6.0 Electrical Grounding Systems and Protection

Diunggah oleh

Chidiebere Samuel OkogwuJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

6.0 Electrical Grounding Systems and Protection

Diunggah oleh

Chidiebere Samuel OkogwuHak Cipta:

Format Tersedia

SITP Electrical Installation

6.0 ELECTRICAL GROUNDING SYSTEMS AND

PROTECTION

There are two reasons that proper electrical grounding systems must be installed

in electrical distribution systems. The first, and primary, reason is to protect

operational personnel and other people around the equipment from receiving

electrical shocks. Proper electrical grounding can minimize or eliminate these

shock hazards. The second reason for electrical grounding involves the

equipment. Proper grounding can protect equipment from failure. Also, some

electronic equipment will not work properly without a good, almost perfect

grounding system. Most grounding systems are connected to building grounds. A

few others have a relative ground wire, which runs directly from device to device.

Examples of equipment requiring good electrical grounds are computer systems

and communications equipment.

A conventional 115/230 V distribution system is shown in Figure 1. There are

three wires from the distribution transformer secondary to the breaker or fuse

panel. Two wires have 230 V across them. Half of the voltage, 115 V, appears

between each 230 V wire and the centre wire. The centre wire is electrically

grounded at the distribution transformer. This ground consists of a wire run from

the transformer centre tap to a spike in the ground soil. At the distribution panel,

the voltage is fed to various 115 V and 230 V load through circuit breakers or

fuses. An electrical ground is run from the neutral bar in the distribution panel to

earth ground via a water pipe. For good soil conditions, the resistance between

grounds is effectively near 0Ω .

Figure 2 illustrates what can happen if the frame or case of an electrical device is

installed without a ground. Assume that there is only two-conductor wiring to the

device. The electrical device can be a monitor, computer, lamp, or some other

such device, or it can be the conduit, receptacle, or similar element.

Omoigui, M.O. Page 1 of 7 Univation

SITP Electrical Installation

Improper equipment grounding would occur if a three-wire system with a three-

prong, grounding receptacle plug were not used. Metal conduit and receptacles

are to be grounded by a separate wire, which is missing in this instance. To

compound the safety problem, the device case is not grounded with a separate

ground wire. There is no GFI, either.

An example of this situation could be a fan motor on a bare ground floor. The fan

motor is installed on a plastic, non-conducting frame. The bare floor has moisture

on it. Suppose that the wire connected to terminal B has an insulation crack. The

Omoigui, M.O. Page 2 of 7 Univation

SITP Electrical Installation

copper of the wire with the cracked insulation touches the frame. Now someone

who wants to clean the motor touches the frame. The person is in luck. The

frame is nearly at ground potential, and nothing happens. Now, suppose the ″hot”

wire, A, touches the frame. When the person touches the frame, he or she

becomes a parallel load to 115 V. A person has about 1500 Ω resistance. Then,

the race is on as to which goes first –the fuse or the person. The person will

probably be badly hurt or even killed. A few milli-amperes are enough to cause

serious injury. A current of 120mA is enough to kill a person.

In contrast, the proper grounding system shown in Figure 3 would prevent injury.

As soon as B becomes shorted, the fuse blows. The circuit is therefore

deenergized. A person touching the frame is protected. Figure 3 has an ideal

grounding system of 0Ω . Such an ideal cannot always be attained. One sure way

to make sure the ground has very low resistance is to run a separate ground wire

as shown.

One word of caution: You may assume that the larger, round grounding prong on

the plug works infallibly. It does not. There have been cases where the cord

ground wire has opened up. In such a case there is no ground shock protection.

Omoigui, M.O. Page 3 of 7 Univation

SITP Electrical Installation

In another situation the receptacle ground is not connected to anything. This

connection can be checked visually or with an ohmmeter.

Ungrounded plug ground connections are especially possible in older building

installations. An appropriate ohmmeter check is always good insurance that the

proper ground circuit exists.

Grounds are not always perfect. A ground wire has resistance depending on

its size. Connections have some resistance. The earth soil itself has resistance,

which varies with the soil type and moisture content. The distribution-panel

ground-bar connection can also have some resistance value. Figure 4 shows

some imperfect grounds, which can be typical of actual installations. The ground

at the transformer, the ground at the panel, or the ground from the load device to

building ground can have some resistance. Three possibilities are shown.

Assume there is a short from wire A to the metal case, as before. By Ohm’s law,

the current for A in Figure 4A is 115 V/16Ω = 7.2 A. The fuse will not necessarily

blow –only if the load current is an added 7.8 A or more. By voltage divider, the

frame will have 15/16 × 115 V, or 108 V above ground potential. This is

dangerous.

The other examples, in Figure 4B and C, can have values calculated similarly.

For part B there will be 5.5 A and only 5 V (a better situation) at the frame. For C

there are two-ground resistance in parallel to consider. The wire will have only

3.4 A, but there will be 78 V at the frame. The whole point is that a poor ground

will not give good personnel hazard protection. Improved grounding systems are

needed in these cases.

Sometimes, no ground is used in a transformer secondary circuit. The grounding

of the supply voltage can cause instrumentation or operational problems.

Ungrounded AC supplies are generally satisfactory at low voltages, such as 115

V or 240 V. There can be some hazard with no ground of the supply voltage as

Omoigui, M.O. Page 4 of 7 Univation

SITP Electrical Installation

shown in Figure 5. There is a 2300 V primary of a transformer. Its feeder line is

grounded back at the previous transformer. Suppose that the primary becomes

shorted to the secondary as shown. Now lines A and B are at 2300 V above

ground-a dangerous situation. If the transformer secondary were grounded at

one terminal, the 2300 V protective fuse would blow. In any case, the frame of

the load should be grounded as shown, even if the 115 V circuit is not.

As a further ground shock protection, newer plug receptacle combinations have

one of the two load current prongs larger than the other. The plug and its proper

wiring are shown in Figure 6. The high or 115 V, side is required to be connected

to the fuse. If the fuse blows, the device will then be at ground potential, near 0

V. If either the receptacle or the plug is wired incorrectly, there is a problem. If

the fuse blows, the device’s inner wiring will remain at 115 V above as illustrated.

Omoigui, M.O. Page 5 of 7 Univation

SITP Electrical Installation

Single-phase circuit grounding has been discussed. Grounding of three-phase

circuits is smaller, but more involved and complicated. Figure 7 shows two basic

methods of wye circuits grounding. In Figure 7A is a system in which the neutral

doubles as the ground. This arrangement generally functions safely. What if the

neutral was to open up? There would be no safety ground even though the main

lines were still energized.

A more costly but surer wye grounding system is shown in part B. A separate

grounding wire is run in addition to the neutral. If neutral opens up, there is still

protection. This system is called the three-phase, five-wire distribution system.

Omoigui, M.O. Page 6 of 7 Univation

SITP Electrical Installation

Delta systems are grounded in various ways. Three of the delta grounding

methods is shown in Figure 8. These are; no ground, ground at one corner, and

ground in the middle of one phase. These grounds must match the grounding

systems of parallel delta connections

Omoigui, M.O. Page 7 of 7 Univation

Anda mungkin juga menyukai

- Bolts Torque CalculatorDokumen3 halamanBolts Torque CalculatorAlexandre LaraBelum ada peringkat

- Earthing CalculationDokumen88 halamanEarthing CalculationRamesh Epili100% (17)

- Quiz 1.1 Philippine Electrical Code 2017 - JOPIADokumen4 halamanQuiz 1.1 Philippine Electrical Code 2017 - JOPIAGABRIEL ABRAM JOPIABelum ada peringkat

- GroundingDokumen49 halamanGroundingNAITIKBelum ada peringkat

- Upgrading The ProtectionDokumen4 halamanUpgrading The ProtectionMukesh KumarBelum ada peringkat

- Bonding and Grounding for Electrical SafetyDokumen40 halamanBonding and Grounding for Electrical Safetyrhap_0925060Belum ada peringkat

- 3202.31.DIES - INSTRUMENT CABLE SCHEDULE.24015 - Rev02Dokumen6 halaman3202.31.DIES - INSTRUMENT CABLE SCHEDULE.24015 - Rev02Chidiebere Samuel OkogwuBelum ada peringkat

- Earthing in A Nutshell Classification Isolated Neutral Methods of Neutral GroundingDokumen14 halamanEarthing in A Nutshell Classification Isolated Neutral Methods of Neutral GroundingJorge AzabacheBelum ada peringkat

- Loss of Neutral in LVDokumen4 halamanLoss of Neutral in LVAthanasios Antonopoulos100% (1)

- Earthing Systems in Electrical Supply - Peter Witt - TESLA INSTITUTEDokumen30 halamanEarthing Systems in Electrical Supply - Peter Witt - TESLA INSTITUTEAmine Etude100% (2)

- Grounding PowerDokumen8 halamanGrounding PowerFaisal Naeem100% (1)

- Afa Sebf9066-00Dokumen95 halamanAfa Sebf9066-00Edwarth MazaBelum ada peringkat

- Ingersoll Rand AC185D Operators ManualDokumen284 halamanIngersoll Rand AC185D Operators ManualAntonio Carrion100% (2)

- Handouts of The Presentations - Seminar On Introduction To New Guidelines For Seismic Design of Road BridgesDokumen105 halamanHandouts of The Presentations - Seminar On Introduction To New Guidelines For Seismic Design of Road BridgesChaitu Rishan100% (1)

- Earthing Structures SystemsDokumen72 halamanEarthing Structures SystemsIsaac AppiagyeiBelum ada peringkat

- White Paper Series Electrical Ground RulesDokumen22 halamanWhite Paper Series Electrical Ground RulesChristianBelum ada peringkat

- Catalogo de Parte COP 2550 UX +Dokumen112 halamanCatalogo de Parte COP 2550 UX +Alvaro Varas100% (2)

- Electrical Grounding Systems ExplainedDokumen5 halamanElectrical Grounding Systems ExplainedEri Febriansya100% (1)

- Nec 250Dokumen7 halamanNec 250Sujeet ManolkarBelum ada peringkat

- Marine BoilersDokumen16 halamanMarine BoilersPawan Beniwal100% (1)

- Top Five Causes of Switchgear FailureDokumen3 halamanTop Five Causes of Switchgear FailureGlenn Adalia Bonita75% (4)

- APC Neutral Wire Facts and MythologyDokumen8 halamanAPC Neutral Wire Facts and MythologyAnjar TriyokoBelum ada peringkat

- Steel Erection ITPDokumen26 halamanSteel Erection ITPIksan Adityo MulyoBelum ada peringkat

- Tile Adhesives, Tile Grouts and Plastering SkimDokumen30 halamanTile Adhesives, Tile Grouts and Plastering SkimNykha Alenton100% (1)

- ArresterFacts 032 The Sheath Voltage LimiterDokumen9 halamanArresterFacts 032 The Sheath Voltage Limiterdwas1314Belum ada peringkat

- Increasing Availability of LV Electrical NetworksDokumen30 halamanIncreasing Availability of LV Electrical Networksverde24Belum ada peringkat

- Standard Design of SilosDokumen12 halamanStandard Design of SilosTarun VermaBelum ada peringkat

- Introduction to Power System ProtectionDari EverandIntroduction to Power System ProtectionPenilaian: 5 dari 5 bintang5/5 (1)

- GB Prorox-Product CatalogDokumen19 halamanGB Prorox-Product CatalogGozuengineer GozuBelum ada peringkat

- Building Energy Efficiency Technical Guideline For Passive Design PDFDokumen196 halamanBuilding Energy Efficiency Technical Guideline For Passive Design PDFFirrdhaus Sahabuddin100% (1)

- Electrical Safety: Systems and Devices: Learning ObjectivesDokumen16 halamanElectrical Safety: Systems and Devices: Learning ObjectivesTara CollierBelum ada peringkat

- Agilent Technologies: Considerations For Instrument GroundingDokumen9 halamanAgilent Technologies: Considerations For Instrument GroundingjosethompsonBelum ada peringkat

- Eathing and Grounding 1 ProtectionDokumen116 halamanEathing and Grounding 1 ProtectionAnees KhanBelum ada peringkat

- Circuit Voltage: Systems Operation - FundamentalsDokumen8 halamanCircuit Voltage: Systems Operation - Fundamentalsrigoberto otinianoBelum ada peringkat

- Electrical GroundingDokumen45 halamanElectrical GroundingMILTON XAVIER REMACHE SASIGBelum ada peringkat

- Protect Your Power System with Proper GroundingDokumen2 halamanProtect Your Power System with Proper GroundingMujtaba HusseinBelum ada peringkat

- Why Grounding Is Used ?Dokumen25 halamanWhy Grounding Is Used ?sanjpandea2zBelum ada peringkat

- Application Considerations For High Resistance Ground Retrofits in Pulp and Paper MillsDokumen8 halamanApplication Considerations For High Resistance Ground Retrofits in Pulp and Paper MillsLong LeoBelum ada peringkat

- Experiment No.-03 - Grounding of Electrical Equipment.: ObjectiveDokumen10 halamanExperiment No.-03 - Grounding of Electrical Equipment.: Objectiveshaiyek taslimBelum ada peringkat

- Grounding non separately derived generator systemsDokumen6 halamanGrounding non separately derived generator systemsrmendozaingBelum ada peringkat

- Leading Leakage CurrentDokumen7 halamanLeading Leakage Currentrbalaji1987Belum ada peringkat

- earthing-calculation (3)Dokumen91 halamanearthing-calculation (3)Ramji RamakrishnanBelum ada peringkat

- Nvent ERICO Grounding MythsDokumen9 halamanNvent ERICO Grounding MythsMahmoud GwailyBelum ada peringkat

- GRNDP1Dokumen9 halamanGRNDP1ricardo zuletaBelum ada peringkat

- 3.6 Electrical HazardsDokumen4 halaman3.6 Electrical HazardsNur Fatin ErniBelum ada peringkat

- Voltagem em CircuitosDokumen8 halamanVoltagem em CircuitosWellington FrançaBelum ada peringkat

- Electrical Earthing GroundingDokumen3 halamanElectrical Earthing GroundingAnshuman SinhaBelum ada peringkat

- How To Ground A CircuitDokumen9 halamanHow To Ground A CircuitjackBelum ada peringkat

- Cable Engineering in Substation and Power PlantDokumen7 halamanCable Engineering in Substation and Power PlantVasudev AgrawalBelum ada peringkat

- Silo - Tips Earthing System of Electrical CircuitDokumen24 halamanSilo - Tips Earthing System of Electrical Circuitgerry jabinesBelum ada peringkat

- Fidoshook 725 RPDokumen6 halamanFidoshook 725 RPfollowjesusBelum ada peringkat

- Kau Ha Niemi 2004Dokumen4 halamanKau Ha Niemi 2004Ravishankar KankaleBelum ada peringkat

- Gfcis For Ac DC SystemsDokumen11 halamanGfcis For Ac DC SystemsZevaBelum ada peringkat

- 05 Grounding RegulationsDokumen14 halaman05 Grounding RegulationsEng Amr ElorbanyBelum ada peringkat

- Joseph SeminarDokumen33 halamanJoseph SeminarEdul BrianBelum ada peringkat

- 9781408515181Dokumen3 halaman9781408515181bhawanisr@gmail.comBelum ada peringkat

- Earthing or Grounding of Electric Distribution Systems: Dr. Chandrashekhar N. Bhende School of Electrical SciencesDokumen10 halamanEarthing or Grounding of Electric Distribution Systems: Dr. Chandrashekhar N. Bhende School of Electrical Sciencesjainam ravalBelum ada peringkat

- Voltage Protection TNCR025Dokumen6 halamanVoltage Protection TNCR025salic2013Belum ada peringkat

- Earthing SystemDokumen9 halamanEarthing SystemmaheshshettymteducarBelum ada peringkat

- 70 Grounding Power CableDokumen3 halaman70 Grounding Power CableemilioaraBelum ada peringkat

- Grounding systems and electrical wiring basicsDokumen11 halamanGrounding systems and electrical wiring basicsgerrzen64Belum ada peringkat

- Effective Grounding For PV PlantsDokumen4 halamanEffective Grounding For PV PlantsAnonymous NGXdt2BxBelum ada peringkat

- 3-phase breaker protectionDokumen6 halaman3-phase breaker protectionGRETEL HERRERA JIBAJABelum ada peringkat

- Grounding Neutral EarthingDokumen12 halamanGrounding Neutral EarthingHernàn NùñezBelum ada peringkat

- ElectricDokumen2 halamanElectricharris314Belum ada peringkat

- 016 - UPS Applications Guide General ElectricDokumen9 halaman016 - UPS Applications Guide General ElectricDante FilhoBelum ada peringkat

- UPS Application Guide: 16 Neutral SystemsDokumen9 halamanUPS Application Guide: 16 Neutral SystemstceterexBelum ada peringkat

- Electrical Installation Lecture No.12 DR - Mohammed Tawfeeq Al-ZuhairiDokumen10 halamanElectrical Installation Lecture No.12 DR - Mohammed Tawfeeq Al-ZuhairiTĩnh LặngBelum ada peringkat

- Earthing SchemesDokumen16 halamanEarthing SchemesKatik XalxoBelum ada peringkat

- Circuit VoltageDokumen7 halamanCircuit VoltageKhaled Naseem Abu-SabhaBelum ada peringkat

- 3202.31.DIES - INSTRUMENT TUBING SCHEDULE.24018 - Rev03Dokumen5 halaman3202.31.DIES - INSTRUMENT TUBING SCHEDULE.24018 - Rev03Chidiebere Samuel OkogwuBelum ada peringkat

- Alternative Source For Gas Supply To Indorama ProjectDokumen4 halamanAlternative Source For Gas Supply To Indorama ProjectChidiebere Samuel OkogwuBelum ada peringkat

- Start Time SN Job Step Hazard Hazard Controls Status CommentsDokumen3 halamanStart Time SN Job Step Hazard Hazard Controls Status CommentsChidiebere Samuel OkogwuBelum ada peringkat

- Install PDFDokumen12 halamanInstall PDFMd NazrulBelum ada peringkat

- VerbalReasoningTest1 QuestionDokumen12 halamanVerbalReasoningTest1 QuestionChidiebere Samuel OkogwuBelum ada peringkat

- Thin Material: Nozzle Segment Indication ZonesDokumen1 halamanThin Material: Nozzle Segment Indication ZonesChidiebere Samuel OkogwuBelum ada peringkat

- Dragnet Abstract Reasoning Test 1&2 SolutionsDokumen10 halamanDragnet Abstract Reasoning Test 1&2 SolutionsChidiebere Samuel OkogwuBelum ada peringkat

- Alternative Gas Supply for IndoramaDokumen19 halamanAlternative Gas Supply for IndoramaChidiebere Samuel OkogwuBelum ada peringkat

- Start Time SN Job Step Hazard Harzard Controls Status CommentsDokumen3 halamanStart Time SN Job Step Hazard Harzard Controls Status CommentsChidiebere Samuel OkogwuBelum ada peringkat

- TTD Setup For Ajax (2015 - 11 - 23 10 - 24 - 32 UTC)Dokumen1 halamanTTD Setup For Ajax (2015 - 11 - 23 10 - 24 - 32 UTC)Chidiebere Samuel OkogwuBelum ada peringkat

- Family KKS Maintenance Period Detail PM TasksDokumen6 halamanFamily KKS Maintenance Period Detail PM TasksChidiebere Samuel OkogwuBelum ada peringkat

- Errosion: Nozzle Segment Indication ZonesDokumen1 halamanErrosion: Nozzle Segment Indication ZonesChidiebere Samuel OkogwuBelum ada peringkat

- Nozzle Segment Indication Zones: A B C B D D E FDokumen1 halamanNozzle Segment Indication Zones: A B C B D D E FChidiebere Samuel OkogwuBelum ada peringkat

- Kvaerner Energy LTD Thermal Power Division CSD Field Technical InstructionDokumen2 halamanKvaerner Energy LTD Thermal Power Division CSD Field Technical InstructionChidiebere Samuel OkogwuBelum ada peringkat

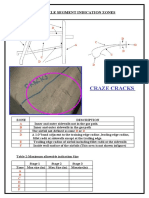

- Craze Cracks: Nozzle Segment Indication ZonesDokumen1 halamanCraze Cracks: Nozzle Segment Indication ZonesChidiebere Samuel OkogwuBelum ada peringkat

- Field Technical Instruction: John Brown Engineering Customer Service DivisionDokumen2 halamanField Technical Instruction: John Brown Engineering Customer Service DivisionChidiebere Samuel OkogwuBelum ada peringkat

- Nozzle Segment Indication Zones GuideDokumen1 halamanNozzle Segment Indication Zones GuideChidiebere Samuel OkogwuBelum ada peringkat

- KVAERNER ENERGY LTD THERMAL POWER DIVISION CSD FIELD TECHNICAL INSTRUCTIONDokumen2 halamanKVAERNER ENERGY LTD THERMAL POWER DIVISION CSD FIELD TECHNICAL INSTRUCTIONChidiebere Samuel OkogwuBelum ada peringkat

- FTI0257Dokumen3 halamanFTI0257Chidiebere Samuel OkogwuBelum ada peringkat

- Kvaerner Energy LTD Thermal Power Division CSD Field Technical InstructionDokumen2 halamanKvaerner Energy LTD Thermal Power Division CSD Field Technical InstructionChidiebere Samuel OkogwuBelum ada peringkat

- Kvaerner Energy LTD Thermal Power Division CSD Field Technical InstructionDokumen2 halamanKvaerner Energy LTD Thermal Power Division CSD Field Technical InstructionChidiebere Samuel OkogwuBelum ada peringkat

- Technical Information Letter: Replacement of 6B ST Age-2 BucketsDokumen1 halamanTechnical Information Letter: Replacement of 6B ST Age-2 BucketsChidiebere Samuel OkogwuBelum ada peringkat

- Kvaerner Energy LTD Thermal Power Division C.S.D. Field Technical InstructionDokumen2 halamanKvaerner Energy LTD Thermal Power Division C.S.D. Field Technical InstructionChidiebere Samuel OkogwuBelum ada peringkat

- Kvaerner Energy LTD Thermal Power Division CSD Field Technical InstructionDokumen2 halamanKvaerner Energy LTD Thermal Power Division CSD Field Technical InstructionChidiebere Samuel OkogwuBelum ada peringkat

- T12833-Purge Air CHK VLVDokumen6 halamanT12833-Purge Air CHK VLVJEORJEBelum ada peringkat

- Kvaerner Energy LTD Thermal Power Division CSD Field Technical InstructionDokumen1 halamanKvaerner Energy LTD Thermal Power Division CSD Field Technical InstructionChidiebere Samuel OkogwuBelum ada peringkat

- Kvaerner Energy LTD Thermal Power Division CSD Field Technical InstructionDokumen2 halamanKvaerner Energy LTD Thermal Power Division CSD Field Technical InstructionChidiebere Samuel OkogwuBelum ada peringkat

- Technical Information Letter: Five-Wire Flame Detector System ReplacementDokumen1 halamanTechnical Information Letter: Five-Wire Flame Detector System ReplacementChidiebere Samuel OkogwuBelum ada peringkat

- Technical Information Letter: Excessive Gas Fuel Flow at Start-Up (F-Class)Dokumen5 halamanTechnical Information Letter: Excessive Gas Fuel Flow at Start-Up (F-Class)Chidiebere Samuel Okogwu100% (1)

- LONG TERM CONSTRUCTION REVENUEDokumen5 halamanLONG TERM CONSTRUCTION REVENUERoxell CaibogBelum ada peringkat

- Kisi-Kisi & Kartu Soal Usbn-A1Dokumen8 halamanKisi-Kisi & Kartu Soal Usbn-A1yc574haBelum ada peringkat

- TEST YOUR KNOWLEDGE - WELDED JOINTS QUIZDokumen2 halamanTEST YOUR KNOWLEDGE - WELDED JOINTS QUIZkalpanaadhi100% (1)

- Light Weight Flyash Brick Using Expanded Polystyrene (EPS)Dokumen4 halamanLight Weight Flyash Brick Using Expanded Polystyrene (EPS)jasimabdBelum ada peringkat

- Autodesk Medical Center GridsDokumen86 halamanAutodesk Medical Center GridsLula CaracoletaBelum ada peringkat

- V. Hari Krishna, R111794, Civil Engineering 4 Year, RGUKT, RK Valley, IdupulapayaDokumen24 halamanV. Hari Krishna, R111794, Civil Engineering 4 Year, RGUKT, RK Valley, IdupulapayaMahesh RamtekeBelum ada peringkat

- Input EchoDokumen62 halamanInput EchoAkhil JoseBelum ada peringkat

- Fastenings For The Rehabilitation of Historical Structures-Abstract Standard FormatDokumen2 halamanFastenings For The Rehabilitation of Historical Structures-Abstract Standard FormatRay RamiloBelum ada peringkat

- 1 PDFDokumen85 halaman1 PDFtim winkelmanBelum ada peringkat

- 18 Silbond and SilaidDokumen4 halaman18 Silbond and SilaidsviruindiaBelum ada peringkat

- Muhammad Rehan Khalil: Summary of CareerDokumen3 halamanMuhammad Rehan Khalil: Summary of CareerRehAn KhAlil100% (1)

- Paroc Pro Roof Slab 20 Kpa: Product DatasheetDokumen2 halamanParoc Pro Roof Slab 20 Kpa: Product Datasheetcarlos martinezBelum ada peringkat

- Polymers 13 03480 v2Dokumen13 halamanPolymers 13 03480 v2SEBASDAZACBelum ada peringkat

- Prueba y Ajuste Sistema HidraulicoDokumen55 halamanPrueba y Ajuste Sistema HidraulicoIginio Malaver VargasBelum ada peringkat

- 17 4Dokumen2 halaman17 4fedaquiBelum ada peringkat

- Copper Bonded Steel Earth RodDokumen9 halamanCopper Bonded Steel Earth Rodemmanuel_nyirendaBelum ada peringkat

- Joseph Allen SteinDokumen43 halamanJoseph Allen Steinashna bansalBelum ada peringkat