1,333,9 1 8,. ' Patented Mar. 16, 1920. V: M. Horie

Diunggah oleh

Vincent Grangé-PradérasDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

1,333,9 1 8,. ' Patented Mar. 16, 1920. V: M. Horie

Diunggah oleh

Vincent Grangé-PradérasHak Cipta:

Format Tersedia

M. HORIE.

CAMERA SELF TIMER.

APPLICATION FILED MAY 22, 1919.

1,333,9 1 8,. ' Patented Mar. 16, 1920. v

UNITED STATES PATENT OFFICE.

MASAJ I HORIE, OF LOS ANGELES, CALIFORNIA.

CAMERA SELF-TIMER.

v1,333,918. > Speci?cation of Letters Patent. Patented Mar. 16, 1920.

Application ?led May 22, 1919. Serial No. 298,981.

To all whom it may concern: walls 22 and 23, of the camera 24, when

Be it known that I, MASAJI Honm, a sub open for an exposure.

ject of the Emperor of Japan, residing at The cover 12 is provided with a rotatively

Los'Angeles, in the county of Los Angeles mounted ratchet 25, which is operated by

and State of California, have invented a turning the handle 26in a clockwise direc 60

new and useful Improvement in Camera tion. Spring ratchet members 27 prevent

Self-‘Timers, of which the following is a rotation of member25 in the- contrary di

specification. rection. The screw 28 is provided with a

This invention relates to improved means head 29 having an integral pin 30 project

10 for tripping a camera shutter, whereby an ing from the top, and with ratchet teeth

interval of from ten seconds to three minutes 31 projecting from the bottom of the

will elapse between release of the timer and head. The main spring 32 is connected

its action in tripping the shutter on the at the outer ‘end to pin 30, on the en

camera. ‘ ‘j larged screw head 29, and connected at the

15 The object of the invention is to time the inner end to shaft 33, integral with and 70

tripping of the camera shutter to occur after projecting from ratchet A‘ pawl 34

an interval of time, to enable the photog is normally in- engagement with ratchet

rapher to be included in the photograph teeth 31 and prevents rotation of the screw

that is taken by the‘ camera. 28. The release lever 35, comprising the arm

20 Another object of the invention is to pro 36 projecting from the casing, the ring 37, 75

vide a timer which may be quickly attached and the socket arm 38, is pivotally mounted

to and detached from the camera, and which within .the casing, having the oppositely

may be attached to the camera in different disposed trunnions 39, and a plunger 40,

positions relative to the shutter release ‘mounted in socketv arm 38. A spring 41

lever, and to provide a timer which may be.

holds plunger 40 in engagement with pawl 80

operated with a cord or cable. 34. When the lever is in the operative posi

Other objects and advantages may appear tion, the plunger holds pawl 34 in engage

in the subjoined detail description. ment with the ratchet head 29, and when

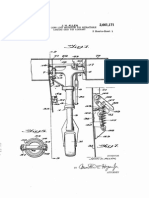

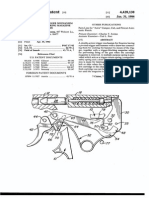

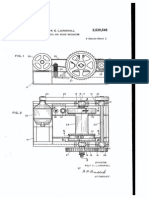

Upon the annexed drawings, Figure 1 is the lever is in the opposite position, the

30 a sectional view of my improved timing de pawl 34 is in engagement with a lug 42, 85

vice. Fig. 2 is a perspective view of a camera projecting from casing 11.

with my timing device applied thereto. Fig. A hollow and split plunger 43, ‘is formed -

3 is a transverse section of the casing cover, with a threaded head or nut 44, in engage-v

taken on the line X3~X3, of Fig. 1. Fig. 4 ment with screw 28. A clamp 45 extends

35 is a bottom plan view of the actuating through plunger 43, and the jaws 46, ex

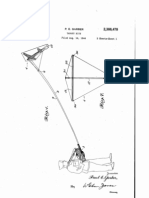

screw. Fig. 5 is a plan view of the brake. tend through slots 47 in the plunger; VA

Fig. 6 is a top plan view of the timer. Fig. shaft 48, fixed to clamp member 45, extends

7, is a transverse section taken on line through the lower end 68, ofv plunger 43,

X7'—i 7 of Fig. 1. Fig. 8 is a. perspective and is provided with a head 49. A trip

40 detail View of the clamp for the operating lever 50 is swivelly mounted on. the shaft 48, 95

nut. Fig. 9 is a perspective detail view of and may be set in any position relative to

the release lever for the timer. Fig. 10 is the plunger 43. A spring 51 is interposed

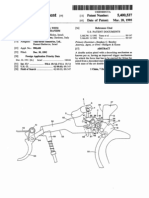

a fragmentary view showing the ratchet between the head 49 and the‘ washer 52

screw-head, releasing pawl, and lever. which presses upon the lever 50. Spring 51.

45 Referring to the drawings, the timing de tends to force the clamp jaws 46 against the 100

vice consists of the casing 11 provided with lower beveled and'iinclined faces of slots 47,.

a cover‘ 12, and a securing member 13. The ‘and therefore locks- the threaded head 44 in

member 13 is secured to clamp member 14. engagement with screw 28. The clamp jaws

Clamp members 14 and 15 are pivotally con 46 extend vbetween the guides 53, serving to

50 nected to the pintle member 16, and are prevent’ rotation of the plunger 43. The 105

maintained in opposed relation by the opening 54, through which the plunger 43

spring 17 interposed between the extremi extends, is of greater diameter one way,

ties 18 and 19. The respective opposite ex serving to allow the split head 44 to slide

tremities or jaws 20 and 21, of the clamp as a ratchet over the screw 28 when pressed

55 members, are adapted to engage with the upward by the operator. 110

2 1,333,918

In use, the device is clamped to the an arm swivelly connected to the plunger

camera adjacent to the lever 55 which serves screwadapted

and

to

to operate the shutter trip, a

actuate the plunger, and means for

to trip the shutter. The head 4:9 is pressed actuating the screw with a rotary move

by the operator, which forces the clamp 45

upward, releasing the split head 4:4: from ment.3. In a camera timer, the combination

engagement with the screw 28, and the with a casing, of a ratchet-wheel rotatively

plunger 43 is forced to the uppermost posl mounted a handle projecting from 65

tion. The lever 35 is shifted to the position the casingtherein,

and integral with the ratchet

as shown in Fig. 10, thereby forcing the wheel, spring pawls arranged

pawl 34 in engagement with ratchet screw rotation of the ratchet-wheel in toa counter

prevent

head 29; The handle 26 is turned to wind

the main spring, and the device is set for clockwise direction, a screw disposed cen

use. A brake 56, consisting of the yoke 57, trally within the casing, a circular'head for

the nut 58, and screw 59, adapted to force the screw, a pin projecting, from the screw

15 the brake shoes 60 against the cylindrical head, a main spring having one extremity

connected to the ratchet wheel and the op

ortion 61, of the screwQS, is adjusted to posite extremity connected to the pin, a

regulate the speed of the screw. This may

be'done by turning the screw 59. The de plunger projecting from the casing and 75

vice is further adjusted by clamping. the working longitudinally therein, a split

same relatively nearerjto or farther from screw head on said plunger in engagement

the shutter trip lever. The operator releases with

the

the screw, a clamp adapted to hold

screw head in engagement with the

the device by manipulating the lever 35, and screw, a shaft the clamp extending from 80

may then take a position to be photographed the plunger, a on head on the end of the shaft,

by the camera. Lever 35 may be operated a spring interposed between the shaft

by a cable.

From the foregoing description, it may rotation of the plunger, ameans

head and the plunger, ‘to prevent

trip-arm swivelly

be seen that I have provided simple and mounted on the end of the plunger 85

efficient means for timing the release of the jecting from the casing, pawl meanspro~ to

camera shutter, the invention not being lim prevent rotation of the circular screw-head,

30 ited to the precise construction shown, but and a lever projecting from the casing and

including such changes and alterations as adapted to move the pawl into and out of

may fall within the scope of the appended engagement with the circular screw-head. 90

claims. 4. In a camera timer, a plunger, a shut

What is claimed is: ' ter-trip—arm mounted onthe plunger and

1. In a camera timer, the combination

with a casing, of a cover for the casing, a adapted to engage with the camera trip

ratchet wheel rotatively mounted in the lever,

clamp

a casing for the plunger, means to

the casing to the camera adjacent to 95

cover, a handle projecting from the cover the camera trip-lever, a screw to actuate the

and adapted to wind the ratchet'wheel with plunger, spring means to actuate the screw,

a clockwise movement, a. screw extending

centrally within the casing, a circular head ratchet

actuate

means for winding the spring to

the screw, means to prevent rotation

on the screw, a pin projecting from the top of the screw, and’ means for releasing the 10C

of the circular head, a spring having one

extremity connected to the pin and the op screw. 7 I

5. In a camera timer, a casing, means for

45 posite and inner end connected to the attaching the casing to the camera adjacent

ratchet wheel, a plunger working longitudi to the shutter trip lever,'spring- actuated

nally within the casing, a split screw head screw, a plunger projecting from the eas 102

on the plunger, a shutter trip lever swivelly

mounted in the opposite end of the plunger, ing and adapted to actuate the shutter trip

lever, a pawl to prevent rotation of the

50 means to prevent rotation of the plunger, spring-actuated screw, means for manually

ratchet teeth on the bottom of the screw

releasing the pawl, and brake means for re

head, a pawl in engagement with the ratchet tarding the movement of the spring-actu 111

tepth, and a lever to release the pawl, and

extending from the casing. ated screw.

A casing, means for) attaching the In testimony whereof I hereunto aiiix my

155 signature.

casing to a camera adjacent to the shutter MASAJI HORIE.

trip, a plunger projecting from the casing,

Anda mungkin juga menyukai

- Us955823 PDFDokumen3 halamanUs955823 PDFSashikant SharmaBelum ada peringkat

- Us965386 PDFDokumen6 halamanUs965386 PDFJin SongBelum ada peringkat

- Revolver PatentDokumen5 halamanRevolver PatentdududadamikeBelum ada peringkat

- 3/ Z7 VZMZM/ZZ : V. Holek 2,216,412Dokumen3 halaman3/ Z7 VZMZM/ZZ : V. Holek 2,216,412wererBelum ada peringkat

- Rig-E???': Gill!Dokumen6 halamanRig-E???': Gill!luiscremaschiBelum ada peringkat

- Us 1454454Dokumen3 halamanUs 1454454dfdfsdBelum ada peringkat

- MMM-@U: H. M. SpragueDokumen4 halamanMMM-@U: H. M. SpraguedjsfBelum ada peringkat

- Com Pur ShutterDokumen14 halamanCom Pur ShutterrrpokemongorrBelum ada peringkat

- Us3443375 PDFDokumen3 halamanUs3443375 PDFRamos GabeBelum ada peringkat

- Berthier Us1366863Dokumen9 halamanBerthier Us1366863cll1968Belum ada peringkat

- Tow Target Release Mechanism (1927)Dokumen5 halamanTow Target Release Mechanism (1927)CAP History LibraryBelum ada peringkat

- Belt Fed BAR (Belgium) US2136512Dokumen4 halamanBelt Fed BAR (Belgium) US2136512apoorva singhBelum ada peringkat

- Dec. 1, 1953 J. H. Allen: Filed Oct. 11, 1951Dokumen8 halamanDec. 1, 1953 J. H. Allen: Filed Oct. 11, 1951Rezicky ImamBelum ada peringkat

- NAA .32 ACP专利 PDFDokumen8 halamanNAA .32 ACP专利 PDFJin SongBelum ada peringkat

- Viewfinder ProjectDokumen4 halamanViewfinder ProjectAndrei PoseaBelum ada peringkat

- Target Kite (1944)Dokumen7 halamanTarget Kite (1944)CAP History LibraryBelum ada peringkat

- United States Patent (191 (11) Patent Number: 4,857,881Dokumen9 halamanUnited States Patent (191 (11) Patent Number: 4,857,881Harish MahadevanBelum ada peringkat

- Thompson Proto US1425810Dokumen4 halamanThompson Proto US1425810apoorva singhBelum ada peringkat

- Us 1893840Dokumen6 halamanUs 1893840Robert BercovitzBelum ada peringkat

- Us2127655 PDFDokumen5 halamanUs2127655 PDFbelchior alvaroBelum ada peringkat

- Oct. 5, 1965 G. L. Mittelsteadt 3,209,480: Filed Aug. 28, 1964Dokumen5 halamanOct. 5, 1965 G. L. Mittelsteadt 3,209,480: Filed Aug. 28, 1964Юрий РуденкоBelum ada peringkat

- Apron MechanismDokumen7 halamanApron Mechanismgopalpaul0% (2)

- No. 687,172. Patlmtedl Nov. I9, I90I.: Variable Speed GearingDokumen4 halamanNo. 687,172. Patlmtedl Nov. I9, I90I.: Variable Speed Gearingbelchior alvaroBelum ada peringkat

- Engineering Vol 69 1900-03-09Dokumen29 halamanEngineering Vol 69 1900-03-09ian_newBelum ada peringkat

- United States Patent 1191: MasuyamaDokumen7 halamanUnited States Patent 1191: MasuyamaAbdullah AljabriBelum ada peringkat

- April 25, 1933. J. 5. Finlay Et Al: Filed Feb 25, 1932Dokumen8 halamanApril 25, 1933. J. 5. Finlay Et Al: Filed Feb 25, 1932jojaberiBelum ada peringkat

- US2259748Dokumen3 halamanUS2259748Christian MavarezBelum ada peringkat

- Cheshire: Composing Room Machine Filed June 1927 3 Sheets-SheetDokumen7 halamanCheshire: Composing Room Machine Filed June 1927 3 Sheets-SheetmephitBelum ada peringkat

- Pantente Primer DollyDokumen6 halamanPantente Primer DollyJorge SotoBelum ada peringkat

- United States "Patents PDFDokumen17 halamanUnited States "Patents PDFTien Nguyen VanBelum ada peringkat

- Us1434007 PDFDokumen5 halamanUs1434007 PDFsebastian escobarBelum ada peringkat

- US2525422Dokumen6 halamanUS2525422Rambabu ChBelum ada peringkat

- Raschel Machine With Stitch Comb and Knock-Over BarDokumen6 halamanRaschel Machine With Stitch Comb and Knock-Over Barntd1011Belum ada peringkat

- Us1446763 PDFDokumen7 halamanUs1446763 PDFJin SongBelum ada peringkat

- US2579903 - Periscopic Sextant - Kollsman, 1951Dokumen9 halamanUS2579903 - Periscopic Sextant - Kollsman, 1951devheadbot100% (1)

- Us 4407085Dokumen5 halamanUs 4407085rte678Belum ada peringkat

- Jan. 4, L 1966 T. W. Spack 3,227,148Dokumen6 halamanJan. 4, L 1966 T. W. Spack 3,227,148MainAvelBelum ada peringkat

- Us 5117735Dokumen14 halamanUs 5117735sdfsdf333Belum ada peringkat

- Us2371574 PDFDokumen5 halamanUs2371574 PDFbelchior alvaroBelum ada peringkat

- Owen Sub Machine Gun PatentDokumen11 halamanOwen Sub Machine Gun PatentBallistics67% (3)

- Patented June 1, 1901. No. 675,999.: L. HellfritzschDokumen4 halamanPatented June 1, 1901. No. 675,999.: L. HellfritzschСлэйтер Строительная компанияBelum ada peringkat

- Land Rover SU Carb OverhaulDokumen10 halamanLand Rover SU Carb OverhaulAdamCzulewiczBelum ada peringkat

- Us804694 PDFDokumen9 halamanUs804694 PDFZelenyBelum ada peringkat

- 24% Zevery A. Aeger.: H. F. Wheeler Patented June 17, 1890Dokumen4 halaman24% Zevery A. Aeger.: H. F. Wheeler Patented June 17, 1890Слэйтер Строительная компанияBelum ada peringkat

- United States Patent (191Dokumen11 halamanUnited States Patent (1919aszerfBelum ada peringkat

- Diseño ElectricoDokumen5 halamanDiseño ElectricoemernelsonmanBelum ada peringkat

- L'il Wu" MM: Jan. 30, 1951 R, E - Ljungkull 2,539,545Dokumen12 halamanL'il Wu" MM: Jan. 30, 1951 R, E - Ljungkull 2,539,545lfilippiniBelum ada peringkat

- Milliam G. Airchhoff: SasaaaaaaaaaaaaaaaaaaaaaDokumen4 halamanMilliam G. Airchhoff: SasaaaaaaaaaaaaaaaaaaaaaOscar Lora SiñaniBelum ada peringkat

- Projectile Loom Projectile Weaving Machines Working Procedure of Projectile LoomDokumen3 halamanProjectile Loom Projectile Weaving Machines Working Procedure of Projectile LoomObak PrithibiBelum ada peringkat

- Mannlicher Us975256Dokumen3 halamanMannlicher Us975256cll1968Belum ada peringkat

- US2160338 Shuttle Picking Mechanism PDFDokumen5 halamanUS2160338 Shuttle Picking Mechanism PDFParikshit PaulBelum ada peringkat

- Us2330407 PDFDokumen13 halamanUs2330407 PDFbelchior alvaroBelum ada peringkat

- Us1517483 PDFDokumen10 halamanUs1517483 PDFJin SongBelum ada peringkat

- Far As: 1,148,470. Patented June 15, 1915Dokumen6 halamanFar As: 1,148,470. Patented June 15, 1915Слэйтер Строительная компанияBelum ada peringkat

- Us2291241 PDFDokumen5 halamanUs2291241 PDFbelchior alvaroBelum ada peringkat

- US2755738 Rocket Fuze 3.5 Inch Rocket M404 PatentDokumen3 halamanUS2755738 Rocket Fuze 3.5 Inch Rocket M404 Patentrichardwb1Belum ada peringkat

- Colt 1895 Manual PDFDokumen38 halamanColt 1895 Manual PDFBruce JollyBelum ada peringkat

- Us 3960084Dokumen3 halamanUs 3960084rte678Belum ada peringkat

- W, B. Kidder. : Tree Climbing MotorDokumen4 halamanW, B. Kidder. : Tree Climbing Motormonem2014Belum ada peringkat

- Blackstone Fortress Escalation - DatasheetsDokumen8 halamanBlackstone Fortress Escalation - DatasheetsVincent Grangé-Pradéras0% (1)

- Naomiki Sato Origami Roses and Flowers PDFDokumen90 halamanNaomiki Sato Origami Roses and Flowers PDFAnonymous XuxMEqBelum ada peringkat

- Commanders InternationalDokumen12 halamanCommanders InternationalVincent Grangé-PradérasBelum ada peringkat

- Custodian GuardDokumen16 halamanCustodian GuardVincent Grangé-PradérasBelum ada peringkat

- Training An Artificial Neural Network To Play Tic Tac Toe PDFDokumen16 halamanTraining An Artificial Neural Network To Play Tic Tac Toe PDFVincent Grangé-PradérasBelum ada peringkat

- OriroboDokumen123 halamanOriroboVincent Grangé-Pradéras100% (2)

- Dave Brill - CigarettesDokumen4 halamanDave Brill - CigarettesVincent Grangé-PradérasBelum ada peringkat

- Hagimori ListDokumen1 halamanHagimori ListVincent Grangé-PradérasBelum ada peringkat

- K. Cazin Des. 120,583: Filed March 20, 1940Dokumen2 halamanK. Cazin Des. 120,583: Filed March 20, 1940Vincent Grangé-PradérasBelum ada peringkat

- Us 1633228Dokumen8 halamanUs 1633228Vincent Grangé-PradérasBelum ada peringkat

- Instant Go SetDokumen3 halamanInstant Go SetVincent Grangé-PradérasBelum ada peringkat

- Email Gateway DefenceDokumen8 halamanEmail Gateway DefenceNiven MaharjanBelum ada peringkat

- 8 Form Reading The Stronger ManDokumen8 halaman8 Form Reading The Stronger Manмаксим соловейBelum ada peringkat

- Table of Content - 6279Dokumen4 halamanTable of Content - 6279Wing Laam Tam (Bobo)Belum ada peringkat

- Maven - Download Apache MavenDokumen1 halamanMaven - Download Apache Mavenjuanc_faundezBelum ada peringkat

- Possible Test1Dokumen32 halamanPossible Test1Azim Jivani100% (3)

- Filipino: Markahan 3 - Modyul 2: Elehiya NG Bhutan (Elemento NG Elehiya)Dokumen15 halamanFilipino: Markahan 3 - Modyul 2: Elehiya NG Bhutan (Elemento NG Elehiya)JomajFalcatanDelaCruz100% (1)

- Elastic and Inelastic Collisions Lab ReportDokumen16 halamanElastic and Inelastic Collisions Lab ReportDelfina FariasBelum ada peringkat

- Paul M.C. (Ed.) - Fiber Laser PDFDokumen415 halamanPaul M.C. (Ed.) - Fiber Laser PDFXuan Phuong Huynh100% (1)

- nomination-form-6873-MAZAHIR HUSSAINDokumen3 halamannomination-form-6873-MAZAHIR HUSSAINMazahir HussainBelum ada peringkat

- Privacy Protection Based Access Control Scheme in Cloud-Based Services - 1crore ProjectsDokumen5 halamanPrivacy Protection Based Access Control Scheme in Cloud-Based Services - 1crore ProjectsLalitha PonnamBelum ada peringkat

- 203 - The Poky Little Puppy - See, Hear, ReadDokumen28 halaman203 - The Poky Little Puppy - See, Hear, ReadAndrew Rukin100% (2)

- Grace & The Double LifeDokumen34 halamanGrace & The Double LifeSanty Pogo50% (2)

- Bakri Balloon PDFDokumen5 halamanBakri Balloon PDFNoraBelum ada peringkat

- Final ProjectDokumen80 halamanFinal ProjectMinkal PatelBelum ada peringkat

- Engine Start Button E46 MANUALDokumen6 halamanEngine Start Button E46 MANUALBilly GeorgiouBelum ada peringkat

- A Study On Manufacturing Strategy of Fillpack TechnologyDokumen6 halamanA Study On Manufacturing Strategy of Fillpack TechnologySumit RautBelum ada peringkat

- Puyat V de GuzmanDokumen6 halamanPuyat V de GuzmanDwight LoBelum ada peringkat

- 2-CFOT Handout 23Dokumen113 halaman2-CFOT Handout 23SumitBelum ada peringkat

- Chapter - 1: Richard GersterDokumen80 halamanChapter - 1: Richard GersterSanjay ShankpalBelum ada peringkat

- Sembawang Marine 3 August 2012Dokumen6 halamanSembawang Marine 3 August 2012tansillyBelum ada peringkat

- As A Developing Country, Who Should Be The Primary Managers of Our National Development?Dokumen3 halamanAs A Developing Country, Who Should Be The Primary Managers of Our National Development?wheathering withyouBelum ada peringkat

- Stick DiagramDokumen72 halamanStick DiagramBhanu Bond0% (1)

- Quaid-e-Azam (Rahmatullah) Said Very Clearly That The Rights of The - Will Be Fully Protected in PakistanDokumen7 halamanQuaid-e-Azam (Rahmatullah) Said Very Clearly That The Rights of The - Will Be Fully Protected in PakistanAmna ShahzadBelum ada peringkat

- A.zerrouki Et El The Natural Circulation Solar Water Heater ModelDokumen11 halamanA.zerrouki Et El The Natural Circulation Solar Water Heater ModelJuan-Pierre HerbothBelum ada peringkat

- Compiler Design - 2Dokumen104 halamanCompiler Design - 2jemal12174Belum ada peringkat

- VPRS 4300V VPRM5450Dokumen3 halamanVPRS 4300V VPRM5450Tuan MinhBelum ada peringkat

- 5 1 5 PDFDokumen376 halaman5 1 5 PDFSaransh KejriwalBelum ada peringkat

- Cis 252 Lab1Dokumen4 halamanCis 252 Lab1Jack RyanBelum ada peringkat

- Ferrari Challenge ManualDokumen121 halamanFerrari Challenge ManualStakos MakBelum ada peringkat

- Unit 5 - Week 4: Assignment 4Dokumen4 halamanUnit 5 - Week 4: Assignment 4RITESH NANDANBelum ada peringkat