CFLHD Production Rates

Diunggah oleh

abhiazadHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

CFLHD Production Rates

Diunggah oleh

abhiazadHak Cipta:

Format Tersedia

Last Revised: Nov 8, 2016

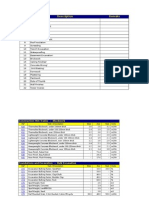

PRODUCTION RATES - ENGLISH

Typical Production Rate

Activity Unit Notes for Production Rates

Low Average High

MOBILIZATION

Projects less than $1 million Day 3

Major bridge project Day 14 26 28

Paving only project Day 2 3 5

Grading only / Minor Earthwork Day 4 10 20

Grading and paving / Major Earthwork Day 7 12 20

Grading, paving and bridge project Day 12 17 22

SURVEY AND STAKING

Verify FHWA control Day 1 2 3

Stake centerline LF 1,600 3,200 4,800 Use lower rates for smaller projects

Slope, Reference and Clearing Stakes LF 600 800 1,600 Use higher rates for flat, lightly/non-vegetated terrain

Use lower rates for smaller projects; rates represent one course of aggregate (ie: red

Grade finishing stakes LF 800 1,600 2,400 tops, blue tops, etc); include time for survey of each aggregate course; use higher rates

where Machine Guidance is anticipated (ie: large linear projects)

Rate will depend on size and type of structure/device, project topography, and proximity

Stake drainage structure/device EA 4 8 16 of each structure to eachother (ie: will the surveyor have to relocate base station

multiple times?)

EROSION CONTROL

Silt fence / Wattles LF 200 1,000 1,700 Use lower rates for excessive boulders and heavy trees, steep terrain.

Matting SY 600 1,800 2,800 Use lower rates for isolated small areas, oddly shaped, etc.

CLEARING & GRUBBING

Projects with a lot of large trees,

AC 0.3 1.3 2.7

rugged terrain, or heavy brush

Projects with fewer large trees,

AC 1 3 6

flatter terrain, or less heavy brush

EARTHWORK

Use lower rates for excessive boulders and steep terrain, smaller projects, and long haul

Strip and stockpile topsoil CY 300 700 1,200

to stockpile location.

Subexcavation

Use 14 days when cofferdam required, minimum.

(no shoring or dewatering needed)

1' to 5' deep CY 125 325 500 Rates from RS Means.

5' to 10' deep CY 225 600 1,000 Rates from RS Means.

Roadway Excavation

Projects with less than

50,000 CY of earthwork CY 400 1,600 2,500 Note 2. Also consider number of sites (ie: will multiple sites be in production at once?)

or haul distance of 5 miles or more

Projects with more than

CY 1,200 2,800 4,500 Note 2. Also consider number of sites (ie: will multiple sites be in production at once?)

50,000 CY of earthwork

Rates from RS Means. Use on jobs with minor rock cuts or where blasting is not

Rock excavation by hammer CY 80 240 640

permitted

Rock excavated by ripping CY 300 900 1,500 Use lower rates for harder, yet rippable, rock. Use higher rates for softer rock.

Use lower rates for difficult access and harder rock; these prod. Rates include pioneering,

Rock excavated by blasting CY 150 250 400

drilling, blasting, loading and haul away activities but do not include scaling

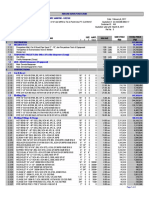

Typical Production Rate

Activity Unit Notes for Production Rates

Low Average High

Structure Excavation (most soils) CY 60 120 180 Rates from RS Means

Structure Excavation (sand/gravel) CY 100 160 220 Rates from RS Means

Embankment Construction CY 250 1,100 2,600 Note 2

Typical Production Rate

Activity Unit Notes for Production Rates

Low Average High

REMOVALS

PCC pavement SY 500 1,000 2,500 Reduce rates for lower quantity and increased pavement depth.

Reduce rates for lower quantity and increased pavement depth; rates are based on

Asphalt pavement SY 500 3,500 8,000

milled/pulverized removal rates

Rates will vary depending on how much work is required to return it to the original

condition. Large areas with simple horizontal and veritcal geometry will have a

Roadway Obliteration SY 80 400 1,500

production rate up to 1500 SY/day. Areas that require additional fill or projects with

multiple small obliteration sites will have lower production rates.

Concrete curb & gutter LF 200 360 1,100 Rate will vary based on quantity, dimensions, and condition of curb/gutter to be removed

site conditions must be considered: rate will increase significantly if material can be

Sidewalk SY 100 600 1,200

removed with a equipment operated hammer vs. labor operated hammer

Guardrail LF 310 600 870

Pipe <36" diameter LF 120 240 360

Pipe >36" diameter LF 95 150 270

Pavement Cutting (AC) LF 800 1,600 2,400 As depth increases, reduce rates.

Pavement Cutting (PCC) LF 800 1,600 2,400 As depth increases, reduce rates.

Structures, minor DAY 5 10 20

Structures, major DAY 1 3 5

DRAINAGE

Prod. Rates include forming, tieing, casting and stripping but do not include excavation or

Box culvert, Cast-in-place LF 2 10 16 backfill. Site specific conditions (box size, traffic requirements, existing structure

removal, foundation, dewatering, etc…) should also be considered.

Prod. Rates include placement only. Excavation, and backfill/compaction, off-site

production times and transportation should be considered as well. Site specific conditions

Box culvert, Precast LF 40 70 140

(box size, traffic requirements, existing structure removal, foundation, dewatering, etc…)

should also be considered.

Inlets and manholes, new or adjust EA 1 2 3 As Total in a Line increases, increase production. Pre cast, use higher rate.

Redue rates for sliver fills, deep fills, rocky soil, smaller projects. Consider traffic volume.

Pipe culvert, 24" and smaller LF 40 80 120

Under average conditions, assume 1 installation per day per crew.

Reduce rates for sliver fills, deep fills, rocky soil, smaller projects. Consider traffic

Pipe culvert, 30" to 42" LF 30 70 100

volume. Under average conditions, assume 1 installation per day per crew.

Reduce rates for sliver fills, deep fills, rocky soil, smaller projects. Consider traffic

Pipe culvert, 48" and larger LF 20 55 80

volume. Under average conditions, assume 1 installation per day per crew.

Riprap, aprons CY 20 40 60 Reduce rates for rocky soil, steep sliver fills, smaller projects.

Riprap lined ditches LF 100 200 300 Reduce rates for rocky soil, steep sliver fills, smaller projects.

Underdrain LF 200 400 800 Reduce rates for rocky soil, smaller projects, and large trenches dimensions.

Unit is for exposed face sqft; rates are for minor drainage structures; as wall area

Wingwall/Headwall SF 14 35 90

increases, increase production rates; add 7 days for cure and backfill.

SUBGRADE AND BASE

Rates includes scarification and compaction efforts; As application area increases,

Subgrade stabilization, lime SY 900 4,000 6,000

increase production rate.

Rates includes scarification and compaction efforts; As application area increases,

Subgrade stabilization, cement SY 900 4,000 5,000

increase production rate.

Subgrade stabilization, asphalt SY 900 3,000 Limited data available; Rates includes scarification and compaction efforts

Recycling, Cold In Place SY 12,000 15,000 Limited data available

Asphalt Pavement Milling SY 2,000 3,000 6,500

Pulverizing SY 2,000 4,000 12,500 reduce rates if pulverizing deeper than 3"

rates include lay down but do not include final grading operations; consider project

Aggregate Base TONS 400 1,000 1,800

specific conditions; these activities may be combined with smaller quantities

Aggregate Shoulder CY 100 350 500

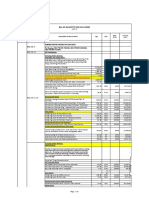

Typical Production Rate

Activity Unit Notes for Production Rates

Low Average High

As quantity increases, increase production rate. Allow for sequencing of one lane at a

Cement Treated Base SY 1,940 4,050 5,920

time and curing.

Rates are for two lanes; rates do not include survey time; rates represent one course (ie:

Finishing Subgrade/Base Course/Surface

LF 500 1,000 2,000 red tops, blue tops, etc); decrease rates for rocky subgrade; increase rates if it is

Course

anticipated that AMG will be used (larger projects);

PAVING

Asphalt paving (HACP) TONS 550 1,000 1,700 Note 2

Project specific restrictions should be closely considered; increase rates as quantity

Asphalt surface treatment (fog seal) TONS 3 20 58

increases, and where traffic passage can be limited/elliminated

Prime coat SY 3,900 10,000 20,000 Production rate will typically be controlled by Asphalt paving production rate

Tack coat TONS 1 3 8 Production rate will typically be controlled by Asphalt paving production rate

Rates dependent upon difficulty of paving, based on accessibility, ditch dimensions and

Paved Ditch SY 250 500 750

continuous ditch length. Longer ditches will generally have higher production rates.

Portland Cement Concrete Pavement (slip Slip forming, increase production rates with increase in paving length; production rate

SY 460 2,500 5,000

forming) varies significatly based on pavement depth.

Conventional forming;sharp curves and angles decrease production; note: slip form

Portland Cement Concrete Pavement

SY 20 300 600 concrete paving will have significantly higher production rates; use RS Means if slip form

(conventional forming)

paving is anticipated (ie: for vary large concrete paving projects).

Chip Seal SY 2,500 13,500 21,000 Add one day to complete brooming

Approach roads, minor HACP TONS 80 250 350

Project specific conditions should be considered; Larger sites will yeild higher rates;

Full Depth Patch SY 60 160 400

smaller multiple sites will yield lower rates

Typical Production Rate

Activity Unit Notes for Production Rates

Low Average High

CURBS, GUTTERS, AND SIDEWALK

Curb & Gutter, Concrete LF 160 480 900 Reduce rates for hand mixed/placed

Curb, Concrete LF 160 480 900 Reduce rates for hand mixed/placed.

Curb, Bituminous LF 650 1,200 1,850

Curb, Stone LF 50 100 150 Limited data available

Sidewalks, Concrete SY 80 160 280

GUARDRAIL AND GUARDWALL

W-beam or box beam guardrail LF 250 500 1,000 Use lower rates for stiff/rocky soils.

Steel Backed Timber guardrail LF 600 Limited data available

Cable guardrail LF 800 Limited data available

BRIDGES AND STRUCTURES

Limited Data available; increase rate for higher quantities and sandy soil; decrease rates

Cofferdams SY 100 200 300

for rocky, or cobbly soil

Rates include forming, tieing, pouring; Add cure time and time for stripping forms;

Column/Pier Cap/Abutment Construction CY 2 4 8 Recommend breaking down into individual work activities (ie: survey, form, tie rebar,

pour concrete, cure, strip forms);

Rates include forming, tieing, pouring; Add cure time and time for stripping forms;

Recommend breaking down into individual work activities (ie: survey, form, tie rebar,

Deck Construction SF 100 250 400

pour concrete, cure, strip forms); Reduce production rate for decks with complicated

geometry. Add 14 days for curing for all rates.

Note 1; Increase rate for shaft clusters, good accessibility and drilling space; soil type is

Drilled Shafts LF 10 112 280 primary controling factor; reduce rate slightly for cobbly soil, bore diameter and lower

quantities; reduce rate significatly for harder rock

Membrane Waterproofing SF 1,500 Limited data available

Allow time for relaxation/testing/redriving; reduce rate for larger diameter/sectional area

Piles, Driving Concrete LF 100 250 500

piles; time

Allow consult

for with geotech. For site specificreduce

relaxation/testing/redriving; considerations

rate for larger diameter/sectional area

Piles, Driving Steel LF 100 250 500

piles; consult with geotech. For site specific considerations

Includes tieing, prestressing, casting, curing and transportation for one set of girders

(ie:for one casting of girders); NOTE: assume 3 girders (typical) per set/casting;

Prestressed girders (fabrication) DAYS 10 13 20

tieing/prestressing and casting times (approximately 3-4 days) will overlap cure times for

each previous set

Rates are for placement, not fabrication. Use lower rate for poor access, and longer

Prestressed girders (setting) EA 3 6 12

beams. Add fabrication, curing and transportation time (below)

Reinforcement (Substructure) Lbs 3,000 4,000 5,000 Rates include tieing rebar only

Reinforcement (Superstructure) Lbs 3,000 4,400 5,800 Typical = 3 days/span; rates include tieing rebar only

Production rate will be primarily controlled by size of pour; increase rates for larger

Structural Concrete CY 20 110 200

structural sections/quantities; reduce rates for poor accessibility to pour site

Structural steel beams (setting) EA 3 6 12

Structure Steel, Erecting Lbs 25,000 Limited data available

Sidewalks and parapets DAYS 5/span Limited data available; recommend conducting project-specific cost based UPA

Limited data available. Rates include excavation and backfill. Recommend site/project-

Wall, MSE SF 40 150 220

specific requirements are considered. Increase rate as quantity increases.

Wall, gabion SF 40 300 600 Limited data available; rates do not include excavation

Wall, Stone masonry SF 35 50 100 Limited data available; rates include excavation and are based on exposed face area

Retaining Wall, Reinforced Concrete SF 10 22 60 Limited data available; reduce rates for form liner or stone masonry facing

Typical Production Rate

Activity Unit Notes for Production Rates

Low Average High

RIPRAP, ROCKERIES, ROCK EMBANKMENTS

Site specific requirements should be closely considered. Reduce rates for multiple small

Class 2 and smaller CY 10 80 200

sites, and large amounts of excavation; Increase rates are for larger qtys

Site specific requirements should be closely considered. Reduce rates for multiple small

Class 3 & 4 CY 20 80 150

sites, and large amounts of excavation; Increase rates are for larger qtys

Site specific requirements should be closely considered. Reduce rates for multiple small

Class 5 & 6 CY 40 100 150

sites, and large amounts of excavation; Increase rates are for larger qtys

Site specific requirements should be closely considered. Reduce rates for multiple small

Class 7 and larger CY 20 100 200

sites, and large amounts of excavation; Increase rates are for larger qtys

Rates are for grouting of already placed riprap, apply to quantity of grout to be placed,

and do not include placement of riprap; Site specific conditions should be closely

Riprap Grouting CY 100 150 200

considered, including concrete/grout haul distance, assumed grout coverage, riprap size,

site access, etc…

Site specific requirements should be closely considered. Reduce rates for multiple small

Special Rock Embankment CY 75 180 280

sites, and large amounts of excavation; Increase rates are for larger qtys

Site specific requirements should be closely considered. Reduce rates for multiple small

Rock Buttress CY 25 55 92

sites, and large amounts of excavation; Increase rates are for larger qtys

Site specific requirements should be closely considered. Reduce rates for multiple small

Rockery SY 4 20 40

sites, and large amounts of excavation; Increase rates are for larger qtys

SIGNING AND STRIPING

Pavement Marking, Paint LF 20,000 50,000 85,000

Pavement Marking, Thermoplastic LF 3,100 5,600 10,000 Limited data avail

Pavement Marking, Symbol EA 5 10 18

Delineators EA 35 50 100 Use lower rates for stiff/rocky soil.

Signs EA 10 20 30 Use lower rates for stiff/rocky soil.

REVEGETATION

Mulching, Hydraulic Method AC 2.5 8 11

Seeding, Hydraulic Method AC 2.5 8 11

Place conserved topsoil CY 200 800 1,200 Includes shaping/compacting.

Typical Production Rate

Activity Unit Notes for Production Rates

Low Average High

MISCELLANEOUS

Concrete barrier, pre-cast LF 100 200 300

Curb ramp, concrete SY 12 22 30 reduce rate for mulitple smaller ramps; increase rate for larger, longer ramps

Ditch checks structures (Riprap) EA 4 15 25 rates are for riprap ditch check structures

Ditch check structures (Wattles) EA 20 50 100 rates are for wattle check structures; reduce rates for rocky soil

Final clean up STA 10 30 50 rates will vary based on project size and scope

Finishing, aggregate base STA 10 25 50 rates include staking, final grading and QC verification of red tops

rates include staking, final grading and QC verification of bue tops; reduce rates in rocky

Finishing, subgrade STA 5 12 25

subgrade

rate will depend on lift dimensions and geotextile frequency; closer geotextile layers will

Geotextiles, stabilization SY 500 1,000 2,000

increase production

rate will depend rate

on lift dimensions, understrain length and frequency; larger, more

Geotextiles, underdrain SY 100 140 350

frequent sections of underdrain will increase production rate

Sheet piling SY 55 82 110 limited data available; reduce rate by half if removal is required.

Temp bridge DAY 7 14 21 Includes erecting and dismantling; rates will vary based on site-specific conditions

Temp detours DAY 2 5 7 Use lower rates for simpler detours, minor earthwork and surfacing.

Studies find significant correlation between production rates and the following influences:

Activity: Influence:

Bridge deck Curved or staight

Drilled Shafts Total length, clustered shafts, accessibility Note 1 below

Excavation Work Area Quantity

Embankment Work Area Quantity, Work Zone Congestion

Lime Treated Subgrade Work Area Quantity, Length of Work Area

Flexible Base Work Area Quantity, Length of Work Area

Cement Treated Base Work Area Quantity, Length of Work Area

Hot Mix Pavement Work Area Quantity, Course Type (Bottom or Final Mat)

Conc Pavement-Slip Form Work Area Quantity, Length of Work Area

Conc Pavement-Conventional Forming Work Area Quantity, Configuration (Curves, angles)

MSE Walls Size of wall (If a wall has different components, see above rates)

Pre Cast Box Culvert Length, Soil Type, Clay Content of Soil

Cast in place Box Culvert Length

RCP Length, Orientation to Road

Inlets and Manholes Quantity in a line, CIP vs Pre Cast

Wingwall/Headwall Wall Surface Area

Note 1 No difference was found between cased and uncased shafts. Clusters = areas where multiple shafts

can be installed with no major relocation of the drill rig. Locations with good accessibility would be

w/in 30' of a current operational road; locations with good room for drill rig and other equipment to

maneuver would be over 2500 SQFT per hole

Note 2 Base Rate Adjustment Factors

Factors Adjustment for Noted Conditions

Location Rural = 1.0 Small City = 0.85 Big city = .75

Traffic conditions Light = 1.0 Moderate = .88 High = .70

Complexity is technical difficulty or unusual Complexity Low = 1.0 Medium = .85 High = .70

project conditions Soil conditions Good = 1.0 Fair = .85 Poor = .65

Quantity of work Large = 1.0 Medium = .88 Small = .75

DO NOT USE MORE THAN 2 FACTORS FOR AN ITEM OF WORK

Anda mungkin juga menyukai

- CFLHD Production RatesDokumen5 halamanCFLHD Production RatesroldskiBelum ada peringkat

- Construction NormsDokumen18 halamanConstruction Normston100% (1)

- Production RatesDokumen2 halamanProduction RatesJet Toledo100% (1)

- Productivity ListDokumen31 halamanProductivity ListAnthony AgnerBelum ada peringkat

- Bill of Quantity Items Print Preview: Current Tender DetailsDokumen2 halamanBill of Quantity Items Print Preview: Current Tender DetailsAbu MariamBelum ada peringkat

- P6 Piping Tank FarmDokumen6 halamanP6 Piping Tank FarmIvan Sanzana RodríguezBelum ada peringkat

- Progress Tracking Sheet-Piping Touch Up PaintingDokumen1 halamanProgress Tracking Sheet-Piping Touch Up PaintingRedouane MerabteneBelum ada peringkat

- Name/Location of Project: Department of Public Works and HighwaysDokumen32 halamanName/Location of Project: Department of Public Works and HighwaysCelsoRapiBelum ada peringkat

- Standard Mnahours & Calculation of Duration of ActivtiesDokumen9 halamanStandard Mnahours & Calculation of Duration of ActivtiesMubashir100% (1)

- Interim Payment For Painting WorksDokumen136 halamanInterim Payment For Painting Worksarchie_728Belum ada peringkat

- 151591149-Productivity-Rate-Labor-Eqpt (4) .Xls - LABOR PRODUCTION TABLE ITEM NO A WORK DESCRIPTION M.H UNIT MANHOURS PER QUANTITY (MDokumen9 halaman151591149-Productivity-Rate-Labor-Eqpt (4) .Xls - LABOR PRODUCTION TABLE ITEM NO A WORK DESCRIPTION M.H UNIT MANHOURS PER QUANTITY (MZelalem MengistuBelum ada peringkat

- 009 - Productivity RatesDokumen183 halaman009 - Productivity RatesMohamed AtefBelum ada peringkat

- Labour Productivity ChartDokumen12 halamanLabour Productivity ChartAnonymous UibQYvc6100% (2)

- Transportation Project Scheduling Worksheet: Mobilization and Traffic ControlDokumen8 halamanTransportation Project Scheduling Worksheet: Mobilization and Traffic Controlsadaaammm sadaaammmBelum ada peringkat

- Labour Output of Steel Fixers in Selected Building Construction Sites in Malaysia - Journal of Applied Sciences & Environmental SustainabilityDokumen11 halamanLabour Output of Steel Fixers in Selected Building Construction Sites in Malaysia - Journal of Applied Sciences & Environmental SustainabilityPaul MaposaBelum ada peringkat

- PM High Rise Building Schedule PDFDokumen32 halamanPM High Rise Building Schedule PDFXozan100% (1)

- Productivity Rates Downloaded From Planning PlanetDokumen100 halamanProductivity Rates Downloaded From Planning PlanetGlenn Calingasan100% (1)

- Arabic Reference For Primavera - Part 1 (Time Schedule) - by Eng. Said El NaggarDokumen779 halamanArabic Reference For Primavera - Part 1 (Time Schedule) - by Eng. Said El Naggarsaidnaggar100% (2)

- PWD Schedule-Schedule of Rates of PWD (W.B) 2015 For Road Bridge Work (Vol-III) Wef 30.08.2018 PDFDokumen367 halamanPWD Schedule-Schedule of Rates of PWD (W.B) 2015 For Road Bridge Work (Vol-III) Wef 30.08.2018 PDFAlipurBelum ada peringkat

- S-Curve Rev.2 Due To Eot No. 1Dokumen1 halamanS-Curve Rev.2 Due To Eot No. 1Budi DermawanBelum ada peringkat

- Revised Construction Man DaysDokumen9 halamanRevised Construction Man DaysChristian LlorcaBelum ada peringkat

- Revised Standard Data For ElectrificationDokumen120 halamanRevised Standard Data For Electrificationsrikanth0483287Belum ada peringkat

- 1.1 Welder Test 86,350,000: PackageDokumen2 halaman1.1 Welder Test 86,350,000: PackageAhmad Dzulfiqar RahmanBelum ada peringkat

- Pt. Duta Utama Tehnik Abadi: Daily ReportDokumen45 halamanPt. Duta Utama Tehnik Abadi: Daily ReportMa'rifatullahBelum ada peringkat

- PDF Standard Construction Productivity Norms ManpowerDokumen1 halamanPDF Standard Construction Productivity Norms ManpowereldredvongaringBelum ada peringkat

- Productivity NormsDokumen2 halamanProductivity NormsMartin Buniag100% (1)

- Sample Project EstimationDokumen6 halamanSample Project EstimationRosnani ResdiBelum ada peringkat

- Productivity Rate Labor ChartDokumen11 halamanProductivity Rate Labor ChartJhun Magtangol Jr.100% (1)

- 1 Earth Works: Description Rate UnitDokumen4 halaman1 Earth Works: Description Rate UnitPrakash Rao GurpurBelum ada peringkat

- CMGT 7205 - Excavation Assignment - ScribdDokumen11 halamanCMGT 7205 - Excavation Assignment - ScribdDale HinesBelum ada peringkat

- Payment Certificate FormatDokumen1 halamanPayment Certificate FormatLizmelanie Trinidad GarciaBelum ada peringkat

- Mock-Up Time Schedule Infrastructure Project East PortsaidDokumen1 halamanMock-Up Time Schedule Infrastructure Project East PortsaidWaheed ElbeihBelum ada peringkat

- NAME OF WORK: Rail Link Project For Maithon Power Ltd. at Maithon (Jharkhand)Dokumen1 halamanNAME OF WORK: Rail Link Project For Maithon Power Ltd. at Maithon (Jharkhand)Venkat Eswarlu BBelum ada peringkat

- Infrastructure Based Building Based: Civil WorkDokumen12 halamanInfrastructure Based Building Based: Civil WorkRajesh MamidalaBelum ada peringkat

- Activity Id Plan: DescriptionDokumen4 halamanActivity Id Plan: DescriptionAbdul RaqeebBelum ada peringkat

- BASELINESCHEDULENARRATIVEDokumen24 halamanBASELINESCHEDULENARRATIVEJose RibeiroBelum ada peringkat

- Civil Rate Anyl 1Dokumen72 halamanCivil Rate Anyl 1SarinBelum ada peringkat

- Manhour StandardsDokumen6 halamanManhour StandardsErick EnriquezBelum ada peringkat

- Wooden Wall Cladding 1st Fix Wooden Wall Cladding 2 ND FixDokumen3 halamanWooden Wall Cladding 1st Fix Wooden Wall Cladding 2 ND Fixsayr0sBelum ada peringkat

- Copper Pipe-BOQ-currency RiyalDokumen1 halamanCopper Pipe-BOQ-currency RiyaljatinBelum ada peringkat

- Septic TankDokumen32 halamanSeptic TankKorupoluBelum ada peringkat

- Labor Productivity Output RateDokumen12 halamanLabor Productivity Output RateCarl Manzano100% (1)

- Excavation: Item No. Description of Work Qty Unit Manhour Hour/Day Manpower DurationDokumen34 halamanExcavation: Item No. Description of Work Qty Unit Manhour Hour/Day Manpower DurationvanessaBelum ada peringkat

- Annexure I - Bill of Quantities - PricedDokumen16 halamanAnnexure I - Bill of Quantities - PricedjatinBelum ada peringkat

- Table For Piping Manhour Estimative CalculationDokumen20 halamanTable For Piping Manhour Estimative CalculationdanieltraduBelum ada peringkat

- DIV-02 Labor (Site Work)Dokumen27 halamanDIV-02 Labor (Site Work)tnazirovBelum ada peringkat

- 3 Months Look Ahead PlanDokumen6 halaman3 Months Look Ahead PlananjnaBelum ada peringkat

- Quantity Estimate and Work ProgressDokumen4 halamanQuantity Estimate and Work ProgressrayguntanBelum ada peringkat

- Steel Structure Drawing XAT10 20X10Dokumen9 halamanSteel Structure Drawing XAT10 20X10Casio AutomaBelum ada peringkat

- EMCO Productivity Electrical - Rev02 (12.11.2013)Dokumen42 halamanEMCO Productivity Electrical - Rev02 (12.11.2013)rize1159100% (1)

- Estimate of Duct For OFCDokumen12 halamanEstimate of Duct For OFCrajinder kutaalBelum ada peringkat

- Productivity Rate (Piping Works)Dokumen21 halamanProductivity Rate (Piping Works)Ahmed Essam TimonBelum ada peringkat

- Construction Activity SchedulingDokumen7 halamanConstruction Activity Schedulingsameh_yehia_2Belum ada peringkat

- Man-Day Estimates and DurationsDokumen2 halamanMan-Day Estimates and DurationsCARNEBALBelum ada peringkat

- 3 Delay Analysis - 25 March 2014Dokumen3 halaman3 Delay Analysis - 25 March 2014Zitheeq UmarBelum ada peringkat

- 285a Consolidated Construction Productivity-RatesDokumen95 halaman285a Consolidated Construction Productivity-RatesgmpintorBelum ada peringkat

- Calculation of Duration of Activities Based On Standard ManhoursDokumen20 halamanCalculation of Duration of Activities Based On Standard ManhoursMubashirBelum ada peringkat

- Steel PVC CPVC Pipes Dimensions Weight ChartDokumen5 halamanSteel PVC CPVC Pipes Dimensions Weight Chartdh24992499Belum ada peringkat

- Dhamra HouseDokumen3 halamanDhamra HouseSOUMITRA BERABelum ada peringkat

- Salama - L&D - T&C EnglishDokumen14 halamanSalama - L&D - T&C EnglishabhiazadBelum ada peringkat

- This Time, Gift Your Loved Ones: The Perfect Present!Dokumen22 halamanThis Time, Gift Your Loved Ones: The Perfect Present!abhiazadBelum ada peringkat

- Split Air ConditionerDokumen45 halamanSplit Air ConditionerabhiazadBelum ada peringkat

- Sustainability in Construction Concept Application and Certification SystemsDokumen1 halamanSustainability in Construction Concept Application and Certification SystemsabhiazadBelum ada peringkat

- Unit 2 PDFDokumen4 halamanUnit 2 PDFabhiazad100% (1)

- Planting Schedule 23FEB18Dokumen6 halamanPlanting Schedule 23FEB18abhiazadBelum ada peringkat

- KPI-Primavera Test1 PDFDokumen7 halamanKPI-Primavera Test1 PDFabhiazadBelum ada peringkat

- All India Severe WeatherDokumen8 halamanAll India Severe WeatherabhiazadBelum ada peringkat

- KPI-Primavera Test1 PDFDokumen7 halamanKPI-Primavera Test1 PDFabhiazadBelum ada peringkat

- Primavera 6 - User Already Loggedin Error - SolutionDokumen1 halamanPrimavera 6 - User Already Loggedin Error - SolutionabhiazadBelum ada peringkat

- Division 4 MasonryDokumen39 halamanDivision 4 MasonryLynette CabantingBelum ada peringkat

- Civil Engineering Design CriteriaDokumen32 halamanCivil Engineering Design Criteriacall1986100% (1)

- Housing Project BOQ Billing FormatDokumen125 halamanHousing Project BOQ Billing Formatarchie_728100% (5)

- Bachelor Thesis Prestressed ConcreteDokumen130 halamanBachelor Thesis Prestressed ConcretemostafaBelum ada peringkat

- Chapter 3Dokumen8 halamanChapter 3LambertoTalplacidoJr.Belum ada peringkat

- Technical PapersDokumen778 halamanTechnical PapersANIL KUMARBelum ada peringkat

- List of Accredited Portland Cement Concrete Batching Plants (By Weight) (As of October 2019)Dokumen14 halamanList of Accredited Portland Cement Concrete Batching Plants (By Weight) (As of October 2019)REdBelum ada peringkat

- Fiber Reinforced ConcreteDokumen16 halamanFiber Reinforced ConcreteNaviya K NaviyaBelum ada peringkat

- PMP Products RefDokumen11 halamanPMP Products RefPavan KrishnaBelum ada peringkat

- Sika Concrete HandbookDokumen151 halamanSika Concrete HandbookFatjon ShahaBelum ada peringkat

- Precast Concrete ConstructionDokumen12 halamanPrecast Concrete ConstructionRemya R. KumarBelum ada peringkat

- Construction ActivitiesDokumen20 halamanConstruction ActivitiesErika Kirby100% (19)

- Use of SCC and Rca For Sustainable ConstructionDokumen5 halamanUse of SCC and Rca For Sustainable ConstructionesatjournalsBelum ada peringkat

- Waterproofing, Construction Chemicals Manufacturers & Suppliers IndiaDokumen8 halamanWaterproofing, Construction Chemicals Manufacturers & Suppliers IndiaNagesh ShuklaBelum ada peringkat

- Construction and Building MaterialsDokumen15 halamanConstruction and Building Materialsahmedwaleed9711Belum ada peringkat

- HSR Basic Rate 2018Dokumen10 halamanHSR Basic Rate 2018R A P RathnaseeliBelum ada peringkat

- Manhole DetailsDokumen1 halamanManhole DetailskmmansafBelum ada peringkat

- Concreting MethodologyDokumen2 halamanConcreting Methodologyervnglen08Belum ada peringkat

- Acceptance and Lab Standers PDFDokumen106 halamanAcceptance and Lab Standers PDFAyman KandeelBelum ada peringkat

- RC Detailing To Eurocode 2Dokumen39 halamanRC Detailing To Eurocode 2Sandipan DharBelum ada peringkat

- TCVN 3105.1993 Heavyweight Concrete Compound and Heavyweight Concrete - Samling, Making and Curing of Test SpecimensDokumen6 halamanTCVN 3105.1993 Heavyweight Concrete Compound and Heavyweight Concrete - Samling, Making and Curing of Test SpecimensNgo Tien VinhBelum ada peringkat

- Lighweight Concrete (LWC)Dokumen41 halamanLighweight Concrete (LWC)Muhammad AimiBelum ada peringkat

- FEM-Design - Intoduction CourseDokumen46 halamanFEM-Design - Intoduction CourseAbulfazl MuhammadiBelum ada peringkat

- 02-Architectural SpecificationDokumen280 halaman02-Architectural SpecificationNomi JeBelum ada peringkat

- Library of Standard BQ Descriptions For Malaysian Civil Engineering SDokumen218 halamanLibrary of Standard BQ Descriptions For Malaysian Civil Engineering SSharina Sulaiman94% (33)

- Idspl B 2212 MNB 007+614DN 101Dokumen36 halamanIdspl B 2212 MNB 007+614DN 101khushikaadi56Belum ada peringkat

- Kahramaa Architectural SpecificationsDokumen471 halamanKahramaa Architectural SpecificationsLepanto SakyodBelum ada peringkat

- Annex 1 TDS Nitoprime Zincrich Saudi ArabiaDokumen3 halamanAnnex 1 TDS Nitoprime Zincrich Saudi ArabiaMdShahbazAhmedBelum ada peringkat

- Design of Reinforced Concrete Structures Prof. N. Dhang Department of Civil Engineering Indian Institute of Technology, Kharagpur Lecture - 11Dokumen29 halamanDesign of Reinforced Concrete Structures Prof. N. Dhang Department of Civil Engineering Indian Institute of Technology, Kharagpur Lecture - 11BEZAWADA VAMSI KRISHNABelum ada peringkat

- Cikomould Pu: Technical Data SheetDokumen2 halamanCikomould Pu: Technical Data SheetVaittianathan MahavapillaiBelum ada peringkat