HZ Tecaflon PVDF Natural Se de 201709

Diunggah oleh

Ha Tran KhiemJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

HZ Tecaflon PVDF Natural Se de 201709

Diunggah oleh

Ha Tran KhiemHak Cipta:

Format Tersedia

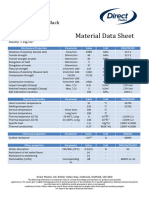

TECAFLON PVDF natural - Stock Shapes

Chemic al Des ignat ion Main feat ures Target Indus t ries

PVDF (Polyvinylidene fluoride) very good chemical resistance chemical technology

inherent flame retardant electronics

Colour

continuous service temperature up to energy industry

white opaque 150 °C food technology

Dens it y good slide and wear properties medical technology

1.78 g/cm3 very good weldable mechanical engineering

very good electrical insulation

very good UV and weather resistance

Me ch a n i ca l p ro p e rti e s p a ra m e te r va l u e unit n o rm co m m e n t

Modulus of elasticity 1mm/min 2200 MPa DIN EN ISO 527-2 1) (1) For tensile test: spec imen

(tensile test) type 1b

(2) For flexural test: support

Tensile strength 50mm/min 62 MPa DIN EN ISO 527-2 span 64mm, norm spec imen.

(3) Spec imen 10x10x10mm

Tensile strength at yield 50mm/min 62 MPa DIN EN ISO 527-2 (4) Spec imen 10x10x50mm,

50mm/min DIN EN ISO 527-2 modulus range between 0.5

Elongation at yield 8 % and 1% c ompression.

Elongation at break 50mm/min 17 % DIN EN ISO 527-2 (5) For Charpy test: support

span 64mm, norm spec imen.

Flexural strength 2mm/min, 10 N 77 MPa DIN EN ISO 178 2) (6) Spec imen in 4mm

thic kness

Modulus of elasticity 2mm/min, 10 N 2100 MPa DIN EN ISO 178

(flexural test)

Compression strength 1% / 2% 16 / 28 MPa EN ISO 604 3)

5mm/min, 10 N

Compression modulus 5mm/min, 10 N 1900 MPa EN ISO 604 4)

Impact strength (Charpy) max. 7,5J 150 kJ/m 2 DIN EN ISO 179-1eU 5)

Ball indentation hardness 129 MPa ISO 2039-1 6)

Th e rm a l p ro p e rti e s p a ra m e te r va l u e unit n o rm co m m e n t

Glass transition temperature -40 °C DIN EN ISO 11357 1) (1) Found in public sourc es.

(2) Found in public sourc es.

Melting temperature 171 °C DIN EN ISO 11357 Individual testing regarding

applic ation c onditions is

Service temperature short term 150 °C 2) mandatory.

Service temperature long term 150 °C

Thermal expansion (CLTE) 23-60°C, long. 16 10 -5 K -1 DIN EN ISO 11359-1;2

Thermal expansion (CLTE) 23-100°C, long. 18 10 -5 K -1 DIN EN ISO 11359-1;2

Specific heat 1.3 J/(g*K) ISO 22007-4:2008

Thermal conductivity 0.25 W/(K*m) ISO 22007-4:2008

El e ctri ca l p ro p e rti e s p a ra m e te r va l u e unit n o rm co m m e n t

Specific surface resistance 10 14 Ω DIN IEC 60093

Oth e r p ro p e rti e s p a ra m e te r va l u e unit n o rm co m m e n t

Water absorption 24h / 96h (23°C) <0.01 / % DIN EN ISO 62 1) (1) Ø c a. 50mm, h=13mm

<0.01 (2) + good resistanc e

(3) Corresponding means no

Resistance to hot water/ bases + - 2) listing at UL (yellow c ard).

The information might be

Resistance to weathering + taken from resin, stoc k shape

corresponding to DIN IEC 60695-11-10; 3) or estimation. Individual

Flammability (UL94) V0 testing regarding applic ation

c onditions is mandatory.

Our information and statements reflec t the c urrent state of our knowledge and shall inform about our produc ts and their applic ations. They do not assure or guarantee

c hemic al resistanc e, quality of produc ts and their merc hantability in a legally binding way. Our produc ts are not defined for use in medic al or dental implants. Existing

c ommerc ial patents have to be observed. The c orresponding values and information are no minimum or maximum values, but guideline values that c an be used

primarily for c omparison purposes for material selec tion. These values are within the normal toleranc e range of produc t properties and do not represent guaranteed

property values. Therefore they shall not be used for spec ific ation purposes. Unless otherwise noted, these values were determined by tests at referenc e dimensions

(typic ally rods with diameter 40-60 mm ac c ording to DIN EN 15860) on extruded and mac hined spec imen. As the properties depend on the dimensions of the semi-

finished produc ts and the orientation in the c omponent (esp. in reinforc ed grades), the material may not be used without a separate testing under individual

c irc umstanc es. The c ustomer is solely responsible for the quality and suitability of produc ts for the applic ation and has to test usage and proc essing prior to use. Data

sheet values are subjec t to periodic review, the most rec ent update c an be found at www.ensinger-online.c om. Tec hnic al c hanges reserved.

Ensinger Sw eden AB Tel +46 171 477050 Date: 2017/03/28 Version: AB

Stenvretsgatan 5 Fax +46 171 440418

749 40 Enköping - Sw eden w w w .ensinger.se

Anda mungkin juga menyukai

- Tecatron Gf40 Black en All 201711Dokumen2 halamanTecatron Gf40 Black en All 201711JorgeMariscalBelum ada peringkat

- TECAMID 66 GF30 Black 0Dokumen1 halamanTECAMID 66 GF30 Black 0VTHafnergmx.deBelum ada peringkat

- Pa6 BlackDokumen2 halamanPa6 BlackworkatarBelum ada peringkat

- TECAPEEK PVX Black 7 PDFDokumen1 halamanTECAPEEK PVX Black 7 PDFHARSHABelum ada peringkat

- HZ Tecafine PMP Natural in de 201604Dokumen1 halamanHZ Tecafine PMP Natural in de 201604Luis Alberto Silva NavarroBelum ada peringkat

- Material Data Sheet PA 6 GF30 Black: Main FeaturesDokumen2 halamanMaterial Data Sheet PA 6 GF30 Black: Main FeaturesmohanBelum ada peringkat

- TECAPEEK CF30 Black 7 PDFDokumen1 halamanTECAPEEK CF30 Black 7 PDFHARSHABelum ada peringkat

- TECAFINE PMP Natural - Stock Shapes (Rods, Plates, Tubes)Dokumen1 halamanTECAFINE PMP Natural - Stock Shapes (Rods, Plates, Tubes)yatheendravarmaBelum ada peringkat

- TECAPEEK GF30 Natural - Stock ShapesDokumen1 halamanTECAPEEK GF30 Natural - Stock ShapesHARSHABelum ada peringkat

- TECACOMP PPA LDS Black 4108 0Dokumen2 halamanTECACOMP PPA LDS Black 4108 0H. BeatsBelum ada peringkat

- Propertie NilonDokumen3 halamanPropertie Nilonmuhammad daffaBelum ada peringkat

- TECASINT 1011 Natural - Stock ShapesDokumen2 halamanTECASINT 1011 Natural - Stock ShapesGreeshmaBelum ada peringkat

- TRO CX7323 - E11 - Ad PDFDokumen2 halamanTRO CX7323 - E11 - Ad PDFJosip DuvnjakBelum ada peringkat

- Tecasint 1011 Natural 0Dokumen1 halamanTecasint 1011 Natural 0Suraj_73Belum ada peringkat

- Riteflex 640aDokumen3 halamanRiteflex 640aazaleaemersonBelum ada peringkat

- POM KEPITAL F30-03 enDokumen2 halamanPOM KEPITAL F30-03 enAthonioMourinhoBelum ada peringkat

- PET Glide DatabladDokumen1 halamanPET Glide DatabladMuhammad IrfanBelum ada peringkat

- Technyl Safe C 116FC NCDokumen3 halamanTechnyl Safe C 116FC NCkls.thorodinsonBelum ada peringkat

- Celanex 3316Dokumen5 halamanCelanex 3316klausoshoBelum ada peringkat

- HOSTAFORM® C 9021 TF-enDokumen4 halamanHOSTAFORM® C 9021 TF-enshahin_723Belum ada peringkat

- Property Test Method Unit Typicalvalue : BL 4M License Grade Code HM 8355 (THT)Dokumen1 halamanProperty Test Method Unit Typicalvalue : BL 4M License Grade Code HM 8355 (THT)MohamadMostafaviBelum ada peringkat

- Pa 6 GF 30 (En)Dokumen1 halamanPa 6 GF 30 (En)Alessandro WeissBelum ada peringkat

- Durafide 6165A6 TDSDokumen6 halamanDurafide 6165A6 TDSCassianBelum ada peringkat

- Material Data Sheet: Urban@plastum - CZ WWW - Plastum.czDokumen1 halamanMaterial Data Sheet: Urban@plastum - CZ WWW - Plastum.czDavis GBelum ada peringkat

- Murtfeldt Material S Group Material-S-1000-Green Technical Data enDokumen1 halamanMurtfeldt Material S Group Material-S-1000-Green Technical Data enPedro Henriques RamosBelum ada peringkat

- Kepital F20 - 03Dokumen2 halamanKepital F20 - 03Kumaar RanjanBelum ada peringkat

- NORYL™ Resin - SE1GFN2 - Asia - Technical - Data - Sheet PDFDokumen3 halamanNORYL™ Resin - SE1GFN2 - Asia - Technical - Data - Sheet PDFbhushansalunkeBelum ada peringkat

- PC Caracteristicas PDFDokumen3 halamanPC Caracteristicas PDFIceMan3Belum ada peringkat

- Styrolution PS 165N/L: General Purpose Polystyrene (GPPS)Dokumen3 halamanStyrolution PS 165N/L: General Purpose Polystyrene (GPPS)Inês MorgadoBelum ada peringkat

- HOSTAFORM® C 27021 - POM - Unfilled: DescriptionDokumen5 halamanHOSTAFORM® C 27021 - POM - Unfilled: Descriptionrahul vermaBelum ada peringkat

- Advanced-PP 1102LQ - 0Dokumen1 halamanAdvanced-PP 1102LQ - 0Narender RawatBelum ada peringkat

- Polystone P Homopolymer: Technical Data SheetDokumen1 halamanPolystone P Homopolymer: Technical Data Sheetmuchamad yasinBelum ada peringkat

- Acetal Natural Data SheetDokumen1 halamanAcetal Natural Data SheetvijayBelum ada peringkat

- VASITESA MEXICO Datasheet - Polystone - P - Homopolymer - Grey - ENDokumen1 halamanVASITESA MEXICO Datasheet - Polystone - P - Homopolymer - Grey - ENIsrael AristaBelum ada peringkat

- Property Test Method Unit Typicalvalue : BL3 License Grade Code HF 4670 (THT)Dokumen1 halamanProperty Test Method Unit Typicalvalue : BL3 License Grade Code HF 4670 (THT)MohamadMostafaviBelum ada peringkat

- TDS CPE V3.010-EnDokumen3 halamanTDS CPE V3.010-EnspicefooBelum ada peringkat

- Original Material "S" Green: Technical InformationDokumen1 halamanOriginal Material "S" Green: Technical InformationPedro Henriques RamosBelum ada peringkat

- Ficha Técnica Nylon MolyDokumen1 halamanFicha Técnica Nylon MolyHector ArciniegasBelum ada peringkat

- Bakelite PF 31Dokumen3 halamanBakelite PF 31dioguitomsolhaBelum ada peringkat

- Dupont Delrin 527UV BK701Dokumen4 halamanDupont Delrin 527UV BK701Phung LucBelum ada peringkat

- Nylon 6Dokumen1 halamanNylon 6luuiissBelum ada peringkat

- Sustatron Pps GF 40: Technical Data SheetDokumen1 halamanSustatron Pps GF 40: Technical Data SheetyatheendravarmaBelum ada peringkat

- Technical Data Sheet PC: Filament SpecificationsDokumen3 halamanTechnical Data Sheet PC: Filament SpecificationsVladimir SarmientoBelum ada peringkat

- PA6EDokumen1 halamanPA6EDiego ReggianiniBelum ada peringkat

- PET Technical Handbook 1Dokumen61 halamanPET Technical Handbook 1karismaBelum ada peringkat

- Advanced PP 1102KDokumen1 halamanAdvanced PP 1102KLaxman AhirBelum ada peringkat

- Datasheet SustaPEEK ENDokumen1 halamanDatasheet SustaPEEK ENazwar1105Belum ada peringkat

- ABS - Novodur P2HGVDokumen2 halamanABS - Novodur P2HGVarmandoBelum ada peringkat

- Policarbonato Macizo Polygal Plazit PDFDokumen4 halamanPolicarbonato Macizo Polygal Plazit PDFnicolas peraltaBelum ada peringkat

- ProductFile 131206155656Dokumen1 halamanProductFile 131206155656Michael HajzerBelum ada peringkat

- Allbro Material-Properties-Smc-DmcDokumen1 halamanAllbro Material-Properties-Smc-Dmcfajar agungBelum ada peringkat

- Tds A1105 en 2017pdfpdfDokumen2 halamanTds A1105 en 2017pdfpdfagungBelum ada peringkat

- Policarbonato Teijin Panlite Ad-5503Dokumen1 halamanPolicarbonato Teijin Panlite Ad-5503marioBelum ada peringkat

- Plancha de Poliprolieno Datasheet - Polystone - P - Homopolymer - Natural - ENDokumen1 halamanPlancha de Poliprolieno Datasheet - Polystone - P - Homopolymer - Natural - ENMiltonBelum ada peringkat

- Dupont™ Crastin Sk615Sf Nc010 (Preliminary Data) : Thermoplastic Polyester ResinDokumen6 halamanDupont™ Crastin Sk615Sf Nc010 (Preliminary Data) : Thermoplastic Polyester ResinomarBelum ada peringkat

- Product Information Product Information Product Information Product InformationDokumen2 halamanProduct Information Product Information Product Information Product InformationMorkizgaBelum ada peringkat

- SC-1100R DatasheetDokumen2 halamanSC-1100R DatasheetAgus IrawanBelum ada peringkat

- POM - KEPITAL F20-03 - Standard GradeDokumen2 halamanPOM - KEPITAL F20-03 - Standard GradeMadhav RajpurohitBelum ada peringkat

- PRS Geotech Data Spec Neoloy Category B V8.1aDokumen2 halamanPRS Geotech Data Spec Neoloy Category B V8.1aJonas MachadoBelum ada peringkat

- (IEEE Press Series on RF and Microwave Technology) Paul F. Goldsmith-Quasioptical Systems_ Gaussian Beam Quasioptical Propogation and Applications (IEEE Press Series on RF and Microwave Technology)-Wi.pdfDokumen425 halaman(IEEE Press Series on RF and Microwave Technology) Paul F. Goldsmith-Quasioptical Systems_ Gaussian Beam Quasioptical Propogation and Applications (IEEE Press Series on RF and Microwave Technology)-Wi.pdfHa Tran KhiemBelum ada peringkat

- Theoretical Calculation and Experiment of Microwave Electromagnetic Property of Ni (C) NanocapsulesDokumen8 halamanTheoretical Calculation and Experiment of Microwave Electromagnetic Property of Ni (C) NanocapsulesHa Tran KhiemBelum ada peringkat

- ACES Journal August 2011 Paper 04Dokumen7 halamanACES Journal August 2011 Paper 04Ha Tran KhiemBelum ada peringkat

- ACES Journal August 2011 Paper 04Dokumen7 halamanACES Journal August 2011 Paper 04Ha Tran KhiemBelum ada peringkat

- EMC Conference AgendaDokumen90 halamanEMC Conference AgendaHa Tran KhiemBelum ada peringkat

- AN1156Dokumen4 halamanAN1156Ha Tran KhiemBelum ada peringkat

- MaterialData 15036Dokumen1 halamanMaterialData 15036Ha Tran KhiemBelum ada peringkat

- Tips DRC LVS CadenceDokumen5 halamanTips DRC LVS CadenceHa Tran KhiemBelum ada peringkat

- Characterization and Modeling of Microwave Absorbers in The RF and Antenna ProjectsDokumen4 halamanCharacterization and Modeling of Microwave Absorbers in The RF and Antenna ProjectsHa Tran KhiemBelum ada peringkat

- Free Space Materials Characterization2010Dokumen53 halamanFree Space Materials Characterization2010Ha Tran KhiemBelum ada peringkat

- Tips DRC LVS CadenceDokumen5 halamanTips DRC LVS CadenceHa Tran KhiemBelum ada peringkat

- ECE321 Lab3Dokumen9 halamanECE321 Lab3Ha Tran KhiemBelum ada peringkat

- Air LineDokumen25 halamanAir LineHa Tran KhiemBelum ada peringkat

- Atlas Technical Handbook of ST Steel 05 2008 PDFDokumen45 halamanAtlas Technical Handbook of ST Steel 05 2008 PDFPoncho RmzBelum ada peringkat

- Immanuel Kant: On The Right To Punish and To Grant Clemency. IDokumen27 halamanImmanuel Kant: On The Right To Punish and To Grant Clemency. IHa Tran KhiemBelum ada peringkat

- Chap7 PDFDokumen58 halamanChap7 PDFPauloBelum ada peringkat

- CH 05Dokumen17 halamanCH 05nouriBelum ada peringkat

- EM Pro Simulation: Geometr y Port/Feed Simulatio N Setting Post-Processin GDokumen9 halamanEM Pro Simulation: Geometr y Port/Feed Simulatio N Setting Post-Processin GHa Tran KhiemBelum ada peringkat

- Astm A586 04Dokumen6 halamanAstm A586 04beTxxYBelum ada peringkat

- EBBEF2p-A Computer Code For Analyzing Beams On Elastic FoundationsDokumen18 halamanEBBEF2p-A Computer Code For Analyzing Beams On Elastic FoundationshoojzteBelum ada peringkat

- ISRM Rock Bolt Index ProceduresDokumen22 halamanISRM Rock Bolt Index ProceduresDavid UnnadadzeBelum ada peringkat

- Key Design PDFDokumen11 halamanKey Design PDFjohn139138Belum ada peringkat

- Basic Prestressed ConcreteDokumen229 halamanBasic Prestressed ConcreteVance KangBelum ada peringkat

- Elastic Plastic NotesDokumen89 halamanElastic Plastic NotesFlorin BucBelum ada peringkat

- Chemical Engineering ThermodynamicsDokumen86 halamanChemical Engineering ThermodynamicsSreedhar BabuBelum ada peringkat

- Chapter 1 Introduction To RC DesignDokumen38 halamanChapter 1 Introduction To RC Designabood buriahi100% (1)

- Assignment 1 (2019)Dokumen3 halamanAssignment 1 (2019)Chairil ChairilBelum ada peringkat

- Hbeam 150X150Dokumen4 halamanHbeam 150X150M IQbalBelum ada peringkat

- STL261S Assignment 2 - 2022Dokumen5 halamanSTL261S Assignment 2 - 2022SimphiweBelum ada peringkat

- BHCurve LabmanualDokumen7 halamanBHCurve LabmanualRaja Wajhi Ullah NisarBelum ada peringkat

- 4 Circular Concrete Tanks Without PrestressingDokumen138 halaman4 Circular Concrete Tanks Without PrestressingDario MonteiroBelum ada peringkat

- Effect of Cold Working On BrassDokumen3 halamanEffect of Cold Working On BrassHasnain AliBelum ada peringkat

- ISO 178 - Flexural TestingDokumen10 halamanISO 178 - Flexural Testingkhuelv100% (1)

- CE 320 - Fluid Mechanics - Module 1 Lesson 1 PDFDokumen14 halamanCE 320 - Fluid Mechanics - Module 1 Lesson 1 PDFMichael Christ IcagoyBelum ada peringkat

- TorsionDokumen5 halamanTorsionWilson TengBelum ada peringkat

- 0910 PPGDokumen6 halaman0910 PPGmihailmiBelum ada peringkat

- Lab 2 - Shear Force and Bending Moment DiagramDokumen8 halamanLab 2 - Shear Force and Bending Moment Diagramaiman azhar100% (1)

- 1 s2.0 S0020740301000832 MainDokumen20 halaman1 s2.0 S0020740301000832 MainashrayvalsanBelum ada peringkat

- Theme: Technology in Chemistry Chapter: Polymer Title of Project: Stationery HolderDokumen30 halamanTheme: Technology in Chemistry Chapter: Polymer Title of Project: Stationery HolderTecky JerryBelum ada peringkat

- Design of Machine Elements-I (DME-I)Dokumen2 halamanDesign of Machine Elements-I (DME-I)durgaraokamireddyBelum ada peringkat

- Eurocode 3 Lecture NotesDokumen30 halamanEurocode 3 Lecture Noteskhx2Belum ada peringkat

- Plain & Reinforced Concrete - II: Lesson No 02: Design Methodology Dr. Musaad Zaheer Nazir KhanDokumen20 halamanPlain & Reinforced Concrete - II: Lesson No 02: Design Methodology Dr. Musaad Zaheer Nazir KhanMuhammad Salman JavaidBelum ada peringkat

- Guided Revision Plan-Score AdvancedDokumen5 halamanGuided Revision Plan-Score AdvancedPratham PatelBelum ada peringkat

- ADA307702Dokumen234 halamanADA307702Andres Rodriguez HerreraBelum ada peringkat

- Impact Testing: of TextilesDokumen9 halamanImpact Testing: of Textilesരജീഷ് വി എംBelum ada peringkat

- Quality Education For A Better Mindanao A. Bonifacio Avenue, Tibanga, 9200 Iligan City Philippines +63.63.221.4056Dokumen7 halamanQuality Education For A Better Mindanao A. Bonifacio Avenue, Tibanga, 9200 Iligan City Philippines +63.63.221.4056Al Ignatius MabolisBelum ada peringkat

- 4.3 Mechanical Anchoring-Systems (289-389) PDFDokumen104 halaman4.3 Mechanical Anchoring-Systems (289-389) PDFpabmataBelum ada peringkat