P&ID

Diunggah oleh

Faiz NordinHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

P&ID

Diunggah oleh

Faiz NordinHak Cipta:

Format Tersedia

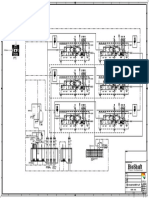

Piping and instrumentation diagram

From Wikipedia, the free encyclopedia

A piping and instrumentation diagram (P&ID) is a detailed diagram in the process industry which

shows the piping and vessels in the process flow, together with the instrumentation and control

devices.

Superordinate to the piping and instrumentation flowsheet is the process flow diagram (PFD) which

indicates the more general flow of plant processes and equipment and relationship between major

equipment of a plant facility.

Contents

1 Contents and function

2 Identification and reference designation

3 Symbols of chemical apparatus and equipment

4 See also

5 External links

Contents and function

Example of a single industrial control loop; showing continuously modulated control of process flow.

Piping and instrumentation diagram of pump with storage tank. Symbols according to EN ISO 10628

and EN 62424.

A more complex example of a P&ID.

A piping and instrumentation diagram (P&ID) is defined by the Institute of Instrumentation and

Control as follows:

A diagram which shows the interconnection of process equipment and the instrumentation used to

control the process. In the process industry, a standard set of symbols is used to prepare drawings of

processes. The instrument symbols used in these drawings are generally based on International

Society of Automation (ISA) Standard S5.1

The primary schematic drawing used for laying out a process control installation.

They usually contain the following information:

Process piping, sizes and identification, including:

Pipe classes or piping line numbers

Flow directions

Interconnections references

Permanent start-up, flush and bypass lines

Mechanical equipment and process control instrumentation and designation (names, numbers,

unique tag identifiers), including:

Valves and their identifications (e.g. isolation, shutoff, relief and safety valves)

Control inputs and outputs (sensors and final elements, interlocks)

Miscellaneous - vents, drains, flanges, special fittings, sampling lines, reducers and increasers

Interfaces for class changes

Computer control system

Identification of components and subsystems delivered by others

P&IDs are originally drawn up at the design stage from a combination of process flow sheet data, the

mechanical process equipment design, and the instrumentation engineering design. During the

design stage, the diagram also provides the basis for the development of system control schemes,

allowing for further safety and operational investigations, such as a Hazard and operability study

(HAZOP). To do this, it is critical to demonstrate the physical sequence of equipment and systems, as

well as how these systems connect.

P&IDs also play a significant role in the maintenance and modification of the process after initial

build. Modifications are red-penned onto the diagrams and are vital records of the current plant

design.

They are also vital in enabling development of;

Control and shutdown schemes

Safety and regulatory requirements

Start-up sequences

Operational understanding.

P&IDs form the basis for the live mimic diagrams displayed on graphical user interfaces of large

industrial control systems such as SCADA and distributed control systems.

Identification and reference designation

Based on STANDARD ANSI/ISA S5.1 and ISO 14617-6, the P&ID is used for the identification of

measurements within the process. The identifications consist of up to 5 letters. The first

identification letter is for the measured value, the second is a modifier, 3rd indicates

passive/readout function, 4th - active/output function, and the 5th is the function modifier. This is

followed by loop number, which is unique to that loop. For instance FIC045 means it is the Flow

Indicating Controller in control loop 045. This is also known as the "tag" identifier of the field device,

which is normally given to the location and function of the instrument. The same loop may have

FT045 - which is the flow transmitter in the same loop.

Letter Column 1 (Measured value) Column 2 (Modifier) Column 3 (Readout/passive

function) Column 4 (Output/active function) Column 5 (Function modifier)

A Analysis Alarm

B Burner, combustion User choice User choice User choice

C User's choice (usually conductivity) Control Close

D User's choice (usually density) Difference Deviation

E Voltage Sensor

F Flow rate Ratio

G User's choice (usually gaging/gauging) Gas Glass/gauge/viewing

H Hand High

I Current Indicate

J Power Scan

K Time, time schedule Time rate of change Control station

L Level Light Low

M User's choice Middle / intermediate

N User's choice (usually torque) User choice User choice User choice

O User's choice Orifice Open

P Pressure Point/test connection

Q Quantity Totalize/integrate Totalize/integrate

R Radiation Record Run

S Speed, frequency Switch Stop

T Temperature Transmit

U Multivariable Multifunction Multifunction

V Vibration, mechanical analysis Valve or damper

W Weight, force Well or probe

X User's choice (usually on-off valve as XV) X-axis Accessory devices, unclassified

Unclassified Unclassified

Y Event, state, presence Y-axis Auxiliary devices

Z Position, dimension Z-axis or Safety Actuator, driver or unclassified final control

element

Anda mungkin juga menyukai

- Of Nsf/Ansi 44: Technical RequirementsDokumen2 halamanOf Nsf/Ansi 44: Technical Requirementsthe_expensiveBelum ada peringkat

- Mazda 323f RelejiDokumen7 halamanMazda 323f RelejimrgbbBelum ada peringkat

- Mihir's Handbook of Chemical Process Engineering (Excerpts)Dokumen74 halamanMihir's Handbook of Chemical Process Engineering (Excerpts)Mihir Patel100% (4)

- PFI PROFILTER Activated Carbon Filter With Mild Steel TankDokumen1 halamanPFI PROFILTER Activated Carbon Filter With Mild Steel Tankbennypartono407Belum ada peringkat

- 3in Elamr Drawing Illustration in One FileDokumen43 halaman3in Elamr Drawing Illustration in One FileusamakhattakBelum ada peringkat

- Tablas Mecanicas KR C2 PDFDokumen10 halamanTablas Mecanicas KR C2 PDFarturoBelum ada peringkat

- Piping and Instrumentation Diagram - WikipediaDokumen18 halamanPiping and Instrumentation Diagram - WikipediaVishy100% (1)

- Instructions For Laying Steel Pipes 032014 PDFDokumen29 halamanInstructions For Laying Steel Pipes 032014 PDFleeyuen_aBelum ada peringkat

- DMX PumpsDokumen33 halamanDMX PumpsGROIIMBelum ada peringkat

- Double Wall Corrugated (DWC) HDPE PipeDokumen3 halamanDouble Wall Corrugated (DWC) HDPE PipeHimanshu BavishiBelum ada peringkat

- Central Medical Gas: Distribution SystemDokumen21 halamanCentral Medical Gas: Distribution SystemPronceBelum ada peringkat

- Water Demand ManagementDokumen17 halamanWater Demand ManagementShaira Mae VillolaBelum ada peringkat

- F913 Gaskets For Joining Plastic PipeDokumen5 halamanF913 Gaskets For Joining Plastic Pipelepm30Belum ada peringkat

- P&ID - STP-Yanbu SWCC (6units)Dokumen1 halamanP&ID - STP-Yanbu SWCC (6units)Ashraf BayomiBelum ada peringkat

- WAE Drinking Water Fountains India: Manufacturers & SuppliersDokumen4 halamanWAE Drinking Water Fountains India: Manufacturers & SuppliersWae IndiaBelum ada peringkat

- How Accurate Is Accurate Parts 1-2-3Dokumen10 halamanHow Accurate Is Accurate Parts 1-2-3wlmostiaBelum ada peringkat

- Film Evaporation TechnologyDokumen12 halamanFilm Evaporation TechnologyVanessa Denise AguilarBelum ada peringkat

- Troubleshooting Guide: Asset Family Centrifugal Process PumpsDokumen1 halamanTroubleshooting Guide: Asset Family Centrifugal Process PumpsPedro ViegasBelum ada peringkat

- Water Sampling For Bacteriological Exam Water District GroupDokumen12 halamanWater Sampling For Bacteriological Exam Water District GroupBen Fraizal UkailBelum ada peringkat

- TCN PDFDokumen66 halamanTCN PDFJahangir AlamBelum ada peringkat

- TrueUnion - True Union Ball ValveDokumen4 halamanTrueUnion - True Union Ball ValveKarthick VenkateshBelum ada peringkat

- ANN Based PH Control ReportDokumen36 halamanANN Based PH Control ReportSumit GuptaBelum ada peringkat

- Construction of Digital Water Level Indi PDFDokumen6 halamanConstruction of Digital Water Level Indi PDFnadia elenaBelum ada peringkat

- Installation of Underground Drainage Piping: ChecklistDokumen1 halamanInstallation of Underground Drainage Piping: Checklistakash nairBelum ada peringkat

- Ms KRT 2553 804 10 14Dokumen40 halamanMs KRT 2553 804 10 14sharandeep1112Belum ada peringkat

- The Session Will Start at 13:05 and Will Be Recorded: Please Login To Socrative Student: Room Name: Weston3103Dokumen21 halamanThe Session Will Start at 13:05 and Will Be Recorded: Please Login To Socrative Student: Room Name: Weston3103EMILY BLANDFORDBelum ada peringkat

- Lockstop SDS GreenstreakDokumen8 halamanLockstop SDS Greenstreakrobox514Belum ada peringkat

- FiltersDokumen11 halamanFiltersRegarz ArrowBelum ada peringkat

- Emergency Shut Down Valve:: Actuated Valve Partial or Total Process ShutdownDokumen3 halamanEmergency Shut Down Valve:: Actuated Valve Partial or Total Process ShutdownPrasanna kumar subudhiBelum ada peringkat

- Emerson - SAPAG Butterfly ValveDokumen14 halamanEmerson - SAPAG Butterfly ValvekuraimundBelum ada peringkat

- Surge AnalysisDokumen30 halamanSurge AnalysisRadhakrishna MadabhushiBelum ada peringkat

- MSI Pipe and Valve InternationalDokumen27 halamanMSI Pipe and Valve InternationalbawwsswwabBelum ada peringkat

- Instrumentation EngineeringDokumen19 halamanInstrumentation EngineeringKuldeepsingh ChandelBelum ada peringkat

- Underground Pipe CertDokumen2 halamanUnderground Pipe CertnomarblesBelum ada peringkat

- 3.1.WasteWater Treatment Procedure - FLOCDokumen4 halaman3.1.WasteWater Treatment Procedure - FLOChaseeb100% (1)

- M12 PDFDokumen22 halamanM12 PDFAdrian GuzmanBelum ada peringkat

- Types of Piping Drawings: Piping and Instrumentation DiagramDokumen18 halamanTypes of Piping Drawings: Piping and Instrumentation Diagramakash dawareBelum ada peringkat

- Field Welding Inspection ManualDokumen40 halamanField Welding Inspection ManualrosennmBelum ada peringkat

- Project Reference: R.F.Q. Reference: Spec. Reference: Date:: Technical Data SheetDokumen2 halamanProject Reference: R.F.Q. Reference: Spec. Reference: Date:: Technical Data SheetIoana PopescuBelum ada peringkat

- Air Filter PDFDokumen15 halamanAir Filter PDFArun KarthikeyanBelum ada peringkat

- D.I. Catalogue) 9th Edition) PDFDokumen70 halamanD.I. Catalogue) 9th Edition) PDFArunprasad MurugesanBelum ada peringkat

- 1industrial Safety UIDokumen87 halaman1industrial Safety UISri HarshaBelum ada peringkat

- Operation and Control Philosophy Watering System - EnglishDokumen3 halamanOperation and Control Philosophy Watering System - Englishjohn jose partidas gutierrezBelum ada peringkat

- Samsung VRF Installation Trend For BuildingDokumen55 halamanSamsung VRF Installation Trend For BuildingNaseemBelum ada peringkat

- CPI CPI-BrochureDokumen22 halamanCPI CPI-BrochureMazwan Che MansorBelum ada peringkat

- Update Operation ManualDokumen67 halamanUpdate Operation ManualFaisal Sr. ExecutiveBelum ada peringkat

- Lecture 6 - Actuators, Inputs & OutputsDokumen20 halamanLecture 6 - Actuators, Inputs & OutputsEMILY BLANDFORDBelum ada peringkat

- GM3SEK's Amateur Radio Technical Notebook: RF Power AmplifiersDokumen2 halamanGM3SEK's Amateur Radio Technical Notebook: RF Power Amplifierssree479Belum ada peringkat

- uPVC & PVC Pipes Catalogue uPVC & PVC Pipes Catalogue: High Standard PipeDokumen35 halamanuPVC & PVC Pipes Catalogue uPVC & PVC Pipes Catalogue: High Standard PipeFerryTimothyBelum ada peringkat

- Disk Electrostatic Automatic Coating System - OTSON - DM - OTS - 5000!3!0Dokumen16 halamanDisk Electrostatic Automatic Coating System - OTSON - DM - OTS - 5000!3!0otsontek9227Belum ada peringkat

- Design Package Deliverable S 90Dokumen5 halamanDesign Package Deliverable S 90Viet Nguyen HungBelum ada peringkat

- Conduit and Cable ScheduleDokumen1 halamanConduit and Cable ScheduleFarhan SaadatBelum ada peringkat

- Why Is PH Control A Problem?Dokumen13 halamanWhy Is PH Control A Problem?Krishna JashaBelum ada peringkat

- SS 512-2005 - PreviewDokumen11 halamanSS 512-2005 - PreviewJohn50% (2)

- FloVENT PDFDokumen12 halamanFloVENT PDFVigiiBelum ada peringkat

- SPD ApplicationsDokumen1 halamanSPD ApplicationsLucio Loyloy SanchezBelum ada peringkat

- Sanitary Engineer II: Passbooks Study GuideDari EverandSanitary Engineer II: Passbooks Study GuideBelum ada peringkat

- 3b Basic Instrument SymbolsDokumen5 halaman3b Basic Instrument SymbolsM-E-D-ScribdBelum ada peringkat

- Inst CodesDokumen2 halamanInst CodesShaik FirdosiBelum ada peringkat

- Assignment No. 2Dokumen6 halamanAssignment No. 2Angelo MacatangayBelum ada peringkat

- Isa Symbology Plant DiagramsDokumen3 halamanIsa Symbology Plant DiagramsMohammed Abdul JabbarBelum ada peringkat

- Pipe and Identification DiagramsDokumen11 halamanPipe and Identification DiagramsNancy VivianaBelum ada peringkat

- Study of Instrumentation Symbols As Per ISA StandardsDokumen54 halamanStudy of Instrumentation Symbols As Per ISA Standardspra578100% (1)

- UNSPSCDokumen2 halamanUNSPSCFaiz NordinBelum ada peringkat

- UNSPSCDokumen2 halamanUNSPSCFaiz NordinBelum ada peringkat

- UNSPSCDokumen2 halamanUNSPSCFaiz NordinBelum ada peringkat

- CorrosionDokumen6 halamanCorrosionFaiz NordinBelum ada peringkat

- ManualDokumen4 halamanManualFaiz NordinBelum ada peringkat

- SisDokumen3 halamanSisFaiz NordinBelum ada peringkat

- Business Headlines Newspaper DateDokumen1 halamanBusiness Headlines Newspaper DateFaiz NordinBelum ada peringkat

- Faiz Rna NordinDokumen59 halamanFaiz Rna NordinFaiz NordinBelum ada peringkat

- Artificial LiftDokumen2 halamanArtificial LiftFaiz NordinBelum ada peringkat

- Faiz Rna NordinDokumen59 halamanFaiz Rna NordinFaiz NordinBelum ada peringkat

- Swot Analysis: Weaknesses StrengthsDokumen1 halamanSwot Analysis: Weaknesses StrengthsFaiz NordinBelum ada peringkat

- The Sales Tax and The Price of An Item Sold in A Particular StateDokumen2 halamanThe Sales Tax and The Price of An Item Sold in A Particular StateFaiz NordinBelum ada peringkat

- One Grid Cell GraphDokumen1 halamanOne Grid Cell GraphFaiz NordinBelum ada peringkat

- A Guide To Well ConstructionDokumen127 halamanA Guide To Well ConstructionbimalbkBelum ada peringkat

- Name: Muhammad Faiz Bin Nordin MATRIC ID: 17514 Course: Petroleum EngineeringDokumen4 halamanName: Muhammad Faiz Bin Nordin MATRIC ID: 17514 Course: Petroleum EngineeringFaiz NordinBelum ada peringkat

- Vector Calculus FCM 1123: Lectu Re Tutor Ial LabDokumen3 halamanVector Calculus FCM 1123: Lectu Re Tutor Ial LabKianseng LeeBelum ada peringkat

- Experimental ValueDokumen3 halamanExperimental ValueFaiz NordinBelum ada peringkat

- Meritor Mt46 50Dokumen120 halamanMeritor Mt46 50julioBelum ada peringkat

- Specifications and Repair Procedures For C4.4 Cylinder BlocksDokumen8 halamanSpecifications and Repair Procedures For C4.4 Cylinder BlocksMarielis ContrerasBelum ada peringkat

- Theory of StructureDokumen10 halamanTheory of Structurebharat shuklaBelum ada peringkat

- Chapter-5 Stresses in BeamsDokumen16 halamanChapter-5 Stresses in BeamsFitsum OmituBelum ada peringkat

- High Speed Spindle Design and ConstructionDokumen13 halamanHigh Speed Spindle Design and ConstructionSahil KumarBelum ada peringkat

- Simulation and Dynamic Analysis of Remotely Operated Vehicle (ROV) Using PID Controller For Pitch MovementDokumen9 halamanSimulation and Dynamic Analysis of Remotely Operated Vehicle (ROV) Using PID Controller For Pitch Movementahsikhan007Belum ada peringkat

- GraphsDokumen23 halamanGraphsNi MeshBelum ada peringkat

- 2015 Nissan Sentra Fe + S 1.8l, l4, Des Mra8de, Ee. Uu. 2Dokumen2 halaman2015 Nissan Sentra Fe + S 1.8l, l4, Des Mra8de, Ee. Uu. 2Misa GamezBelum ada peringkat

- 6-4.11.2. Differential Pressure TestDokumen8 halaman6-4.11.2. Differential Pressure TestCharles PereiraBelum ada peringkat

- Installation,-Operating and Maintenance Instructions: HADEF Aluminum Spur Gear Chain Hoist Type 10/19Dokumen16 halamanInstallation,-Operating and Maintenance Instructions: HADEF Aluminum Spur Gear Chain Hoist Type 10/19Guillermo ManchayBelum ada peringkat

- SA-980-P-11444 - API 685 Fuel Hydrant Pump PZ - Vert02Dokumen5 halamanSA-980-P-11444 - API 685 Fuel Hydrant Pump PZ - Vert02altipatlarBelum ada peringkat

- Biland Sa-250: Technical SpecificationsDokumen4 halamanBiland Sa-250: Technical SpecificationsNofriagara Davit HarnawanBelum ada peringkat

- NES 339 Requirements For Steering and Stabilizer Systems For HM Surface Ships and Royal Fleet Auxiliaries - Category 1Dokumen66 halamanNES 339 Requirements For Steering and Stabilizer Systems For HM Surface Ships and Royal Fleet Auxiliaries - Category 1JEORJEBelum ada peringkat

- PTP Pre Insulated Pipe Supports CatalogDokumen206 halamanPTP Pre Insulated Pipe Supports Catalogklich77Belum ada peringkat

- Shear Connectors On Concrete-To-Concrete Interface Surfaces: A Numerical Investigation On 3D FramesDokumen13 halamanShear Connectors On Concrete-To-Concrete Interface Surfaces: A Numerical Investigation On 3D FramesPedro SantosBelum ada peringkat

- Experiment 7: Work, Power and EnergyDokumen8 halamanExperiment 7: Work, Power and EnergynatlasBelum ada peringkat

- Supercavitation Seminar ReportDokumen19 halamanSupercavitation Seminar ReportSeema NadigBelum ada peringkat

- CTMS Example - Motor Position Control ModelingDokumen4 halamanCTMS Example - Motor Position Control ModelingKartik DetrojaBelum ada peringkat

- Domestic Commercial EngDokumen56 halamanDomestic Commercial EngDana LoreBelum ada peringkat

- Manual HaulotteDokumen82 halamanManual HaulotteRock Saybolt100% (3)

- Xtra Strong (XS) Size Steel Pipe Weights TAble CalculatorDokumen1 halamanXtra Strong (XS) Size Steel Pipe Weights TAble CalculatorshownpuBelum ada peringkat

- Sop & Jsa For Pipe LeakageDokumen1 halamanSop & Jsa For Pipe LeakageSoumya ChatterjeeBelum ada peringkat

- Lecture Notes - Forging CalculationDokumen21 halamanLecture Notes - Forging CalculationFabiano, Jr. BarcenalBelum ada peringkat

- Datasheet - AWC 25-350 A - EnglishDokumen4 halamanDatasheet - AWC 25-350 A - EnglishLeonardo Augusto Ramirez SaenzBelum ada peringkat

- BRAKE & pLANETARY GP 229-9967Dokumen5 halamanBRAKE & pLANETARY GP 229-9967hernan dueñasBelum ada peringkat

- Single Compression Cable Glands - Comet PDFDokumen2 halamanSingle Compression Cable Glands - Comet PDFdip461Belum ada peringkat