Esab, Coreshield 40 (275-En - US-FactSheet - Main-01) (26.10.16)

Diunggah oleh

RodrigoJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Esab, Coreshield 40 (275-En - US-FactSheet - Main-01) (26.10.16)

Diunggah oleh

RodrigoHak Cipta:

Format Tersedia

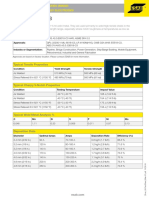

SELF-SHIELDED FLUX-CORED WIRES (FCAW)

MILD STEEL WIRES

Coreshield 40

Coreshield 40 is a self-shielded flux cored wire primarily designed for multiple pass, horizontal and flat position welding

of low and medium carbon steels when toughness is not a requirement. The larger sizes achieve very high deposit rates

for very low joining costs. The low penetration, convex fillet bead shape and ability for the slag to desulfurize the deposit

make it an ideal choice when crack resistance is a primary consideration. The flat position deposits are smooth and

uniform with good wetting into the side walls. The core ingredients are carefully balanced to stabilize the droplet transfer,

enhance the ability to handle mill scale and easily detach the slag for quick cleaning. Coreshield 40 is designed to operate

on DCEP (electrode positive) with longer electrical stickout. The longer extension increases the deposit potential by

preheating the wire.

Classifications: AWS A5.20:E70T-4, AWS A5.36:E70T4-Z-CS3, ASME SFA 5.20, ASME SFA 5.36

Industry or Segmentation: Railcars, Industrial and General Fabrication, Civil Construction

Typical Tensile Properties

Condition Yield Strength Tensile Strength Elongation

As Welded 430 MPa (62 ksi) 595 MPa (86 ksi) 29 %

Typical Weld Metal Analysis %

C Mn Si S P Al

0.20 0.30 0.30 0.007 0.012 1.30

Deposition Data

Diameter Amps Volts Wire Feed Speed Deposition Rate Efficiency

2.0 mm (5/64 in.) 220 A 27 V 305 cm/min (120 in./min) 2.7 kg/h (6 lb/h) 77 %

2.0 mm (5/64 in.) 300 A 28 V 452 cm/min (178 in./min) 4.26 kg/h (9.4 lb/h) 85 %

2.0 mm (5/64 in.) 400 A 29 V 584 cm/min (230 in./min) 5.26 kg/h (11.6 lb/h) 84 %

2.4 mm (3/32 in.) 350 A 28 V 498 cm/min (196 in./min) 6.26 kg/h (13.8 lb/h) 82 %

2.4 mm (3/32 in.) 375 A 29 V 539 cm/min (212 in./min) 6.85 kg/h (15.1 lb/h) 84 %

2.4 mm (3/32 in.) 400 A 30 V 582 cm/min (229 in./min) 7.3 kg/h (116.1 lb/h) 84 %

275-en_US-FactSheet_Main-01.pdf 10/26/16

esab.com

Anda mungkin juga menyukai

- Dual Shield II 70T-12H4: Gas-Shielded Flux-Cored Wires (Fcaw) Mild Steel WiresDokumen2 halamanDual Shield II 70T-12H4: Gas-Shielded Flux-Cored Wires (Fcaw) Mild Steel WiresPhilippe TrudelBelum ada peringkat

- Dual Shield II 101H4MDokumen2 halamanDual Shield II 101H4Madanmeneses1Belum ada peringkat

- Esab, Atom Arc 9018 (29-En - US-FactSheet - Main-01, 2016.10.26)Dokumen1 halamanEsab, Atom Arc 9018 (29-En - US-FactSheet - Main-01, 2016.10.26)RodrigoBelum ada peringkat

- Coreweld 70: Metal-Cored Wires (Mcaw) Mild Steel WiresDokumen2 halamanCoreweld 70: Metal-Cored Wires (Mcaw) Mild Steel WiresJerald GuevarraBelum ada peringkat

- Dual Shield 7100 Ultra: Gas-Shielded Flux-Cored Wires (Fcaw) Mild Steel WiresDokumen3 halamanDual Shield 7100 Ultra: Gas-Shielded Flux-Cored Wires (Fcaw) Mild Steel Wiresadanmeneses1Belum ada peringkat

- Electrodo Aws 7018-1 EsabDokumen1 halamanElectrodo Aws 7018-1 EsabHORACIOBelum ada peringkat

- Dual Shield 810X-NI1: Gas-Shielded Flux-Cored Wires (Fcaw) Low Alloy WiresDokumen2 halamanDual Shield 810X-NI1: Gas-Shielded Flux-Cored Wires (Fcaw) Low Alloy Wiresadanmeneses1Belum ada peringkat

- Dual Shiel Ii 101Dokumen2 halamanDual Shiel Ii 101Robin carcamoBelum ada peringkat

- Esab, Atom Arc 8018 (26-En - US-FactSheet - Main-01, 2016.10.26)Dokumen1 halamanEsab, Atom Arc 8018 (26-En - US-FactSheet - Main-01, 2016.10.26)RodrigoBelum ada peringkat

- Dual Shield II 101 1.6 MMDokumen2 halamanDual Shield II 101 1.6 MMadanmeneses1Belum ada peringkat

- Esab, Dual Shield 810X Ni1 (248 en - US FactSheet - Main 01)Dokumen2 halamanEsab, Dual Shield 810X Ni1 (248 en - US FactSheet - Main 01)RodrigoBelum ada peringkat

- Dual Shield 710X: Gas-Shielded Flux-Cored Wires (Fcaw) Mild Steel WiresDokumen3 halamanDual Shield 710X: Gas-Shielded Flux-Cored Wires (Fcaw) Mild Steel WiresPhilippe TrudelBelum ada peringkat

- Dual Shield II 81-K2: Gas-Shielded Flux-Cored Wires (Fcaw) Low Alloy WiresDokumen2 halamanDual Shield II 81-K2: Gas-Shielded Flux-Cored Wires (Fcaw) Low Alloy WiresMOhammed PatelBelum ada peringkat

- Atom Arc 7018: Covered (Stick) Electrodes (Smaw) Low Hydrogen ElectrodesDokumen2 halamanAtom Arc 7018: Covered (Stick) Electrodes (Smaw) Low Hydrogen ElectrodesKrishna VachaBelum ada peringkat

- Atom Arc 7018-B2L: Typical Tensile PropertiesDokumen1 halamanAtom Arc 7018-B2L: Typical Tensile PropertiesPubcrawlBelum ada peringkat

- ESAB Filler Metal GuideDokumen1 halamanESAB Filler Metal GuidekapsarcBelum ada peringkat

- FICHADokumen2 halamanFICHAadmisecoinperuBelum ada peringkat

- Atom Arc 8018Dokumen2 halamanAtom Arc 8018Jagan TnBelum ada peringkat

- Atom Arc 7018-1: Covered (Stick) Electrodes (Smaw) Low Hydrogen ElectrodesDokumen2 halamanAtom Arc 7018-1: Covered (Stick) Electrodes (Smaw) Low Hydrogen ElectrodesFranklin Aranda ChacónBelum ada peringkat

- Esab, Dual Shield II 110 (265-En - US-FactSheet - Main-01) (26.10.16)Dokumen2 halamanEsab, Dual Shield II 110 (265-En - US-FactSheet - Main-01) (26.10.16)RodrigoBelum ada peringkat

- 274 en - US FactSheet - Main 01Dokumen2 halaman274 en - US FactSheet - Main 01Luisa FernandaBelum ada peringkat

- Dual Shield T-115: Gas-Shielded Flux-Cored Wires (Fcaw) Low Alloy WiresDokumen2 halamanDual Shield T-115: Gas-Shielded Flux-Cored Wires (Fcaw) Low Alloy WiresPEPITO GRILLO2Belum ada peringkat

- Tech Data Sheet: Dual Shield T-115Dokumen3 halamanTech Data Sheet: Dual Shield T-115carlosBelum ada peringkat

- 278 en US FactSheet Main 01Dokumen1 halaman278 en US FactSheet Main 01Jorge Manuel GuillermoBelum ada peringkat

- Dual Shield 7100 Ultra: Typical Tensile PropertiesDokumen3 halamanDual Shield 7100 Ultra: Typical Tensile PropertiesDino Paul Castro HidalgoBelum ada peringkat

- Sureweld 6010: Covered (Stick) Electrodes (Smaw) Mild Steel ElectrodesDokumen1 halamanSureweld 6010: Covered (Stick) Electrodes (Smaw) Mild Steel ElectrodesGibbs PerBelum ada peringkat

- Covered (Stick) Electrodes (SMAW)Dokumen5 halamanCovered (Stick) Electrodes (SMAW)Hanny Dewi SaragihBelum ada peringkat

- COR-1076C Coreweld Brochure 141118Dokumen28 halamanCOR-1076C Coreweld Brochure 141118Thanh TamBelum ada peringkat

- OK Autrod 2209: Typical Tensile PropertiesDokumen1 halamanOK Autrod 2209: Typical Tensile PropertiesjavadmohammadiBelum ada peringkat

- Dual Shield T-75: Typical Tensile PropertiesDokumen2 halamanDual Shield T-75: Typical Tensile PropertiescfloresBelum ada peringkat

- Tech Data Sheet: DUAL SHIELD 8000-Ni2Dokumen3 halamanTech Data Sheet: DUAL SHIELD 8000-Ni2carlosBelum ada peringkat

- OK Weartrode 30: Covered (Stick) Electrodes (Smaw) Hardfacing ElectrodesDokumen1 halamanOK Weartrode 30: Covered (Stick) Electrodes (Smaw) Hardfacing Electrodesraghubhaimantra4136Belum ada peringkat

- Tech Data Sheet: Dual Shield Ii 100-D1Dokumen3 halamanTech Data Sheet: Dual Shield Ii 100-D1carlosBelum ada peringkat

- Esab, Dual Shield T-115 (24!02!17, 266-En - US-FactSheet - Main-01)Dokumen2 halamanEsab, Dual Shield T-115 (24!02!17, 266-En - US-FactSheet - Main-01)RodrigoBelum ada peringkat

- Innershield NS-3M: Welding Positions Key FeaturesDokumen2 halamanInnershield NS-3M: Welding Positions Key FeaturesGiancarlo BlandinoBelum ada peringkat

- Pipeweld 6010 Plus: Covered (Stick) Electrodes (Smaw) Mild Steel ElectrodesDokumen1 halamanPipeweld 6010 Plus: Covered (Stick) Electrodes (Smaw) Mild Steel ElectrodesRys Multiventas SacBelum ada peringkat

- CSF-71T Technical Report EN - V2Dokumen7 halamanCSF-71T Technical Report EN - V2Miroslav ThôngBelum ada peringkat

- Esab Welding RodDokumen1 halamanEsab Welding Rodv ictor manuel MunozBelum ada peringkat

- Saudi Cable Catalogue - Low VoltageDokumen1 halamanSaudi Cable Catalogue - Low VoltageMd SaquibBelum ada peringkat

- Metalshield Clarity MC - 707: Conformances Key FeaturesDokumen2 halamanMetalshield Clarity MC - 707: Conformances Key FeaturesRumman Ul AhsanBelum ada peringkat

- Glaistytieji Elektrodai (Smaw) Žemos Vandenilio Jonų Koncentracijos ElektrodaiDokumen2 halamanGlaistytieji Elektrodai (Smaw) Žemos Vandenilio Jonų Koncentracijos ElektrodaiKiranBelum ada peringkat

- Dual Shield 7100 LC PDFDokumen3 halamanDual Shield 7100 LC PDFNicolas MaximilianoBelum ada peringkat

- Fy 19Dokumen11 halamanFy 19angattiBelum ada peringkat

- ITC Catalog25Dokumen108 halamanITC Catalog25ariadi supriyantoBelum ada peringkat

- Data Sheet Acss TW Dove (Ma3)Dokumen1 halamanData Sheet Acss TW Dove (Ma3)kjkljkljlkjljlkBelum ada peringkat

- SFTPreal10 Cat6A 6x4p Loom 650MHz AWG26Dokumen2 halamanSFTPreal10 Cat6A 6x4p Loom 650MHz AWG26Slobodan ĐenićBelum ada peringkat

- Shield Bright 309L-1Dokumen1 halamanShield Bright 309L-1adanmeneses1Belum ada peringkat

- ESB 255051815 SpecSheetDokumen2 halamanESB 255051815 SpecSheetanupmenon menonBelum ada peringkat

- HUATONG ESP CableDokumen18 halamanHUATONG ESP CableSIMON S. FLORES G.100% (1)

- Covered (Stick) Electrodes (Smaw) Low Hydrogen Electrodes: Typical Tensile PropertiesDokumen1 halamanCovered (Stick) Electrodes (Smaw) Low Hydrogen Electrodes: Typical Tensile PropertiesKrishna VachaBelum ada peringkat

- Main GirderDokumen5 halamanMain GirderkkgcBelum ada peringkat

- Dyadic Systems SCN6 40kgfDokumen1 halamanDyadic Systems SCN6 40kgfServo2GoBelum ada peringkat

- Covered (Stick) Electrodes (Smaw) Mild Steel Electrodes: Typical Tensile PropertiesDokumen1 halamanCovered (Stick) Electrodes (Smaw) Mild Steel Electrodes: Typical Tensile PropertiesKannan MurugesanBelum ada peringkat

- Welding Generators MPMDokumen1 halamanWelding Generators MPMLucioBelum ada peringkat

- ESAB Dual Shield 7100 UltraDokumen3 halamanESAB Dual Shield 7100 UltrahaldunBelum ada peringkat

- TDS Al XLPE SWA PVC - NA2XRYDokumen3 halamanTDS Al XLPE SWA PVC - NA2XRYvsumedhaBelum ada peringkat

- Covered (Stick) Electrodes (Smaw) Low Hydrogen ElectrodesDokumen2 halamanCovered (Stick) Electrodes (Smaw) Low Hydrogen Electrodesdarmawan listyonoBelum ada peringkat

- Atom Arc 8018: Features Typical Mechanical PropertiesDokumen2 halamanAtom Arc 8018: Features Typical Mechanical PropertiesFranklin Aranda ChacónBelum ada peringkat

- A 906 - A 906m - 99 - Qtkwni9bota2ts1sruqDokumen8 halamanA 906 - A 906m - 99 - Qtkwni9bota2ts1sruqZam DresBelum ada peringkat

- Zeron 100 Brochure Rolled AlloysDokumen8 halamanZeron 100 Brochure Rolled AlloysRodrigoBelum ada peringkat

- Beyond A1 Plus SB Unit 8 SML PDFDokumen11 halamanBeyond A1 Plus SB Unit 8 SML PDFAlex Rödriguez R50% (2)

- Lincoln, Tech-Rod ® 99 (c141022)Dokumen2 halamanLincoln, Tech-Rod ® 99 (c141022)RodrigoBelum ada peringkat

- Lincoln, TECHALLOY® 606 (c14107)Dokumen2 halamanLincoln, TECHALLOY® 606 (c14107)RodrigoBelum ada peringkat

- Unibraze Er80s-B2 (Tig)Dokumen1 halamanUnibraze Er80s-B2 (Tig)RodrigoBelum ada peringkat

- Lincoln, Superarc LA-90Dokumen2 halamanLincoln, Superarc LA-90RodrigoBelum ada peringkat

- 2015 KOBELCO Defect PDFDokumen25 halaman2015 KOBELCO Defect PDFayushBelum ada peringkat

- Steel Castings, Carbon, For General ApplicationDokumen4 halamanSteel Castings, Carbon, For General ApplicationJuan Carlos Chura QuispeBelum ada peringkat

- Espesificaciones de MaterialesDokumen2 halamanEspesificaciones de MaterialesDanyAlex GarciaBelum ada peringkat

- Lincoln GMAW Welding GuideDokumen96 halamanLincoln GMAW Welding GuideМич БјукенонBelum ada peringkat

- Essential Factors in Gas Shielded Metal Arc Welding GMAW - 5edDokumen33 halamanEssential Factors in Gas Shielded Metal Arc Welding GMAW - 5edCarlo MonsalveBelum ada peringkat

- Verticalshrouds Proteccion VerticalDokumen4 halamanVerticalshrouds Proteccion VerticalRodrigoBelum ada peringkat

- ABC 5edDokumen93 halamanABC 5edJuan Diego Garcia EsquenBelum ada peringkat

- Dual Shield 7100 Ultra: Typical Tensile PropertiesDokumen3 halamanDual Shield 7100 Ultra: Typical Tensile PropertiesDino Paul Castro HidalgoBelum ada peringkat

- Esab, OK Autrod 12.10 (A345311)Dokumen1 halamanEsab, OK Autrod 12.10 (A345311)RodrigoBelum ada peringkat

- Esab, OK Flux 10.71 (30.06.16), 420014-En - US-FactSheet - Main-01Dokumen2 halamanEsab, OK Flux 10.71 (30.06.16), 420014-En - US-FactSheet - Main-01RodrigoBelum ada peringkat

- Esab, Dual Shield T-115 (24!02!17, 266-En - US-FactSheet - Main-01)Dokumen2 halamanEsab, Dual Shield T-115 (24!02!17, 266-En - US-FactSheet - Main-01)RodrigoBelum ada peringkat

- Esab, OK Autrod 12.10 (A345311)Dokumen1 halamanEsab, OK Autrod 12.10 (A345311)RodrigoBelum ada peringkat

- Esab, OK Autrod 12.22 (1222252800)Dokumen1 halamanEsab, OK Autrod 12.22 (1222252800)RodrigoBelum ada peringkat

- Dual Shield 7100 Ultra: Typical Tensile PropertiesDokumen3 halamanDual Shield 7100 Ultra: Typical Tensile PropertiesDino Paul Castro HidalgoBelum ada peringkat

- Esab, Dual Shield 810X Ni1 (248 en - US FactSheet - Main 01)Dokumen2 halamanEsab, Dual Shield 810X Ni1 (248 en - US FactSheet - Main 01)RodrigoBelum ada peringkat

- Esab, Dual Shield II 110 (265-En - US-FactSheet - Main-01) (26.10.16)Dokumen2 halamanEsab, Dual Shield II 110 (265-En - US-FactSheet - Main-01) (26.10.16)RodrigoBelum ada peringkat

- Esab, OK Flux 10.71 (30.06.16), 420014-En - US-FactSheet - Main-01Dokumen2 halamanEsab, OK Flux 10.71 (30.06.16), 420014-En - US-FactSheet - Main-01RodrigoBelum ada peringkat

- Esab, Atom Arc 8018 (26-En - US-FactSheet - Main-01, 2016.10.26)Dokumen1 halamanEsab, Atom Arc 8018 (26-En - US-FactSheet - Main-01, 2016.10.26)RodrigoBelum ada peringkat

- Hobart, Hoballoy - 8018b2 (Aws E8018-B2 h4r)Dokumen2 halamanHobart, Hoballoy - 8018b2 (Aws E8018-B2 h4r)RodrigoBelum ada peringkat

- Esab, OK Tigrod NiCr-3 (21.06.16) (411170-En - US-FactSheet - Main-01)Dokumen1 halamanEsab, OK Tigrod NiCr-3 (21.06.16) (411170-En - US-FactSheet - Main-01)RodrigoBelum ada peringkat

- Fillet Weld DesignDokumen2 halamanFillet Weld Designsaj0205037Belum ada peringkat

- Portafolio SoldDokumen1 halamanPortafolio SoldRodrigoBelum ada peringkat

- EML2322L-Abrasive Water Jet ProcessesDokumen16 halamanEML2322L-Abrasive Water Jet ProcessesTurgut GülmezBelum ada peringkat

- List of PracticalsDokumen5 halamanList of PracticalsSakil K SBelum ada peringkat

- E Beam WeldingDokumen2 halamanE Beam WeldingDhilip DanielBelum ada peringkat

- Reballing ProfilesDokumen1 halamanReballing Profilesnerea_giordano75% (4)

- Ri-670-23 Gloss Silver Asp8aDokumen1 halamanRi-670-23 Gloss Silver Asp8aSergio PluchinskyBelum ada peringkat

- Concrete TechnologyDokumen14 halamanConcrete TechnologyShraddha DateyBelum ada peringkat

- Thread Types - James Glen PDFDokumen7 halamanThread Types - James Glen PDFVikranth ReddyBelum ada peringkat

- Chemical Mechanical PolishingDokumen18 halamanChemical Mechanical PolishingSuryaBelum ada peringkat

- Nitoseal Pu280 (Sealant)Dokumen2 halamanNitoseal Pu280 (Sealant)Kris SiregarBelum ada peringkat

- Quality Control Plan: Project: BourseDokumen4 halamanQuality Control Plan: Project: Bourseroekyat hendrawanBelum ada peringkat

- 2014 21 WoodturningDokumen38 halaman2014 21 WoodturningfrannetoBelum ada peringkat

- Alfa Laval Product Leaflet Aldec enDokumen4 halamanAlfa Laval Product Leaflet Aldec enmuhammadariBelum ada peringkat

- TSB 20230830 - New Launch Lifelong SATT WM - Technical DetailsDokumen7 halamanTSB 20230830 - New Launch Lifelong SATT WM - Technical DetailsNavjot KaurBelum ada peringkat

- How To Build An Outdoor Lounge ChairDokumen11 halamanHow To Build An Outdoor Lounge ChairJ MartinBelum ada peringkat

- Aerosols: High Performance SpraysDokumen2 halamanAerosols: High Performance SpraysKhaldoun BayazidBelum ada peringkat

- VGO HydrocrackingDokumen14 halamanVGO HydrocrackingAndy DolmanBelum ada peringkat

- Organic Chem: RecrystallizationDokumen4 halamanOrganic Chem: RecrystallizationpaoloBelum ada peringkat

- 8F1.BG01 ZSSW 40057364 LV008 0Dokumen1 halaman8F1.BG01 ZSSW 40057364 LV008 0maquinascarlosBelum ada peringkat

- Electrochemistry of CorrosionDokumen19 halamanElectrochemistry of CorrosionElambarithi KalyanakumarBelum ada peringkat

- MIL-DTL-5541 Rev F - Part1Dokumen1 halamanMIL-DTL-5541 Rev F - Part1David WongBelum ada peringkat

- WPS AWS TemplateDokumen3 halamanWPS AWS TemplateMohd SaffririzalBelum ada peringkat

- Pickling Tubing StringsDokumen3 halamanPickling Tubing StringsHuong Viet100% (1)

- DS - 752-Rev01 - Epilux 485 HB IntermediateDokumen2 halamanDS - 752-Rev01 - Epilux 485 HB IntermediatePammy JainBelum ada peringkat

- Kerosene Leak TestDokumen4 halamanKerosene Leak Testskc50% (2)

- InvoisDokumen54 halamanInvoisAnonymous Ff1qA9RLCBelum ada peringkat

- Plastering: Presented byDokumen18 halamanPlastering: Presented byVighnesh MalagiBelum ada peringkat

- Catalyst HandBook - Second Edition - JMDokumen290 halamanCatalyst HandBook - Second Edition - JMAhmed NagyBelum ada peringkat

- By Product PlantDokumen6 halamanBy Product PlantRajan BhandariBelum ada peringkat

- Logan Fishing Bumper Sub (English)Dokumen26 halamanLogan Fishing Bumper Sub (English)Gianfranco Exequiel Sebastian GarciaBelum ada peringkat

- Meijer Grand Chute Building Packages BiddersDokumen33 halamanMeijer Grand Chute Building Packages BiddersAlex RayBelum ada peringkat