Specs 670-26 - C27

Diunggah oleh

Hery Mardiono HeryJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Specs 670-26 - C27

Diunggah oleh

Hery Mardiono HeryHak Cipta:

Format Tersedia

0067D1412026H

4 April 2016

Page 1 of 12

SPECIFICATIONS

FOR

ELLICOTT

670 SERIES DRAGON MODEL

CUTTERHEAD DREDGE

FOR 26 FEET (8 METER) DIGGING DEPTH

© ELLICOTT DREDGES, LLC - 2016

Ellicott is a registered trademark of Ellicott Dredges, LLC

0067D1412026H

4 April 2016

Page 2 of 12

TABLE OF CONTENTS

SECTION DESCRIPTION PAGE

1 General ........................................................................................ 3

2 Center Hull Tank .......................................................................... 3

3 Side Hull Tank (Port and Starboard) ............................................. 4

4 Dredge Pump ............................................................................... 5

5 Diesel Engine ............................................................................... 5

6 Swing Winches ............................................................................. 6

7 Ladder Hoist ................................................................................. 6

8 Spud Hoists .................................................................................. 6

9 Hydraulic System .......................................................................... 7

10 Dredge Piping ............................................................................... 7

11 Service Water System .................................................................. 7

12 Electrical System .......................................................................... 8

13 Lighting System ............................................................................ 8

14 Lever Room and Control Panel..................................................... 8

15 Spuds ........................................................................................... 9

16 Dredging Ladder ........................................................................... 9

17 Safety Equipment ......................................................................... 10

18 Painting ........................................................................................ 10

19 Shop and Field Testing ................................................................. 11

20 Instruction Manuals ...................................................................... 11

21 Options ......................................................................................... 11

22 Summary ...................................................................................... 12

Ellicott is a registered trademark of Ellicott Dredges, LLC

0067D1412026H

4 April 2016

Page 3 of 12

SPECIFICATIONS

ELLICOTT SERIES 670

1. GENERAL:

Length - overall - feet (meters) 69'-6" (21.18)

Width - overall - feet (meters) 20'-2" (6.15)

Height - overall - feet (meters) 36'-6" (11.12)

(Spuds installed and elevated)

Height - overall - feet (meters) 11'-4" (3.45)

(Spuds, spud hoists, muffler, removed)

Dry Weight - approximate, 65 (58,968)

(With spuds) - U.S. Tons (Kg)

Draft - maximum - feet (meters) 2’-8” (.83)

(With spuds installed and elevated)

Minimum digging depth - feet (meters) 4’-0” (1.22)

Maximum digging depth - feet (meters) 26'-0" (8.0)

(@ 60 degrees)

Channel width @ 80° total swing angle

@ minimum digging depth - feet (meters) 90’-0” (27.44)

Channel width @ 80° total swing angle

@ maximum digging depth - feet (meters) 70’-0” (21.34)

Fuel capacity - gallons (m3) 2700 (10.4)

2. CENTER HULL TANK: ONE (1)

Welded steel construction with ladder well forward.

Designed to A.B.S. River Rules.

1/4" (6 mm) end plates.

1.4" (6 mm) bottom plate.

1/4" (6 mm) side plates.

Ellicott is a registered trademark of Ellicott Dredges, LLC

0067D1412026H

4 April 2016

Page 4 of 12

2. CENTER HULL TANK: ONE (1) (Continued):

1/4" (6 mm) deck plate.

3/16" (5 mm) internal bulkheads.

Built-in hydraulic oil tank.

Built-in fuel oil tanks

Watertight manhole covers.

Four lifting lugs. (Suitable for lifting complete dry dredge less spuds)

Length ) 50'-0" (15.24)

Depth ) Moulded - feet (meters) 4'-0" (1.22)

Width ) 11'-10-7/8" (3.63)

3. SIDE HULL TANKS: (ONE (1) PORT AND ONE (1) STARBOARD)

Welded steel construction. Easily demountable from center hull tank using vertical

pins.

Designed to A.B.S. River Rules.

3/16" (5 mm) end plates.

3/16" (5 mm) bottom plate.

3/16" (5 mm) side plates.

3/16" (5 mm) deck plate.

Watertight manhole covers.

Built-in ballast tanks.

Three (3) deck cleats each (mounted on outboard edge).

Four (4) lifting lugs.

Length ) 50'-0" (15.24)

Depth ) Moulded - feet (meters) 4'-0" (1.22)

Width ) Each tank 3'-11-3/8” (1.20)

Ellicott is a registered trademark of Ellicott Dredges, LLC

0067D1412026H

4 April 2016

Page 5 of 12

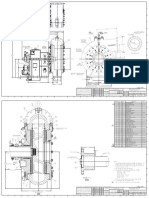

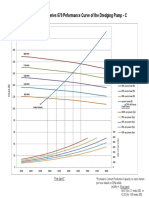

4. DREDGE PUMP:

Ellicott Series 600 pump.

37" (940 mm) diameter high efficiency impeller with 7” (178 mm) particle clearance

and patented recessed expeller vanes on both suction and engine sides - thread

mounted.

Alloy cast iron (Ni-Hard 4) wearing parts - pump case, impeller and head liners - 500

BHN minimum.

Steel side heads, front head is adjustable to suit liner and impeller wear.

Packed stuffing box with flushing water connection and replaceable 316 stainless

steel heavy duty shaft sleeve for sea and fresh water service.

Heavy duty alloy steel pump shaft with high capacity anti-friction roller bearings for

thrust and radial loads with internal stainless steel oil cooler and dual grease purged

seals on water end. Shaft equipped with wrench flats to facilitate impeller removal.

Bearing housing internally sandblasted to white metal and coated with oil proof

crankcase sealer.

Gear belt driven by diesel engine.

Pump compartment sized to allow dredge to remain afloat when pump compartment

is flooded to the main deck.

5. DIESEL ENGINE:

Caterpillar Model C27 DITA tube cooled with mechanical multi-plate disconnect

clutch and residential muffler.

Rated 800 SHP (596 kw) continuous at 1800 R.P.M.

24 volt D.C. electric starting with 60 amp alternator and 220 amp-hour batteries.

Throttle control operable from lever room.

Remote oil pressure and jacket water temperature gauges and tachometer with hour

meter in lever room.

Ellicott is a registered trademark of Ellicott Dredges, LLC

0067D1412026H

4 April 2016

Page 6 of 12

6. SWING WINCHES:

Two (2) reversible independent hydraulically driven swing winches - 10,500 pounds

(4763 Kg) line pull @ 75 feet (22.8 meters) per minute.

5/8" (16 mm) diameter rope

Totally enclosed planetary gearing with anti-friction bearings.

Gear type hydraulic motor.

Dynamic hydraulic braking for normal swinging for reduced maintenance.

Totally enclosed automatic mooring brake - friction type.

Single lever control for each winch in lever room.

Reinforced hull for winch support.

7. LADDER HOIST:

Double acting hydraulic cylinder with spherical ball bushed fittings for misalignment

compensation, and chrome plated rod.

Single lever control from lever room with raise, lower and neutral positions.

8. SPUD HOISTS:

Two (2) independent hydraulic cylinder operated sling lift wire rope spud hoists.

Cylinders have rod end cushions and freefall valve for good spud penetration.

Cylinders also have chrome plated rods and spherical ball bushing end fittings.

Grease lubricated sheaves and 1/2 inch diameter wire rope arranged for two (2) part

tackle.

Single lever control for each spud in control room.

Ellicott is a registered trademark of Ellicott Dredges, LLC

0067D1412026H

4 April 2016

Page 7 of 12

9. HYDRAULIC SYSTEM:

Tandem hydraulic gear pump flexible coupled to front end of diesel engine.

330 gallon (1250 liter) reservoir with level gauge and temperature gauge.

Individual circuits for cutter, swing winches, spud hoists, and ladder hoist. Single

lever control for each function in lever room.

Pump protected with suction strainer (75 mesh, with magnets) and return line filter

(10 micron).

All circuits protected with relief valves.

Forward, neutral and reverse available for all functions. Speed control provided for

swing winches and cutter.

10. DREDGE PIPING:

16" O.D. wall abrasion resistant suction pipe bolted in ladder.

Heavy duty flanged rubber suction hose designed for full vacuum service, provides

for flexibility between hull and ladder.

Flanged suction cleanout trap with gasketed cover provided on dredge pump. (Stone

box)

16" O.D. discharge pipe on hull with standard connector flange at stern.

16" O.D. (305 mm) cast steel flap valve in deck discharge pipe.

11. SERVICE WATER SYSTEM: (FOR DREDGE PUMP GLAND FLUSHING, OIL

COOLING AND PRIMING)

Centrifugal service water pump. Belt driven from engine - anti-friction bearings - cast

iron construction - provides 60 GPM (227 l.p.m.) and minimum of 10 psi (0.7 kg\cm2)

over dredge pump discharge pressure.

Sea chest with cleanable strainer and shut-off valve.

Dredge pump priming eductor (water powered) with piping system included.

Deck wash valve (hose bib) included.

Ellicott is a registered trademark of Ellicott Dredges, LLC

0067D1412026H

4 April 2016

Page 8 of 12

12. ELECTRICAL SYSTEM:

24 volt D.C. circuit powered from diesel engine starting batteries.

13. LIGHTING SYSTEM:

24 volt D.C. lighting system.

Two (2) floodlights for aft end, two (2) floodlights for forward end - 24 volt.

One (1) dome light in lever room - 24 V.

One (1) light in pump room - 24 V.

14. LEVER ROOM AND CONTROL PANEL:

Removable welded steel lever room with tinted Plexiglas windows all around and

lockable door.

Sound proofing and insulation of minimum one inch (25.4 mm) thick foam rubber.

360 degree rotating operators chair with adjustable position.

Desk type control panel with fingertip levers for all dredging functions and illuminated

dials for night operation.

Following instrument controls included:

a. Dredge pump vacuum gauge.

b. Dredge pump discharge gauge.

c. Cutter hydraulic pressure gauge.

d. Swing hydraulic pressure gauge.

e. Service water pressure gauge.

f. Engine tachometer.

g. Engine oil pressure gauge with alarm light.

h. Engine water temperature gauge with alarm light.

i. Engine throttle control.

j. Instrument light switch with dimmer.

k. Cutter forward - neutral-reverse-speed control.

l. Port swing forward - neutral-reverse-speed control

Ellicott is a registered trademark of Ellicott Dredges, LLC

0067D1412026H

4 April 2016

Page 9 of 12

14. LEVER ROOM AND CONTROL PANEL (Continued):

m. Starboard swing forward - neutral-reverse-speed control.

n. Port spud - raise - neutral-freefall control.

o. Starboard spud - raise - neutral-freefall control.

p. Ladder - raise -neutral-lower control.

q. Dynamic hydraulic braking for each swing winch.

r. Ladder depth gauge - sliding board type in view of operator.

s. Switch panel for all lights (circuit breaker panel).

t. Low level alarm for hydraulic oil reservoir.

15. SPUDS:

Two (2) tubular steel spuds.

16 inches (406 mm) O.D. X 0.375 inches (9.5 mm) minimum wall X 35'-0" (10.67 m)

long.

Steel point on lower end and cap with lifting lug on upper end.

Cross tubes for stowing with two (2) cross pins.

Fabricated steel spud guides at deck and bottom with removable pin connected

gates.

Spud wells and associated hull structure are designed to withstand spud failure

loads.

16. DREDGING LADDER:

Heavy duty dredging ladder fabricated from structural steel with suction pipe mounted

internally to eliminate dragging at shallow digging depths. All structural components

shall have a minimum length of 8 feet (2.44 m) without weld joints where applicable.

Approximately 30 feet (9.15 m) long from centerline of trunnion pin to end of cutter.

26'-0" (8 m) dredging depth @ 60 degree inclination.

Heavy duty trunnions with removable grease lubricated pins mounted in hull ladder

well.

Steel stowage pins for securing ladder for towing and maintenance.

Ellicott is a registered trademark of Ellicott Dredges, LLC

0067D1412026H

4 April 2016

Page 10 of 12

16. DREDGING LADDER (Continued):

Submerged piston type hydraulic cutter motor and planetary reducer with direct

spline connection to cutter shaft.

100 H.P. (74.6 Kw) cutter motor at 36 R.P.M. cutter speed.

41.0 inch (1041 mm) diameter - 6 blade cutter - cast steel plain edge blades with

keyed and tapered shaft connection.

Alloy steel cutter shaft with anti-friction bearings and watertight seal - spline

connected to reducer. Oil filled housing with positive internal pressure.

Grease lubricated swing sheave blocks for 5/8 inch (16 mm) diameter rope.

17. SAFETY EQUIPMENT:

1. Deck edge safety rail - OSHA approved.

2. Life vests (three)

3. Life rings (two)

4. A.B.C. fire extinguishers (two)

5. Automatic bilge pump system (24 V.D.C.) for dredge pump compartment.

18. PAINTING:

The dredge shall be painted according to Ellicott's standard schedule. The hull

(consisting of the center tank and side tanks) shall be sandblasted before painting

internally and externally to a commercial grade (SSPC-SP-6). All other steel work

shall be wire brushed and thoroughly cleaned of loose mill scale, rust, oil, or other

foreign matter before painting.

The hull shall be given one (1) coat of Carbomastic 15 or equal on the interior and

exterior of (5) mils thickness and an additional coat of Carboline D890 or equal on

the exterior of (5) mils thickness.

All fuel compartments shall receive one (1) coat of a fuel oil resistant elastomer

coating (minimum thickness 1.0 mils).

All other surfaces shall receive a primer coat of five (5) mils thickness of Carbomastic

15 or equal and a finish coat of five (5) mils thickness of Carboline D890 or equal.

Ellicott is a registered trademark of Ellicott Dredges, LLC

0067D1412026H

4 April 2016

Page 11 of 12

18. PAINTING (Continued):

The primer coat will be allowed to dry thoroughly and harden before application of the

finish coat. Carbomastic 15 is a high solids aluminum epoxy mastic. Carboline D890

is a high solids epoxy polyamide.

Colors shall be Ellicott standard:

Hull - Blue

House - White

Ladder & Machinery - Red

Spuds - Black

19. SHOP AND FIELD TESTING:

The dredge shall be completely assembled in Ellicott's shop and tested as far as

practical under no load or simulated load conditions to insure proper operation.

Upon launching and final assembly, the dredge shall be fully tested by Ellicott to

insure that all equipment is operating properly.

Ellicott is a registered trademark of Ellicott Dredges, LLC

0067D1412026H

4 April 2016

Page 12 of 12

20. INSTRUCTION MANUALS AND DOCUMENTS:

Two (2) sets of manuals shall be provided. Each set shall include the following:

- Instructions for the operation and maintenance of the dredge.

- Repair parts information for equipment manufactured by Ellicott.

- Operating instructions and parts information for equipment supplied by Ellicott's

subcontractors.

- Field assembly and launching recommendations.

21. OPTIONS (AVAILABLE AT ADDITIONAL COST):

Tool kit

Swing winch cables 5/8 inch (16 mm) diameter x 200 feet (61 m) long

Lifting rig

Hull zinc’s (cathodic protection)

Cutter knife

Suction cleanout knife

21. OPTIONS (AVAILABLE AT ADDITIONAL COST):

Impeller lifting hook

Pump handling crane

Stern jib crane for discharge hose

Lever room heater

Lever room air conditioner

Production meter

6 blade cutter with replaceable teeth

12 inch (305 mm) discharge hose

Swing anchors - 2 @ 500 pounds (227 Kg)

Mast with navigation signals

Engine located in a lockable enclosure with removable service panels, ventilation

provisions and sound insulation to minimize external noise.

Ellicott is a registered trademark of Ellicott Dredges, LLC

0067D1412026H

4 April 2016

Page 13 of 12

22. SUMMARY:

All materials and machinery components will be new and the workmanship shall be of

high order.

It is the policy of manufacturer to make continual improvements in the design and

manufacture of our products; therefore, the right is reserved to modify these

specifications to provide for the use of any such improvements which may have been

developed prior to the time of actual manufacture.

Ellicott is a registered trademark of Ellicott Dredges, LLC

Anda mungkin juga menyukai

- Conreting Record 15Dokumen2 halamanConreting Record 15Hery Mardiono HeryBelum ada peringkat

- Frame Section CDokumen1 halamanFrame Section CHery Mardiono HeryBelum ada peringkat

- You Created This PDF From An Application That Is Not Licensed To Print To Novapdf PrinterDokumen1 halamanYou Created This PDF From An Application That Is Not Licensed To Print To Novapdf PrinterHery Mardiono HeryBelum ada peringkat

- C - 370 Pump AnalysisDokumen1 halamanC - 370 Pump AnalysisHery Mardiono HeryBelum ada peringkat

- Rangka Baja Peluncur Dredger-Layout2Dokumen1 halamanRangka Baja Peluncur Dredger-Layout2Hery Mardiono HeryBelum ada peringkat

- 450mm Booster Pump GA - 15394000Dokumen4 halaman450mm Booster Pump GA - 15394000Hery Mardiono HeryBelum ada peringkat

- Rangka Baja Peluncur Dredger-Layout1Dokumen1 halamanRangka Baja Peluncur Dredger-Layout1Hery Mardiono HeryBelum ada peringkat

- Rangka Baja Peluncur Dredger-Layout3Dokumen1 halamanRangka Baja Peluncur Dredger-Layout3Hery Mardiono HeryBelum ada peringkat

- Specs 1270-33 18 X 18Dokumen22 halamanSpecs 1270-33 18 X 18Hery Mardiono Hery100% (2)

- Specification Anchor BoatDokumen7 halamanSpecification Anchor BoatHery Mardiono HeryBelum ada peringkat

- Recommended Stock Spare Parts For Dredge Series 370: Ellicott Dredges, LLCDokumen1 halamanRecommended Stock Spare Parts For Dredge Series 370: Ellicott Dredges, LLCHery Mardiono HeryBelum ada peringkat

- B - 670 Pump PerformanceDokumen1 halamanB - 670 Pump PerformanceHery Mardiono HeryBelum ada peringkat

- Dsi-Usa Dywidag Tie Rods Us 02Dokumen12 halamanDsi-Usa Dywidag Tie Rods Us 02Hery Mardiono HeryBelum ada peringkat

- Living Quarter Plan of Temporary Stock YardDokumen2 halamanLiving Quarter Plan of Temporary Stock YardHery Mardiono HeryBelum ada peringkat

- 3.5 - 10m Foundation Winch & Cylinder - 15106603Dokumen1 halaman3.5 - 10m Foundation Winch & Cylinder - 15106603Hery Mardiono Hery100% (1)

- B - 370 Pump PerformanceDokumen1 halamanB - 370 Pump PerformanceHery Mardiono HeryBelum ada peringkat

- 3.7 - 1270 Pump Assy - 15114504 - 1 PDFDokumen2 halaman3.7 - 1270 Pump Assy - 15114504 - 1 PDFHery Mardiono HeryBelum ada peringkat

- Arcel or MittalDokumen2 halamanArcel or MittalHery Mardiono HeryBelum ada peringkat

- A - 670 Theoretical Pump Performance PDFDokumen1 halamanA - 670 Theoretical Pump Performance PDFHery Mardiono HeryBelum ada peringkat

- Dredging Pump Performance Curve Series 1270Dokumen1 halamanDredging Pump Performance Curve Series 1270Hery Mardiono HeryBelum ada peringkat

- 3.7 - 1270 Pump Assy - 15114504Dokumen2 halaman3.7 - 1270 Pump Assy - 15114504Hery Mardiono HeryBelum ada peringkat

- C - 670 Pump AnalysisDokumen1 halamanC - 670 Pump AnalysisHery Mardiono HeryBelum ada peringkat

- 6300 L20 InvertedSiphonsDokumen0 halaman6300 L20 InvertedSiphonschakfarmerBelum ada peringkat

- A - 670 Theoretical Pump PerformanceDokumen1 halamanA - 670 Theoretical Pump PerformanceHery Mardiono HeryBelum ada peringkat

- Denah Kasir & Display Asesoris Layout DiagramDokumen1 halamanDenah Kasir & Display Asesoris Layout DiagramHery Mardiono HeryBelum ada peringkat

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Effect of Temperature On The Viscosity of The FluidDokumen3 halamanEffect of Temperature On The Viscosity of The Fluidjaimeboterogomez100% (1)

- Air System 789BDokumen3 halamanAir System 789BRobbyPratamaBelum ada peringkat

- 5012 PDFDokumen2 halaman5012 PDFBhupesh yadavBelum ada peringkat

- Kohler Command CV680 - CV23 Service ManualDokumen88 halamanKohler Command CV680 - CV23 Service ManualJames Porter75% (4)

- Curves Are Approximate, Pump Is Guaranteed For One Set of Conditions Capacity, Head, and EfficiencyDokumen4 halamanCurves Are Approximate, Pump Is Guaranteed For One Set of Conditions Capacity, Head, and EfficiencyjmeleBelum ada peringkat

- The Training Resource Disk For The Level 1 Diploma in Principles of Light Vehicle Operations - Sample PagesDokumen3 halamanThe Training Resource Disk For The Level 1 Diploma in Principles of Light Vehicle Operations - Sample PagesPearson SchoolsBelum ada peringkat

- Hydraulic Mining Shovel: 2x Cat C27 1209 KW / 1,620 1141 KW / 1,529 294 Tonnes / 324 Tons 30 Tonnes / 33 TonsDokumen28 halamanHydraulic Mining Shovel: 2x Cat C27 1209 KW / 1,620 1141 KW / 1,529 294 Tonnes / 324 Tons 30 Tonnes / 33 TonsZaita FregaBelum ada peringkat

- 416C Backhoe Loader Pump OperationDokumen10 halaman416C Backhoe Loader Pump OperationLeandro SalBelum ada peringkat

- DX5 Cross SectionalDokumen6 halamanDX5 Cross Sectionaldanielh776Belum ada peringkat

- Diesel Engine Power Plant Generates Small Amounts of ElectricityDokumen8 halamanDiesel Engine Power Plant Generates Small Amounts of Electricityfawad javadBelum ada peringkat

- Catalogo Tecnico Gb-S v07Dokumen29 halamanCatalogo Tecnico Gb-S v07farou9 bmzBelum ada peringkat

- Significant Small Ships 2006Dokumen60 halamanSignificant Small Ships 2006nf_azevedo100% (2)

- Power Products 50 HZ (7,5 - 880 KVA)Dokumen12 halamanPower Products 50 HZ (7,5 - 880 KVA)Nay SoeBelum ada peringkat

- ZF8HP55 VBL InteractiveDokumen1 halamanZF8HP55 VBL InteractiveMauricio Exequiel Chavez50% (2)

- r66 Poh Full BookDokumen238 halamanr66 Poh Full BookAmi Kar100% (1)

- Zhu Tong PDFDokumen58 halamanZhu Tong PDFajayaghimireBelum ada peringkat

- Ag. Power, Machinery, and Allied Subject - Part 1Dokumen101 halamanAg. Power, Machinery, and Allied Subject - Part 1Joebert SabidoBelum ada peringkat

- Quiz 10 Boiler, Engines and TurbinesDokumen13 halamanQuiz 10 Boiler, Engines and Turbinesashishutage_50897935Belum ada peringkat

- Shimpo Circulute 3000 CatalogDokumen35 halamanShimpo Circulute 3000 CatalogElectromateBelum ada peringkat

- Molten Carbonate Fuel Cell PresentationDokumen10 halamanMolten Carbonate Fuel Cell PresentationDeep GreyBelum ada peringkat

- Nioec SP-43-12Dokumen25 halamanNioec SP-43-12werrteBelum ada peringkat

- EDG Deisel ConsumptionDokumen2 halamanEDG Deisel ConsumptionANUTEJ CHITIMELABelum ada peringkat

- Air Compressor Script AUX MACHDokumen5 halamanAir Compressor Script AUX MACHRalph Jay M. TaladroBelum ada peringkat

- MITdDokumen18 halamanMITdali4299Belum ada peringkat

- Global Oil and Gas IndustryDokumen23 halamanGlobal Oil and Gas IndustryYash Agarwal100% (1)

- 3 Phase Power CalculationDokumen5 halaman3 Phase Power CalculationChris Osea AlvarezBelum ada peringkat

- MR346CLIO1Dokumen364 halamanMR346CLIO1chiki64100% (5)

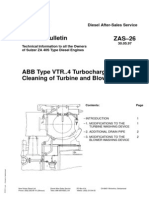

- Service Bulletin ZAS-26: 30.05.97 Technical Information To All The Owners of Sulzer ZA 40S Type Diesel EnginesDokumen14 halamanService Bulletin ZAS-26: 30.05.97 Technical Information To All The Owners of Sulzer ZA 40S Type Diesel EnginesYohan JayaBelum ada peringkat

- PC8000Dokumen8 halamanPC8000Foromaquinas100% (3)

- Notice: Natural Gas and Liquefied Natural Gas Import/Export Authorization Holders Procedural OrderDokumen8 halamanNotice: Natural Gas and Liquefied Natural Gas Import/Export Authorization Holders Procedural OrderJustia.comBelum ada peringkat