4330V Nickel-Molybdenum-Vanadium Through Hardening Steel - Hillfoot Multi Metals

Diunggah oleh

idontlikeebooksDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

4330V Nickel-Molybdenum-Vanadium Through Hardening Steel - Hillfoot Multi Metals

Diunggah oleh

idontlikeebooksHak Cipta:

Format Tersedia

MATERIAL DATASHEET

Title:

4330Vmod

Material Grade: 4330Vmod

Material Condition(s): Untreated / Annealed / Quench and tempered (optionally also Stress Relieved)

Surface Finish: As rolled / As forged / Bright turned

Associated Standard: ASTM A29

ASTM A322

Description:

A through hardening steel capable of very high strengths in large sections from hardening and tempering

treatments due to its high hardenability. It is typically used for drilling parts where longer tool life and higher

strength is required than conventional 4145. However, it does not meet the approval of NACE MR0175 due to its

high nickel content.

The relatively low carbon making this grade useful for applications involving shock loading or stress

concentrations, and where good fracture toughness is required. It can be welded, however preheating and post-

weld heat treatment are desirable to prevent cracking. Good forgability is also demonstrated but preheating and

furnace cooling are recommended due to its high hardenability.

Typical applications: Subs, crossovers, reamers, drill shoes, drill jars, tools

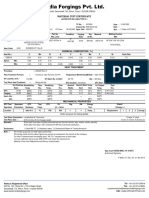

1. STEELMAKING

Method/ Refining: Electric Arc Furnace / Basic Oxygen Furnace followed by VDG

Grain Size: 5-8

Min. reduction ratio: 4:1 min (typically 3:1 on sections > 300mm)

C Si Mn S P Cr Ni* Mo V Al Cu Sn

Min 0.30 0.15 0.75 0.8 1.7 0.40 0.05 0.01

Max 0.33 0.35 1.00 0.010 0.015 1.0 2.0 0.65 0.10 0.04 0.35 0.035

* Ni content is often modified to 1.7-3.0 to ensure greater hardenability

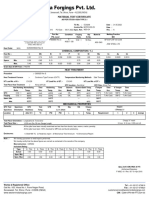

2. TYPICAL MECHANICAL PROPERTIES

Tensile and hardness test (at room temperature) Impact test (KV)

Test type Yield 0.2 % UTS Elong R of A

Hardness RT -20°C

(Re) proof (Rm) (A) (Z)

Variation Sample dia Unit KSI KSI KSI % % HB J J

Min 150 165 15 50 341 54 40

4330V + QT 150mm

Max 372

Min 150 160 13 35 319 54

4330V + QT 320mm

Max 390

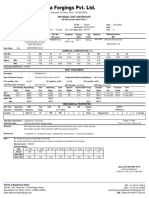

3. INSPECTION

NDT procedure: ASTM A388/A388M

Acceptance Standard API 6A PSL Level 3

Tel: 0114 233 1133 www.hillfoot.com

Anda mungkin juga menyukai

- MIL-H-6875H Heat Treatment of SteelDokumen29 halamanMIL-H-6875H Heat Treatment of Steelgoathead61Belum ada peringkat

- HOLE TYPE IQI (Penetrameter)Dokumen5 halamanHOLE TYPE IQI (Penetrameter)Eswar Enterprises Qc100% (1)

- A1031A1031M-12 Standard Specification For Steel, Sheet and Strip, Heavy-Thickness Coils, Alloy, Drawing Steel and Structural Steel, Hot-RolledDokumen5 halamanA1031A1031M-12 Standard Specification For Steel, Sheet and Strip, Heavy-Thickness Coils, Alloy, Drawing Steel and Structural Steel, Hot-Rolledtjt4779Belum ada peringkat

- General Requirements For Copper Alloy CastingsDokumen6 halamanGeneral Requirements For Copper Alloy CastingsLC ChongBelum ada peringkat

- Avoiding Fretting Corrosion by Design PDFDokumen4 halamanAvoiding Fretting Corrosion by Design PDFHalil İbrahim KüplüBelum ada peringkat

- ASTM-A108-07 Standard Specification For Steel Bar Carbon and Alloy Cold-Finished1 PDFDokumen7 halamanASTM-A108-07 Standard Specification For Steel Bar Carbon and Alloy Cold-Finished1 PDFCarlos Sanchez MarinBelum ada peringkat

- Sound Insulation - NRCDokumen372 halamanSound Insulation - NRCKhader Abu-daggaBelum ada peringkat

- Metallurgical Changes in Steels Due To Cryogenic Processing Its Applications Full ReportDokumen15 halamanMetallurgical Changes in Steels Due To Cryogenic Processing Its Applications Full ReportABHI THAKKAR100% (1)

- B214 07 (2011)Dokumen4 halamanB214 07 (2011)diego rodriguezBelum ada peringkat

- KL UHP Catalog 2011-02 PDFDokumen30 halamanKL UHP Catalog 2011-02 PDFaconibet9040Belum ada peringkat

- ASTM-A-325-02 Standard Specification For Structural Bolts. Steel, Heat Treated, 120 - 105 Ksi Minimum Tensile Strength PDFDokumen8 halamanASTM-A-325-02 Standard Specification For Structural Bolts. Steel, Heat Treated, 120 - 105 Ksi Minimum Tensile Strength PDFFattahi KarimBelum ada peringkat

- Dimensions of Weld Neck Flanges and Stud Bolts ASME B16.5 NPS 3Dokumen1 halamanDimensions of Weld Neck Flanges and Stud Bolts ASME B16.5 NPS 3Hanafi MansorBelum ada peringkat

- Acoples TB Wood SDokumen100 halamanAcoples TB Wood SLuis CastrovillariBelum ada peringkat

- ASME P NumbersDokumen2 halamanASME P NumbersArjun RawatBelum ada peringkat

- 55 Aluminum-Zinc Alloy Coated Steel Technical Bulletin 6 - Cut Edge Protection v20153Dokumen2 halaman55 Aluminum-Zinc Alloy Coated Steel Technical Bulletin 6 - Cut Edge Protection v20153Syed Raja AdeelBelum ada peringkat

- A470 99 PDFDokumen6 halamanA470 99 PDFJohano Araújo100% (1)

- American Fastener - ASTM, SAE, and ISO Grade Markings Bolt SpecificationDokumen8 halamanAmerican Fastener - ASTM, SAE, and ISO Grade Markings Bolt Specificationamir_hossein858Belum ada peringkat

- Tata Motors PCBUDokumen42 halamanTata Motors PCBUGirish Sp100% (1)

- Devmat 108: Product Description Specification DataDokumen2 halamanDevmat 108: Product Description Specification DataFlor Handal VarelaBelum ada peringkat

- Guidelines For Evaluating Aging Penstocks (Book, 1995) (WorldCat - Org)Dokumen2 halamanGuidelines For Evaluating Aging Penstocks (Book, 1995) (WorldCat - Org)rshegdeBelum ada peringkat

- DS 099 Rev01 Zinc Anode 304 MZDokumen2 halamanDS 099 Rev01 Zinc Anode 304 MZsojeckBelum ada peringkat

- Choosing The Right Conformal Coating The Facts & MythsDokumen4 halamanChoosing The Right Conformal Coating The Facts & Mythssdfdfs7253Belum ada peringkat

- Ni Resist and Ductile Ni Resist Alloys 11018Dokumen40 halamanNi Resist and Ductile Ni Resist Alloys 11018Prasad Aher100% (1)

- Durham Foundry NiResistDokumen1 halamanDurham Foundry NiResistTerminatorX75Belum ada peringkat

- Understanding DecarburizationDokumen6 halamanUnderstanding Decarburizationoquintero990% (1)

- Alternatives For Hot Metal Production - Cupola, Induction and Arc FurnaceDokumen27 halamanAlternatives For Hot Metal Production - Cupola, Induction and Arc FurnaceJorge Madias100% (1)

- Astm IndexDokumen30 halamanAstm IndexAnshul JainBelum ada peringkat

- Astm B344-01Dokumen3 halamanAstm B344-01Srinivasan KrishnamoorthyBelum ada peringkat

- Inconel 718 Alloy 718 Uns n07718 Din 2.4668Dokumen3 halamanInconel 718 Alloy 718 Uns n07718 Din 2.4668SamkitBelum ada peringkat

- Using Hand Micrometers To Measure The Thickness of Uncoated Steel Sheet and Nonmetallic and Metallic-Coated Steel SheetDokumen4 halamanUsing Hand Micrometers To Measure The Thickness of Uncoated Steel Sheet and Nonmetallic and Metallic-Coated Steel SheetDanZel Dan100% (1)

- 03 Automatic Submerged Arc Welding Air Liquide Welding 5347173341045849449Dokumen14 halaman03 Automatic Submerged Arc Welding Air Liquide Welding 5347173341045849449daemsal100% (1)

- Gear & Design Gearbox DJSDokumen12 halamanGear & Design Gearbox DJSAnonymous z4Fe39jBelum ada peringkat

- Copper Alloy Guide EnglishDokumen2 halamanCopper Alloy Guide Englishdesc82Belum ada peringkat

- High-Strength Low-Alloy Structural Steel With 50 Ksi (345 Mpa) Minimum Yield Point To 4 In. (100 MM) ThickDokumen2 halamanHigh-Strength Low-Alloy Structural Steel With 50 Ksi (345 Mpa) Minimum Yield Point To 4 In. (100 MM) ThickSadashiva sahooBelum ada peringkat

- NCh2369.Of2003 (English April 25 2005) Seismic Design of Industrial Struct and FacilDokumen131 halamanNCh2369.Of2003 (English April 25 2005) Seismic Design of Industrial Struct and FaciliagpconceBelum ada peringkat

- Astm A240 Uns S32205Dokumen3 halamanAstm A240 Uns S32205Mintone Sajayah BekabekaBelum ada peringkat

- FAQ Processes For Surface Hardening of Stainless Steels Bodycote S3PDokumen4 halamanFAQ Processes For Surface Hardening of Stainless Steels Bodycote S3PSinan YıldızBelum ada peringkat

- SFD Aisc 360 05Dokumen200 halamanSFD Aisc 360 05Anacarina MagoBelum ada peringkat

- Steel Selection CriteriaDokumen34 halamanSteel Selection CriteriaAcharya KrishnanandaBelum ada peringkat

- Technology Development For Hardfacing ofDokumen2 halamanTechnology Development For Hardfacing ofabraham silva hernandezBelum ada peringkat

- Aluminum 2024 T6Dokumen4 halamanAluminum 2024 T6Thiru Kumaran0% (1)

- Res Q SteelDokumen4 halamanRes Q SteelTrịnh Minh KhoaBelum ada peringkat

- Corrosion of Metals Associated With Wood PDFDokumen6 halamanCorrosion of Metals Associated With Wood PDFPaul Dan OctavianBelum ada peringkat

- Timken Practical Data For MetallurgistsDokumen154 halamanTimken Practical Data For Metallurgistsbobbutts2142Belum ada peringkat

- 4140 30-36HRc Chromium-Molybdenum Through Hardening Steel - Hillfoot Multi Metals PDFDokumen1 halaman4140 30-36HRc Chromium-Molybdenum Through Hardening Steel - Hillfoot Multi Metals PDFHeri Fadli SinagaBelum ada peringkat

- 4140 30-36HRc Chromium-Molybdenum Through Hardening Steel - Hillfoot Multi Metals PDFDokumen1 halaman4140 30-36HRc Chromium-Molybdenum Through Hardening Steel - Hillfoot Multi Metals PDFHeri Fadli SinagaBelum ada peringkat

- 1900 - EC2157-signedDokumen4 halaman1900 - EC2157-signedDeepak HoleBelum ada peringkat

- 1300 EC2192 SignedDokumen4 halaman1300 EC2192 SignedDeepak HoleBelum ada peringkat

- 42CrMo4 Chromium-Molybdenum Through Hardening Steel - Hillfoot Multi Metals PDFDokumen1 halaman42CrMo4 Chromium-Molybdenum Through Hardening Steel - Hillfoot Multi Metals PDFSantosh KumarBelum ada peringkat

- 1466 - Ec0044Dokumen5 halaman1466 - Ec0044Deipak HoleBelum ada peringkat

- 1485 - Ec0251Dokumen6 halaman1485 - Ec0251Deepak HoleBelum ada peringkat

- 1485 - Ec0234Dokumen5 halaman1485 - Ec0234Deepak HoleBelum ada peringkat

- 1485 - Ec0216Dokumen6 halaman1485 - Ec0216Deepak HoleBelum ada peringkat

- 1299 - Ec0583Dokumen5 halaman1299 - Ec0583Deipak HoleBelum ada peringkat

- 1485 - Ec0208Dokumen5 halaman1485 - Ec0208Deepak HoleBelum ada peringkat

- 1485 - Ec0231Dokumen6 halaman1485 - Ec0231Deepak HoleBelum ada peringkat

- L1 34264 en T Thermanit MTS 3 Se en v2Dokumen1 halamanL1 34264 en T Thermanit MTS 3 Se en v2Enrique MurgiaBelum ada peringkat

- 1591 EC2213 SignedDokumen5 halaman1591 EC2213 SignedDeepak HoleBelum ada peringkat

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsDari EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsBelum ada peringkat

- Materials Data for Cyclic Loading: Low-Alloy SteelsDari EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsPenilaian: 5 dari 5 bintang5/5 (2)

- Water Safety Risk Assessment Guide v1.0Dokumen4 halamanWater Safety Risk Assessment Guide v1.0idontlikeebooksBelum ada peringkat

- NL48Dokumen1 halamanNL48idontlikeebooksBelum ada peringkat

- Gold Medallion Assessors Guide v1.2 2023Dokumen9 halamanGold Medallion Assessors Guide v1.2 2023idontlikeebooksBelum ada peringkat

- Bronze Medallion (BM) Theory Questions (Assessment Task 1)Dokumen23 halamanBronze Medallion (BM) Theory Questions (Assessment Task 1)idontlikeebooksBelum ada peringkat

- Psar35 m5 Rescue V December 2022Dokumen37 halamanPsar35 m5 Rescue V December 2022idontlikeebooksBelum ada peringkat

- 2023 State Age Championships Final Event Information 1Dokumen10 halaman2023 State Age Championships Final Event Information 1idontlikeebooksBelum ada peringkat

- Lime Slaking 101 Whitepaper 4-06-22Dokumen8 halamanLime Slaking 101 Whitepaper 4-06-22idontlikeebooksBelum ada peringkat

- AISI Type W2 Tool Steel, Water Quenched at 775°C (1425°F), and TemperedDokumen2 halamanAISI Type W2 Tool Steel, Water Quenched at 775°C (1425°F), and TemperedidontlikeebooksBelum ada peringkat

- STT Vertimill Retrofit 03282022Dokumen2 halamanSTT Vertimill Retrofit 03282022idontlikeebooksBelum ada peringkat

- Memo 2023 Age Championships Water Safety RosterDokumen3 halamanMemo 2023 Age Championships Water Safety RosteridontlikeebooksBelum ada peringkat

- Pulp & PaperDokumen18 halamanPulp & PaperidontlikeebooksBelum ada peringkat

- ITP - Frames 63 To 355 Low VoltageDokumen5 halamanITP - Frames 63 To 355 Low VoltageidontlikeebooksBelum ada peringkat

- TeSys Giga Contactors - LC1G225KUENDokumen5 halamanTeSys Giga Contactors - LC1G225KUENidontlikeebooksBelum ada peringkat

- WEG Indústrias S.A.: Performance Curves Related To SpeedDokumen1 halamanWEG Indústrias S.A.: Performance Curves Related To SpeedidontlikeebooksBelum ada peringkat

- Itp - HV MotorsDokumen5 halamanItp - HV MotorsidontlikeebooksBelum ada peringkat

- ITP - AutomationDokumen43 halamanITP - AutomationidontlikeebooksBelum ada peringkat

- WEG Application Book 261 Brochure EnglishDokumen33 halamanWEG Application Book 261 Brochure EnglishidontlikeebooksBelum ada peringkat

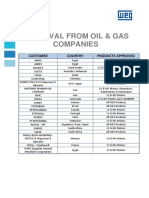

- Oil & Gas - Reference ListDokumen1 halamanOil & Gas - Reference ListidontlikeebooksBelum ada peringkat

- Synchronous Motors - Reference ListDokumen2 halamanSynchronous Motors - Reference ListidontlikeebooksBelum ada peringkat

- Synchronous Machines - Reference ListDokumen6 halamanSynchronous Machines - Reference ListidontlikeebooksBelum ada peringkat

- Turbogenerators - Reference ListDokumen12 halamanTurbogenerators - Reference ListidontlikeebooksBelum ada peringkat

- Reference List - Drives WAA For Projects 2004-2005Dokumen5 halamanReference List - Drives WAA For Projects 2004-2005idontlikeebooksBelum ada peringkat

- Reference List - WMDokumen20 halamanReference List - WMidontlikeebooksBelum ada peringkat

- Castings, Iron-Chromium-Nickel-Molybdenum Corrosion-Resistant, Duplex (Austenitic/Ferritic) For General ApplicationDokumen4 halamanCastings, Iron-Chromium-Nickel-Molybdenum Corrosion-Resistant, Duplex (Austenitic/Ferritic) For General ApplicationАлександр БобурковBelum ada peringkat

- A Comparative Study On Cutting Tool Performance PDFDokumen6 halamanA Comparative Study On Cutting Tool Performance PDFdevmecz2696Belum ada peringkat

- Habashi F. Handbook of Extractive Metallurgy I (Wiley, 1998) (ISBN 3527287922) (T) (494s) - OcredDokumen494 halamanHabashi F. Handbook of Extractive Metallurgy I (Wiley, 1998) (ISBN 3527287922) (T) (494s) - OcredjonathanBelum ada peringkat

- Welding Consumable Calculation (WCC) : Doc. No P.O No Rev. No Project Details Technical Requirement ConsumablesDokumen26 halamanWelding Consumable Calculation (WCC) : Doc. No P.O No Rev. No Project Details Technical Requirement ConsumablesAhmad KamilBelum ada peringkat

- Chinese Standard For Pressure VesselDokumen40 halamanChinese Standard For Pressure VesselirfanlarikhotmailcomBelum ada peringkat

- Knowledge Management Tata SteelDokumen0 halamanKnowledge Management Tata SteelAshish ShuklaBelum ada peringkat

- Installation Specification For Driven PilesDokumen38 halamanInstallation Specification For Driven PilesSuryanto TjiongBelum ada peringkat

- Premier ValvesDokumen12 halamanPremier Valvesneelkant sharmaBelum ada peringkat

- THG Hooks Forged Hooks Catalogue SheetDokumen5 halamanTHG Hooks Forged Hooks Catalogue SheetjhonBelum ada peringkat

- Zinc Refining ProcessDokumen5 halamanZinc Refining ProcesshaharameshBelum ada peringkat

- 3-A® Sanitary Standards - 17-11Dokumen11 halaman3-A® Sanitary Standards - 17-11CHRISTIAN ZAVALABelum ada peringkat

- AK Carbon Steel PB 201307Dokumen70 halamanAK Carbon Steel PB 201307SilveradoBelum ada peringkat

- Spear & Jackson Product Guide 2015Dokumen152 halamanSpear & Jackson Product Guide 2015Denise2512Belum ada peringkat

- Prior Austen It e Grain SizeDokumen39 halamanPrior Austen It e Grain SizePearl MassanBelum ada peringkat

- Experimental 2017 - Fire Resistance of Concrete-Filled Steel Plate Composite (CFSPC) WallsDokumen14 halamanExperimental 2017 - Fire Resistance of Concrete-Filled Steel Plate Composite (CFSPC) WallsMaha Ass'adBelum ada peringkat

- Buildings Department Practice Note For Authorized Persons, Registered Structural Engineers and Registered Geotechnical Engineers APP-37Dokumen22 halamanBuildings Department Practice Note For Authorized Persons, Registered Structural Engineers and Registered Geotechnical Engineers APP-37Mahesh SuranaBelum ada peringkat

- Catalog: About Us Certification Services Contact Project InsuranceDokumen30 halamanCatalog: About Us Certification Services Contact Project InsuranceNehaKarunyaBelum ada peringkat

- I Et 301000 1200 540 p4x 001 - A - Prelim PDFDokumen44 halamanI Et 301000 1200 540 p4x 001 - A - Prelim PDFzsx zsxBelum ada peringkat

- Tolco Pipe Hangers PDFDokumen80 halamanTolco Pipe Hangers PDFHeather C BarretoBelum ada peringkat

- Effect of Heat Treatment On An AISI 304 Austenitic Stainless Steel Evaluated by The Ultrasonic Attenuation CoefficientDokumen6 halamanEffect of Heat Treatment On An AISI 304 Austenitic Stainless Steel Evaluated by The Ultrasonic Attenuation CoefficientChaguy VergaraBelum ada peringkat

- SoR 2009 10Dokumen25 halamanSoR 2009 10MuraliKrishna NaiduBelum ada peringkat

- Eco Analysis Tata SteelDokumen79 halamanEco Analysis Tata SteelRavNeet KaUrBelum ada peringkat

- Piping WPS SMAWDokumen2 halamanPiping WPS SMAWJk KarthikBelum ada peringkat

- DIN 17007-4-1963, Material Type NumberDokumen9 halamanDIN 17007-4-1963, Material Type NumberLloyd R. PonceBelum ada peringkat

- KOSORI Test Facilities-LeafletDokumen26 halamanKOSORI Test Facilities-LeafletRichard HollidayBelum ada peringkat

- Is 1570Dokumen139 halamanIs 1570jajodia239Belum ada peringkat

- Reliance Mud Pump Expendables Catalog PDFDokumen17 halamanReliance Mud Pump Expendables Catalog PDFhebert perez100% (1)

- Astm 255 PDFDokumen26 halamanAstm 255 PDFMariela BelénBelum ada peringkat

- Interview: Chairman, Structwel Designers and ConsultantsDokumen3 halamanInterview: Chairman, Structwel Designers and ConsultantsChaitanya Raj GoyalBelum ada peringkat

- Cablofil CSI MasterFormat Spec-FullDokumen13 halamanCablofil CSI MasterFormat Spec-Fulltamer_farouk8744Belum ada peringkat