Gardenia

Diunggah oleh

lady chaseHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Gardenia

Diunggah oleh

lady chaseHak Cipta:

Format Tersedia

Gardenia

Company Profile

Gardenia began as a humble in-store bakery in Bukit Timah Plaza ,

Singapore in 1978. Mr. Horacio Slocumm, the owner gets the name “ Gardenia “

from his favorite flower. Mr. Slocumm brought with him 35 years of baking

experience with one of America’s leading chain of bakeries then Gradenia was

born. For many years, Gardenia has been the market leader in Singapore and

has expanded its operations in Asia to other countries such as Malaysia and

Thailand, with the latest in the Gardenia chain of bakeries being here in the

Philippines in 1997.

In 2011, Gardenia opened its new bakery in Lapu-Lapu City, Cebu,

producing a daily capacity of 50,000 loaves of bread serving the needs of the

entire province of Cebu and the Northern Mindanao area.

Product

Gardenia Philippines offers a wide array of superior bakery products

including white, wheat and health breads, flavored loaves, pandesal and snack

items like snack cakes, muffins and toasts. The most popular Classic White Bread

is cholesterol free and bromate free, has zero transfat, and is vitamin and

mineral fortified, exceeding DOH recommendations. The classic white bread is

made from Uncle Slocumm’s American recipe that’s really soft, great tasting,

smells good and nutritious. It also contains essential vitamins such as Vitamin A,

B1, B2, B3, C and minerals like Calcium, Iodine, Iron and Folate. About 50% of the

product is made from the necessary ingredients to make bread like wheat flour,

water, sugar, and salt. Its product slogan “So good…you can even eat it on its

own” best describes the product benefits. They only use high quality ingredients

for their products.

Process Strategy

In producing and manufacturing Gardenia Bread, the company uses

Continuous Mass Production Process. The breads are produce continuously in

high-volumes approximately 2000 loaves per hour and are make-to-stock

because of large inventories of final product. The process involves automated,

special-purpose equipment. It is a continuous process because the materials or

fluids that are being processed are continuously in motion, undergoing

chemical reactions or subject to mechanical or heat treatment.

Continuous usually means operating 24 hours per day, seven days per week

with infrequent maintenance shutdowns and the company operates 24/7

Facility Layout

Gardenia has a product-oriented plant layout, making the raw materials

and machinery follow the product path. In every stage of production the

machineries’ functions change and also the materials needed are added

simultaneously throughout the process. This kind of layout is seldom to be

changed.

Quality Management

Gardenia has been awarded with International Organization for

Standardization ISO 9001: 2000 certifications from 2003 to 2009 and has now

upgraded to ISO 9001:2008 in compliance with Quality Management System

and certification for product quality excellence. Moreover, Gardenia is HACCP

(Hazard Analysis and Critical Control Point) certified since 2003 to present—proof

of the company’s adherence to the systematic approach in the identification,

evaluation, and control of food safety standards. From 2004–2010, Gardenia

was accorded Superbrands status by Superbrands Ltd., an independent

authority and arbiter on branding. This award reaffirms that Gardenia has met

the stringent criteria of market dominance, longevity, goodwill, customer loyalty

and overall market acceptance. Another notable award is the Annual National

Consumers’ Award (ANCA) as the “Outstanding Bread Manufacturer” for five

straight years.

It can also be noticed that the Gardenia has a G-Locks in every bread

bags which aid in controlling the quality of their bread. These are color-coded

locks imprinted with the price, batch number for traceability, and expiry date

completes the whole package which ensures the freshness of every bread bag.

Human Resource and Job Design

Gardenia has 153 regular employees in different departments and the

others are contractual. The production area workers are required to be at least

high school graduate and willing to undergo training. The employees are sent to

the company’s modern manufacturing facility in Laguna for intensive training

especially on the most advanced baking technique, HACCP and ISO

procedures.

Location

Gardenia’s main branch is located at Laguna and the management

decided that it is strategic to put up a plant in Cebu specifically at Pajo St.

Lapu-Lapu City. This is done because the company does not want to

compromise the freshness of their products to be delivered all throughout

Visayas and Mindanao. The Lapu-Lapu plant now serves the bread requirements

of Cebu, Bohol , Butuan, Malaybalay, Iligan, Cagayan de Oro and Davao.

Inventory Management

The Company uses the First In, First Out Method of managing their

inventory since the Gardenia products has only a shelf life of one (1) week. This is

also to avoid any spoilage of their bread and to manage any costs. As soon as

products come out of the factory, delivery vans leave the production plant as

early as 4 o’clock in the morning to bring the products to specific locations and

replacing unsold breads in store shelves with freshly baked products.

Supply Chain Management

Pilmico and General Media Corporation are the suppliers of Gardenia’s

raw materials within the Philippines and the other ingredients are coming from

foreign countries like the raisins and chocolates for some of their products. The

finished products are distributed to their outlets, supermarkets and other retail

store all Visayas and Mindanao.

Scheduling

The Gardenia’s production area operates 24 hours a day for 7 days a

week. They have 3 shifts with 8 hours per shift to ensure that they can deliver

freshly baked breads to the consumers.

Maintenance

Gardenia currently adapts preventive maintenance wherein their facilities

and machineries are regularly checked and cleaned to avoid any over hauling

and unexpected shutdowns. Once in a month they allot a whole-day cleaning

and maintenance for the plant.

Anda mungkin juga menyukai

- Iso Ims Qehs ManualDokumen110 halamanIso Ims Qehs ManualmanutdudaBelum ada peringkat

- Quality Assurance Program PlanDokumen128 halamanQuality Assurance Program PlanVictor50% (2)

- Process of GardeniaDokumen8 halamanProcess of Gardeniarickstagrams67% (3)

- DD Situation AnalysisDokumen79 halamanDD Situation Analysiskwykevin580177% (13)

- Maria Abriel C. Buena Advance II: About IQ OptionDokumen4 halamanMaria Abriel C. Buena Advance II: About IQ Optionlady chase50% (2)

- GardeniaDokumen57 halamanGardeniaCris Diane G. Datingginoo50% (2)

- Quality ManagementDokumen2 halamanQuality ManagementCharity Venus100% (3)

- Gardenia ReportDokumen13 halamanGardenia ReportGoon Tsu Ying100% (1)

- Gardenia MarketingDokumen21 halamanGardenia Marketingmrmasha82% (95)

- Marketing Plan SURF & ARIELDokumen25 halamanMarketing Plan SURF & ARIELTabz Hussain100% (10)

- SWOT (Gardenia)Dokumen2 halamanSWOT (Gardenia)John Michael Antonio CuaBelum ada peringkat

- Gardenia Marketing Plan PDFDokumen33 halamanGardenia Marketing Plan PDFSittie Ainna A. UnteBelum ada peringkat

- Analyze The Gardenia in Porter Five Competitive ForcesDokumen7 halamanAnalyze The Gardenia in Porter Five Competitive ForcesChesca AlonBelum ada peringkat

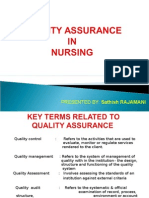

- Quality Assurance in Nursing: Presented by Mr. Migron Rubin M.Sc. Nursing Ist Year Pragyan College of NursingDokumen75 halamanQuality Assurance in Nursing: Presented by Mr. Migron Rubin M.Sc. Nursing Ist Year Pragyan College of Nursingsangeeta sharma100% (1)

- Goldilocks-All Bout GoldilocksDokumen13 halamanGoldilocks-All Bout GoldilocksCharisse Nhet Clemente64% (14)

- Customer Relationship Management EbookDokumen371 halamanCustomer Relationship Management EbookShubham kumar100% (3)

- Company Name: Gardenia Bakeries Phils., Inc. Company ProfileDokumen5 halamanCompany Name: Gardenia Bakeries Phils., Inc. Company ProfileJeric Israel0% (1)

- Gardenia PaperDokumen45 halamanGardenia PaperCris Diane G. Datingginoo100% (3)

- Plant VisitDokumen20 halamanPlant Visitandyaugustin67% (3)

- (Date) : School of Business and Social SciencesDokumen21 halaman(Date) : School of Business and Social SciencesRamko IlyasBelum ada peringkat

- Full Set of Marketing PlanDokumen50 halamanFull Set of Marketing Planren_temanku82% (17)

- TQMDokumen30 halamanTQMSrikanth Thandra50% (2)

- Bplan 100 Plus-Full FinalDokumen20 halamanBplan 100 Plus-Full FinalMagendren Raman80% (5)

- Unilever Quality Management ProcessDokumen3 halamanUnilever Quality Management Processdvs99100% (1)

- GardeniaDokumen17 halamanGardeniaMc Dowell Campang100% (1)

- Chapter 2 Managment History-1Dokumen26 halamanChapter 2 Managment History-1Husnain HaiderBelum ada peringkat

- Gardenia PhilippinesDokumen31 halamanGardenia PhilippinesLindsay Mercado100% (1)

- Gardenia - Case StudyDokumen17 halamanGardenia - Case StudyMac Itaralde67% (3)

- Gardenia Bakeries Philippines, IncDokumen33 halamanGardenia Bakeries Philippines, IncMarie Astrid Amboy42% (12)

- Quality Assurance in NursingDokumen17 halamanQuality Assurance in NursingSathish Rajamani88% (17)

- TQM Module 2Dokumen29 halamanTQM Module 2Maroma AllenBelum ada peringkat

- PESTL Analysis Yakult (Section B, Group 3)Dokumen13 halamanPESTL Analysis Yakult (Section B, Group 3)Ammar Al-kadhimiBelum ada peringkat

- Iso 15189Dokumen10 halamanIso 15189Ainun JariahBelum ada peringkat

- Strengths: I. Situational Analysis A. Swot/Tows AnalysisDokumen64 halamanStrengths: I. Situational Analysis A. Swot/Tows AnalysisAna Lovella Lubiano100% (9)

- Tracing Back Its History: Gardenia's Humble BeginningsDokumen15 halamanTracing Back Its History: Gardenia's Humble BeginningsErosBelum ada peringkat

- Manufacturing Process of Gardenia PhilippinesDokumen11 halamanManufacturing Process of Gardenia PhilippinesMic Baldevarona83% (6)

- Risk Management For Medical Devices and The New BS EN ISO 14971Dokumen25 halamanRisk Management For Medical Devices and The New BS EN ISO 14971Sandra Milena Sanabria BarreraBelum ada peringkat

- Integrated Marketing Communication and Strategies (SURF)Dokumen6 halamanIntegrated Marketing Communication and Strategies (SURF)Ray Alvin Red0% (1)

- MR DiyDokumen5 halamanMR DiyEiman Shaukat100% (1)

- Operation Management Assignment Gardenia ReportDokumen27 halamanOperation Management Assignment Gardenia ReportMaizul Deraman86% (7)

- ChatimeDokumen14 halamanChatimeAriff LuqmanBelum ada peringkat

- Survey Questionnaire For BSA GraduatesDokumen7 halamanSurvey Questionnaire For BSA Graduateslady chase100% (1)

- Gardenia DistributionDokumen6 halamanGardenia Distributiondharma0% (2)

- LOGISTICSDokumen16 halamanLOGISTICSAudrey Mina0% (1)

- Gardenia - Ad ResearchDokumen11 halamanGardenia - Ad ResearchBianca SalongaBelum ada peringkat

- Gardenia BreadsDokumen1 halamanGardenia BreadsSujith John McKumkal100% (1)

- Gardenia ProcessDokumen2 halamanGardenia ProcessJhun Michael LocusBelum ada peringkat

- Gardenia Bakeries Philippines IncDokumen33 halamanGardenia Bakeries Philippines IncTrisha CabralBelum ada peringkat

- Global Production and Sourcing : - The Case of Gardenia Bakery in South East AsiaDokumen6 halamanGlobal Production and Sourcing : - The Case of Gardenia Bakery in South East AsiainventionjournalsBelum ada peringkat

- History of Gardenia BakeiesDokumen2 halamanHistory of Gardenia BakeiesAxel Lee75% (12)

- Marketing PlanDokumen18 halamanMarketing PlanRose Putih0% (2)

- Gardenia Marketing PlanDokumen18 halamanGardenia Marketing PlanANA100% (2)

- Dunkin DonutsDokumen4 halamanDunkin DonutsKim Ericka BautistaBelum ada peringkat

- Chapter 3 Swot and Issues AnalysisDokumen7 halamanChapter 3 Swot and Issues AnalysisLina Ahmad100% (1)

- Gardenia Bakeries v2Dokumen5 halamanGardenia Bakeries v2lexsanchezBelum ada peringkat

- The Gardenia Brand BGHDokumen3 halamanThe Gardenia Brand BGHFranchesca Lyn Ometer100% (1)

- Term Project: Offered On The Shelves But Not Really Aware by Consumers. You HaveDokumen2 halamanTerm Project: Offered On The Shelves But Not Really Aware by Consumers. You HaveSyi Sya100% (1)

- MKW1120 - Assignment 2Dokumen10 halamanMKW1120 - Assignment 2angelaers100% (2)

- Gardenia Price List Nov. 2019Dokumen2 halamanGardenia Price List Nov. 2019jhanine davidBelum ada peringkat

- TQMDokumen8 halamanTQMNiña AlfonsoBelum ada peringkat

- The Magnolia Fresh Chicken StoryDokumen3 halamanThe Magnolia Fresh Chicken StoryAnnamaAnnamaBelum ada peringkat

- Report TPT 250 Mara LinerDokumen12 halamanReport TPT 250 Mara LinerMaznie HaninBelum ada peringkat

- Preventing Bread Waste - A National Success Story From TurkeyDokumen4 halamanPreventing Bread Waste - A National Success Story From TurkeyMilling and Grain magazineBelum ada peringkat

- Ajinomoto HistoryDokumen4 halamanAjinomoto HistoryMohd Izwan100% (1)

- The New Industry AnalysisDokumen174 halamanThe New Industry AnalysisAnonymous 5BnsCI2VjBelum ada peringkat

- Assinment MarketingDokumen3 halamanAssinment MarketingFarah Shahirah100% (1)

- FranchisingDokumen5 halamanFranchisingTwinkle TricksBelum ada peringkat

- Yakult: MKTG1199 - Marketing Principles Semester 1, 2014 Assessment: Marketing PlanDokumen19 halamanYakult: MKTG1199 - Marketing Principles Semester 1, 2014 Assessment: Marketing PlanDeepBelum ada peringkat

- Studymode GardemiaDokumen8 halamanStudymode GardemiaSittie Ainna A. UnteBelum ada peringkat

- Gardenia BakeriesDokumen4 halamanGardenia BakeriesRiza May VillanuevaBelum ada peringkat

- Introduction 1Dokumen1 halamanIntroduction 1kc.malimbanBelum ada peringkat

- Company Study (Gardenia)Dokumen39 halamanCompany Study (Gardenia)japcornelioBelum ada peringkat

- Castronuevo, Rogelio Iii - Tem Act. 3 MidtermDokumen10 halamanCastronuevo, Rogelio Iii - Tem Act. 3 Midtermit.rjcastronuevoBelum ada peringkat

- CH 7 AnswersDokumen5 halamanCH 7 Answersthenikkitr0% (1)

- Mahmuod Computer - 1547330540919Dokumen17 halamanMahmuod Computer - 1547330540919lady chaseBelum ada peringkat

- Facility Layout 5Dokumen36 halamanFacility Layout 5lady chaseBelum ada peringkat

- Ch14 Raiborn SMDokumen37 halamanCh14 Raiborn SMlady chaseBelum ada peringkat

- InertiaDokumen1 halamanInertialady chaseBelum ada peringkat

- AccrReqCPA Academe 4Dokumen1 halamanAccrReqCPA Academe 4mhilet_chiBelum ada peringkat

- 10 Train Tax Reform ItemsDokumen2 halaman10 Train Tax Reform Itemsian clark MarinduqueBelum ada peringkat

- Chapter7 BayDokumen18 halamanChapter7 BayJoreleen Marie AyuyaoBelum ada peringkat

- Proposed Context DiagramDokumen1 halamanProposed Context Diagramlady chaseBelum ada peringkat

- Continuing Professional Development: Annex CDokumen20 halamanContinuing Professional Development: Annex Clady chaseBelum ada peringkat

- Quantitative ResearchDokumen4 halamanQuantitative Researchlady chase100% (1)

- RR No. 5-2017Dokumen9 halamanRR No. 5-2017Mary Mae PeñafloridaBelum ada peringkat

- 10 Train Tax Reform ItemsDokumen2 halaman10 Train Tax Reform Itemsian clark MarinduqueBelum ada peringkat

- Mono and DicotDokumen3 halamanMono and Dicotlady chaseBelum ada peringkat

- Notre Dame of Midsayap College College of Criminal Justice Education Midsayap, CotabatoDokumen3 halamanNotre Dame of Midsayap College College of Criminal Justice Education Midsayap, Cotabatolady chaseBelum ada peringkat

- MAY 14, 2017 5:30pm at Barangay Bagolibas Covert Court, Aleosan, CotabatoDokumen1 halamanMAY 14, 2017 5:30pm at Barangay Bagolibas Covert Court, Aleosan, Cotabatolady chaseBelum ada peringkat

- Enron StoryDokumen6 halamanEnron Storylady chaseBelum ada peringkat

- QUIz MasDokumen1 halamanQUIz Maslady chaseBelum ada peringkat

- What Is 'Quantitative Analysis'Dokumen3 halamanWhat Is 'Quantitative Analysis'lady chaseBelum ada peringkat

- Quantitative ResearchlkjDokumen3 halamanQuantitative Researchlkjlady chaseBelum ada peringkat

- MAY 14, 2017 5:30pm at Barangay Bagolibas Covert Court, Aleosan, CotabatoDokumen1 halamanMAY 14, 2017 5:30pm at Barangay Bagolibas Covert Court, Aleosan, Cotabatolady chaseBelum ada peringkat

- A Businiss PlanDokumen5 halamanA Businiss Planlady chaseBelum ada peringkat

- RespDokumen3 halamanResplady chaseBelum ada peringkat

- Income Tax Return: Mansor GlangDokumen1 halamanIncome Tax Return: Mansor Glanglady chaseBelum ada peringkat

- BIO Respiratory SystemDokumen30 halamanBIO Respiratory Systemlady chaseBelum ada peringkat

- Section: The LimitDokumen12 halamanSection: The Limitlady chaseBelum ada peringkat

- Project ManagementDokumen48 halamanProject Managementlady chaseBelum ada peringkat

- 02 - Grade 4 Textbook For STAMEQ - EN PDFDokumen48 halaman02 - Grade 4 Textbook For STAMEQ - EN PDFThành Nam DươngBelum ada peringkat

- Total Quality Management in RMG SectorDokumen16 halamanTotal Quality Management in RMG SectorNurul Ahad SayemBelum ada peringkat

- F&B ManagementDokumen29 halamanF&B ManagementscotlandkamBelum ada peringkat

- Management Review Agenda TS 16949Dokumen2 halamanManagement Review Agenda TS 16949ArunBelum ada peringkat

- Chapter V-PM IT Project Managment Chapter 4 Reading Covered by YourselfDokumen48 halamanChapter V-PM IT Project Managment Chapter 4 Reading Covered by Yourselfalemneh bayehBelum ada peringkat

- Samples of Test Bank For Introduction To Managerial Accounting 5th Canadian Edition by Peter C. BrewerDokumen15 halamanSamples of Test Bank For Introduction To Managerial Accounting 5th Canadian Edition by Peter C. BrewerKeertimanSharmaBelum ada peringkat

- The Regional Municipality of York: RecommendationDokumen9 halamanThe Regional Municipality of York: Recommendationdas_joydebBelum ada peringkat

- Models Guidelines ShingoDokumen37 halamanModels Guidelines ShingoManel VazquezBelum ada peringkat

- 1 Day Training White Belt Arps 2021Dokumen178 halaman1 Day Training White Belt Arps 2021Muhammad ImronBelum ada peringkat

- Samsung Quality Handbook - QMS Model PDCA Cycle 2021Dokumen20 halamanSamsung Quality Handbook - QMS Model PDCA Cycle 2021Trung PhanBelum ada peringkat

- Answer KeyDokumen25 halamanAnswer KeyTojin T PanickerBelum ada peringkat

- 2 Research QuestionnaireDokumen6 halaman2 Research QuestionnaireP M NairBelum ada peringkat

- Project 1Dokumen25 halamanProject 1Pinto Joseph100% (1)

- IATF - Overview-Team BreakoutDokumen12 halamanIATF - Overview-Team BreakoutGREENEXE BUSINESS CONSULTANTBelum ada peringkat

- Chapter 10 - Total Quality Management (TQM)Dokumen16 halamanChapter 10 - Total Quality Management (TQM)m-1750311Belum ada peringkat

- Six Sigma Philosophy 1Dokumen3 halamanSix Sigma Philosophy 1Pranali S. SawantBelum ada peringkat

- U S Steel Tubular Products Standard and Line PipeDokumen69 halamanU S Steel Tubular Products Standard and Line PipeChaitanya Sai TBelum ada peringkat

- Ge6757 2m Rejinpaul IIDokumen38 halamanGe6757 2m Rejinpaul IIl8o8r8d8s8i8v8Belum ada peringkat

- Quality Manual: LORD Corporation Corporate Headquarters 111 Lord Drive P.O. Box 8012 Cary, North Carolina 27512-8012Dokumen42 halamanQuality Manual: LORD Corporation Corporate Headquarters 111 Lord Drive P.O. Box 8012 Cary, North Carolina 27512-8012Prakash kumarTripathiBelum ada peringkat