3408 and 3412 Industrial and Epg Diesel Engines1 PDF

Diunggah oleh

Khaleel Khan100%(1)100% menganggap dokumen ini bermanfaat (1 suara)

161 tayangan82 halamanJudul Asli

104103126-3408-and-3412-Industrial-and-Epg-Diesel-Engines1.pdf

Hak Cipta

© © All Rights Reserved

Format Tersedia

PDF atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF atau baca online dari Scribd

100%(1)100% menganggap dokumen ini bermanfaat (1 suara)

161 tayangan82 halaman3408 and 3412 Industrial and Epg Diesel Engines1 PDF

Diunggah oleh

Khaleel KhanHak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF atau baca online dari Scribd

Anda di halaman 1dari 82

CATERPILLAR” ss

‘September 1988

=

Operation &

Maintenances. :

So

3408 and 3412 nee ee

and EPG Diesel Engines

81Z1-UP

Q\ IMPORTANT SAFETY NOTICE

Most accidents involving engine opers

jatety rules of precautions. An accident can

ing potentially hazardous situations:

Improper operation is dangerous and could result in injury or

death.

READ AND UNDERSTAND ALL SAFETY PRECAUTIONS AND

WARNINGS BEFORE OPERATING THIS ENGINE.

@ outlined in the “Safety” Section of

jon of operations where hazards

exist. Warning decals have also been put on the engine to

provide instructions and to identity specific hazards which, it

ot heeded, could cause bodily injury or death to you or other

persons. These warnings in the Guide and on the engine

ns that may result only in engine damage are

identified by CAUTION decals on the engine and in the Guide.

pillar cannot anticipate every possible circumstance that

ht involve a potential hazard. The warnings in this Guide and

fon the engine are therefore not all inclusive. if an operation is

not performed as specitically recommended by Caterpillar, you

must satisty yourselt that it is safe for you and others. You

‘should also ensure that the engine will not be damaged or made

tunsate by the method of operation you choose.

‘The proper and safe lubrication and maintenance procedures for this

engine, recommended by Caterpillar, are outlined in the "Lubrication &

Maintenance” Section of this Guide.

Improper performance of lubrication ot maintenance procedures is dar

erous and could result in injury or death. Read and understand the

“Lubrication & Maintenance” Section before performing any lubrication

(oF maintenance.

FOREWORD

‘This guide contains operation insttuctons and bce

tion and maintenance information,

‘The operation sectonis a reterence for the new oper:

stor and a retrosher for the experienced one. Read —

‘Staty — and Keep It handy.

lustrations guide the operator through correct proce

‘ures of checking, staring, operating ané stopping the

engine

‘The maintenance sections a guide to equipment care

‘Te tustrated, step-by-step natructions are grouped by

servicing intervals. ems inthe Lubiction and Manto

nance Chart” are raferanced to the detased instructions

that folow

Use the service meter to determine servicing ite:

vals, Calendar inervais shown may be used stead of

Service meter intervals f they provide mare convenient

Servicing schedules and approximate the indicated ser-

vce meter reading. Recommended service should al

ways be performed at the terval thal occurs f

Under extremely severe, dusty of wet operating com

tions, mere requent ication than spectied inthe

‘Laincation and Maintenance Chart” may be neces

Perform service on items at mutes of the original

‘equrement. For example, at Every 500 Service Meter

Unis, alza service those items bsted under Every 250

Service Moter Uns, Every 80 Service Moter Units and

Every 10 Service Meter Unis

‘Some photographs in this publication show details or

attachmants that may Be diferent fam your engine

‘Also, guards and covers may have boon removod for

Iustrative purposes.

Cominuing improvement and advancement of product

design may have caused changes fo you engine which

fire not Included nthe pubieaton

Each publication I reviewed and revised, as euied

to update and include these changes in lator edions

Whenever a question arises regarding your engine or

this pubteation. please consult your Caterpilar dealer

for the latest avaiable information,

Engine Identification

Caterpilar engines are dentiied with SERIAL NUM.

BERS and ARRANGEMENT NUMBERS. in some cases

MODIFICATION NUMBERS are also used. These nur

bors are shown on the serial number plate mounted on

the engine

CCaterpilar dealers needa these numbers to deter

rine wich componente ware included on te engine

when ft wag assembled at the factory. Ths permits

‘accurate Identification of replacement part numbers

Ordering Parts

Qualty Caterpiar replacement parts are avaiable

from Caterpilar dealers throughout the worl. Thee

parts stocks are upto date and clude al pars normally

Fequirod 0 protect your vvestment In Caterpilar er

fines. When ordering parts, your order should specity

the quant, part number part name and sal nomber

frrangement number and modiication number of the

fengne for which te parts are needed Fin doubt about

{he part azmber, please provi your dealer wth com

plete description ofthe nooded item,

TABLE OF CONTENTS

Mooel. VIEWS

SAFETY PRECAUTIONS

OPERATING INSTRUCTIONS

PRE-START INSPECTION AND

PROCEDURES

STARTING THE ENGINE

AIR STARTING

STARTING AIDS

GENERATOR

AFTER ENGINE STARTS.

[STARTING THE LOAD

ENGINE OPERATION

ALTITUDE OPERATION

STOPPING

AFTER STOPPING CHECKS AND PROCEDURES

[ATTACHMENTS

AUTOMATIC START-STOP

WOODWARD GOVERNORS

EMERGENCY SHUTOFF DEVICES.

"AND ALARWS.

EMERGENCY STOPPING

MAINTENANCE RECOMMENDATIONS

SPECIFICATIONS.

LUBRICATION

FUEL

(COOLANT

LUBRICATION AND MAINTENANCE

INSTAUCTIONS

LUBRICATION AND MAINTENANCE

‘CHART

LUBRICATION INSTRUCTIONS

‘COOLING SYSTEM

FusL SYSTEM

AIRINDUCTION AND EXHAUST

‘SYSTEMS,

ELECTRICAL SYSTEM

POWER COUPLINGS

ENGINE STORAGE

GENERATOR STORAGE

PREVENTIVE MAINTENANCE RECOMMEND:

IRVONS FON STANDBY GENERATOR SETS

(GENERATOR MAINTENANCE

‘TROUBLESHOOTING

MAINTENANCE RECORD

Ey

ea

32

99

«a

58

56

580

560

ss

87

6

3408 GENERATOR

SET ENGINE

GAUGE PANEL COOLANT FILL CAP

GeneRaron | expansion ranx

FUEL.

PRIMING. ;

at FAN DRIVE,

see

FUEL,

FILTER on COOLER +

CRANKCASE DRAIN

lL FILTER

‘TEMPERATURE

REGULATOR

Goo

“-/ water PUMP

% y one

on cOoLeR”

3408

INDUSTRIAL

ENGINE

GOVERNOR

AFTERCOOLER aim cLeANER

— I oneurers CRANKCASE ORAIN

TEMPERATURE

REGULATORS

.

a ’

GovenNgn AFTERGOOLER OIL FILL CaP

3412

INDUSTRIAL

ENGINE

CONTROL PANEL, AIR CLEANER

OW FILTERS

™/™ celenron —--PUELFILTERS

SAFETY PRECAUTIONS

Safety is everyone's business ands basicaly th

use of good common sense. A general quide of

‘Safety precautions ara given below. but each instal-

iatonfas tgown peculiarities which cannot always

be predicted and covered by established ules. Past

Sxpenience and common sense are neoded for the

ecessary safety measures. Attention to safety will

Relp avotd senius accidents. Be alert, Watch for

haraids, Use preventive measures. Correct de

fieieneies immediately

‘The fallowing safety precautions are # general

‘guide to sate operation

“To prevent personal injury, install guards over

all exposed rotating parts.

2.To prevent hearing damage, woar ear protec-

tive devices vf working Insida an enclosed en

bine room with engine running

3. To prevent head injury, wear safety hat when

lnorking in the area of overhead equipment.

4. Wear safety glasses and shoes as requited.

Do not wear loose clothing whenever working

around engines er machinery.

Wipe up spilled ol, fuel or coolant.

Keep batteries in a well ventilated area. Do not

Smoke aroundatierles. Hydrogen gas, whichis,

present nthe area of the batteries, is highly

explosive.

Provide adequate and sate waste oll disposal

‘store oily rags in fireproof containers, Don't

leave rags on engine.

A WARNING

When using pressure air, woar safety

and provective clothi

Surer used for cleaning

2ikgiem®,

10. Remove all tools,

Toase items fram the engine before starting,

11, Disconnect and tape the battery ground lead

Detore working on an engine topreventacciden:

{al starting. Be sure an automatic startstop sys

tem cannot operate and start tho engine while

working on

6

12, Do not attempt repairs you do not understand.

Follow instructions.

13, Stop engine before adjusting or repairing en

gine or driven equipment.

14. Remove radiator cap slowly. Cooling systems

Ean be pressurized and hot fluid wil flash to

Stoam as pressure is removed

46: Never start an engine with the governor linkage

disconnected

16. Replace or repair broken or damaged equip

ment. Use proper tools

47. Do not smoke while retueling. Observe NO

SMOKING sighs.

18, Never store flammable liquids near the engine

19. All electrical equipment must be grounded ac-

cording to local Building codes,

20. Check all connections periodically for tightness

‘and insulation

21. Insulate all connections and disconnected

22. Do not use carbon tetrachloride tire extin

uishers, Fumes are toxic and the liquid has @

Seteriorating effect on Insulation.

£28, Do not touch the heat sink on the generator

Fegulstor when the generater Is running. Its

tlectrically "nat

24. Do not work on electrically “hot” equipment

25. Always disconnect the engine starter circuit

when working on the goneratcr.

26. Hot engine oil can cause burns when drained.

‘Allow the ol to €00! below I40"F or provide pro-

fection whon draining the hot oi

27. Never remove a plug to chock pressure withthe

gine running, Shut down the engine and as

Sure there is ne pressure before removing plug

28. Whon starting an engine after repair, make pro

Vistons for shutting of aie supply in case theres

fan overepeed on start up.

29. Never look into an open cylinder port and turn

over the engine. Oil or water in the cylinder wil

be ejected violently.

OPERATION INSTRUCTIONS

PRE-START INSPECTION AND

PROCEDURES

1. Make a "walk-arouna'” ingpection ofthe engine

and components for the all, water oF fuel leaks

and general appearance. Correct minor adjust

iments betore they develop nto major repair

jobs.

2. Check the erankease oil love). Maintain the oil

level Between the ADD and FULL marks on the

lipstick. See OIL SPECIFICATIONS for typo of

wannine

hac oe cana ee anh

tn pind

roy eutwara unr igh pressure ond euuse

eaeecne

4. Check the engine jacket coolant level. Slowly

turn the pressure cap unt the cap is removed

Maintaincoolantloveltothe base at the ilipipe.

5. Chock the fuel supply. Keep fuel tanks full, as

partially tiles tanks will collect moisture. See

{he FUEL SPECIFICATIONS for type of Tue!

KEEP THE FUEL SUPPLY CLEAN

6. Open the raw water valve on the engine jacket

heat exchanger system (i so equipped). Prime

the raw water pump the raw water system has

boen draine

7. Reset shutolt devices. See the topic, AT.

TACHMENTS, Emorgency Shutolf Devices and

Raarms

OVERSPEED RESET

tthe engine is equipped with an ar saety shutoff

antral. ang nas inpped to the shutot! position

Foset the latch fo the run position

Oe

AIR SHUTOFF RESET

£8, Open theusl supply valve. the engine has not

fun for some time it may be necessary to arime

the system. See the topic, PRIMING THE FUEL

System

9. Disconnect any battery charger which is not

protected against starting motor drain,

10. Disengage the clutoh, or open the circuit

breaker on a generator sat.

STARTING THE ENGINE

CAUTION

Do not engage the starter when the flywheel Is

moving.

Electric Starting

1. Move the govarnor control lever to approximate

half engine speed position

2. Use starting aids if required. See the topic,

STARTING AIDS.

43, Push the START button: or turn the HEAT-

START switch fo the START position. depend-

‘ngupon the control he engine has. Release the

‘control's soon a8 the angine starts.

For generator sole, place the AUTO-MAN switch

Inthe MAN position tocrank the engine. As soon as

the engine starts, and the engine spoed reac!

{600 rpm and oil prossure ts approximately 22 psi

(1 Skovem), the starter motor will disconnect from

the elreut. (The STOP position is used f0 stop the

iesel engine.)

Ifthe engine fails to startin 10 seconds, move the

‘governor control lever to the fuel off position, then

ontinue to crank for 10 seconds. This wll clear the

ylinders of unburned Tush.

It the engine falls to start after 80 seconds of

cranking, allow the engine to cool for 2 minutes

botore repeating the starting procedure,

CAUTION

Prolonged cranking at low oil pressure can actl-

wate the mechanical safety shut-off. If the reset

ever isin the shut-off position, reset the

mechanical shut-off control

caution

NEVER use starting aids when the engine is

‘warm and running.

It the engine is equipped with a Woodward PSG

Governor. see the topie, WOODWARD GOVER-

NORS Yor the governor operation instructions.

Air Starting

1, Open and close the blood valve onthe bottom of

the alr tank to drain condensation and ail car

ryover

2. Check the air supply pressure. The air start

‘must have 100 PSI (7 xg/em) to operate prop

erly.

8. Keep ol level, in the oiler jar. at least halt fll

‘Add’ necessary. See the LUBRICATION

AND MAINTENANCE PROCEDURES, Filing

Motor Oiler

4. Push the ar valve controlin to crank the engine.

‘As soon as ho angine starts, release the valve.

Starting Aids

Many variables can affect cold weather starting

Use the chart as a guide, but actual experience wil

determine when aids are necessary and how they

‘Should be used. Your engine may have one or more

fof the following starting aids:

Glow Plugs (Precombustion Chamber

Engines Only)

1. Push in an turn the HEAT-START switch tothe

HEAT position and nold for the approximate

heating time shawn in the STARTING AID

CHART

Orr

o

starr

e

SX

2. Turn the HEAT-STAAT switch to the START

position

HEATA,

oF

o

HEAT A ASTART

£

3. I necessary, when the engine starts turn the

HEAT-START switch tothe HEAT position. Hold

the switen in this position until the engine is

Funning smoothly

4, Release the switch

s

weata: Xa start

s

CAUTION

NEVER use glow plugs when the engine is warm

‘and running,

‘STARTING AID CHART

‘STARTING TEMPERATURE ‘STARTING AID HEATING TIME

Above 60 (15°C) None None

aor 030 : Teal

Gscwoo Giow Pug i

apr oor, ae

ec eemel Glow Pgs 2 Minute

Below OF (-2007 Gow Plugs antes

Heating of jacket water/and or crankcase ol; and/or use of extra battery capacity may be

required

Starting Fluid

A warninc

tions on the container.

CAUTION

Spray starting fluid only while cranking the

gine.

1. Heatthe glow plugs (If equipped) forthe approx

imate neating me shown inthe STARTING AID

CHART.

OFF

HEATA_— ASTART

Tuen the HEAT-STAAT switch to START posi

CAUTION

Wait at least 2 seconds before spraying starting

fuld again.

3. If necessary, repeat the procedure.

4. Alter the engine starts, it may be necessary to

feturn the HEAT-STAAT switch to the HEAT

position until the engine runs smoothly

Jacket Water Heater

(attachment)

Invery low temperatures, the lubricating oll must

be marmad to allow starting. A jacket water heater

an maintain the water temperature. at approx

mately 90°F (32°C). The warm water willkeep the ol

inthe upper partol the engine block warm enough to

tow wnen starting,

Dipstick Oil Heater

CAUTION

Contact your Caterpillar dealer before installing

4 dipstick crankcase ol heater

tion While cranking, spray starting uid into the

Siriniet or sircleaner for approximately 1 9ec

na

10

GENERATOR

Starting Single Unit Operation

iminary engine starting checks.

Be sure the main or line circuit broaker is open.

Start the engine and allow it to warm up.

Close the main circuit breaker

Apply the load. Donat try to apply full/oadin one.

‘move, rather apply the load in increments to

‘maintain system frequency ata constant level

Make all pe

1

2

3

4

5.

‘Standby Generator Sets

Most standby units are automatic. They start

pickup the load, run and stop without an operatorin

dance. Standby units ean not change the gov

mor control selting automatically. The throtile

‘must be preset forthe proper operation ofthat unit

Whenever the set's exorcised oF operated manu

ally. bo sure the throttle setting is correct for au-

omatie operation. Check all switches to seo thoy

2a properly set: Start Selector Switch in AUTOMA-

‘Tie'postion ane any Emergency Stop Switches in

RUN position

Paralteling

Units may be paralleleg at no load or paralleled

with units undertoad. To parallel two or more units

the folowing conditions must be met

1. Same phase rotation

2. Same voltage level

3, Same voltage droop.

4. Same frequency

5. Voltagos must be in phaso.

The fist condition is established by “phased

wiring connections of initial Installation

The second and third conditions are usually es-

tablished by semi-permanent adjustments to tho

generator contrels

‘The fourth and fifth conditions ate under contro!

of the operation in manual paralleling systems (or

Under automatic contrl in automatic parallling

systems).

To Parallel

1, Start the unit to be paralleled

2. Turn the synchronizer lights on

3. Alter the engine has tun long enough to warm

up, bring Itup to synchronous speed (the same

frequency as the unit on the line). The sy

hronizinglignts wil Bogin to link

4, Using the governor contol, adjust the speed

Until the lights Bink very slowly,

‘5 The lights are off when the voltages of the two

units are in phase. At this point, very quickly

Close the breaker while the lights are out

Ths trguaney of eineomign

Load Division

‘Once two units have been paralleled, their share

of the load is determines by the governor control

setting. If two units of the same capacity and the

‘Same governor characteristics have the same gov:

‘ernor control setting they wil share the load equal

Wy

‘To add load ta one engine, slowly increase the

governor control setting of that engine, oF slowly

Socrease the governor contra setting of the engine

‘iving up load.

Load Transfer

[At this point open the circuit breaker to remove

‘any remaining ioag on tho outgoing generator sot

1. Increase the governor speed contro! ofthe unit

1 the high idle position to assume the load.

2. Reduce the governor speed control of the out

{going unit until the generator amperage Is at a

minimum. (The amperage may never be zero

due ocireulaling currents) Atthis point transter

the load

Stopping

‘Toremove a generator Irom the line do the follow:

ing:

1. Check the load. it must be loss than the rated

Capacity of ramaining units

2. Be sure the NEUTRAL of one of the remaining

units 18 grounded,

3, Remove the load from the outgoing unit as de

Seribed in Load Division and Load Transter

4 Open the eireult breaker

5

lun the engine for § minutes without a load, to

low it to e001 Stop the engine

After Engine Starts

A, warning

3 oF adjustments,

‘work on machinery wl

1, Observe the oil pressure gauge immediately

alter starting

CAUTION

Pressure is not indicated within seconds,

‘stop the engine and have necessary repairs

made.

u

2. Move the governor control to low idle allow the

{gine foreach normal operating range (usvally

Soveral minutes). Make another "walk-around

Inspection for leaks, etc

STARTING THE LOAD

Driven Equipment without Load

To engage the stiven equipment before applying

toad

1. Move the governor control half engine speed,

2. Engage the driven equipment without load on

the equipment

3, Make sure the engine and equipment gauges

register In the operating range.

4, Move the governor contralto high ile ulload)

position.

5. Apply the load to the driven equipment.

Driven Equipment With Load

1, Move the governor control to half engine speed.

Make sure the engine gauges register in the

normal operating range:

2, Move the governor control to high idle (ull load)

position.

2. Engage the load

ENGINE OPERATION

After the engine starts, and at frequent intervals,

while the engine is operating, the gauges should be

Observed. Determine the normal reading for each

{auge. Investigate the cause whenever there is @

Signficant change inthe reading,

Gauges

‘Tachometer

“Ihe tachometer indicates engine RPM. The high

lle RPM and the (ull load APM are stamped on the

tengine’s information plate. The engine can be op-

erated between these two speed limits for long

periods of fme without shortening engine lite, Pro:

fonged operation at high ide with lite or no load

can cause adverse engine operation

Engine Oll Pressure

It the gauge reading fluctuates after the load is

stable:

1, Remove the load

2. Reduce engine speed to low idle

3, Observe the oil eval. Maintain the oll evel b

ween the ADD and FULL mark onthe dipstick It

the reading continues to fluctuate when the olf

levels correct stop engine and call your Cate

pillar dealer.

Engine Jacket Water Temperature

The engine should operate within the NORMAL

(green) range. I the engine is operating inthe (red)

ange and steam becomes apparent

4, Reduce the load and engine RPM.

2, Inspect for coolant leaks,

3, Determine if the engine must be shut down im-

‘mediately: orif the engine can be safely cooled

By reducing the loa

See COOLING SYSTEM MAINTENANCE IN-

STRUCTIONS,

CAUTION

Do not add cold water to ahot engine: Cracking

af engine components may secur. Aliow the en-

Sine fo.cool, then add cool

Iv the temperature gauge reading registers in or

rear the cold range {white) while operating under

Toad

1. Check the water temperature gauge for accu

ray.

2. Check the temperature regulators for proper

temperature range. Replace regulators. If

necessary

See COOLING SYSTEM MAINTENANCE for

DETAUS.

Fuel pressure

If the fue iter gauge registers in the OUT range,

clean the primary fue! filer, so equipped. install

few secondary or final us! fiter elements H gauge

Siill registers OUT. See the FUEL MAINTENANCE

INSTRUCTIONS ang FUEL SPECIFICATIONS.

Amme

The ammeter reading is normal when the ingi-

ceatoris at or on the (2) side of 2er0, when the

fengine is running at rated speed. It indicator isto

the lolt(-) sido of zero, investigate and correct

Air Cleaner Service Indicator

‘When the gauge Indicator locks inthe red range,

service the air cleaner. With the engine stopped:

See AIR INDUCTION AND EXHAUST SYSTEM

MAINTENANCE INSTRUCTIONS

Calibrated Gauges

Calibrated gauges are used on some engines to

‘monitor tho engine systoms. Ifan abnormal engine

Condition develops, determine ane analyze and

Correct the cause before a failure and downtime

The operating limits gon in the “OPERATING.

RANGES FOR ENGINES" chart are based on the

tengine running at continuous rated speed and load,

afer warm-up, using SAE 30, oll. It any of the

gauges rogister st oF outside the operating limits,

Investigate and correct any malfunction, See

TROUBLESHOOTING GUIDE tor guidance.

WaRNING

‘Shut the engine down if work on or around the

‘engine ie requir

DO_NOT OPERATE THE ENGINE WITH THE

GAUGES REGISTERING AT OR OUTSIDE THE

tinarrs

B

(a

eee

I

‘Tachometer.

‘Left Inlet manifold temperature

Right inlet manifold temperature.

{Left and right exhaust manifold temepratures.

5. Engine oll temperature

6. Engine jacket water lemperature.

7. Engine oll pressure.

8. Fuel pressure.

OPERATING RANGES FOR ENGINES WITH CALIBRATED GAUGES

(Engine running at continuous rating and load.)

(OPERATING RANGE

GAUGE iu MAXIMUM

Teckel Walr Temperature (Ould Wer (70) 2IOF (OO)

Inet Mario Ar Temperature

Mercooled (0) 00°F (149°0)

Newateroooed (OD 200°F (149°0)

Bihaust Temperature

‘Atocooled Po) eo 4270)

Non-atteroookd (OD BO0F 4270),

Oi Temperature

‘atoreooles (eo) 200 (N00)

Non-atiercaled (OD W2F (770), BOF (100)

Tene 20 PSI(ia8 KPa) | 62 PSI(A27 KPa)

i (15 halen?) (¢kgfom?)

Fuel Pressure 17 PSI(117 KPa) | 90PSI(207 Pa)

inigion’) fryer

Altitude Operation

‘The fuel system settings and altitude limits aro

stamped on the engine information plate. When an

fengine 's moved to a higher altitude, these settings

must be changes by your Caterpillar dealer in order

te provent damaging tho turbocharger, and to pro

Vide maximum engine efficiency

a

It the engine is moves to lower alttuce than that

which is stampad on the angine information plate,

the engine can be operated safely; however, tl

oliver less than rated horsepower, ang the fol

Setungs should be changed by your Calerpliar

ealer to obtain rated horsepower

Stopping

1. Flywheel clutch operation: Quickly pull the

Clutch ever tothe released position. For electic

Set operation, sec the GENERATOR SET OP-

ERATION instructions. For Woodward Gover

for operation, see the topic, WOODWARD

GOVERNORS: Stopping the Engine

2. Reduce engine speed to hall speed. Aun for 5

minutes to e201 engine

3. Reduce engine speed to low isle

4. Observe the crankcase oll level while the on:

{gine is ing, Maintain the oll evel between the

ADD and FULL marks on the side of the cipstick

Stamped, CHECK WITH ENGINE RUNNING,

See the LUBRICATION AND MAINTENANCE

SECTION,

5. Stop the engine.

After Stopping Checks

‘And Procedures

1. Fill the fual tank, See the LUBRICATION AND

MAINTENANCE SECTION: Fuel Tank Maint

Drain the raw water system it below freezing

mperatures aro expected: see: Draining Raw

ater System

1 below freezing temperatures are expected,

allow the engine jacket water expansion tank 0

foe; then check the coolant for proper anti:

ze protection. Add pormanent-type anti

reeze, i roquired

4 Repair any leaks, make major adjustments,

tignten loose bolts, ete

5. Odserve the Service Meter reading. Pertorm

the periodic maintenance as instructed in the

LUBRICATION AND MAINTENANCE CHART

SERVICE METER

ATTACHMENTS,

Automatic Start-Stop

{An automatic start-stop system is used when an

‘ongine must star! when a specific condition occurs

with no one invattendance. The engine will start

Increase speed, pick-up te load, operate the load

Unt a second gondition occurs, remove the load,

feoel and stop. The folowing conditions must exist

for the engine to start unattended:

Either the ambient (engine room) temperature

must be al least 70°F (20°C): oF, the engine jacket

Water temperature must be at least 80°F (92°C)

‘Gne or two 3 kw jacket water heaters can maintain

this temperature.

Protection Devices

The Caterpillar generator mounted control pane!

{is equipped with protection devices to protect the

fongine wile cranking.

Batteries.

Lights or buttons may indicate itafaulthas occur

red inthe battery charging system causing the bat

tery to be elther undercharges or overcharged

Overcranking

‘Atimer allows the engine to crank either once for

0seconds, orto crank inrough ston second erank-

ing eyeles (depending upon the device used) while

Unattended. ittne engine doos not start before the

time elapsed, the fuel system will be shutot! and a

light will naicate a starting failure

Engine Operation

Prealarm systems provide an audible and/or a

visual indication for fow cil pressure, high water

temperature, low tue! supply or low jacket water

temperature before the condition becomes ertical

hose alarms are self resetting when the condition

is corrected,

‘The engine may also be equipped with shutdown,

devices. low oll pressure, high jacket water temp-

feralure of an engine overspeed condition occurs,

the engine wil be shutdown and a corresponding

button or light wil indicate the cause of the shut

Gown, These devices must Oe reset alter repairs

have been made ang betore starting. See the topic,

EMERGENCY SHUTOFF DEVICES AND ALARMS.

Generator set control panels should be equipped

with-an ammeter. a lrequeney moter and a voltme-

Ter" Depending upon the type of operation, the

panel may alse be oquipped with other meters ang

fights. Know these instruments and their normal

readings. They will indicate how the generator setis

performing

Shutting Down

timer allows tho transter switch to transter the

fad to another source and to cantinue engine run-

ring for up to 2 minutes for cooling purposes before

stopping,

Engine Exerciser

At preset times, the exerciser will start run and

stop the engine in atder to ensure both proper lub

tation of all engine paris and proper equipment

‘operation if and when the standby unit is needed

Become familiar with all instructions included

withthe equipment

Woodward Governors

Woodward Governors are usually electrically op

erated trom a contro! panel

Generator Set Control Panel

‘The generator set control panel is located on top

of the generator andis equipped withthe following

Controls and gauges

Panel lights (1) are controlled by an ON/OFF

switen (7)-An ammeter (2) requency meter (3) anc

a voltmeter (8) show the output of the generator.

‘Two gauges (5 and) show engine oll pressure and

water tomporature respectively. Tho am’

Selector switch (12) gives the operator a choice of

whieh phase (71. T2.6r T3) of the generator output

the ammeter (2) wil show. Voltage level rheostat

{@) takes the place of the voltage level rheostat in

the generator regulator assembly

Tho engine control switch (8) has four positions

MANUAL. AUTOMATIC, STOP and OFF Placing

the control in the MANUAL position will start the

tengine and allow the operator io manually connect

the ganerator to the load. the unit Is used for

standby application with a remate transfer switch

the AUTOMATIC position 1 Used. In this position

the engine will automatically start and take up the

load when commercial power has stopped. Placing

the control inthe STOP or OFF position will stop the

engine. Whenin the AUTOMATIC or MANUAL posi-

tian, the engine will automatically stop if the com-

mercial power nas started or the engne has afault

‘The PSG governor control switch allows the

‘operator to contra the engine rpm trom the panel.

the engine 's equipped with glow plugs. they are

Controliad by an ON/OFF heat switch (15).

Ifthe engine has a fault, engine talurelight/roset

sswiteh (11) wilh operate. ‘The lgat/switen (11) wil

activate a shutdown relay to stop the engine. A

Shutdown indicator (14) will also operate to show

the cause ofthe fault. The shutdown indicators (14)

{ive an indication that the fault was either oll pres

Sure, water temperature or overspeed. A four

shutdown indicator will show an overerank cond.

tion. AD.C. ammeter and a governor contrel switch

Will take the place of buttons (10 and 13) respec.

tively itordered. The shutdown indicators have four

‘auxiliary contacts: one for each time ts shutown

indicator operates. The contacts are connected toa

emote annunciator panel orderea

‘The shutdown indicator lights can be checked for

malfunction by depressing he shutdown indicators

Replace burned ut bulbs immediately

CONTROL PANEL

4. Panel lights. 2. Alternating current ammeter. 3.

Frequency meter. 4. Alternating current voltme:

ter. 5. Oil pressure gauge. 6. Water temperature

‘gauge. 7. ON/OFF toggle switch for panel lights. 8.

Engine control switch. 9 Voltage level rheostat. 10.

Button (direct current ammeter # ordered). 11. Ene

‘ine failure light/reset switch, 12. Ammeter selector

Switch. 13.Button (governor control switch fengine

is equipped with a PSG governor). 14. Shutdown

indicator (oll pressure, wator temperature, ov

speed and overcrank). 15. Button; heat switch (iso

‘equipped). 16. Panel; prealarm module (i 0 equip.

ped).

Starting The Engine

1 Perform all prestart checks outlined previously.

2, Place the CONTROL switch in the MANUAL.

position to crank the engine.

‘3, When the engine staris and engine rpm reaches

{600 rpm and the ol pressure registers 22 pst

(1.5 kg/m) the Starting motor will automati-

cally disconect from the start circuit

4. Stat the load.

Regulate the engine speed with the RAISE-

LOWER ewiteh tothe requited instrument pane!

gauge readings.

‘Stopping The Engine

1 Remove the load. See GENERATOR SET OP.

ERATION inetructions ifequipped with an elec

inie set generator.

2, Reduce engine speed to low idle: Push down

and hold the RAISE-LOWER switch until the en-

{ine low idle speed Is reached

43. While the engine is idling, check the engine oi

level Oi level must be maintained between the

‘ADO and FULL marks on the side of tha dipstick

marked "CHECK WITH ENGINE RUNNING

4. Stop the engine.

Solenoid Shutoft

‘a. Move the control switch to the STOP or OFF

positions. (Do not confuse this with the

PRAISE-LOWER™ switch)

ON-OFF-STOP SWITCH

is

PSG Governor:

. Move the shutotf lover forward, oF hold the

lever up. depending upon Installation. Hold

the lever in this position until the engine

stops,

5. Fill the fuel tank. See the LUBRICATION AND

MAINTENANCE section.

6. Drain the raw water system if below freezing

temperatures are expecte

7. Observe the Service Meter reading. Perform

the periodic maintenance as instructed in the

LUBRICATION AND MAINTENANCE CHART.

Emergency Shutoff Devices

And Alarms

Pails

the shulelf devices, the conditions which cause

‘each control to function, and the resetting proce-

‘ure required to start your engine.

CAUTION

Always determine the cause of the shutdown,

fand have the necessary repairs made before

Starting the engine. See TROUBLESHOOTING

GUIDE:

Do not use an emergency shutoff device for @

normal stopping procedure,

The operation of all electric shutoff controls is,

similar: A critical operating condition actuates

Switch which closes the citeult to the shutoff sol

‘enotd, whion stops the engine. The shutoff control

may require resetting betore the engine can start

High Water Temperature Shutoff

“The shutott switch is located in the water temper-

ature regulator housing, Excessive water tempera-

ture closes the switch. No resetting procedure is

required: As the coolant cools, the switch opens,

CAUTION

‘The sensing element must be submerged in the

‘Coolant to operate. Coolant level must be main-

tained in order for the shutoff to operate.

Low Oil Pressure Shutoff Switch

‘CAUTION

Does not protect system from rapid oll loss,

such as line breakage.

‘This device is usually mounted on the side ofthe

‘engine, and oil lines ave connected to the switch

{Low ail pressure closes the switch

Manually operated systems require resetting of

this switch before starting. Automatic. starl-stop

Systems vse a pressure switch which resets sel!

To reset the switch. push the button until it

latches. Alter the engine starts and develops oll

pressure. the bution wil move tothe extended run

hing posivon

CAUTION

‘The button must be in the RUN position to pro-

tect the engine,

It the button remains in the reset position, the

engine oll pump may not be developing normal

ollipressure and checks shoul

Overspeed Shutoff Switch

(Electronic)

‘This switen senses engine speod. The contro!

box is mounted on the engine block. Excessive on

ine speed closes a circu! broaker. To reset tho

Switch, push the reset button,

CAUTION

To provide overspeed protection there must be

Fuel/Oil Pressure Switch

‘This switch is mounted in the tual manifold bet

‘naen the outlet side of the fuel Miter and the fuel

injection pump. Low fuel pressure opens the switch

and the electrical cireuit to either the shutoff so

fold or the cirult between the alternator and the

faternator regulator While the engine Is stopped

‘pen these circuits to prevent the battery trom De-

‘coming discharged,

This switch can also be used with an electric gov

‘ernor, In this application, 01 pressure closes the

‘Switch o allow the electric governor fo control en-

sine speed,

‘This switch does not require resetting

Air Safety Shutoff Control

The air shutotf control is an attachment to the

safety shutolt devices, When an emergency condi

tions occurs, the solenoid pushes the rack into the

shutoff posiiion and a solenoid trips a butterfly

Yalve, located in the inlet manifolg, o the closed

position. The alr safoty shutot" contral mustboreset

Before starting,

‘Alarm Switches:

Alarm switches are set a a lass critical tempera

ture, pressure, or level limit than the comparable

shutoff eantrol. The purpose of the alarm switch is

to warn the operator'an unsafe operating condition

is starting to oceur, and that corrective measures

Should be taken (o avoid possible damage to the

tengine and/or a possible Shutdown of me engine

caution

Even though it could be hazardous to have the

‘engine stop unexpectantly, t the engine over-

Speeds, it should be stopped Immediately

19

When the preset temperature, prossure or fluid

level occurs, eltheralightor an audible alarm willbe

‘energized. The light of alarm will continue to oper-

fate unt the condition is corrected. When the condi-

tion is corrected tne alarm will automatically rest

fand tho ight will ture of.

‘CAUTION

‘The cause of the shutdown must be investigated

and corrected before starling and operating the

engine,

Testing Indicator Lights

Most control panels are equipped with a test

switen. By turning the switch ON. al ofthe Indicator

lights can be checked for proper operation. Test tho

Indicator lights periogically, replace burned out

light bults immediatly

‘Alarm Shutoff Switch

{A switch may be installed in the alarm circuit for

silencing the alarm while the engine is stopped for

fepairs. Be sure the switch Is moved to the closed

(Gn) position and the warning lights are lit before

starting

CAUTION

Place switch in the closed (ON) position when

the engine Is started, so the engine will be pro-

tected

Output Shaft Governor

Operation

When the load can overspeed the torque convor-

tor output shatt, an output shaft governar should be

installed. The output shalt govornor sa speediimit-

Ing device which automatically adjusts engine gov-

‘omor setting according to toad requirement.

Determining Cause Of

‘Shutdown

CAUTION

HW the engine has been shutdown by a safety

device, da not start the engine and place it into

Service without having the cause of the shut-

down investigated and corrected.

Low Oil Pressure Checks

Ifthe iow oil pressure shutotf controlhas stopped

the engine, make the following checks:

1. Check the water temperature gauge. Determine

iftme engine was overneated. Check forexternal

water leaks

20

A warninc

jing water. Do not

the

hi

cap

2. Check the oil level, Oil level must be between

the ADD and FULL marks on the side of the

Uipstick stamped CHECK WITH ENGINE

STOPPED.

2.11 the oil level is below the AOD mark, check

for oil spray and/or oll accumulations. it any

fare found, have the necessary repairs made.

Betore starting, add oll to the FULL mark

4, Reset the shutotl contro

5, Remove the load and start the engine at its

slowest spec. Be prepared to shut the en

fine down manually.

6. Be alert for unusual sounds or noises. If the

fengine knocks, stop the engine immediately

‘and call your Caterpilar deaier

7.1f the engine blows excessive black exhaust

for has excessive crankcase blow-by, the en-

fine may need recanaiioning. Stop the en-

ine and call your Caterpillar dealer

8.1f the engine runs satistactorily, observe the

‘oll pressure gauge. if satisfactory pressure is

hot indicated, shut the engine down: call your

Caterpillar dealer

9.1 proper oil pressure Is registered, check to

see if the reset knob has moved to the un

position. If the knob does not move, stop the

Engine. Check the shutoff control, the ol line

‘nd ihe oll pressure gauge. Have necessary

Fopairs mado.

10.1f the oll pressure gauge registers normal oll

pressure, it the knob on the shutot! control

moves t0 the run position, and if the engine

operation is otherwise satisfactory, determine

ifthe high water temperatura shutott may

have shut down the engine

High Water Temperature

Checks—Engine Running

+, Detormine if the load was too great for the

engine! Reduce the load ang allow the engine

to coo! while running

2.1 pressure steam or water leaks are visible,

temove the load and stop the engine. Have

‘necessary repairs made.

3. Check for collapsing or deteriorated water

hoses, Have repairs mado,

4. Check for noisy water pump operation. Have

nocessary repairs made

5. Refill the cooling system with a solution of

water and permanent-lype antifreeze if below

freezing temperatures are expected: or with a

solution of approved water and Caterpillar

Corrosion Inhibitor or equivalent, Foliow the

Instructions on the container

A wanninc

High Water Temperature

‘Checks—Engine Stopped and Cold

1. Check coolant level. Determine if the cootant

has proper anifreeze protection. A $0-50 solu-

tion 6 permanent-type antireeze and approved

‘water willgive protection below 20°F (29°C)

2. Check tobe sure the raw water valve has been

‘opened.

3. Check engine room vents and/or louvers. Be

sure the angina is receiving sulficient air

4. Be sure temperature regulators are operating at

proper temperature range.

5. Inspect all water noses caretully for collapsing,

external andinternal failures. Replace hoses as

required,

6. Have the cooling system cleaned

CAUTION

If severe or prolonged 0

red, contact your

fengine checked for po:

ible damage.

Emergency Stopping

To stop in an emergency:

Mechanical Governor Control

Pll upward on the hand grip, and move the con:

trol to the shutott position

Woodward PSG Governor

Move the lever forward against the stop; hold the

lover unt the engine is stopped.

Electric Shutoff Solenoid

Push and hold the ON-OFF-STOP switch in the

‘STOP position unt the engine stops

Air Controls

Push and hold the ON:OFF-STOP switch in the

‘STOP position untirthe engine stops.

MAINTENANCE RECOMMENDATIONS

Cooling

CAUTION

Never add coolant to an overheated engine; allow the

engine fo coal Hest.

Check specie gravity of antifreeze solution tre-

{quently in cold weather fo assure adequate protec-

tion

Coolant should be drained and replaced “Every 2000

Service Meter Units.” With additions of Caterpillar

Cooling System inhibitor or the use of Coolant Conc-

tioner Elemente a8 recommended, the drain period

‘canbe extended o""Every 4000 Service Meter Units.”

All water is corrosive at engine operating tempers

= The cooling system should be protected with

Inhibitor at ll mes regardless of concentration of

‘nlilreeze. This can be done by maintaining 2 3%

Concentration of guid Caterpilar Cooling System

Inmbitor or by using Coolant Conaltioner Element

Never use both the liquid cooling system inhib

land coolant elements at the same time.

Do not use Caterpillar Cooling System Inhibitor or

Coolant Concitioner Elements with Dowtherm 208

Full-Fill Coolant

Whenever ctaning and rafiing cooling system, a

ways recheck the coolant level when he engine reaches

‘Normal operating tempersture

Filing at over U.S. gallos (19 Mors) per minute can

cause ar pockets inthe cooing system

Premix antifreeze solution to provide protection to the

lowest expected ambient temperature, Pure unciutes

fnttroeze wil freeze a1 10"F (28°C).

Operate with a thermostat in the cooing system all

year-round. Cooing System problems can arise without

2 ihermastat.

Electrical

caurion

When using jumper cables to start the engine, b

Sure to connect in parallel POSITIVE (-) to POS!

ive (/) and NEGATIVE (~) to NEGATIVE (~ )

‘Scheduled Oil Sampling

Use Scheduled Ol Sampling to monitor the engine's

condition and maintenance requrements.

Each of sample should be taken when the ois hot

and well mived, to insure @ sample whichis representa

tive ofthe ol nthe compartment

CConsutt your Caterpilar dealer for complete informa:

tion endassistance mestablehing a Scheudied Ol Sav

ping program for your equipment

Fuel

CAUTION

Fil tue! tank atthe end of each day of oper

Grive out moisture laden air and to prevent conden-

Sation: Do not fil the tank tothe brim. The fuel @x-

ands when it gets warm and may overflow:

‘Water and sediment shoud be drained from the fue

tank atthe start of]each shit or after the ful tank has

been tiled and alowed to stand for 5 to 10 minutes

Drain ful tank of moisture and sediment as required

by prevaling conditions

‘ter changing fue titers, always bleas tel system to

remove air bsobes fom system.

Air intake

Service air cleaners when RED band in indicator locks

in vise positon

SPECIFICATIONS

LUBRICATION

SPECIFICATIONS

Crankcase Lubricating Oils

Use ols which meet Engine Service Classification CD

(MIL-L-2104) oF CD/TO-2. Tose are agdiive-ype ols

that have been approved for use in Caterpllar Dose

Engines.

Consut the "EMA Lubreating Oils Data Book,” Form

'SEBUS939, for listing of CD ol brand.

‘The proper SAE grade of oo seletis determined by the

ambien! temperature at which the engine is started and

the maximum ambient temperature in which the engine

wil be operating, See chert for recommended viscosity

and temperature range

To determine i the olin the crankeaso wil tow in cold

weather. remove tol dipstick before staring! the ol

‘wil Tow aff the is fhid enough to eeulate propery

Lubricating Grease

Uso Multipurpose-

ps

1¢ Grease (MPGM) which

Contains 3-88 molybdenum disulfide contorming to

MIL:M-7866, and a suitable corrosion inhibitor

NLGINo. 2 Gradels eutable formost temperatures

Use NUGI No. 0 of No. 1 Grade for extremely low

temperature

Recommended Lubricant Viscosities

"Wer spetng tion SP [277 er oe Cal Wey Reason Gian avd Maviaranos Gace, Fors SED,

Air Starting Motor Oiler: Use SAE 10W in all

temperatures.

Flywheel Clutch Bearing Reservoir: Use SAE 30

‘nal temperatures,

REFILL CAPACITIES

WODEL | US.GAL | LITRE | IMP. GAL.

3406 72 | 455. 10

ae 6 305. 13

FUEL SPECIFICATIONS.

No, 2 tue! oil and No. 20 diesel fuel are recom:

mended tor use In Caterpilar Diesel Engines, In

Extreme caid tomporatures use No.1 fuel cil or No,

1D iasel fuel

In selecting a fuel, note that distilate fuels are

especially desirable because the {uel is heated toa

Vaporous stale and condensed, thus eliminating all

Sediment and residue,

“There is considerable variation in the composi-

tion of fuels aistabuted under the No.2 grade clas-

Sieations, For desirable engine service its most

important to give special attention to cetane no.

later and sediment pour point. cloud point and

Sulphur content USE THE LOWEST PRICE OIS-

TIWUATE FUEL WHICH MEETS THE FOLLOWING

REQUIREMENTS.

Water ang Sediment 0.1% sogimont

Cotane No. (PC Enaine) ‘35 minimum

{Orengine) 40 minimum

Pour Point {G'F (6°0) below

‘ambient temperature

Cloud Point ‘No higher tran

‘biient temper

‘Adjust oll change period

Gravity 33:40 AP. at 60'F (15.6°C)

*See the topic SULPHUR CONTENT.

Catane No: This s an indication of a fuet's igni-

tion quality and should notbe loss than 35 or the PC

tengine and 40 for the DI engine, For high altitude

operation or cold weather starting, anigher cotano

number fs required

Water and Sediment: A good clean fue! will con:

tain no more than 0 1% sediment and water. Dirty

{els lead to early filter plugging and in aoaition can

{esultin the formation of gums and resins reducing

fter and engine ite

Sulphur Content”

Pour Point: The pour point of the fuel has no

effect on engine performance, as tong as the fuel is

fiuid enough to flow from the fuel tank the engine,

‘The pour point of the fuel should be al loast 10°F

(G:C) Below tno lowest almospherle temperature at

finich the engine must start and operate. Ine

tremely cold temperatures it may be necessary to

Use No. t fuel gilor No. 1D diesel fuel

Cloud Point: Cloud point is the temperature at

which wax crystals become visible and is general

‘above the pour point of the fuel. The cloud por

Should be ho higher than the Towest atmospheric

{emporatore at which the engine must start 1o keep

the fuel iter elements from plugging with wax crys

tals

Sulfur Content: The percentage of sur inthe tut

‘wifatect he engine of recommendations. H the fel has

‘ver 0.5 sulfur content, he CD engine oil must have a

“TBN of 20 mes the percentage of fuel sultur TEN as,

Tneasuted by the ASTAID 2856 method). Your o supp

shoul be able to furnish te corect ol

Gravity: Gravity isthe measurement of heat units

inacortainamount of fuel The heavier the fuel (the

lower the number) the morefeat units per volume.

fa fuel with ahigher A P.. gravity is used the power,

roduced will be lower. Select fucis with the lower

Keil gravity reacing

‘Some fuel specifications that meet the above re

urements are

ASTM—D396--No. 1 & No. 2fusle (burner fuels)

ASTM 0975 -No. 1D &No.20 diese! vel ails

BS2a69—Class At to Class A2 engine fuels

Bs2869—Ciass C & Class D burner fuels

DINS1601—Diesel fuel

DINS1603—EL heating oil

Authorizes dealers are familiar with fuels that

have given good results in Caterpillar Diesel En-

{ines and should be consulted regarding fuel use

‘then abnormal conditions occur

COOLANT SPECIFICATIONS

Water used in the jacket water cooling system

should be clean, ang as free as possible trom scale

{forming minerals or earrasive chemicals. Artificially

Softened water should not be used. Treating the

water with Caterpillar Coolant Inhibitor. or equiva-

Tent will help prevent the formation of rust and pit-

ting. It will also retard, and in some cases com-

pletely siminate, mineral depasits in the engine.

‘The mast efficient and satislactory corrosion pro

toction for the cooling systam is to maintain proper

level of coolant innibter and antilteeze solution

{ine use of auxiliary water filters Is rot recom

mended.

During freezing weather use the proper perma:

rent type antireeze and water solution to prevent

freezing

Before placing the engine in operation, make

sure a 3% concentration of Caterpillar Corrosion

Inhibitor or equivalent hae been added to the coo!

Ing system. This 3% concentration must be main:

tained in cooling systems which ae filled with water

land systems protected with etfiiene glycol anti

feeze mixture, regardless of anlireeze concentra-

ton

WARNING

‘void contact with

Anda mungkin juga menyukai

- Four Simple Steps To SynchronisingDokumen1 halamanFour Simple Steps To SynchronisingAung MhBelum ada peringkat

- 056-072 Dead Bus SyncDokumen2 halaman056-072 Dead Bus SyncYasser JaviBelum ada peringkat

- 056-057 SW1andSW2Dokumen2 halaman056-057 SW1andSW2Jesus IzaguirreBelum ada peringkat

- 056-045 PLC As Load Demand ControllerDokumen2 halaman056-045 PLC As Load Demand ControllerKhaleel KhanBelum ada peringkat

- kVA, kW, KVAr and Power Factor ExplainedDokumen2 halamankVA, kW, KVAr and Power Factor ExplainedGabriel OrellanBelum ada peringkat

- Guide To Load Share System Design and CommissioningDokumen35 halamanGuide To Load Share System Design and CommissioningpeefincaBelum ada peringkat

- 056-020 Loss of Excitation PDFDokumen1 halaman056-020 Loss of Excitation PDFFernando MendozaBelum ada peringkat

- 057-004 CAN Guide PDFDokumen88 halaman057-004 CAN Guide PDFMeriem ZAGRIRI100% (1)

- 056-022 Breaker ControlDokumen4 halaman056-022 Breaker ControlkazishahBelum ada peringkat

- 056-054 7510 in Fixed ExportDokumen2 halaman056-054 7510 in Fixed ExportYasser JaviBelum ada peringkat

- 057-046 GLS2 GuideDokumen76 halaman057-046 GLS2 Guidecassiomec100% (1)

- Set Module Access PIN CodesDokumen2 halamanSet Module Access PIN CodesJoaquin Chavez ArquiñigoBelum ada peringkat

- 056-024 GSM ModemDokumen3 halaman056-024 GSM Modem100003Belum ada peringkat

- PLC Programming Guide For Dse ControllersDokumen30 halamanPLC Programming Guide For Dse ControllersAimi Mizuki Murtic100% (4)

- Gencomm Control KeysDokumen4 halamanGencomm Control Keyskazishah100% (1)

- 056-018 Negative Phase Sequence PDFDokumen2 halaman056-018 Negative Phase Sequence PDFCarlitos MenesBelum ada peringkat

- DSE generator overcurrent protection settingsDokumen2 halamanDSE generator overcurrent protection settingsAndersonBelum ada peringkat

- 056-021 Mains DecouplingDokumen2 halaman056-021 Mains DecouplingRafael FernandoBelum ada peringkat

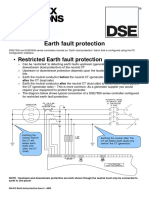

- 056-019 Earth Fault Protection PDFDokumen2 halaman056-019 Earth Fault Protection PDFmigas_migue2856Belum ada peringkat

- 056-033 Synchronising RequirementsDokumen2 halaman056-033 Synchronising RequirementsKhaleel KhanBelum ada peringkat

- 056-047 Out of Sync and Failed To CloseDokumen2 halaman056-047 Out of Sync and Failed To Closeharigopalk12100% (2)

- 056-013 Load Demand Scheme PDFDokumen2 halaman056-013 Load Demand Scheme PDFMartonoBelum ada peringkat

- 056-017 PC Configuration InterfacingDokumen2 halaman056-017 PC Configuration InterfacingKhaleel KhanBelum ada peringkat

- Using CTs with DSE ProductsDokumen2 halamanUsing CTs with DSE ProductsJoaquin Chavez ArquiñigoBelum ada peringkat

- Caterpillar 3412c1 PDFDokumen123 halamanCaterpillar 3412c1 PDFKhaleel KhanBelum ada peringkat

- JADelmas PlaqAPS Anglais HD 2Dokumen20 halamanJADelmas PlaqAPS Anglais HD 2Dwi FitriantoBelum ada peringkat

- MSC Link Functions and ConnectionsDokumen2 halamanMSC Link Functions and ConnectionsAsif MehmoodBelum ada peringkat

- Four Simple Steps To SynchronisingDokumen1 halamanFour Simple Steps To SynchronisingAung MhBelum ada peringkat

- Manual Motor C13 y C15Dokumen256 halamanManual Motor C13 y C15Luis Arturo Arenales Mayta100% (23)

- Caterpillar Switchgear Training Manual 3 S PDFDokumen206 halamanCaterpillar Switchgear Training Manual 3 S PDFKhaleel KhanBelum ada peringkat

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5782)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (72)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)