2523

Diunggah oleh

sangkil05Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

2523

Diunggah oleh

sangkil05Hak Cipta:

Format Tersedia

Hardware Kit Instructions

GlobalGear® Changing Side Ports to Angle Ports

Housing Kit Instructions

Kit Contents

Item # Description Quantity

1 Housing (No Ports) 1

2 Foot 1

3 Cover Gasket 1

4 Bracket Gasket 1

5 Port Gaskets (GG120 - 250 sizes only) 2

6 Hex Head Bolts 4

7 Lock Washers 4

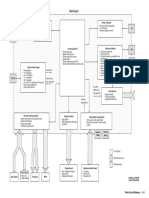

Bracket/Bushing

Assembly Bearing

Carrier

Relief Valve Assembly

Cover/Pin Assembly

Idler/Bushing Assembly

Foot

Bracket Gasket Cover Gasket

Housing

Remove the Cover/Idler Gear Assembly

Prior to removing the cover, the general position should be marked in relationship to the housing. Once done, remove the cover bolts

and the cover.

Remove the cover gasket.

Note: On pumps with relief valves, the cover can be removed with the relief valve still mounted onto the cover.

WARNING

When removing the cover, the idler gear will generally stay on the pin. Avoid tilting the cover downward as the idler may slide off,

causing injury or damage.

ID#010 Excellence at work. Excellence in life.

Separate the Drive Module Assembly from the Housing

Remove the screws that hold the bracket to the housing.

The drive module assembly can be separated from the housing. Caution should be used, as parts can be heavy. The use of a lifting

device may be required.

Remove the bracket gasket.

Attach the Drive Module Assembly to the New Housing

Attach the foot to the new housing with the appropriate port angle alignment using the hex head bolts provided with the kit.

Place the gasket on the bracket, aligning the gasket holes to allow venting through the seal flush hole. Note the location of the flush.

Slide the drive module into the housing. Do not bolt the housing and drive module together at this time. The bracket may need to be

rotated.

Attach the bearing carrier to the foot with the hex head bolts supplied with the kit.

Rotating the Bracket

The standard bracket for the GlobalGear® pumps provides a vent to the seal chamber from one of the housing’s ports (typically the

suction port).

If rotation of the bracket is required to provide a vent then perform the following.

• Remove the hex head bolts that attach the bracket to the bearing carrier

• Rotate the bracket to the appropriate location

• The bracket gasket must rotate with the bracket

• Re-attach the bracket to the bearing carrier and housing using the hex head bolts

Pipe Plugs Orifice Plug Suction Port

Internal Flush Holes

Version Page 2 of 3

Install Cover and Idler Assembly

Place the idler assembly on the cover. Ensure the idler rotates freely.

Place the gasket on the cover.

Tilt the top of the cover away from the pump until the crescent can be fitted into the rotor I.D. Then rotate the idler until its teeth mesh

with the rotor teeth.

Assemble with cover bolts.

Install Ports

For GG15 – GG90 size pumps, both housing styles (90° and 180°) use bolt-on ports, so reuse the ports that are attached to the original

180° housing.

• Remove the bolts or studs that hold the ports to the original housing

• Remove the ports from the original housing

• Install new port gaskets

• Assemble the original ports to the pump, using the original port fasteners

For GG120 – GG250 size pumps, the 180° housings use integrally cast ports, so use a new port kit, and refer to the instructions provided

with that kit.

The end clearances must now be adjusted. Refer to instructions in Service Manual 73.

Torque requirements on the mounting hardware:

M6 hardware 6 - 9 lbs-ft (8 – 12 N-M)

M8 hardware 14 - 21 lbs-ft (19 – 28 N-M)

M10 hardware 30 - 40 lbs-ft (40 – 54 N-M)

M12 hardware 55 - 65 lbs-ft (75 – 88 N-M)

(Reference: SAE specification)

Tuthill Pump Group Excellence at work. Excellence in life.

USA • United Kingdom • China

www.tuthillpump.com

Anda mungkin juga menyukai

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- Palm Oil Mill Processing SystemDokumen20 halamanPalm Oil Mill Processing Systemreza32393100% (3)

- Semi Mechanized MillDokumen4 halamanSemi Mechanized Millsangkil05Belum ada peringkat

- 331 401 3 10 08Dokumen4 halaman331 401 3 10 08silverfurBelum ada peringkat

- Steam TablesDokumen16 halamanSteam TablesSantosh KumarBelum ada peringkat

- URL LeadershipDokumen1 halamanURL Leadershipsangkil05Belum ada peringkat

- Balance of Palm Oil in ProcessDokumen2 halamanBalance of Palm Oil in Processsangkil05Belum ada peringkat

- Diploma 2014 285970 BibliographyDokumen2 halamanDiploma 2014 285970 Bibliographysangkil05Belum ada peringkat

- 2531Dokumen5 halaman2531sangkil05Belum ada peringkat

- World GreenDokumen1 halamanWorld Greensangkil05Belum ada peringkat

- Modification of Nut Fibre MachineDokumen12 halamanModification of Nut Fibre Machinesangkil05Belum ada peringkat

- 2524Dokumen21 halaman2524sangkil05Belum ada peringkat

- Mechanized Tools in POP Utilization or RejectionDokumen7 halamanMechanized Tools in POP Utilization or Rejectionsangkil05Belum ada peringkat

- 331 401 3 10 08Dokumen4 halaman331 401 3 10 08silverfurBelum ada peringkat

- 1 Small Scale Palm Oil MachinesDokumen9 halaman1 Small Scale Palm Oil Machinessangkil05Belum ada peringkat

- CommuterLine Schedule Version 15 June 2015 Red Line Jakarta Kota BogorDokumen18 halamanCommuterLine Schedule Version 15 June 2015 Red Line Jakarta Kota Bogorsangkil05Belum ada peringkat

- World's Largest Science, Technology & Medicine Open Access Book PublisherDokumen34 halamanWorld's Largest Science, Technology & Medicine Open Access Book Publishersangkil05Belum ada peringkat

- Portal Statis Tertentu 1Dokumen11 halamanPortal Statis Tertentu 1sangkil05Belum ada peringkat

- PLC TrainingDokumen16 halamanPLC Trainingsangkil05Belum ada peringkat

- Palm Oil Manufacturing and ApplicationDokumen33 halamanPalm Oil Manufacturing and Applicationsangkil05Belum ada peringkat

- Portal Statis Tertentu 1Dokumen11 halamanPortal Statis Tertentu 1sangkil05Belum ada peringkat

- Marketing Manager FpsDokumen6 halamanMarketing Manager Fpssangkil05Belum ada peringkat

- Lowongan Kerja Agronomist PTDokumen1 halamanLowongan Kerja Agronomist PTsangkil05Belum ada peringkat

- Humor SuroboyoDokumen28 halamanHumor Suroboyoibaihaqi100% (2)

- Mbti TestDokumen4 halamanMbti Testapi-233605868Belum ada peringkat

- Tabel 15b Konsumsi Rata PDFDokumen1 halamanTabel 15b Konsumsi Rata PDFsangkil05Belum ada peringkat

- Ads RackselDokumen3 halamanAds RackselKiem TaBelum ada peringkat

- Sample - Belt Bucket Elevator DesignDokumen7 halamanSample - Belt Bucket Elevator Designmfhasnain100% (1)

- New System To Beat The Heat PDFDokumen2 halamanNew System To Beat The Heat PDFsangkil05Belum ada peringkat

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Model of Automatic Bottle Filling and Capping Mechanism: Logistics and Supply Chain ManagementDokumen17 halamanModel of Automatic Bottle Filling and Capping Mechanism: Logistics and Supply Chain ManagementNguyễn QuỳnhBelum ada peringkat

- Dreame T20 Cordless Vacuum Cleaner User ManualsDokumen79 halamanDreame T20 Cordless Vacuum Cleaner User ManualsIgnacio SeisdedosBelum ada peringkat

- Planos Electrónicos Monitor Fetal Corometrics Modelo 170 SeriesDokumen88 halamanPlanos Electrónicos Monitor Fetal Corometrics Modelo 170 Seriesviviana vargasBelum ada peringkat

- P38 EAS Service BulletinsDokumen32 halamanP38 EAS Service BulletinsGerard Katchouni100% (4)

- Adani BessDokumen45 halamanAdani Bessdan_geplBelum ada peringkat

- IH Stainless Steel Centrifugal PumpDokumen6 halamanIH Stainless Steel Centrifugal PumpshunanlatheefBelum ada peringkat

- Rubycon Al Eectrolytics DatasheetDokumen2 halamanRubycon Al Eectrolytics DatasheetEdgar DauzonBelum ada peringkat

- Non-Contact Water Level Monitoring Using Labviewwith Arduino and Ultrasonic SensorDokumen5 halamanNon-Contact Water Level Monitoring Using Labviewwith Arduino and Ultrasonic SensorMidzie PedroBelum ada peringkat

- ThinkBook 14 G2 ITL 20VDA0VVIHDokumen2 halamanThinkBook 14 G2 ITL 20VDA0VVIHSatyaprakash PandeyBelum ada peringkat

- Hytera tc610 User GuideDokumen41 halamanHytera tc610 User GuideAriel BecerraBelum ada peringkat

- Ls Saft GesamtuebersichtDokumen2 halamanLs Saft GesamtuebersichtMedSparkBelum ada peringkat

- BL Micro NXP Microcontroller Overview3Dokumen2 halamanBL Micro NXP Microcontroller Overview3Balaji PotnuriBelum ada peringkat

- RS1117Dokumen10 halamanRS1117asismamenBelum ada peringkat

- Sadržaj Osnovnog Kompleta Za PreživljavanjeDokumen1 halamanSadržaj Osnovnog Kompleta Za PreživljavanjeMarko VukovicBelum ada peringkat

- CSP-P Seismic Energy Source: Applied Acoustic Engineering LTDDokumen2 halamanCSP-P Seismic Energy Source: Applied Acoustic Engineering LTDDadang KurniaBelum ada peringkat

- 773E Hydraulic SystemDokumen2 halaman773E Hydraulic SystemDipendra BhattacharyaBelum ada peringkat

- Mitsubishi PUHZ RP250YKADokumen142 halamanMitsubishi PUHZ RP250YKAAlexandru BocosBelum ada peringkat

- BS 7671 - Chapters 46 To 55 - Draft For Public ConsultationDokumen100 halamanBS 7671 - Chapters 46 To 55 - Draft For Public ConsultationUsman AshrafBelum ada peringkat

- T/LL140 Series Fuel Level Sensor: Technical DataDokumen1 halamanT/LL140 Series Fuel Level Sensor: Technical Datacarlos andres mendezBelum ada peringkat

- MHD Product Introduction - EnglishDokumen43 halamanMHD Product Introduction - Englishosama tariqBelum ada peringkat

- 2009 Audi A3: Quick Reference GuideDokumen16 halaman2009 Audi A3: Quick Reference GuideFotokopirnicaSonyPSBelum ada peringkat

- Alcohol Detection and Automatic Ignition Lock System To Check Driving Under Influence (DUI)Dokumen13 halamanAlcohol Detection and Automatic Ignition Lock System To Check Driving Under Influence (DUI)Kshitij Kumar Singh ChauhanBelum ada peringkat

- Flyer RCS 9698G H GatewayDokumen2 halamanFlyer RCS 9698G H GatewayBorisBelum ada peringkat

- Thermal Switch: 17AME-H Series: FeaturesDokumen2 halamanThermal Switch: 17AME-H Series: FeaturesHotel WijayaBelum ada peringkat

- Minisonic Assembly HeadDokumen70 halamanMinisonic Assembly Headcesar cabezas rojasBelum ada peringkat

- NCR-330 Navtex Receiver Instruction Manual: Downloaded From Manuals Search EngineDokumen75 halamanNCR-330 Navtex Receiver Instruction Manual: Downloaded From Manuals Search EnginePhuocTranThienBelum ada peringkat

- Hydraulic Puller Kit TMHC 110E: ApplicationDokumen2 halamanHydraulic Puller Kit TMHC 110E: Applicationsbosch54Belum ada peringkat

- DHW - LC Series Factsheet - AUS NZ NOV 2019 - DHW00025 PDFDokumen2 halamanDHW - LC Series Factsheet - AUS NZ NOV 2019 - DHW00025 PDFjustforaspinBelum ada peringkat

- Microguard 414 Troubleshooting Manual PDFDokumen84 halamanMicroguard 414 Troubleshooting Manual PDFDaniel Castillo PeñaBelum ada peringkat

- PB Kandang Ayam A.N Joni Paduraksa B2 33 KvaDokumen64 halamanPB Kandang Ayam A.N Joni Paduraksa B2 33 KvaFajar PradanaBelum ada peringkat