)

can contribute to improve the operational criteria for three-

phase separators commonly used in offshore applications. Water retention time (min)

Peak wave-frequency (rad/s)

Keywords: FPSO motions; waves; separator; performance

Circular frequency component (rad/s)

Pitch motion (degree)

NOMENCLATURE Roll motion (degree)

Wave amplitude component (m)

Arbitrary phase angle component (rad)

Emulsion cross section area that surpasses the

Free surface elevation (m)

weir (m2)

Maximum section area of emulsion to avoid the Incident wave amplitude, m

passage of free water (m2) RAOs phase (rad)

Free water cross section area that surpasses the 0.07 if or 0.09 if

weir (m2) Water viscosity (cP)

Total emulsion section area that surpasses the Oil viscosity (cP)

weir (m2)

Difference in specific gravities (oil/water)

Wave number component (m)

Viscosity of continuous phase (cP)

Water/oil droplet that settled/rise (microns)

FPSO Floating Production Storage and Offloading

Vessel diameter (m)

FWKO Free Water Knockout Separator

1 Copyright © 2017 ASME

Downloaded From: http://proceedings.asmedigitalcollection.asme.org/ on 01/03/2018 Terms of Use: http://www.asme.org/about-asme/terms-of-use

INTRODUCTION Pourahmadi Laleh et al. [6] have shown through CFD studies,

During the last decades, new technologies were developed that the performance of the FWKO separator can be greatly

to expand global oil and gas reserves given the increasing improved by introducing appropriate internal baffles.

demand of energy. The excessive motions of FPSO are caused Unlike previous studies, this paper proposes a new

not only by severe environmental conditions, but also in mild simplified methodology to calculate an indicator of the

environment may lead the platform unit with spread mooring emulsion quality separated in a FWKO influenced by roll and

system to unfavorable sea conditions, such as in beam seas [1]. pitch motions.

Chakrabarti [2] defines that one of the key elements in the

design of offshore platforms is to determine the environmental

loads acting on the floating structure for different operational

conditions. Knowledge of vertical motions and accelerations in

a floating structure are important to estimate excitation that

affect operations on the process plant equipment and to ensure

that the crew can work safely [1].

The separation process of crude oil is a combination of

different mechanisms that are dependent on the entire vessel

configuration, the fluid properties, particle size, and degree of

gas turbulence to achieve mixture separation. Recent studies

report the importance of vessel motions in the separation of oil,

gas and water, which is particularly difficult on floating

platforms since the wave motion tends to mix the phases.

According to Lapidaire et al. [3], these motions cause

accelerations that produce a secondary effect on liquid, which

creates resonant waves and dispersion of liquid phases at the

oil-water interface. The reduction of roll and pitch motions

amplitude is important to enhance the separator performance.

Many proposals can be found in the literature to increase

the oil and gas processing efficiency in floating platforms.

Recently, a new idea of larger scale “wash tank” is suggested as

a pre-processor for conventional separators. This tank is used

for initial separation of oil and water with the aid of de-

emulsifying fluid for maximizing process efficiency [5]. On the

other hand, subsea separators are also introduced for

maximizing production efficiency in deepwater oil wells. The

fluids separation on sea bottom is an alternative used to

minimize the production of undesirable fluid. The main

advantage is the reinjection of the water produced on the

separation process in order to reduce lifting costs [4].

The main objective of this paper is to propose a procedure

to evaluate the quality of the emulsion separated in a horizontal

Free Water Knockout separator (FWKO) influenced by pitch

and roll motions in ocean waves. For this analysis, the

environmental conditions adopted for the sea waves are

representative of the sea state from Santos Basin, Brazil.

The methodology adopted, as well as the case study

definition, the numerical simulation results and the main

conclusions, are described in the following sections.

Figure 1. Flowchart of the methodology proposed

METHODOLOGY The methodology developed has been structured in three

Recently published studies in Computational Fluid parts, as shown in Figure 1. Initially, the Response Amplitude

Dynamics (CFD), about three-phase separators, provide an Operator (RAO) for the FPSO is calculated. Then, the time

enhanced simulation of fluid phase separation during the most histories are obtained from the JONSWAP spectrum.

complicated motions. Frankiewicz et al. [5] evaluated the Afterwards, time series of roll and pitch motions in FWKO

design of internal devices for a three-phase separator in order to separator are calculated, respectively. Based on these results,

mitigate sloshing and improve the separation performance of the emulsion quality indicator is obtained to evaluate the

liquid phases caused by floating platforms motions. separator efficiency.

2 Copyright © 2017 ASME

Downloaded From: http://proceedings.asmedigitalcollection.asme.org/ on 01/03/2018 Terms of Use: http://www.asme.org/about-asme/terms-of-use

FPSO RAO

When a large three-dimensional body interacts with

incident waves, the hydrodynamic coefficients and wave

exciting forces and moments can be obtained by using the first

and second order diffraction/radiation theory. In the where, is the motion response, is the incident wave

diffraction/radiation theory, the total velocity potential can be

amplitude, is the wave frequency component, is the

decomposed into incident, diffraction, and radiation potentials

RAOs phase component, δr is the arbitrary phase component

[7]. The total velocity potential satisfies the Laplace equation as

and is the RAO.

a governing equation and all the required boundary conditions

along the closed boundary, including bottom, free surface, body

Regular Waves. Harmonic progressive waves are

boundary, and radiation boundary. To solve the problem in

described by sinusoidal signals that have as properties the

question, one must take into account the six degrees of freedom

amplitude, the period, and the wavelength. If the wave moves

of the floating unit [7-8].

in the positive x-direction, the wave profile can be expressed as

In the present work, the WAMIT © was used to obtain the

follows:

Response Amplitude Operator (RAO) for FPSO motions in the

frequency domain. This program is based on linear wave

theory, sea water depth finite, motion amplitude assumptions

and the Green’s method, used to determine the intensity of the

source and dipole distributions over the panels used in where, is the free surface elevation, is the wave amplitude,

discretization of the hull wetted surface [9]. is the wave number, is the wave frequency and is the

The procedure for defining the body geometry is essential arbitrary phase angle.

in this analysis. For this purpose, MultiSurf© was used to model Given the wave amplitude, phase and angular frequency,

the FPSO surface geometry with a high degree of accuracy and respectively, it is possible to determine the system motion as

the integration with the WAMIT © has been achieved by linking described by Eq. (1).

RGKernel, which enables a geometry model designed in

MultiSurf© into WAMIT© [7]. Irregular Waves. An irregular wave can be be represented

If the motion of the FPSO gravity center is known for six by the superposition of N sinusoidal regular waves [2].

degrees of freedom, it is easy to calculate the motion of any Due to the random nature of waves, a real sea state is

point on the floating structure using absolute motion usually described in terms of statistical wave parameters such

as significant wave height, spectral peak period, among others.

superposition. The absolute displacement of point of the

A wave spectrum is used to describe a sea state in which the

vessel can be calculated as body displacement due to the

energy distribution over the wave frequencies is known. The

superposition of the translational and rotational motions [10].

most appropriate spectrum would be one measured locally;

The angles of rotation ( -roll, -pitch, γ-yaw) are assumed to

however, since this is uncommon, standard model of wave

be small, which is a requirement for linearization.

spectrum is used. There are many wave spectral formulations,

and the JONSWAP spectrum is frequently used to represent

Motion Response

wave spectrum for the Santos Basin, Brazil.

In most cases, the response of an offshore floating structure By knowledge of wave spectrum for operational conditions

includes the vessel motion influenced by a sea state, the for Santos Basin, a JONSWAP energy spectrum can be

structure vibration and the mooring system. In the most of obtained from the following equation.

cases, these structures are treated as rigid bodies with six

independent degrees of freedom, named as the surge, sway,

heave, roll, pitch and yaw motions.

The analysis of the dynamics of floating structures can be

on either the time domain or the frequency domain. The where, is the significant wave height, is the peak wave

equations of motion for different degrees of freedom are the frequency and is the Peakedness parameter.

same regardless of the selected method of analysis. The major Free surface elevations can be simulated for a given wave

restriction for working in the frequency domain is the viscous energy spectrum by linear superposition of regular wave

damping effects that must be linearized [10]. components [11]. It can be written as:

Based on the sea state, it was possible to obtain the

platform motion response, and it can be regular or irregular

waves. To obtain the motion response it was assumed that the

system is linear and the waves can be superposed. The

amplitude of the incident wave is small; thus causing small

motions on six degrees of freedom. where, is the wave amplitude component, is the wave

In the present study, time histories of the motion response number component, is the wave frequency component and

are obtained for pitch and roll, in regular and irregular waves, is the arbitrary phase component.

according to Eq. (1).

3 Copyright © 2017 ASME

Downloaded From: http://proceedings.asmedigitalcollection.asme.org/ on 01/03/2018 Terms of Use: http://www.asme.org/about-asme/terms-of-use

Since the RAO is obtained and the wave time history is

simulated from the wave energy spectrum, the motion response

in time domain can be obtained from the Eq. (1).

where, is the oil retention time and is the oil

Three-Phase Separator Performance

viscosity.

The three-phase separator is the major equipment for oil The rising oil droplets from free water phase are

and gas separation that produces the primary separation of fluid determined as defined by the Stokes’ law. The free water pad

stream that comes from the wellhead. There are different thickness is given by:

separator configurations but each disposition is specific to a

given operational condition. Horizontal vessels are most

economical for normal oil-water separation, particularly where

there might be problems with emulsions, foam or high gas

liquid ratios [12].

The oil-water separation processes rely on a combination where, is the water retention time and is the water

of mechanical relationships formulated from gravity settling viscosity. Finally, the seam to seam length (Lss) that satisfy the

theory to achieve mixture separation. The Free Water Knockout gas capacity constraint can be calculated as:

(FWKO) with weir, the separator considered for the present

research, is a horizontal gravity separator used to remove the

free water produced with crude oil [12]. It corresponds to the

first separation stage in an offshore process plant.

where, is the vessel effective length and is the vessel

FWKO Fundamental Design. Arnold and Steward [12] diameter.

propose a design procedure to estimate separator dimensions The next step is to define diameter and length for the

(diameter and height) based on inlet fluid properties and separator. The usual ratio between length and diameter is

liquids capacities. This method assumes half-filled liquid around 3 to 5, based on the API [13].

vessel without level control issues and it can be considered a

simplified version of industrial design procedures.

Assumptions are based on the API separator design criteria

[13], for instance:

foaming is solved through chemical injections;

steady state and Stokes’ law are considered;

plug flow assumption and linear movements of

droplets in the settling section is taken, and;

the ratio between length and diameter of the separator

is considered.

The settling theory considers the force balance equation to

calculate the setting velocity for several droplets. It assumes

that bubbles act as spherical particles with a standard

diameter. Water droplets, present in the oil phase, settle under

a terminal velocity and oil droplets in water phase rise to oil

interface with rising speed. Both velocities can be estimated

by the Stokes law, as shown in the following equation:

where, is the terminal velocity, ∆SG is the difference in

specific gravities (oil/water), is the viscosity of continuous

phase and is the water/oil droplet that settled/rise.

The distance that a water droplet can settle may be

determined if the velocity of water droplets setting through oil

phase and time retention of oil phase are known. The oil pad

thickness is given by:

Figure 2. FWKO design process flowchart

4 Copyright © 2017 ASME

Downloaded From: http://proceedings.asmedigitalcollection.asme.org/ on 01/03/2018 Terms of Use: http://www.asme.org/about-asme/terms-of-use

Figure 2 presents the flowchart to define main dimensions When the separator is subjected to motion, the thickness

of a three phase horizontal separator (FWKO). Initially, the (height) of the phases (free water and w/o emulsion) changes

drag coefficient is calculated through an iterative process. In due to pitch angle suffered by vessel, as shown in Figures 4 and

addition, the gas and liquid capacity is used to calculate the 5.

final separator dimensions.

FWKO Quasi-Static Approach. When an oilfield

separator is placed on a floating structure subject to motion,

the greatest concern becomes the motion effect on the

separator performance. Rice [14] discusses five effects of

different degrees of motions on process equipment: Spirit

level effect, resonant waves, primary liquid turbulence,

secondary liquid turbulence and process control effects. All

these effects reduce the effectiveness of emulsion-free water

separation and it does not always result from six marine vessel

motion, only pitch, roll, heave and surge are significant.

The quasi-static approach adopted was necessary in order

to understand what happens with the separator performance Figure 4. FWKO positive angle

subjected to pitch and roll motion. It only takes into account the

inclination (pitch) and rotation (roll) suffered by the separator,

without considering the fluid inertia. In addition, motion

combinations and mixtures of the phases are neglected. For this

reason, the present study emphasizes analysis on the quality of

the emulsion separated on FWKO separator once it will affect

the operation in some of the equipment downstream in the

separating plant. From the equations deduced, all simulations

are performed and the results of this work are obtained.

Case A: FWKO Separator Performance Influenced by Pitch

Motion with Wave Heading of 180 degrees

Since the FWKO dimensions, the liquids layer heights in

separator settling section (previously calculated) and the Figure 5. FWKO negative angle

separator motion is known, it is possible to define an indicator

of emulsion quality based on the amount of free water that When the separator is pitched back and forth, the rising

accompanies the fluid passing through the weir, as shown in and falling action causes the cross-sectional area above the

Figure 3. liquid level to decrease and increase as the level goes up. This

effect only occurs due to the separator cylindrical geometry.

For this reason, the calculation of the emulsion quality indicator

is specified in terms of the “cross section area of fluid that

surpasses the weir”, shown on Figure 6 and calculated by:

Hoi

Hwi

Figure 3. Definition of emulsion quality indicator based on the

highest point in the weir

Figure 6. Cross section area of fluid that surpasses the weir in

pitch motions

5 Copyright © 2017 ASME

Downloaded From: http://proceedings.asmedigitalcollection.asme.org/ on 01/03/2018 Terms of Use: http://www.asme.org/about-asme/terms-of-use

where, is the emulsion cross section area that Figure 8, differently from the pitch motion, in which the free

surpasses the weir, is the free water cross section water could only pass if the whole emulsion had passed as well.

area that surpasses the weir and is the total It is necessary to know the instant in which the free water

emulsion section area that surpasses the weir. begins to pass to the final section. With the knowledge of the

The only parameters upon which the indicator of emulsion minimum angle at which free water begins to pass to the final

quality depends are the emulsion and free water thickness. If section, it is possible to obtain the maximum section area of

> the free water passes to the final section as well; emulsion to avoid passing free water ( ). If

otherwise, only the emulsion passes as desired. These thickness > then the free

variations from the initial state (static) to the final state (quasi- water passes to final section, otherwise only the emulsion

static) are given by the following geometric expressions: passes.

where, is the initial emulsion thickness, is the final

emulsion thickness, is the initial free water thickness and

is the final free water thickness.

The indicator maximum value represents a fluid flow rate

through the weir greater than the design flow rate, caused by

separator motions (Figure 4); meanwhile, the indicator achieves

minimum values if just the designed fluid flow rate passes

(Figure 5).

Case B: FWKO Separator Performance Influenced by Roll

Motion with Wave Heading of 90 degrees Figure 8. The variation cycle of the fluid area

Similarly, to the previous case, the calculation of the

emulsion quality indicator is based on the cross section area of

CASE STUDY

fluid that surpasses the weir, as seen on Figure 7 and calculated An actual FPSO in fully loaded operating condition is

by the following equation: considered in this case study. Table 1 contains the main

characteristics used to model the FPSO hull structure.

Table 1. Main dimensions of the FPSO

Characteristic Value (m)

Total length 288.00

Breadth 54.00

Depth 31.50

Draft 25.32

Figure 7. Section area of fluid that surpasses the weir in roll

motions

The same assumptions established at the beginning of this

analysis are maintained for the calculation of the section area of

fluid influenced by roll motion. For this case, the free water can

surpass the weir without the whole emulsion passing, as seen on

Figure 9. FPSO hull modeling

6 Copyright © 2017 ASME

Downloaded From: http://proceedings.asmedigitalcollection.asme.org/ on 01/03/2018 Terms of Use: http://www.asme.org/about-asme/terms-of-use

The wetted hull surface was divided into 7800 square Properties of the fluid produced from the petroleum

panels. Figure 9 shows a perspective of the FPSO panel reservoir for all cases in this study are as shown in Table 3.

distribution. Then, the WAMIT© was used to solve the radiation These properties are used to analyze the FWKO separator

and diffraction problems for the FPSO, without mooring performance influenced by FPSO motions.

system. Different incident wave conditions were simulated with

WAMIT© to obtain the Response Amplitude Operator (RAO)

of the floating unit. The FPSO reference system is used to set RESULTS AND DISCUSSION

the FPSO heading with to the North. It is oriented clockwise Normalized amplitude and phase for the roll and pitch

from North direction. motions, respectively are shown in. Figures 10 and 11.

For motion in regular waves, it was simulated two loading

cases for wave heading of 180 and 90 degrees (WAMIT ©). The

operational wave condition adopted for case 1 presented ROLL

3,50

constant wave amplitude of 5m and for case 2, a wave

3,00

amplitude of 15 m. All of these simulations were performed

RAO (degree/m) Roll

varying the excitation period in the range of 10 up to 40 2,50

seconds. The environmental conditions adopted for motion in 2,00

irregular waves are representative of the sea state from Santos 1,50

Basin. It was selected a wave scenario for a return period of 100 1,00

years and a hypothetical case (case 2). Sea state is described by

0,50

the JONSWAP wave spectrum, and waves from the south are

selected because it represents the largest and longest waves in 0,00

0 10 20 30 40

the Santos Basin. Table 2 illustrates the loading cases for Period (s)

irregular waves using wave conditions for the Santos Basin. 180

Loads due to wind are not included in the present analysis.

120

Phase (degree)

60

Table 2.Irregular waves in the study 0

0 10 20 30 40

Return Period (100 years) -60

Case 1 Hs (m) Tp (s) -120

11.60 16.30 -180

Period (s)

Hypothetical Case

Case 2 Hs (m) Tp (s) Figure 10. Roll results of computational simulation for wave

30.00 13.09 heading of 90 degrees

PITCH

3,50

Table 3. Production fluid properties data

Properties Value Unit 3,00

RAO (degree/m) Pitch

28 °C 2,50

Operating temperature

2,00

Operating pressure 2300 kPa

1,50

Oil rate 216 m3/hr

1,00

Gas rate 4587 m3/hr

0,50

Water rate 1026 m3/hr

0,00

Oil density 863 kg/m3 0 10 20 30 40

3 Period (s)

Gas density 16.95 kg/m

180

°API 32 120

Phase (degree)

Oil specific gravity 0.87 60

Gas specific gravity 0.60 0

0 10 20 30 40

Water specific gravity 1.00 -60

Oil viscosity 10 cP -120

Gas viscosity 0.01 cP -180

Period (s)

Water viscosity 1 cP

O/W retention time 10 min Figure 11. Pitch results of computational simulation for wave

heading of 180 degrees

7 Copyright © 2017 ASME

Downloaded From: http://proceedings.asmedigitalcollection.asme.org/ on 01/03/2018 Terms of Use: http://www.asme.org/about-asme/terms-of-use

Peak values for each motion can be observed around the consequence, the separated emulsion quality decreases. From

resonant period (Figs 10 and 11). The first order motions in this the value of resonant period and for the same amplitude value,

study play an important role, and they present resonant period if the excitation frequency continues to increase, then the

in the range of energy of the sea energy spectrum. Then, natural angular motion decreases, as seen on Table 5.

periods of the FPSO roll and pitch motions are relevant in the

analysis, and they are shown in the Table 4. Table 5. Results of pitch motions in regular waves

Case 1: amplitude 5m

Table 4. Natural periods of motions for the FPSO Period (s) Frequency (rad/s) Motionmax (degree)

Condition Natural period (s) 39.27 0.16 0.71 0.10

Roll 19.29 31.42 0.20 1.23 0.18

19.04 0.33 2.61 0.38

Pitch 14.41 15.71 0.40 3.18 0.47

13.09 0.48 2.63 0.39

The procedure developed in this study was applied for the 11.02 0.57 0.46 0.07

case studies, in regular and irregular waves, and the separator

Case 2: amplitude 15m

motion simulated. The quality of emulsion separated,

influenced by pitch and roll motions, in quasi-static separator Period (s) Frequency (rad/s) Motionmax (degree)

performance was evaluated following the methodology 39.27 0.16 2.13 0.31

described in the previous section. The first step was to solve a 31.42 0.20 3.69 0.54

set of mathematical equations, based on the fluid properties 19.04 0.33 7.83 1.15

data given by Table 3, and the FWKO separator was defined.

15.71 0.40 9.53 1.41

Then, simulations have been done and the emulsion quality

indicator for the quasi-static state was calculated. 13.09 0.48 7.88 1.14

Figure 12 illustrates one of the most important case in 11.02 0.57 1.38 0.20

which the separator motion was greatest, for pitch motion in

head sea. In the same manner, the FWKO motion and emulsion

indicators were obtained for irregular waves (Table 2). Figure

Incidence Wave 13 shows the result for pitch motions in irregular waves.

16

12

8

4 Incidence Wave

30

0

ζ(m)

-4 20

-8 10

-12

-16 0

ζ(m)

0 50 100 150 200 250 300 350 400 450 500 550 600 -10

Time (s) -20

Separator’s Angular Motion -30

Angular Motion (degree)

9 0 500 1000 1500 2000 2500 3000 3500 4000 4500 5000

6 Time (s)

3

Separator’s Angular Motion

Angular Motion (degree)

0 9

-3 6

-6 3

-9 0

0 50 100 150 200 250 300 350 400 450 500 550 600

-3

Time (s)

-6

Emulsion Quality Indicator -9

1,4 0 500 1000 1500 2000 2500 3000 3500 4000 4500 5000

1,2 Time (s)

1,0

0,8

Emulsion Quality Indicator

1,4

IE

0,6

1,2

0,4

1,0

0,2

0,8

0,0

IE

0 50 100 150 200 250 300 350 400 450 500 550 600 0,6

Time (s) 0,4

0,2

0,0

Figure 12. Wave elevation, separator motion and indicator for 0 500 1000 1500 2000 2500 3000 3500 4000 4500 5000

pitch motion (amplitude 15m and period 13.09s) Time (s)

Figure 13. Wave elevation, separator motion and indicator for

Table 5 shows results for regular waves. When the wave pitch motion (Hs=11.60m and Tp =16.30s)

excitation frequency is close to the pitch resonant frequency

(0.43 rad/s), the amplitude of motion is maximum and a greater FWKO performance was analyzed for the survival

amount of free water passes into the separator final section. In condition, with 100 years return period. The FPSO is designed

8 Copyright © 2017 ASME

Downloaded From: http://proceedings.asmedigitalcollection.asme.org/ on 01/03/2018 Terms of Use: http://www.asme.org/about-asme/terms-of-use

for extreme conditions of the Santos Basin, following the Table 7. Results of roll motions in regular waves

recommended practices by DNV-RP-C205 [15]. For this Case 1: amplitude 5m

reason, the maximum pitch motion of seven degrees was Period (s) Frequency (rad/s) Motionmax (degree)

established. Results for the case of pitch motions in irregular

39.27 0.16 1.10 0.06

waves are shown in Table 6.

31.42 0.20 2.00 0.10

Table 6. Results of pitch motions in irregular waves 19.04 0.33 16.50 0.70

15.71 0.40 5.00 0.22

Case Period (s) MotionMax (degree)

13.09 0.48 2.40 0.12

1 16.30 6.22 0.90 11.02 0.57 1.65 0.09

2 13.09 7.44 1.10 Case 2: amplitude 15m

Period (s) Frequency (rad/s) Motionmax (degree)

The separator motion was the greatest in the case 2 in the

Table 6. Therefore, the separated emulsion quality decreased 39.27 0.16 3.30 0.16

because the free water crossed the weir. Moreover, in this case, 31.42 0.20 6.00 0.27

the indicator reached a value larger than the unity. 19.04 0.33 49.50 2.08

Figure 14 illustrated one of the most important case in 15.71 0.40 15.00 0.64

which the separator motion was greatest, for roll motion, in 13.09 0.48 7.20 0.31

beam sea regular waves.

11.02 0.57 4.95 0.22

Incidence Wave

16 Figure 15 shows extreme values of the separator motion

12

8 under survival conditions.

4

0

ζ(m)

-4 Wave Incidence

-8 30

-12

20

-16

0 50 100 150 200 250 300 350 400 450 500 550 600 10

Time (s) 0

ζ(m)

Separator’s Angular Motion -10

9 -20

Angular Motion (degree)

6 -30

3 0 500 1000 1500 2000 2500 3000 3500 4000 4500 5000

0 Time (s)

-3

Separator’s Angular Motion

-6

Angular Motion (degree)

20

-9 15

0 50 100 150 200 250 300 350 400 450 500 550 600 10

Time (s) 5

0

Emulsion Quality Indicator -5

1,4 -10

1,2 -15

1,0 -20

0,8 0 500 1000 1500 2000 2500 3000 3500 4000 4500 5000

Time (s)

IE

0,6

0,4

0,2 Emulsion Quality Indicator

1,4

0,0

0 50 100 150 200 250 300 350 400 450 500 550 600 1,2

Time (s) 1,0

0,8

IE

0,6

Figure 14. Wave elevation, separator motion and indicator for roll 0,4

motion (amplitude 15m and period 13.09s) 0,2

0,0

0 500 1000 1500 2000 2500 3000 3500 4000 4500 5000

A range of operational conditions was also investigated for Time (s)

the roll motion. However, the case 2 resulted as the largest

angular amplitude. In this case, it is noted that, when the value Figure 15. Wave elevation, separator motion and indicator for roll

of excitation frequency is close to the roll resonant frequency motion (Hs=11.60m and Tp =16.30s)

(0.30 rad/s), the amplitude of motion is maximum and greater

amount of free water passes into the separator final section. In Based on the recommended practice (DNV-RP-C205) [15],

consequence, the separated emulsion quality decreased. From a maximum roll motion angle of fifteen degrees was

the value of resonant period and for the same amplitude value, established. Results for roll motions in irregular waves are

if the wave excitation frequency continues to increase, then the indicated in Table 8.

angular motion decreases, as seen on Table 7.

9 Copyright © 2017 ASME

Downloaded From: http://proceedings.asmedigitalcollection.asme.org/ on 01/03/2018 Terms of Use: http://www.asme.org/about-asme/terms-of-use

Table 8. Results of roll motions in irregular waves [4] Gjengedal, C., 2013, "Subsea Separation of Water and

MotionMax (degree)

Oil", Department of Petroleum Engineering and Applied

Case Period (s)

Geophysics, Ph.D.Thesis, pp. 52. NTNU, Trondheim.

1 16.30 19.31 0.92 [5] Frankiewicz, T.C.; Lee, C.M., 2002, "Using

2 13.09 51.77 2.03 Computational Fluid Dynamics (CFD) Simulation to

Model Fluid Motion in Process Vessels on Fixed and

Return period of 100 years was taken to obtain results for Floating Platforms", SPE Annual Technical Conference

cases of pitch motion (Figure 13) and roll motion (Figure 15), and Exhibition. Society of Petroleum Engineers, Texas,

respectively. Although the same wave energy spectrum is taken USA.

for head sea as well as for beam sea, an important difference is [6] Laleh, A. P.; Svrcek, W.Y.; Monnery, W., 2012,

observed between the pitch and roll motion maximum "Computational Fluid Dynamics-Based Study of an

amplitudes. In addition, this affects directly values of the Oilfield Separator - Part I: A Realistic Simulation”, Oil

emulsion quality indicator. and Gas Facilities, Vol.1, pp. 57-58.

[7] Newman, J.N., Lee, C.-H., 2002, "Integration of

Geometry Definition and Wave Analysis Software",

CONCLUSIONS International Conference on Offshore Mechanics and

In the present paper, the separation performance of a Free Arctic Engineering, Oslo, Norway.

Water Knockout separator (FWKO) under influences of pitch

and roll motions was evaluated. The performance of horizontal [8] Newman, J.N., 1997, "Marine Hydrodynamics", MIT

three-phase separator was defined through an indicator of Press.

emulsion quality based on the amount of free water that [9] American Bureau of Shipping (ABS), 2010, "Dynamic

surpasses the weir in the separator final section. It was observed Loading Approach for FPSO Installations", Houston,

that the offshore separator performance is highly dependent on USA.

the amplitude and frequency of FPSO motions, particularly [10] Journée, J.M.J., Massie, W.W., 2001, "Offshore

angular motions such as pitch and roll. Hydromechanics", Delft University of Technology, Delft.

In extreme sea conditions, the separation performance

[11] Morooka, C.K., Yokoo, I.H., 1997, "Numerical

decreases as the free water level exceeds the weir height with a

Simulation and Spectral Analysis of Irregular Sea

FWKO positive angle (pitch motion effects) or high roll angles

Waves", International Journal of Offshore and Polar

(roll motion effects), as observed from the regular and irregular

Engineering, Vol.7, pp. 189-199.

waves simulations.

From the study, the roll motion was observed as the most [12] Steward, M., Arnold, K., 2008, "Gas-Liquid and Liquid-

critical angular motion for FWKO operation, and it is a current Liquid Separators", Gulf Professional Publishing,

concern of the offshore industry. Elsevier.

As future work, more simulations are desired with different [13] American Petroleum Institute (API), 1989, "Specification

sea wave and FPSO load conditions, respectively. for Oil and Gas Separators", Spec.12J, Washington, USA.

[14] Rice, C.L., 1985, "Effects of Motion on Design of Process

Facilities for Floating Production Systems", Offshore

ACKNOWLEDGMENTS Technology Conference, Houston, Texas.

The authors would like to acknowledge the support from

[15] Det Norske Veritas (DNV), 2010, "Environmental

CAPES and the BG group for the present academic research.

Conditions and Environmental Loads", Recommended

Practice DNV-RP-C205, Norway.

REFERENCES

[1] Cueva, D.E.; Faria, F., 2014, "Roll Motions of FPSOs",

Available in http://oceanicabr.com/files/downloads/roll-

motions-of-fpsos-1.pdf

[2] Chakrabarti, S.K., 1987, "Hydrodynamics of Offshore

Structures", Illinois, USA: WIT Press.

[3] Lapidaire, P.J.; Leeuw, P.J., 1996, "The Effect of Ship

Motion on FPSO Topsides Design", Offshore Technology

Conference, Houston, USA.

10 Copyright © 2017 ASME

Downloaded From: http://proceedings.asmedigitalcollection.asme.org/ on 01/03/2018 Terms of Use: http://www.asme.org/about-asme/terms-of-use

Anda mungkin juga menyukai

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5795)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1091)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- Expt 7 - Hartley Oscillator (2020)Dokumen4 halamanExpt 7 - Hartley Oscillator (2020)samarthBelum ada peringkat

- 2 5px3cywystrfrlsDokumen2 halaman2 5px3cywystrfrlsKrish0% (1)

- Unit 2Dokumen55 halamanUnit 2Venkat ChadalavadaBelum ada peringkat

- APhO Team Selection Test 1Dokumen7 halamanAPhO Team Selection Test 1Marcus PoonBelum ada peringkat

- Bernoulli's Principle PDFDokumen3 halamanBernoulli's Principle PDFAnonymous EUaRVTHTDBelum ada peringkat

- Ds VDT Ds DT S 27 T T S 27 (3) (3) S 54 M:: Rectilinear MotionDokumen15 halamanDs VDT Ds DT S 27 T T S 27 (3) (3) S 54 M:: Rectilinear MotionAndrea MagtutoBelum ada peringkat

- Finite Element Analysis in Geotechnical Engineering Vol 1 TheoryDokumen459 halamanFinite Element Analysis in Geotechnical Engineering Vol 1 Theorysk m hassan100% (8)

- AN1543/D Electronic Lamp Ballast Design: Application NoteDokumen35 halamanAN1543/D Electronic Lamp Ballast Design: Application NoteprovolissimaBelum ada peringkat

- What Is The Difference Between MCB, MCCB, ELCB, and RCCB - EEPDokumen5 halamanWhat Is The Difference Between MCB, MCCB, ELCB, and RCCB - EEPcurazaq100% (1)

- Hamaker H. C., Physica IV. 10, 1058 (1937)Dokumen15 halamanHamaker H. C., Physica IV. 10, 1058 (1937)sk8sudBelum ada peringkat

- HL-500 General-Purpose Limit SwitchDokumen9 halamanHL-500 General-Purpose Limit SwitchMuhamad PriyatnaBelum ada peringkat

- Close Exam 8Dokumen4 halamanClose Exam 8sieged_rj3165Belum ada peringkat

- Modal Analysis of Impeller of A Centrifugal Pump - MidsemDokumen7 halamanModal Analysis of Impeller of A Centrifugal Pump - MidsemKrishnaDuttPandeyKdpBelum ada peringkat

- AC Motors Selection Flow: STEP 1: Select The Motor Size and Gear Ratio From The TorqueDokumen5 halamanAC Motors Selection Flow: STEP 1: Select The Motor Size and Gear Ratio From The TorqueAlmen MatanovićBelum ada peringkat

- Physical Education Nine Ten English VersionDokumen149 halamanPhysical Education Nine Ten English Versiondsafg87g87gawdwBelum ada peringkat

- Lecture 1Dokumen40 halamanLecture 1AmeerUlHaqBelum ada peringkat

- Users Manual: MegohmmeterDokumen41 halamanUsers Manual: MegohmmeterFelipe Ruben AlejoBelum ada peringkat

- Sudden Enlargement & ContractionDokumen2 halamanSudden Enlargement & ContractionFatin HazwaniBelum ada peringkat

- Combivert: AntriebstechnikDokumen14 halamanCombivert: AntriebstechnikOSAMABelum ada peringkat

- Principles and Testing Methods of Earth Ground ResistanceDokumen12 halamanPrinciples and Testing Methods of Earth Ground ResistanceDickson MapokoteraBelum ada peringkat

- Ascham 2008 Physics TrialsDokumen30 halamanAscham 2008 Physics TrialsNhan LeBelum ada peringkat

- Slewing and Trolley Panel PDFDokumen24 halamanSlewing and Trolley Panel PDFkabirmkjgfj0% (1)

- Topic 9 - Motor Starting AnalysisDokumen14 halamanTopic 9 - Motor Starting AnalysisAlla Naveen KumarBelum ada peringkat

- Unit 4 - Dynamics of MachinesDokumen60 halamanUnit 4 - Dynamics of MachinessadasivanBelum ada peringkat

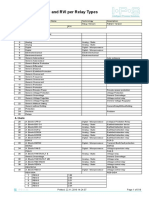

- IPS-EnERGY - Available Relay ModelsDokumen519 halamanIPS-EnERGY - Available Relay Modelskra_amBelum ada peringkat

- Getting Students Over MisconceptionsDokumen62 halamanGetting Students Over MisconceptionsNguyen Trinh Hai NgocBelum ada peringkat

- Michelson InterferometerDokumen9 halamanMichelson InterferometerSachinLambaBelum ada peringkat

- 2.wave OpticsexerciseDokumen32 halaman2.wave OpticsexerciseGomes RibeiroBelum ada peringkat

- 4896 E EEM 3.3 Single-Phase Induction Motor With Bifilar Starting Winding ShortDokumen6 halaman4896 E EEM 3.3 Single-Phase Induction Motor With Bifilar Starting Winding ShortMuhamad FaizalBelum ada peringkat

- The Zero Point Energy of The Quantum-VacuumDokumen5 halamanThe Zero Point Energy of The Quantum-VacuumBob HwknsBelum ada peringkat