Typical Wiring Diagram: 5320 Installation Instructions

Diunggah oleh

Anonymous V9fdC6Deskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Typical Wiring Diagram: 5320 Installation Instructions

Diunggah oleh

Anonymous V9fdC6Hak Cipta:

Format Tersedia

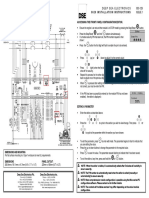

053-014

TYPICAL WIRING DIAGRAM DEEP SEA ELECTRONICS ISSUE4

5320 INSTALLATION INSTRUCTIONS

ACCESSING THE FRONT PANEL CONFIGURATION EDITOR

CONFIGURATION

• Press the Stop/Reset and Info buttons

simultaneously ENTER PIN

• If a module security PIN has been set, the PIN number

****

request is then shown (The first * is flashing) :

• Press + or – buttons to adjust it to the correct value. Press 9 when the first digit is correctly entered.

Repeat this process for the other digits of the PIN number.

• When 9 is pressed after editing the final PIN digit, the PIN is checked for validity. If the number is not

correct, the editor is automatically exited. To retry you must re-enter the editor as described above.

• If the PIN has been successfully entered (or the module PIN CONFIGURATION

has not been enabled) the first configurable parameter is

displayed : Oil pressure pre-alarm

EDITING A PARAMETER 2bar 30PSI 200kPa

• Enter the editor as described above.

• Press the + and – buttons to cycle to the parameter you wish CONFIGURATION

to change.

• Press the 9 button to enter edit mode. When in edit mode Oil pressure pre-alarm

(indicated by the flashing parameter) pressing the + and – 2bar 30PSI 200kPa

buttons will adjust the parameter to the desired value.

• For date and time editing only: press to select between day, month, year, hours and minutes.

• Press the 9 button to ‘save’ the value. The value will stop flashing to confirm that it has been saved.

• To select another value to edit, press the + button. Continuing to press the + and – buttons will cycle

through the adjustable parameters as shown overleaf.

• To exit the front panel configuration editor at any time, press the Stop/Reset button. Ensure you

have saved any changes you have made by pressing the 9 button first.

NOTE:- When the editor is visible, it is automatically exited after 5 minutes of inactivity to

ensure security.

NOTE:- The PIN number is automatically reset when the editor is exited (manually or

automatically) to ensure security.

NOTE:- More comprehensive module configuration is possible using the 5xxx series PC

configuration software in conjunction with the P810 PC interface. Please contact us for further

details.

Deep Sea Electronics Plc. Deep Sea Electronics inc.

Highfield House, Hunmanby Industrial Estate, 3230 Williams Avenue

North Yorkshire. YO14 0PH. Rockford, Illinois 61101-2668,

ENGLAND U.S.A.

Tel:+44 (0)1723 890099. Phone: +1 (815) 316-8706.

Fax: +44 (0)1723 893303.

DIMENSIONS : 240mm x 172mm x 57mm Fax: +1 (815) 316- 8708

LO CALL (from UK BT landlines) :

(9.5” x 6.8” x 2.25”) Telephone 0845 260 8900. Fax 0845 260 8901 TOLL FREE (USA only) : Tel: 1 866 636 9703

PANEL CUTOUT : 220mm x 160mm Email: sales@deepseaplc.com Email: dsesales@deepseausa.com

(8.7” x 6.3”) Web: www.deepseaplc.com Web: www.deepseausa.com

ADJUSTABLE PARAMETERS (Factory default settings are shown in bold italicised text) ADJUSTABLE PARAMETERS (continued)

Section Parameter Display shows Values Section Parameter Display shows Values

Input settings Low Oil Pressure warning Oil pressure pre-alarm 0-4bar (1.17bar) Application Engine speed selection Alternative Frequency Disable, Enable

Low Oil Pressure shutdown Oil pressure shutdown 0-4bar (1.03bar) Volts selection Alternative Voltage Disable, Enable

High Temperature warning Coolant temp pre-alarm 80-140°C (115°C) AC System AC System 3 phase 4 wire

High Temperature shutdown Coolant temp shutdown 80-140°C (120°C) Single phase, 2 wire

Low Temperature warning 3 phase, 3 wire

Low Coolant temp 0-138°C (64°C)

2 phase 3 wire (L1 & L2)

Timers Mains transient delay Mains transient delay 0-30s (2s) 2 phase 3 wire (L1 & L3)

Generator transient delay Gen transient delay 0 -30s (0s) Generator Full Load Generator full load 0-6000A(500A)

Start delay Start delay 0 -10h (5s) Droop control Droop Disable, Enable

Return delay Return delay 0 -5h (30s)

Droop 0% (0%-5%)

Compatible engine ECUs only

Preheat Preheat 0 -5m (0s)

Frequency Adjust Frequency Adjust Cummins CM850 only

Crank attempt Cranking time 0 -60s (10s)

LCD Contrast Contrast |

Crank rest Crank rest 0-60s (10s)

Date/Time Date and Time dd mmm yyyy hh:mm

Safety delay Safety on 0-60s (10s)

Overspeed overshoot Overspeed overshoot 0-10s (2s)

Warming up Warm up 0-60m (0s)

Transfer delay Transfer delay 0-10m (0.7s) ALTERNATIVE AC WIRING

Cooling run Cooling 0-60m (60s) 3 phase, 3 wire

Fail to stop delay Fail to stop 0-2m (30s) For other AC systems please consult the

Low battery volts delay Battery low delay 0-24h (60s) module operators manual

High battery volts delay Battery high delay 0-24h (60s)

Mains (utility) Mains Low Voltage Mains undervolt trip 50-360V ph-N (184V)

Mains High Voltage Mains overvolt trip 50-360V ph-N (276V)

Mains Low Frequency Mains underfreq trip 0-75Hz (45Hz)

Mains High Frequency Mains overfreq trip 0-75Hz (55Hz)

Generator Generator Under voltage shutdown Gen low voltage shutdown 50-360V ph-N (184V)

Generator Under voltage prealarm Gen low voltage prealarm 50-360V ph-N (196V)

Generator Over voltage prealarm Gen high voltage prealarm 50-360V ph-N (265V)

Generator Over voltage shutdown Gen high voltage shutdown 50-360V ph-N (276V)

Generator Under frequency shutdown Gen low frequency shutdown 0 -75Hz (40Hz)

Generator Under frequency prealarm Gen low frequency prealarm 0 -75Hz (42Hz)

Generator Over frequency prealarm Gen high frequency prealarm 0 -75Hz (55Hz)

Generator Over frequency shutdown Gen high frequency shutdown 0 -75Hz (57Hz)

Generator delayed overcurrent Delayed high current 100-200% (100%)

Engine Underspeed (RPM) shutdown Underspeed shutdown 0-6000RPM (1270)

Underspeed (RPM) warning Underspeed prealarm 0-6000RPM (1350)

Overspeed (RPM) warning Overspeed prealarm 0-6000RPM (1650)

Overspeed (RPM) shutdown Overspeed shutdown 0-6000RPM (1710)

Overspeed overshoot % Overspeed overshoot 0-10 (0%)

Low DC Voltage Battery low warning 0-40V (8V)

High DC Voltage Battery high warning 0-40V (33V)

Charge Alternator Failure Charge fail warning 0-39V (6V)

Display Language Language ENGLISH, OTHER

Anda mungkin juga menyukai

- DSE5320 Installation Instructions PDFDokumen2 halamanDSE5320 Installation Instructions PDFBass LineBelum ada peringkat

- Practical, Made Easy Guide To Building, Office And Home Automation Systems - Part TwoDari EverandPractical, Made Easy Guide To Building, Office And Home Automation Systems - Part TwoBelum ada peringkat

- Typical Wiring Diagram: 5320 Installation InstructionsDokumen2 halamanTypical Wiring Diagram: 5320 Installation InstructionsЮля ЕгороваBelum ada peringkat

- Typical Wiring Diagram: 7310 Installation InstructionsDokumen2 halamanTypical Wiring Diagram: 7310 Installation Instructionsabduallah muhammadBelum ada peringkat

- DSE7310 Installation InstructionsDokumen2 halamanDSE7310 Installation InstructionsKwan Kok FeeiBelum ada peringkat

- Typical Wiring Diagram: Accessing The Front Panel Configuration EditorDokumen2 halamanTypical Wiring Diagram: Accessing The Front Panel Configuration EditorHayber FerrerBelum ada peringkat

- DSE8920 Installation InstructionsDokumen2 halamanDSE8920 Installation Instructionssanjaykr upadhyayBelum ada peringkat

- Deep Sea Electronics: DSE8910 & DSE8920 Installation InstructionsDokumen2 halamanDeep Sea Electronics: DSE8910 & DSE8920 Installation InstructionsAziz ArrahalBelum ada peringkat

- 871x Installation InstructionsDokumen2 halaman871x Installation InstructionsMd ShBelum ada peringkat

- Typical Wiring Diagram: Accessing The Front Panel Configuration EditorDokumen2 halamanTypical Wiring Diagram: Accessing The Front Panel Configuration EditorJulio Cesar Hinostroza AlarconBelum ada peringkat

- Typical Wiring Diagram: Deep Sea Electronics 053-027 Issue 8Dokumen2 halamanTypical Wiring Diagram: Deep Sea Electronics 053-027 Issue 8nicolasBelum ada peringkat

- DSEE400 Installation InstructionsDokumen2 halamanDSEE400 Installation InstructionsCH MUBASHER MAQSOOD ALAMBelum ada peringkat

- Gensetauto Mains Utility Failure Control Modulesdse7320downloadsinstallation InstructionsDokumen2 halamanGensetauto Mains Utility Failure Control Modulesdse7320downloadsinstallation InstructionsCarlos AlvaradoBelum ada peringkat

- DSE7320 Installation Instructions PDFDokumen2 halamanDSE7320 Installation Instructions PDFBraulio Nobre100% (1)

- DSE7320 Installation Instructions PDFDokumen2 halamanDSE7320 Installation Instructions PDFRafael Fernando100% (1)

- Deep See 7320Dokumen3 halamanDeep See 7320Bourama KanteBelum ada peringkat

- DSE6110 MKII & DSE6120 MKII Installation Instructions: Deep Sea Electronics 053-173 Issue 1Dokumen2 halamanDSE6110 MKII & DSE6120 MKII Installation Instructions: Deep Sea Electronics 053-173 Issue 1Leonardo ColmenarezBelum ada peringkat

- Typical Wiring Diagram: Deep Sea Electronics 053-085 Issue 3Dokumen2 halamanTypical Wiring Diagram: Deep Sea Electronics 053-085 Issue 3José LubatónBelum ada peringkat

- Typical Wiring Diagram: Deep Sea Electronics 053-088 Issue 2Dokumen2 halamanTypical Wiring Diagram: Deep Sea Electronics 053-088 Issue 2Omar KingBelum ada peringkat

- Deep Sea Electronics: DSEE800 Installation InstructionsDokumen2 halamanDeep Sea Electronics: DSEE800 Installation InstructionsMariane CamargoBelum ada peringkat

- Deep Sea Electronics: Typical Wiring DiagramDokumen2 halamanDeep Sea Electronics: Typical Wiring DiagramBruce LyndeBelum ada peringkat

- Dse7320 Installation Inst PDFDokumen2 halamanDse7320 Installation Inst PDFhhtvnpt100% (1)

- DSEG8600 Installation InstructionsDokumen6 halamanDSEG8600 Installation Instructionsvuvantieu802Belum ada peringkat

- 7220 Instrucciones de Intalacion PDFDokumen2 halaman7220 Instrucciones de Intalacion PDFAttackDenied123Belum ada peringkat

- Deep Sea Electronics 053-027 Issue 4 Typical Wiring DiagramDokumen2 halamanDeep Sea Electronics 053-027 Issue 4 Typical Wiring DiagramAttackDenied123Belum ada peringkat

- Typical Wiring Diagram: Accessing The Front Panel Configuration EditorDokumen2 halamanTypical Wiring Diagram: Accessing The Front Panel Configuration EditorYusuf Adi NugrohoBelum ada peringkat

- Dse7310 MkiiDokumen2 halamanDse7310 Mkiiabera alemayehu0% (1)

- DSE E800 - PLANO Installation-InstructionsDokumen2 halamanDSE E800 - PLANO Installation-InstructionsGONZALOBelum ada peringkat

- DSE7310 MKII DSE7320 MKII Installation Instructions PDFDokumen2 halamanDSE7310 MKII DSE7320 MKII Installation Instructions PDFMeriem ZAGRIRI100% (2)

- DEEP SEA - DSE8620-MKII - Installation InstructionsDokumen2 halamanDEEP SEA - DSE8620-MKII - Installation InstructionsGustavo DuarteBelum ada peringkat

- DSE8610 MKII Installation Instructions PDFDokumen2 halamanDSE8610 MKII Installation Instructions PDFManuel Ortiz Galán100% (1)

- Deep Sea Electronics: Typical Wiring Diagram DSE8610 MKII Installation InstructionsDokumen2 halamanDeep Sea Electronics: Typical Wiring Diagram DSE8610 MKII Installation InstructionssdmelBelum ada peringkat

- Deep Sea Electronics: Typical Wiring Diagram DSE8610 MKII Installation InstructionsDokumen2 halamanDeep Sea Electronics: Typical Wiring Diagram DSE8610 MKII Installation InstructionsMohammad Badii Mosli0% (1)

- Typical Wiring Diagram: 7320 Installation InstructionsDokumen2 halamanTypical Wiring Diagram: 7320 Installation InstructionsMecatrónica IgnacioBelum ada peringkat

- Schematich Dse7320 PDFDokumen2 halamanSchematich Dse7320 PDFMarvin Melendez VanegasBelum ada peringkat

- DSE7310 MKII DSE7310 MKII Installation InstructionsDokumen2 halamanDSE7310 MKII DSE7310 MKII Installation InstructionsMshaatBelum ada peringkat

- 7310 Installation InstructionsDokumen2 halaman7310 Installation InstructionsmohamedBelum ada peringkat

- DSE6110 MKII DSE6120 MKII Installation InstructionsDokumen2 halamanDSE6110 MKII DSE6120 MKII Installation InstructionsBJNE01100% (1)

- Deep Sea Electronics: Typical Wiring Diagram DSE8660 MKII Installation InstructionsDokumen2 halamanDeep Sea Electronics: Typical Wiring Diagram DSE8660 MKII Installation InstructionsElias Herrera Ceron0% (1)

- DSE7410-MKII-DSE7420-MKII ManualDokumen2 halamanDSE7410-MKII-DSE7420-MKII ManualCarlo JasminBelum ada peringkat

- Wiring Diagram DSE7310Dokumen2 halamanWiring Diagram DSE7310michaelmangaa25% (4)

- Dse7310 Installation Inst PDFDokumen2 halamanDse7310 Installation Inst PDFNay Soe100% (1)

- Deep Sea Electronics 053-028 Issue 4 Typical Wiring DiagramDokumen2 halamanDeep Sea Electronics 053-028 Issue 4 Typical Wiring DiagramBaciu NicolaeBelum ada peringkat

- Deep Sea Electronics 053-028 Issue 4 Typical Wiring DiagramDokumen2 halamanDeep Sea Electronics 053-028 Issue 4 Typical Wiring DiagramshwelulinBelum ada peringkat

- Dse7310 Installation Inst PDFDokumen2 halamanDse7310 Installation Inst PDFSalem AliBelum ada peringkat

- DSE8610 MKII Installation InstructionsDokumen2 halamanDSE8610 MKII Installation Instructionsjosch90210Belum ada peringkat

- DSE8610 MKII Installation InstructionsDokumen2 halamanDSE8610 MKII Installation Instructionsrms_rms_rms100% (1)

- DSE 7210 - Installation - InstructionsDokumen2 halamanDSE 7210 - Installation - InstructionsAnas BasarahBelum ada peringkat

- 810 - 820 Reload PDFDokumen7 halaman810 - 820 Reload PDFkumbrovBelum ada peringkat

- DSE7410 MKII DSE7420 MKII Installation InstructionsDokumen2 halamanDSE7410 MKII DSE7420 MKII Installation InstructionsdelsonBelum ada peringkat

- DSE7410 MKII DSE7420 MKII Installation Instructions PDFDokumen2 halamanDSE7410 MKII DSE7420 MKII Installation Instructions PDFArc HieBelum ada peringkat

- DSE7310 MKII DSE7320 MKII Installation InstructionsDokumen2 halamanDSE7310 MKII DSE7320 MKII Installation Instructionsprobeeriets6Belum ada peringkat

- DSE7310 MKII DSE7320 MKII Installation Instructions PDFDokumen2 halamanDSE7310 MKII DSE7320 MKII Installation Instructions PDFDaniel StanBelum ada peringkat

- Typical Wiring Diagram: Accessing The Front Panel Configuration Editor. Accessing The Front Panel Configuration EditorDokumen2 halamanTypical Wiring Diagram: Accessing The Front Panel Configuration Editor. Accessing The Front Panel Configuration EditorMohamed MossadBelum ada peringkat

- DSE8860 Installation InstructionsDokumen2 halamanDSE8860 Installation InstructionsJonas CrixelBelum ada peringkat

- Fanuc O Bakup ProcedureDokumen2 halamanFanuc O Bakup Procedureasif100% (1)

- Deep Sea Electronics: DSE7310 MKII & DSE7320 MKII Installation InstructionsDokumen2 halamanDeep Sea Electronics: DSE7310 MKII & DSE7320 MKII Installation InstructionsBa MamadouBelum ada peringkat

- DSE7310 MKII DSE7310 MKII Installation InstructionsDokumen2 halamanDSE7310 MKII DSE7310 MKII Installation InstructionsVinicius ArceBelum ada peringkat

- Corporate Brochure Part No. TitleDokumen15 halamanCorporate Brochure Part No. TitleAnonymous V9fdC6Belum ada peringkat

- GP - Pro EX Quick Start GuidesDokumen21 halamanGP - Pro EX Quick Start GuidesAnonymous V9fdC6Belum ada peringkat

- EDC 7 Electronic Control UnitDokumen5 halamanEDC 7 Electronic Control UnitAnonymous V9fdC675% (4)

- 20 Pressure SpecificationsDokumen7 halaman20 Pressure SpecificationsAnonymous V9fdC6Belum ada peringkat

- Series 58 Modular Version ISO 4401-03 (CETOP 03) P Max: Bar Max (See Table of Performances)Dokumen4 halamanSeries 58 Modular Version ISO 4401-03 (CETOP 03) P Max: Bar Max (See Table of Performances)Anonymous V9fdC6Belum ada peringkat

- Panel (EMCP) 4.2 Upgrade KitDokumen2 halamanPanel (EMCP) 4.2 Upgrade KitAnonymous V9fdC6Belum ada peringkat

- Potential Network Operators For NetbiterDokumen3 halamanPotential Network Operators For NetbiterAnonymous V9fdC6Belum ada peringkat

- Cat Electronic Technician 2016C v1.0 Product Status ReportDokumen10 halamanCat Electronic Technician 2016C v1.0 Product Status ReportAnonymous V9fdC6Belum ada peringkat

- EC350 Netbiter EasyConnect EC350Dokumen2 halamanEC350 Netbiter EasyConnect EC350Anonymous V9fdC6Belum ada peringkat

- Finally, A Complete Remote Monitoring Interface For The EMCP4 ®Dokumen2 halamanFinally, A Complete Remote Monitoring Interface For The EMCP4 ®Anonymous V9fdC6Belum ada peringkat

- Real Time Error Codes: Testing and AdjustingDokumen4 halamanReal Time Error Codes: Testing and AdjustingAnonymous V9fdC6Belum ada peringkat

- Beckhoff Water Treatment 2008Dokumen16 halamanBeckhoff Water Treatment 2008dwi104Belum ada peringkat

- Wilkinson Divider Even and Odd Mode AnalysisDokumen14 halamanWilkinson Divider Even and Odd Mode AnalysistugasutomoBelum ada peringkat

- Datasheet 25 50KTL V3Dokumen2 halamanDatasheet 25 50KTL V3Houssem KhelilBelum ada peringkat

- Laplace TransformsDokumen81 halamanLaplace TransformsChristopher OrtegaBelum ada peringkat

- Work Sheet DC MotorDokumen10 halamanWork Sheet DC MotoridealparrotBelum ada peringkat

- EMD SyllabusDokumen2 halamanEMD Syllabuskkk212Belum ada peringkat

- Universiti Teknologi Mara Final Examination: Confidential AS/OCT 2010/PHY150Dokumen11 halamanUniversiti Teknologi Mara Final Examination: Confidential AS/OCT 2010/PHY150Immoral FlowerBelum ada peringkat

- AnodeflexDokumen3 halamanAnodeflexFareed KhanBelum ada peringkat

- RE1, RE2: Magnetic Safety SwitchesDokumen2 halamanRE1, RE2: Magnetic Safety SwitchesJesus Alfonso Jimenez AlejosBelum ada peringkat

- bmp180 Pressure Sensor TutorialDokumen14 halamanbmp180 Pressure Sensor Tutorialapi-248437787Belum ada peringkat

- Hydra: The Versatile DoorDokumen14 halamanHydra: The Versatile DoorAnnabella RossiniBelum ada peringkat

- Toshiba Satellite L200 M200 M203 M206 KBTIDokumen59 halamanToshiba Satellite L200 M200 M203 M206 KBTIYakub LismaBelum ada peringkat

- U Cân Laumax W200 BaseDokumen36 halamanU Cân Laumax W200 BaseJose Luna0% (1)

- SMD Type Diodes: Schottky Diodes SS1020 SS10100Dokumen2 halamanSMD Type Diodes: Schottky Diodes SS1020 SS10100Momo MendozaBelum ada peringkat

- Micro-Programmed Versus Hardwired Control UnitsDokumen10 halamanMicro-Programmed Versus Hardwired Control Unitsdg5694Belum ada peringkat

- Grade 9 EPAS Quarter 1 Module 1 REVISEDDokumen22 halamanGrade 9 EPAS Quarter 1 Module 1 REVISEDMarfe Montelibano100% (1)

- Introduction To Arduino PDFDokumen13 halamanIntroduction To Arduino PDFAbhinav ChoudharyBelum ada peringkat

- DT Gen-Technical Data Sheet - DTG1000B-2023Dokumen1 halamanDT Gen-Technical Data Sheet - DTG1000B-2023chris connorsBelum ada peringkat

- Processors, Parallel Processing and Virtual MachinesDokumen12 halamanProcessors, Parallel Processing and Virtual MachinesSaloni ThapaBelum ada peringkat

- Power Quality: Case StudyDokumen6 halamanPower Quality: Case StudymarinflorentinaoanaBelum ada peringkat

- User Manual: SGQ - Ats Automatic Transfer SwitchDokumen11 halamanUser Manual: SGQ - Ats Automatic Transfer SwitchJulio Cesar Hinostroza AlarconBelum ada peringkat

- Wall Mounted Units Hitachi - Wall Mounted Units - Service ManualDokumen190 halamanWall Mounted Units Hitachi - Wall Mounted Units - Service ManualJonas RembertBelum ada peringkat

- Advanced Power Electronics Corp.: DescriptionDokumen5 halamanAdvanced Power Electronics Corp.: DescriptionkalanghoBelum ada peringkat

- Radio Direction FinderDokumen78 halamanRadio Direction Finderbingwazzup100% (1)

- York Chiller Air CooledDokumen108 halamanYork Chiller Air CooledaxelBelum ada peringkat

- Formula LTE NewDokumen11 halamanFormula LTE NewInsyafa NalaprajaBelum ada peringkat

- Hewlett-Packard - AN150-10 - Spectrum Analysis - Field Strenght MeasurementDokumen2 halamanHewlett-Packard - AN150-10 - Spectrum Analysis - Field Strenght Measurementgbr123Belum ada peringkat

- Research Solar PanelDokumen13 halamanResearch Solar PanelCherri Amistoso cheBelum ada peringkat

- McSEIS SX48chXP24bitDokumen2 halamanMcSEIS SX48chXP24bitAhmad Ali Syafi'iBelum ada peringkat

- Mosfet PDFDokumen13 halamanMosfet PDFTad-electronics TadelectronicsBelum ada peringkat