1044 Plant Inspection Career Poster March 2015 PDF

Diunggah oleh

Hoque AnamulJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

1044 Plant Inspection Career Poster March 2015 PDF

Diunggah oleh

Hoque AnamulHak Cipta:

Format Tersedia

CSWIP Plant Inspection Programme – Levels 1, 2 and 3

An internationally recognised certification of competence

Module 1 - Part A Module 1 - Part B

Introduction LEVEL 1

Rules/Regulations and Duties of a Plant Inspector Inspection Methods

Entry Requirements (submit CV for approval)

The modular approach of this 5 days inc. examination 5 days inc. examination

internationally recognised • Legislation, rules and regulations • Use of codes and standards On successful

certification of competence allows Direct Entry Route • An introduction to engineering materials, NDT, visual examination of welds • An introduction to: the inspection of pressure completion of the

Must hold current ISO 9712 Level 2 NDE approvals in 2 methods equipment, vessel, piping, storage tanks, coating

for a clearly defined structured AND CSWIP 3.1 Welding Inspection qualification

• The Plant Inspector - roles and duties, works inspection/ISI/FFP,

CSWIP Examination

inspection safety, basic inspection skills, using codes and standards, and lining

career path. Plant Inspection

inspection reports • An introduction to: risk-based inspection

Via Offshore Visual • ITPs • Inspection reports Level 1 is awarded

The courses are aimed at plant NDT Route Inspector course • Inspecting materials

engineers, integrity engineers Supplementary S1 module

welding/NDT inspectors/

practitioners, materials and

Welding Inspector Route NDT Appreciation Exam format

corrosion engineers, plant Level 1 examination for Module 1 Part A and B consist of two examination papers.

inspectors responsible for course Paper 1 – multiple choice questions

Supplementary S2 module

managing the safety and integrity Paper 2 – extended case study

of ageing process equipment,

pipelines, pressure vessels and CSWIP Scheme Document CSWIP-PI-11-01 ‘Requirements for the Certification of Plant

Mature Candidate Route

storage tanks. Five years’ Plant Inspection experience

Inspectors (Plant Integrity Management)’ can be downloaded from:

http://www.cswip.com/schemes/plant-inspection/

The scheme is designed to suit:

• plant inspectors working for

manufacturing works (Vendor) LEVELS 2 and 3 Module 2 Module 3 Module 4 Module 5

Damage Mechanism Assessment for RBI Risk Based Inspection (RBI) based on API Fitness-for-Service (FFS) Weld Repair of Pressure Equipment

• inspection organisations Entry Requirements and FFS based on API RP 571 and ASME based on API 579-1/ASME FFS-1 - 2007 and Piping

• equipment owners and operators (submit CV for approval)

• classification societies 3 days inc. examination 2 days inc. examination 4 days inc. examination 1 day inc. examination

• insurance companies

Direct Route • Common damage mechanisms in oil and gas • Risk based inspection in accordance with API RP • Introduction to fitness-for-service (FSS) • Selecting an appropriate repair method

production, refining and manufacturing processes 581, API RP 580 and ASME

Must hold a current CSWIP • Material properties and API 579 annexes • Life of weld repair

• safety regulators and where they can be found • Reasons for implementing risk based inspection • Stress analysis for FFS • Type of equipment and industry

Plant Inspector Level 1 • Key process parameters affecting damage • Benefits of using risk based inspection • Identification of damage mechanisms for FFS: • Codes and standards to make weld repairs or

The courses have three goals:

qualification mechanisms

• Practical planning and implementation of RBI alterations

• Interaction with other assessment procedures

• Prevention and control of damage mechanisms

• To ensure inspectors and • Preparing inspection plans • Use of weld procedures and welder qualifications

engineers responsible for

Academic Route* • Most appropriate inspection and non-destructive

testing methods

assessing plant integrity have

• HNC or above qualification

in a relevant engineering Exam format Exam format Exam format Exam format

the essential tools and skills Paper 1 – multiple choice questions Paper 1 – multiple choice questions Paper 1 – multiple choice questions Paper 1 – multiple choice questions

necessary subject Paper 2 – essay questions, case studies. Paper 2 – case studies questions (Open book API 579 - provided)

• To recognise and certify plant • Must meet CSWIP Plant (Open book – API RP 571 - provided) (Open book API RP 580/581 - provided)

inspector competence Inspector Level 1 entry

requirements

• To provide a structured career

path for continuing professional Module 6 Module 7 Module 8 On successful completion of

development of plant integrity Mature Candidate Route* Pressure Vessel Inspection based on Piping Inspector based on API 570 Aboveground Tank Inspector based on FOUR CSWIP modules

• HNC or above qualification API 510 API Std 653 CSWIP Plant Inspection

practitioners through formal

in a relevant engineering 5 days + 1 day examination Level 2 is awarded

training/certification 5 days + 1 day examination 5 days + 1 day examination

subject • Extensive overview of API 510 “Body of Knowledge” • Extensive overview of API 570 “Body of Knowledge” • Extensive overview of API Std 653 “Body of

• ASME welding requirements for pressure piping Knowledge” On successful completion of

• Minimum of five years’ Plant • Pressure vessel materials and fabrication

• Corrosion allowances, inspection and degradation • Review of ASME welding requirements for storage SIX CSWIP modules

Inspector experience • Corrosion allowances, inspection and degradation

mechanisms tanks section IX and API 650

mechanisms CSWIP Plant Inspection

• Remaining life calculations • AMSE NDT principles of Section V Level 3 is awarded

• Remaining life calculations

* Must gain CSWIP Plant • Static head pressure calculations

• Review of API Std 653 inspection, repair, alteration

Inspector Level 1 Part A to and construction of tanks.

Copyright © TWI Ltd 2015

Prospective eligibility for

be awarded certification Exam format Exam format Exam format

Paper 1 – multiple choice questions Paper 1 – multiple choice questions Paper 1 – multiple choice questions Professional Membership

(Open book API 510)** (Open book API 570)** (Open book API Std 653)** at Technician Level (TechWeldI)

– application required

**Candidates to bring relevant API standard

1044.03/15

www.twitraining.com

Anda mungkin juga menyukai

- CSWIP Plant Inspection - Levels 1,2 and 3: An Internationally Recognised Certification of CompetenceDokumen1 halamanCSWIP Plant Inspection - Levels 1,2 and 3: An Internationally Recognised Certification of Competenceafiq ahmadBelum ada peringkat

- Plant Inspection OverviewDokumen2 halamanPlant Inspection OverviewSiva Kumar100% (1)

- Corrosion and Materials in Hydrocarbon Production: A Compendium of Operational and Engineering AspectsDari EverandCorrosion and Materials in Hydrocarbon Production: A Compendium of Operational and Engineering AspectsBelum ada peringkat

- Risk Based Inspection A Complete Guide - 2020 EditionDari EverandRisk Based Inspection A Complete Guide - 2020 EditionBelum ada peringkat

- SAIC-X-3104 Rev 3Dokumen4 halamanSAIC-X-3104 Rev 3Imran khanBelum ada peringkat

- PEC Corrosion MonitoringDokumen4 halamanPEC Corrosion Monitoringmahesh070Belum ada peringkat

- AIE-PR-PRJ-005 - in Service Pipework Inspection Procedure Rev 01Dokumen20 halamanAIE-PR-PRJ-005 - in Service Pipework Inspection Procedure Rev 01faraz_muslimBelum ada peringkat

- Esab, Ok 309L (29.12.16)Dokumen1 halamanEsab, Ok 309L (29.12.16)RodrigoBelum ada peringkat

- 20019.MAT - COR.PRG Selezione Maeriali Servizio Marino Rev. 0 - Aprile 2009Dokumen45 halaman20019.MAT - COR.PRG Selezione Maeriali Servizio Marino Rev. 0 - Aprile 2009MatteoBelum ada peringkat

- Corrosion Rate ConversionDokumen2 halamanCorrosion Rate ConversionBakti PrasetyoBelum ada peringkat

- E2G Training Catalog 2023Dokumen40 halamanE2G Training Catalog 2023kapsarcBelum ada peringkat

- Pheonwj I PRC 0005 0Dokumen54 halamanPheonwj I PRC 0005 0Iksan Adityo Mulyo100% (1)

- Saep 325Dokumen43 halamanSaep 325AbdullahBelum ada peringkat

- Saep 306Dokumen15 halamanSaep 306nadeem shaikh100% (1)

- Saep 343Dokumen74 halamanSaep 343mathew.genesis.inspBelum ada peringkat

- DESOUQ Pipeline Integrity Management System: Developed by / Ahmed Shaaban Desouq Corrosion EngineerDokumen26 halamanDESOUQ Pipeline Integrity Management System: Developed by / Ahmed Shaaban Desouq Corrosion EngineerAmr SalehBelum ada peringkat

- 00 Saip 12Dokumen8 halaman00 Saip 12aamirtec301Belum ada peringkat

- Keys To Maintenance and Repair of Coke Drums Derrick RogersDokumen34 halamanKeys To Maintenance and Repair of Coke Drums Derrick RogersNatrajiBelum ada peringkat

- Corrosion ManagementDokumen6 halamanCorrosion Managementnaren57Belum ada peringkat

- Asset Integrity Management A Complete Guide - 2020 EditionDari EverandAsset Integrity Management A Complete Guide - 2020 EditionBelum ada peringkat

- 17.6 Pipeline Rehabilitation: Materials Design and Lifecycle Performance Guide - Volume 2Dokumen7 halaman17.6 Pipeline Rehabilitation: Materials Design and Lifecycle Performance Guide - Volume 2ankeshkatochBelum ada peringkat

- SCCDADokumen4 halamanSCCDAengineerchemical285038Belum ada peringkat

- 27964E00Dokumen14 halaman27964E00Ua AnyanhunBelum ada peringkat

- SAEP-88 Appendix J: Materials Selection Table (MST) Template (1 of 2)Dokumen2 halamanSAEP-88 Appendix J: Materials Selection Table (MST) Template (1 of 2)Afzal AsifBelum ada peringkat

- Satip D 001 01Dokumen11 halamanSatip D 001 01Rijwan Mohammad0% (1)

- 01 Saip 06Dokumen7 halaman01 Saip 06malika_00Belum ada peringkat

- Saudi Aramco Inspection ChecklistDokumen3 halamanSaudi Aramco Inspection ChecklistDilshad AhemadBelum ada peringkat

- Saudi Aramco Inspection Checklist: Review of WPS & Process Control Procedure (Pipelines) SAIC-W-2038 WeldDokumen4 halamanSaudi Aramco Inspection Checklist: Review of WPS & Process Control Procedure (Pipelines) SAIC-W-2038 Weldhamidjoyia100% (1)

- Toc PL381Dokumen5 halamanToc PL381anjangandak2932Belum ada peringkat

- Inspection Procedure: 00-SAIP-71 31 January 2005 Plant Inspection Index Document Responsibility: Inspection DepartmentDokumen21 halamanInspection Procedure: 00-SAIP-71 31 January 2005 Plant Inspection Index Document Responsibility: Inspection Departmentaamirtec301Belum ada peringkat

- SP-1176 V4.0Dokumen45 halamanSP-1176 V4.0Ghulam HusainBelum ada peringkat

- @StandardSharing-EEMUA 237-2018Dokumen40 halaman@StandardSharing-EEMUA 237-2018Morteza ShakerienBelum ada peringkat

- Saudi Aramco Inspection ChecklistDokumen2 halamanSaudi Aramco Inspection ChecklistRijwan MohammadBelum ada peringkat

- Safety Alert: Failure of Fabricated Test Blind Flange For Hydrostatic TestingDokumen5 halamanSafety Alert: Failure of Fabricated Test Blind Flange For Hydrostatic TestingvietnampetrochemicalBelum ada peringkat

- Installing, Maintaining, and Verifying Your Charpy Impact MachineDokumen26 halamanInstalling, Maintaining, and Verifying Your Charpy Impact MachineTurgay DeryaBelum ada peringkat

- FuturePipe Installation Manual 18-7-05 PDFDokumen25 halamanFuturePipe Installation Manual 18-7-05 PDFPaul WoworBelum ada peringkat

- Test Pack ProcedureDokumen10 halamanTest Pack ProcedureDaengkulle Firmansyah PuteraBelum ada peringkat

- VAIL-20-129-S-007 - Fitness For Service Assessment of Static Equipment - Rev. ADokumen25 halamanVAIL-20-129-S-007 - Fitness For Service Assessment of Static Equipment - Rev. Akunnar corrosionBelum ada peringkat

- SSM Su 5003 BDokumen84 halamanSSM Su 5003 Bresp-ectBelum ada peringkat

- Total Flange Assurance ProcedureDokumen44 halamanTotal Flange Assurance ProcedureMark Darrel AranasBelum ada peringkat

- Corrosion Loop Development - AndikaandDokumen20 halamanCorrosion Loop Development - AndikaandThanh Dat DoanBelum ada peringkat

- Weld Repair of Grade 91 Piping and Components in PDokumen27 halamanWeld Repair of Grade 91 Piping and Components in PKyi HanBelum ada peringkat

- Saudi Aramco Inspection ChecklistDokumen13 halamanSaudi Aramco Inspection ChecklistAli AhmedBelum ada peringkat

- Consultancy in Mechanical Integrity RBI, RCM, FFS, NDT & Vibration Analysis Services Training Based On API ASME and Other StandardsDokumen6 halamanConsultancy in Mechanical Integrity RBI, RCM, FFS, NDT & Vibration Analysis Services Training Based On API ASME and Other StandardsShahbaz KhanBelum ada peringkat

- Saudi Aramco Inspection Checklist: Verify Test Equipment (Safety Assessment) SAIC-A-2009 31-Dec-14 MechDokumen4 halamanSaudi Aramco Inspection Checklist: Verify Test Equipment (Safety Assessment) SAIC-A-2009 31-Dec-14 MechpravinBelum ada peringkat

- Resume Sample PDFDokumen4 halamanResume Sample PDFamitrdttecBelum ada peringkat

- Satip-X-600-02 Rev 1 For CP SystemDokumen4 halamanSatip-X-600-02 Rev 1 For CP SystemSaleem MohammedBelum ada peringkat

- SAIC-W-2015 Rev 7 (NDE Selection)Dokumen17 halamanSAIC-W-2015 Rev 7 (NDE Selection)vijayachiduBelum ada peringkat

- IOW PresentationDokumen20 halamanIOW Presentationbarry nancooBelum ada peringkat

- SEIP For 089-WHB-001: Claus Waste Heat BoilerDokumen6 halamanSEIP For 089-WHB-001: Claus Waste Heat BoilerThinh NguyenBelum ada peringkat

- Cathodic Protection Measurements and Surveys For On-Land Buried PipelinesDokumen35 halamanCathodic Protection Measurements and Surveys For On-Land Buried PipelinesSelimBelum ada peringkat

- Saep 1662Dokumen52 halamanSaep 1662Er Bishwonath ShahBelum ada peringkat

- Calculation PoF and CoFDokumen10 halamanCalculation PoF and CoFHamidBelum ada peringkat

- Nbic IsDokumen2 halamanNbic IsDivakar PanigrahiBelum ada peringkat

- Evaluation of Smartphone Feature Preference by A Modified AHP ApproachDokumen5 halamanEvaluation of Smartphone Feature Preference by A Modified AHP ApproachSeu Ze NinguemBelum ada peringkat

- Publication SAW SOUR SERVICE 2023 PDFDokumen7 halamanPublication SAW SOUR SERVICE 2023 PDFPako RosasBelum ada peringkat

- Investigation and Repair of H (1) - E.R Flange LeakDokumen19 halamanInvestigation and Repair of H (1) - E.R Flange LeakriysallBelum ada peringkat

- Potential Damage PKTDokumen7 halamanPotential Damage PKTFebri Ramdani NugrahaBelum ada peringkat

- Air Cooled Pro-Grip Max TIG Welding TorchDokumen1 halamanAir Cooled Pro-Grip Max TIG Welding TorchHoque AnamulBelum ada peringkat

- 5 Water Cooled Cable Terminations: Pro-Grip MAX - How To OrderDokumen1 halaman5 Water Cooled Cable Terminations: Pro-Grip MAX - How To OrderHoque AnamulBelum ada peringkat

- Brochure Invertig - Pro 240 450 (1) 008Dokumen1 halamanBrochure Invertig - Pro 240 450 (1) 008Hoque AnamulBelum ada peringkat

- 5 Air Cooled Cable Terminations: Pro-Grip MAX - How To OrderDokumen1 halaman5 Air Cooled Cable Terminations: Pro-Grip MAX - How To OrderHoque AnamulBelum ada peringkat

- Standard Collet Large Diameter Gas Lens Collet: Pro-Grip MAX Tig Torch PackagesDokumen1 halamanStandard Collet Large Diameter Gas Lens Collet: Pro-Grip MAX Tig Torch PackagesHoque AnamulBelum ada peringkat

- ECR-18 Torch Parts List PDFDokumen1 halamanECR-18 Torch Parts List PDFHoque AnamulBelum ada peringkat

- Air Cooled Pro-Grip Max TIG Welding TorchDokumen1 halamanAir Cooled Pro-Grip Max TIG Welding TorchHoque AnamulBelum ada peringkat

- 136 136 136 Pro-Grip Max TIG Features & BenefitsDokumen1 halaman136 136 136 Pro-Grip Max TIG Features & BenefitsHoque AnamulBelum ada peringkat

- Pro-Grip Max Switch ConfigurationDokumen1 halamanPro-Grip Max Switch ConfigurationHoque AnamulBelum ada peringkat

- Requistion For Top Plate - V01Dokumen2 halamanRequistion For Top Plate - V01Hoque AnamulBelum ada peringkat

- How To Order Your Pro-Grip Max TIG TorchDokumen1 halamanHow To Order Your Pro-Grip Max TIG TorchHoque AnamulBelum ada peringkat

- Pro-Grip MAX - How To Order: 5 Air Cooled Cable TerminationsDokumen1 halamanPro-Grip MAX - How To Order: 5 Air Cooled Cable TerminationsHoque AnamulBelum ada peringkat

- Form2 ADokumen1 halamanForm2 AHoque AnamulBelum ada peringkat

- Safety Instructions: de Securite de Seguridad BezpieczeństwaDokumen44 halamanSafety Instructions: de Securite de Seguridad BezpieczeństwaHoque AnamulBelum ada peringkat

- Collets: Tig ConsumablesDokumen1 halamanCollets: Tig ConsumablesHoque AnamulBelum ada peringkat

- Back Caps: Tig ConsumablesDokumen1 halamanBack Caps: Tig ConsumablesHoque AnamulBelum ada peringkat

- Ceramics: Tig ConsumablesDokumen1 halamanCeramics: Tig ConsumablesHoque AnamulBelum ada peringkat

- DS MasterTig MLS ACDC AD703 1218 EN PDFDokumen2 halamanDS MasterTig MLS ACDC AD703 1218 EN PDFHoque AnamulBelum ada peringkat

- Warranty Booklet 1902020 1110Dokumen17 halamanWarranty Booklet 1902020 1110Hoque AnamulBelum ada peringkat

- Linde Rates For Welding Test Services-2018Dokumen2 halamanLinde Rates For Welding Test Services-2018Hoque AnamulBelum ada peringkat

- Aws Certified Welding Engineer Program (Cweng) : Registration FormDokumen2 halamanAws Certified Welding Engineer Program (Cweng) : Registration FormHoque AnamulBelum ada peringkat

- H.S.C Physics 1st & 2nd Paper (NCTB Approved) : June 2015Dokumen2 halamanH.S.C Physics 1st & 2nd Paper (NCTB Approved) : June 2015Hoque AnamulBelum ada peringkat

- PreviewDokumen2 halamanPreviewHoque AnamulBelum ada peringkat

- Ical Marking Required To Appear On The Materials: SS Plate/SheetDokumen1 halamanIcal Marking Required To Appear On The Materials: SS Plate/SheetHoque AnamulBelum ada peringkat

- Q Q Q Q: Units Listed Numbers Checked Sources Referenced Inputs ListedDokumen2 halamanQ Q Q Q: Units Listed Numbers Checked Sources Referenced Inputs ListedHoque AnamulBelum ada peringkat

- Ical Marking Required To Appear On The Materials: SS Plate/SheetDokumen1 halamanIcal Marking Required To Appear On The Materials: SS Plate/SheetHoque AnamulBelum ada peringkat

- ROL & ReferencesDokumen112 halamanROL & ReferencesMark Púgnit BonábonBelum ada peringkat

- ECCE Examination Sample Test 2013Dokumen36 halamanECCE Examination Sample Test 2013mariagerothanasi75% (4)

- Acknowledgement: Xhian'z MallariDokumen7 halamanAcknowledgement: Xhian'z Mallariアラン アランBelum ada peringkat

- ConvoDokumen44 halamanConvoLun Ding0% (1)

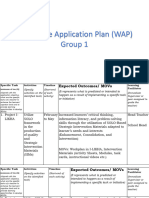

- Group 1 WAP For TeachersDokumen3 halamanGroup 1 WAP For Teachersjudan.fructuosoBelum ada peringkat

- Bse Industry Mentored ProjectDokumen4 halamanBse Industry Mentored ProjectRohit SharmaBelum ada peringkat

- Pre Ap Biology CG WR PDFDokumen65 halamanPre Ap Biology CG WR PDFDr Vinayachandran NBelum ada peringkat

- Lesson Plan For Intervention 1Dokumen3 halamanLesson Plan For Intervention 1api-241744954Belum ada peringkat

- James Hillhouse High School, New HavenDokumen1 halamanJames Hillhouse High School, New HavenHelen BennettBelum ada peringkat

- Paco Catholic School High School Department PAASCU Accredited Merit Record VII-8 (2016-2017)Dokumen6 halamanPaco Catholic School High School Department PAASCU Accredited Merit Record VII-8 (2016-2017)ۦۦ ۦۦBelum ada peringkat

- Chapter 3Dokumen7 halamanChapter 3s151605Belum ada peringkat

- Instructional ConsultanshipDokumen22 halamanInstructional ConsultanshipKrezia Erica CorpinBelum ada peringkat

- Pronunciation - Practice Lists of Sounds PairsDokumen73 halamanPronunciation - Practice Lists of Sounds PairsBriana Songer100% (2)

- Child and Family Health Practice FrameworkDokumen37 halamanChild and Family Health Practice Frameworkwildan yogaBelum ada peringkat

- J&knathan-Gifted With The Journey V1i4Dokumen3 halamanJ&knathan-Gifted With The Journey V1i4api-273060575Belum ada peringkat

- Nadia Smith - Letter of RecommendationDokumen3 halamanNadia Smith - Letter of Recommendationapi-281100772Belum ada peringkat

- Big Book Lesson PlanDokumen6 halamanBig Book Lesson Planapi-317723797Belum ada peringkat

- Curriculum VitaeDokumen8 halamanCurriculum VitaeChristine LuarcaBelum ada peringkat

- Roles of Assessment: Cherryville T. CalixtonDokumen11 halamanRoles of Assessment: Cherryville T. CalixtonWheng Adtud - MamadlaBelum ada peringkat

- Lesson Plan - Physical ScienceDokumen7 halamanLesson Plan - Physical Scienceapi-390871957Belum ada peringkat

- Dua's Before ExamDokumen4 halamanDua's Before ExamRaj BharathBelum ada peringkat

- Metroplex Center Lesson Plan Template For Formal ObservationsDokumen4 halamanMetroplex Center Lesson Plan Template For Formal Observationsapi-484624536Belum ada peringkat

- MMJ Final 6 14x9 21Dokumen90 halamanMMJ Final 6 14x9 21api-345662855Belum ada peringkat

- International Politics - Lesson Plan Resources by Grade LevelDokumen12 halamanInternational Politics - Lesson Plan Resources by Grade LevelMarcio OliveiraBelum ada peringkat

- Private Inspectors Vacancies PDFDokumen4 halamanPrivate Inspectors Vacancies PDFRashid Bumarwa100% (1)

- Dean's Open Letter: INFORMATION FORM and Submit OnlineDokumen6 halamanDean's Open Letter: INFORMATION FORM and Submit OnlineAli RajputBelum ada peringkat

- Jelisa M. AshbyDokumen2 halamanJelisa M. Ashbyjma92Belum ada peringkat

- Principals' Leadership Styles and Teachers' Job Performance in Senior Secondary Schools in Ondo State, NigeriaDokumen9 halamanPrincipals' Leadership Styles and Teachers' Job Performance in Senior Secondary Schools in Ondo State, NigeriaDoc GuembourBelum ada peringkat

- The StealthDokumen6 halamanThe StealthLeonard LauBelum ada peringkat

- p2 SpecimenDokumen12 halamanp2 SpecimenHarry FlemingBelum ada peringkat