A Capillary, Noncirculation Hydroponic Method For Leaf and Semi-Head Lettuce PDF

Diunggah oleh

Emmanuel Avalos HuarteJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

A Capillary, Noncirculation Hydroponic Method For Leaf and Semi-Head Lettuce PDF

Diunggah oleh

Emmanuel Avalos HuarteHak Cipta:

Format Tersedia

A Capillary, terns have been described in which a

small pot or some other plant contain-

tilizer salts included calcium nitrate,

potassium nitrate, potassium phos-

Noncirculating er rests on or above a layer of screen

(Imai, 1987; Kratky et al., 1988,1989).

phate, and sulfates of potassium, mag-

nesium, manganese, zinc, and copper.

Hydroponic The screen encourages root develop-

ment and provides an anchor for plant

‘Green Ice’ leaf lettuce and ‘Green

Mignonette’ semi-head lettuce were

Method for Leaf support. The lower part of the plant seeded in tapered plastic containers

container must be submerged in nutri- (Stuewe and Sons, Corvallis, Ore.), 40

and Semi-head ent solution immediately after trans- mm in diameter and 218 mm deep,

Lettuce planting. As the plants grow, the nutri-

ent solution level must be lowered gra-

filled to the top with 160 ml of a 1 sand

: 1.2 peat : 0.8 vermiculite medium

dually to a point just below the screen. and watered by overhead mist in a

The correct management of the nutri- seedling greenhouse. Care was taken

Bernard A. Kratky1 ent solution level is very important for to pack the media uniformly, thus elimi-

the proper establishment oftransplants, nating voids in the containers. The

and this process involves diligent at- containers with 18 -day-old seedlings

Additional index words, Lactuca tention of the grower. This report were transplanted into the top cover of

sativa, transplanting, gardening, describes a noncirculating capillary hy- the tank such that 47 mm of the seed-

growing systems droponic method for growing leaf and ling container extended above the sur-

semi-head lettuce (Lactuca sativa L.) face and 158 mm remained below the

Summary. A simple, capillary, non- in which no maintenance or monitor- plywoodcover. Therewere ten 4-mm-

circulating hydroponic method is de-

ing is required from the time of trans- diameter holes in the portion of the

scribed. Lettuce seedlings are trans-

planted into 218-mm-long plastic planting until harvesting. tapered plastic containers located be-

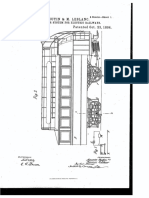

tubes containing 160 ml of growing A shallow tank was built in a green- low the cover, four oval holes (12 × 4

medium and the bottom 25 mm is house located at 1300 m elevation by mm) in the lower 20 mm of the con-

submerged into a tank of nutrient placing two layers of 0.15-mm-thick tainer, and a 7-mm-diameter hole in

solution. No additional fertilization, black polyethylene over a rectangular the bottom of the container.

watering, or monitoring is required frame, 9.7 × 1.2 m (Fig. 1). The frame The bottom 25 mm of each con-

from transplanting until harvesting. was constructed with 50 x 150-mm tainer was immersed in nutrient solu-

Although the nutrient solution level lumber at ground level and 50 mm of tion and the resulting capillary action

may drop below the bottoms of the soil was excavated and removed from was sufficient to wet the medium

tubes, the roots continue to take up within the frame to provide for a deeper throughout the containers, thus auto-

adequate water and nutrients to sus-

tank. Sheets of 13-mm-thick plywood matically watering the plants. No ad-

tain growth. This method does not

require pumps or electrical power. coated with white latex paint and rein- ditional maintenance was required from

‘Green Ice’ leaf lettuce produced 24% forced with 19 x 64-mm lumber (to this time until harvesting. Daily mini-

more salable yield growing with this prevent sagging) were placed over the mum temperatures ranged from 7 to

method than comparable plants grow- frame. Holes 38 mm in diameter were 17C, and daily maximum tempera-

ing in conventional soil culture. drilled in the plywood at 200 × 230- tures ranged from 19 to 31C. No

mm spacings. supplemental lighting was supplied.

Nutrient solution with a pH of After a 35-day growing period,

H

6.5 and an electrical conductivity of 89% of the ‘Green Ice’ and 81% of the

orticulturists routinely have

1.0 mS was added to the polyethylene ‘Green Mignonette’ heads were of

recommended aeration or

tank. It consisted of a 75-mm depth of marketable quality, and the average

circulation of nutrient solu-

water containing the following (in weights were 198 and 176 g/head,

tion in hydroponic systems since 1940,

mg·liter -1): N, 93; P, 33; K, 108; Ca, respectively. In a succeeding trial with

when Arnon and Hoagland reported a

110; Mg, 18; S, 23; Fe, 2; Mn, 1; Zn, 19-day-old transplants and a 32-day

34% yield increase of tomatoes by aer-

0.3; Cu, 0.3; B, l; an Mo, 0.05. Fer- growing period, all of the ‘Green Ice’

ating the nutrient solution (Arnon and

Hoagland, 1940). The additional pro-

duction costs and complexities associ-

ated with aeration and circulation of

nutrient solution have retarded the

adoption of hydroponic practices to

their full potential in commercial agri-

culture. Thus, there is a need to de-

velop simple, low-maintenance hydro-

ponic systems that do not require power

or complex equipment and are rela-

tively low in cost.

Noncirculating hydroponic sys-

1

Horticulturist, University of Hawaii, Beaumont Agri-

cultural Research Center, 461 W. Lanikaula, Hilo, HI

96720. Fig. 1. A capillary, noncirculating hydroponic method for leaf and semi-head lettuce.

206 HortTechnology - Apr./June 1993

and 97% of the ‘Green Mignonette’ Table 1. Salable yields of ‘Green Ice’ lettuce ent solution level drops or remains

were of marketable quality, and the grown by two noncirculating hydroponic constant. However, severe wilting or

methods and conventional soil culture.

average weights were 157 and 134 g/ even death often occurs after a signifi-

head, respectively. cant rise in the nutrient solution level.

The water consumption rates for Once roots have become acclimated to

‘Green Ice’ and ‘Green Mignonette’ a microclimate of moist air, they can

were 14.4 and 12.6 liter·kg-1, respec- no longer tolerate submerged condi-

tively, of harvest fresh weight of let- tions. Therefore, this method is not

tuce. Although the final nutrient solu- suitable for outdoor production be-

tion levels were 6 to 20 mm below the cause rainfall would cause the nutrient

bottom of the containers, the growing solution level to rise.

medium in the containers remained Longer-term crops such as toma-

moist. However, when the nutrient toes would present a challenge to this

z

solution level was 40 mm or more Leaf lettuce. Mean yields of six trials with 15 method because it would be necessary

below the bottom of the containers, heads per treatment and four replications. The to add nutrient solution during the

average transplant age was 20 days and the

the medium in the containers was of- average transplant-to-harvest time was 41 days. growing season. Application incre-

ten dry, but the plant continued to ments should be small to prevent root

growwell. No determination was made because the screen noncirculating injury.

on the maximum distance between the method required diligent attention Other types of tanks have been

container and the nutrient solution during the transplant establishment used successfully with this growing

that would permit satisfactory growth period, the capillary noncirculating method. These includes plastic buck-

of the plants. hydroponic methods enjoys the ad- ets with lids, large planting containers

Lettuce growth from the capil- vantage of high yield potential with no lined with plastic trash bags, insulated

lary, noncirculating hydroponic meth- maintenance from transplanting until coolers, and old refrigerators lined with

od was compared to lettuce growth harvesting. The nutrient solution pH polyethylene.

from the noncirculating screen method values at the end of these trials ranged Additional studies are needed to

and from conventional greenhouse soil from 6.1 to 7.0. adapt this method to crops with longer

(Manu silt loam) in an open-sided, Minimal root growth was ob- growing seasons. The capillary, non-

plastic-covered greenhouse located at served from the 4-mm holes in the circulating hydroponic method offers

a 1300-m elevation. The noncircu- containers located between the origi- promising potential for production of

lating hydroponic methods used poly- nal nutrient solution surface and the intensive crops, for home gardens pro-

ethylene-lined tanks (2.4 × 0.3 × 0.3 plywood cover. However, there was tected from rain, for educational pur-

m) containing the same nutrient solu- substantial root growth from the bot- poses, and for growing plants used in

tion described earlier. Rockwool cubes tom hole and the oval holes of the con- research.

(25 x 25 x 40 mm) served as the plant tainers that were immersed in nutrient

containers for the screen method, and solution at the start of the growing Acknowledgement

the screen was located 75 mm below period. A significant portion of this

The technical assistance of R.

the top cover. The soil bed received a root mass emerged in a conical form

Cupples, R. Kaneko, G. Maehira, Y.

preplant, broadcast, and incorporated and was suspended in the air above the

Takushi, and G. Terasawa is greatly

200-g·m-2 rate of 16N-6P-13K. Plants nutrient solution. Remaining roots

floated both on and below the nutri-

appreciated.

were arranged in double rows spaced

150 x 240 mm apart. There were four ent solution. Roots from adjacent

replicates of each treatment, and the plants intermingled with each other. Literature Cited

experiment was arranged as a random- When the plywood top cover was lifted

Arnon, D.I. and D.R. Hoagland. 1940.

ized complete block. There were six during the growing period, roots tore Crop production in artificial culture solu-

trials with ‘Green Ice’ leaf lettuce, and many roots in the conical suspen- tions and in soils with specific reference to

which were harvested in January, Feb- sion sank below the nutrient solution factors influencing yields and absorption

ruary, April, May, July, and August, level, causing the foliage to wilt or lose of inorganic nutrients. Soil Sci. 50:463-

with an average transplant age of 20 vigor. Thus, it is important not to dis- 484.

days and a transplant-to-harvest time turb the plants while they are growing.

Imai, H. 1987. AVRDC non-circulating

of 41 days. Throughout this period, After lettuce was transplanted in hydroponic system, p. 109-122. In: C.C.

daily minimum temperatures ranged the capillary, noncirculating hydro- Tu and T.F. Sheen (eds.). Proc. Symp on

between 7 and 17C and daily maxi- ponic method, no additional water- Horticultural Production under Structure.

mum temperatures ranged between ing, fertilization, or monitoring of pH Taiwan Agr. Res. Inst., Taichung.

19 and 31C. No supplemental light- or electrical conductivity was required.

Kratky, B.A., J.E. Bowen, and H. Imai.

ing was supplied. Thus, the only cultural operations re-

1988. Observations on a noncirculating

Salable yield of ‘Green Ice’ let- quired for this system are: preparation hydroponic system for tomato production.

tuce was 24% greater from the capil- of the nutrient solution, transplanting, HortScience 23:906-907.

lary, noncirculating hydroponic meth- harvest, cleanup, and, perhaps, disease

od than from the conventional soil or insect control. Kratky, B.A., H. Imai, and J.S. Tsay. 1989.

In the capillary, noncirculating Non-circulating hydroponic systems for

method (Table 1). However, yields

vegetable production. Proc. Natl.Agr. Plas-

from both noncirculating methods hydroponic method, plant growth is

tics Congr. 21:22-27.

were statistically similar. Therefore, not affected adversely when the nutri-

HortTechnology - Apr./June 1993 207

Anda mungkin juga menyukai

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (120)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Bard, Electrochemical DictionaryDokumen993 halamanBard, Electrochemical DictionaryFelipe Marçal MorgantiniBelum ada peringkat

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- RIBA Outline Plan of Work ExplainedDokumen20 halamanRIBA Outline Plan of Work ExplainedkenBelum ada peringkat

- United States Patent (19) : Westerberg Et Al. 11 Patent Number: 5,990,454 (45) Date of Patent: Nov. 23, 1999Dokumen35 halamanUnited States Patent (19) : Westerberg Et Al. 11 Patent Number: 5,990,454 (45) Date of Patent: Nov. 23, 1999Emmanuel Avalos HuarteBelum ada peringkat

- A Suspended Pot, Non-Circulating Hydroponic MethodDokumen7 halamanA Suspended Pot, Non-Circulating Hydroponic MethodEmmanuel Avalos HuarteBelum ada peringkat

- A Suspended Pot, Non-Circulating Hydroponic MethodDokumen7 halamanA Suspended Pot, Non-Circulating Hydroponic MethodEmmanuel Avalos HuarteBelum ada peringkat

- Us465588 PDFDokumen2 halamanUs465588 PDFEmmanuel Avalos HuarteBelum ada peringkat

- United States Patent (10) Patent No.: US 7.946,224 B2Dokumen13 halamanUnited States Patent (10) Patent No.: US 7.946,224 B2Emmanuel Avalos HuarteBelum ada peringkat

- ( ) Notice: Subject To Any Disclaimer, The Term of This E. "C Issn 0. EDokumen23 halaman( ) Notice: Subject To Any Disclaimer, The Term of This E. "C Issn 0. EEmmanuel Avalos HuarteBelum ada peringkat

- Transformer System for Electric Railways PatentDokumen8 halamanTransformer System for Electric Railways PatentEmmanuel Avalos HuarteBelum ada peringkat

- United States Patent: (75) Inventors: Chul Kim, Yongin (KR) Sung HoDokumen8 halamanUnited States Patent: (75) Inventors: Chul Kim, Yongin (KR) Sung HoEmmanuel Avalos HuarteBelum ada peringkat

- No. 225,306. Patented Mar. 9, 1880.: J. ThompsonDokumen2 halamanNo. 225,306. Patented Mar. 9, 1880.: J. ThompsonEmmanuel Avalos HuarteBelum ada peringkat

- United States Patent (10) Patent No.: US 7,739,948 B2: S.O.S.E.E.S.E. Primary Examiner Shawning FuquaDokumen22 halamanUnited States Patent (10) Patent No.: US 7,739,948 B2: S.O.S.E.E.S.E. Primary Examiner Shawning FuquaEmmanuel Avalos HuarteBelum ada peringkat

- Patented Sept. 15, 1891,: S. Wheeler, Wrapping or Toilet Paper, Roll, No. 459,516Dokumen3 halamanPatented Sept. 15, 1891,: S. Wheeler, Wrapping or Toilet Paper, Roll, No. 459,516Oscar DorantesBelum ada peringkat

- Schlenoff 1987Dokumen6 halamanSchlenoff 1987Emmanuel Avalos HuarteBelum ada peringkat

- Us6285999 PDFDokumen12 halamanUs6285999 PDFEmmanuel Avalos HuarteBelum ada peringkat

- US6630507 Hampson Et Al Cannabinoids As Antioxidants NeuroprotectDokumen26 halamanUS6630507 Hampson Et Al Cannabinoids As Antioxidants NeuroprotectstflockBelum ada peringkat

- Base HTMDokumen2 halamanBase HTMEmmanuel Avalos HuarteBelum ada peringkat

- Base CSSDokumen2 halamanBase CSSEmmanuel Avalos HuarteBelum ada peringkat

- Base HTMDokumen2 halamanBase HTMEmmanuel Avalos HuarteBelum ada peringkat

- Ef 5028873Dokumen29 halamanEf 5028873Emmanuel Avalos HuarteBelum ada peringkat

- Torrent Downloaded From Katcr - Co - KickasstorrentsDokumen1 halamanTorrent Downloaded From Katcr - Co - KickasstorrentsEmmanuel Avalos HuarteBelum ada peringkat

- Read MeDokumen1 halamanRead MeDiego HlchBelum ada peringkat

- Electropolymerization of Pyrrole and Electrochemical Study of Polypyrrole: 1. Evidence For Structural Diversity of PolypyrroleDokumen16 halamanElectropolymerization of Pyrrole and Electrochemical Study of Polypyrrole: 1. Evidence For Structural Diversity of PolypyrroleEmmanuel Avalos HuarteBelum ada peringkat

- Tesis GuvenirDokumen191 halamanTesis GuvenirEmmanuel Avalos HuarteBelum ada peringkat

- Rise of Nations UnitsDokumen10 halamanRise of Nations UnitsEmmanuel Avalos HuarteBelum ada peringkat

- Base HTMDokumen2 halamanBase HTMEmmanuel Avalos HuarteBelum ada peringkat

- High Technology Entrepreneurs and The Patent SystemDokumen89 halamanHigh Technology Entrepreneurs and The Patent SystemEmmanuel Avalos HuarteBelum ada peringkat

- Conducting Polymer Coatings in Electrochemical Technology Part 1 - Synthesis and Fundamental AspectsDokumen9 halamanConducting Polymer Coatings in Electrochemical Technology Part 1 - Synthesis and Fundamental AspectsEmmanuel Avalos HuarteBelum ada peringkat

- Are Natural Deep Eutectic Solvents The Missing Link in Understanding Cellular Metabolism and Physiology?Dokumen5 halamanAre Natural Deep Eutectic Solvents The Missing Link in Understanding Cellular Metabolism and Physiology?Emmanuel Avalos HuarteBelum ada peringkat

- Deep Eutectic Solvents AsDokumen9 halamanDeep Eutectic Solvents AsEmmanuel Avalos HuarteBelum ada peringkat

- Polarons, Bipolarons, and SolitonsDokumen7 halamanPolarons, Bipolarons, and SolitonsEmmanuel Avalos HuarteBelum ada peringkat

- Board Question Paper: March 2018: Geography and EconomicsDokumen2 halamanBoard Question Paper: March 2018: Geography and EconomicsVishvajit PatilBelum ada peringkat

- Year 12 Holiday Homework Term 3Dokumen4 halamanYear 12 Holiday Homework Term 3Lucas GauciBelum ada peringkat

- REMOVE CLASS 2024 SOW Peralihan MajuDokumen4 halamanREMOVE CLASS 2024 SOW Peralihan MajuMohd FarezBelum ada peringkat

- GMS175CSDokumen4 halamanGMS175CScorsini999Belum ada peringkat

- Transformers Obj Questions PDFDokumen8 halamanTransformers Obj Questions PDFphaniputta100% (2)

- Map Project Rubric 2018Dokumen2 halamanMap Project Rubric 2018api-292774341Belum ada peringkat

- Danbury BrochureDokumen24 halamanDanbury BrochureQuique MartinBelum ada peringkat

- Frequently Asked Questions About Ailunce HD1: Where Can Find HD1 Software & Firmware?Dokumen5 halamanFrequently Asked Questions About Ailunce HD1: Where Can Find HD1 Software & Firmware?Eric Contra Color0% (1)

- Research on Comparisons between Sabah and Diesel CyclesDokumen8 halamanResearch on Comparisons between Sabah and Diesel CyclesjorgeBelum ada peringkat

- Introduction To Financial Planning Unit 1Dokumen57 halamanIntroduction To Financial Planning Unit 1Joshua GeddamBelum ada peringkat

- 01 - PV - RESCO 1d Workshop - S1 PDFDokumen61 halaman01 - PV - RESCO 1d Workshop - S1 PDFDeasy KurniawatiBelum ada peringkat

- IBM TS2900 Tape Autoloader RBDokumen11 halamanIBM TS2900 Tape Autoloader RBLeonBelum ada peringkat

- Unit 5 EstándarDokumen2 halamanUnit 5 EstándardechillbroBelum ada peringkat

- 1.1 Enterprise AssessmentDokumen1 halaman1.1 Enterprise AssessmentGermanRobertoFongBelum ada peringkat

- Pharmacology Ain Shams 123 - Compress 1Dokumen552 halamanPharmacology Ain Shams 123 - Compress 1ahmed hoty100% (1)

- LETTER OF AUTHORIZATION CREDO INVEST DownloadDokumen1 halamanLETTER OF AUTHORIZATION CREDO INVEST DownloadEsteban Enrique Posan BalcazarBelum ada peringkat

- Red Lion Edict-97 - Manual PDFDokumen282 halamanRed Lion Edict-97 - Manual PDFnaminalatrukBelum ada peringkat

- Chemical ReactionDokumen13 halamanChemical ReactionSujit LawareBelum ada peringkat

- Grab E-Receipt for 15,000 RP Ride on March 30Dokumen1 halamanGrab E-Receipt for 15,000 RP Ride on March 30WellyBelum ada peringkat

- Nettoplcsim S7online Documentation en v0.9.1Dokumen5 halamanNettoplcsim S7online Documentation en v0.9.1SyariefBelum ada peringkat

- Document 25Dokumen455 halamanDocument 25Pcnhs SalBelum ada peringkat

- Summative Test For Quadratic Equations2Dokumen2 halamanSummative Test For Quadratic Equations2AsmiraMangontra0% (1)

- 7 - NIBL - G.R. No. L-15380 Wan V Kim - DigestDokumen1 halaman7 - NIBL - G.R. No. L-15380 Wan V Kim - DigestOjie SantillanBelum ada peringkat

- Gartner CRM Handbook FinalDokumen0 halamanGartner CRM Handbook FinalghanshyamdassBelum ada peringkat

- 2.2valves, Alarm - Ul Product IqDokumen1 halaman2.2valves, Alarm - Ul Product Iqbhima irabattiBelum ada peringkat

- An Introduction To Log ShootingDokumen10 halamanAn Introduction To Log ShootingSorin GociuBelum ada peringkat

- S 1804 2019 (E) - 0Dokumen9 halamanS 1804 2019 (E) - 0Juan Agustin CuadraBelum ada peringkat

- Coffee TestDokumen6 halamanCoffee TestAmit Satyen RaviBelum ada peringkat

- Armv8-A Instruction Set ArchitectureDokumen39 halamanArmv8-A Instruction Set ArchitectureraygarnerBelum ada peringkat