Ferrite Magnets-Ceramic Magnets Datasheet v1

Diunggah oleh

GILBERTO YOSHIDADeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Ferrite Magnets-Ceramic Magnets Datasheet v1

Diunggah oleh

GILBERTO YOSHIDAHak Cipta:

Format Tersedia

Ferrite Magnets/Ceramic Magnets Datasheet

Ferrite Magnets are also known as Ceramic Magnets, Ceramic Ferrite Magnets, (also known as Feroba2, Fer2, Y30

Feroba Magnets and Hard Ferrite Magnets. Ceramic Ferrite magnets are one and HF26/18) and C8 (also known as

of the most widely used permanent magnet materials in the world. Ferrite Feroba3, Fer3 and Y30H-1). C 5

magnets are a low cost magnet material perfectly suited for higher volume / Y30 is a general choice of Ferrite

production runs. Magnet for applications such as

overband magnets. C8 / Y30H-1 is

They are termed ceramic due to their excellent electrical insulation ability. a better choice for applications such

Ferrite magnets are superb in damp, wet or marine environments – Ferrite as loudspeakers and sometimes also

magnets are corrosion free. Because the iron is already in a stable oxidized motors (C8 has a similar Br to C5 but

form in its structure, the iron cannot oxidize (“rust”) any further when in has a higher Hc and Hci).

water.

Ferrite magnets can be produced in

Strontium Ferrite (SrO.6Fe2O3) magnets and Barium Ferrite (BaO.6Fe2O3) many shapes and sizes. Machining to size is limited to

magnets are the two types of ceramic Ferrite magnet. The Strontium Ferrite grinding processes - the electrically insulating Ferrite

magnets are the most commonly manufactured due to having stronger material does not allow wire spark erosion.

magnetic properties.

As such, the main shapes are blocks, discs, rings, arcs,

The Ferrite magnets (Ceramic magnets) have a characteristic “pencil lead” and rods. Other shapes and custom sizes may well be

colour (i.e. a dark grey colour). possible but tooling charges may apply.

They are ferrimagnetic in magnetic performance (good magnetic field and NOTE:- Ferrite magnets are not the same as soft ferrites (as used in

power but, size for size, not as powerful as NdFeB or SmCo). Ferrite Magnets transformers) - they are totally different in operation.

are extremely popular in motor, generator, loudspeaker and marine designs

but are found in almost all industries. e.g. Automotive, Sensor, Machines, “Transformer” ferrites do not retain magnetism (soft ferrite). Ferrite magnets

Aerospace, Military, Advertising, Electrical/Electronic, Academic, Design are permanent magnets - they retain their magnetism (hard ferrite).

House, and R&D.

Ferrite magnets can be used at temperatures up to a maximum of +250 degrees

C (in a few situations perhaps up to +300 degrees C). There are presently 27

grades of Ferrite Magnet available. The two main grades used today are C5

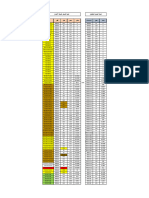

Chinese Standard - increasingly popular in UK, EU and globally

Typical Values

Br Hc (Hcb) Hci (Hcj) BHmax

Material

mT kG kA/m kOe kA/m kOe kJ/m3 MGOe

Y8T 200-235 2.0-2.35 125-160 1.57-2.01 210-280 2.64-3.52 6.5-9.5 0.8-1.2

Y10T 200-235 2.0-2.35 128-160 1.61-2.01 210-280 2.64-3.52 6.4-9.6 0.8-1.2

Y20 320-380 3.2-3.8 135-190 1.70-2.39 140-195 1.76-2.45 18.0-22.0 2.3-2.8

Y22H 310-360 3.1-3.6 220-250 2.76-3.14 280-320 3.52-4.02 20.0-24.0 2.5-3.0

Y23 320-370 3.2-3.7 170-190 2.14-2.39 190-230 2.39-2.89 20.0-25.5 2.5-3.2

Y25 360-400 3.6-4.0 135-170 1.70-2.14 140-200 1.76-2.51 22.5-28.0 2.8-3.5

Y26H 360-390 3.6-3.9 220-250 2.76-3.14 225-255 2.83-3.20 23.0-28.0 2.9-3.5

Y26H-1 360-390 3.6-3.9 200-250 2.51-3.14 225-255 2.83-3.20 23.0-28.0 2.9-3.5

Y26H-2 360-380 3.6-3.8 263-288 3.30-3.62 318-350 4.00-4.40 24.0-28.0 3.0-3.5

Y27H 370-400 3.7-4.0 205-250 2.58-3.14 210-255 2.64-3.20 25.0-29.0 3.1-3.6

Y28 370-400 3.7-4.0 175-210 2.20-2.64 180-220 2.26-2.76 26.0-30.0 3.3-3.8

Y28H-1 380-400 3.8-4.0 240-260 3.02-3.27 250-280 3.14-3.52 27.0-30.0 3.4-3.8

Y28H-2 360-380 3.3-3.8 271-295 3.41-3.71 382-405 4.80-5.09 26.0-30.0 3.3-3.8

Y30 370-400 3.7-4.0 175-210 2.20-2.64 180-220 2.26-2.76 26.0-30.0 3.3-3.8

Y30BH 380-390 3.8-3.9 223-235 2.80-2.95 231-245 2.90-3.08 27.0-30.0 3.4-3.8

Y30H-1 380-400 3.8-4.0 230-275 2.89-3.46 235-290 2.95-3.64 27.0-32.0 3.4-4.0

Y30H-2 395-415 3.95-4.15 275-300 3.46-3.77 310-335 3.90-4.21 27.0-32.5 3.4-4.1

Y32 400-420 4.0-4.2 160-190 2.01-2.39 165-195 2.07-2.45 30.0-33.5 3.8-4.2

Y32H-1 400-420 4.0-4.2 190-230 2.39-2.89 230-250 2.89-3.14 31.5-35.0 4.0-4.4

Y32H-2 400-440 4.0-4.4 224-240 2.81-3.02 230-250 2.89-3.14 31.0-34.0 3.9-4.3

Y33 410-430 4.1-4.3 220-250 2.76-3.14 225-255 2.83-3.20 31.5-35.0 4.0-4.4

Y33H 410-430 4.1-4.3 250-270 3.14-3.39 250-275 3.14-3.46 31.5-35.0 4.0-4.4

Y34 420-440 4.2-4.4 200-230 2.51-2.89 205-235 2.58-2.95 32.5-36.0 4.1-4.5

Y35 430-450 4.3-4.5 215-239 2.70-3.00 217-241 2.73-3.03 33.1-38.2 4.2-4.8

Y36 430-450 4.3-4.5 247-271 3.10-3.41 250-274 3.14-3.44 35.1-38.3 4.4-4.8

Y38 440-460 4.4-4.6 285-305 3.58-3.83 294-310 3.69-3.90 36.6-40.6 4.6-5.1

Y40 440-460 4.4-4.6 330-354 4.15-4.45 340-360 4.27-4.52 37.5-41.8 4.7-5.3

A world leader in magnetic technology

American Standard − used in UK but being Quick Cross Reference Guide

C5 = Feroba2 = Fer2 = Y30 = HF26/18

replaced by Chinese C8/C8A = Feroba3 = Fer3 = Y30H−1.

Typical Values C1 = Y10T / Y8T

Material Br Hc (Hcb) Hci (Hcj) BHmax C7 = Y26H−2

3 C8B = Y33

mT kG kA/m kOe kA/m kOe kJ/m MGOe

C9 = Y30H−2

C1 230 2.300 148 1.86 258 3.50 8.36 1.05

C10 = Y33H

C5 380 3.80 191 2.40 199 2.50 27.0 3.40 C11 = Y34

C7 340 3.40 258 3.23 318 4.00 21.9 2.75 C12 = Y30H−2.

C8 / C8A 385 3.85 235 2.95 242 3.05 27.8 3.50

C8B 420 4.20 232 2.91 236 2.96 32.8 4.12

C9 380 3.80 280 3.52 320 4.01 26.4 3.32

C10 400 4.00 280 3.52 284 3.57 30.04 3.82

Pc=B/H=2 Pci=Pc+1=3

5

40°C Intrinsic 4.5

Induced Field (Flux Density), B (kGauss)

20°C Intrinsic 3.5

20°C Normal

2.5

80°C Intrinsic

1.5

1

100°C Intrinsic

0.5

0

0.0

-4.5

-4.0

-3.5

-3.0

-2.5

-2.0

-1.5

-1.0

-0.5

Applied Field (Demagnetising Field), H (kOersted)

European Standard (IEC 60404−8−1) − not popular in UK or USA

Minimum/Typical Values

Br Hc (Hcb) Hci (Hcj) BHmax

Material

mT kG kA/m kOe kA/m kOe kJ/m3 MGOe

HF8/22 200/220 2.00/2.20 125/140 1.57/1.76 220/230 2.76/2.89 6.5/6.8 0.8/1.1

HF20/19 320/333 3.20/3.33 170/190 2.14/2.39 190/200 2.39/2.51 20.0/21.0 2.5/2.7

HF20/28 310/325 3.10/3.25 220/230 2.76/2.89 280/290 3.52/3.64 20.0/21.0 2.5/2.7

HF22/30 350/365 3.50/3.65 255/265 3.20/3.33 290/300 3.64/3.77 22.0/23.5 2.8/3.0

HF24/16 350/365 3.50/3.65 155/175 1.95/2.20 160/180 2.01/2.26 24.0/25.5 3.0/3.2

HF24/23 350/365 3.50/3.65 220/230 2.76/2.89 230/240 2.89/3.01 24.0/25.5 3.0/3.2

HF24/35 360/370 3.60/3.70 260/270 3.27/3.39 350/360 4.40/4.52 24.0/25.5 3.0/3.2

HF26/16 370/380 3.70/3.80 155/175 1.95/2.20 160/180 2.01/2.26 26.0/27.0 3.2/3.4

HF26/18 370/380 3.70/3.80 175/185 2.20/2.33 180/190 2.26/2.39 26.0/27.0 3.3/3.4

HF26/24 370/380 3.70/3.80 230/240 2.89/3.01 240/250 3.01/3.14 26.0/27.0 3.3/3.4

HF26/26 370/380 3.70/3.80 230/240 2.89/3.01 260/270 3.27/3.39 26.0/27.0 3.3/3.4

HF26/30 385/395 3.85/3.95 260/270 3.27/3.39 300/310 3.77/3.89 26.0/27.0 3.3/3.4

HF28/26 385/395 3.85/3.95 250/265 3.14/3.33 260/275 3.27/3.45 28.0/30.0 3.5/3.8

HF28/28 385/395 3.85/3.95 260/270 3.27/3.39 280/290 3.50/3.60 28.0/30.0 3.5/3.8

HF30/26 395/405 3.95/4.05 250/260 3.14/3.33 260/270 3.27/3.39 30.0/31.5 3.8/3.9

HF32/17 410/420 4.10/4.20 160/170 2.01/2.14 165/175 2.07/2.20 32.0/33.0 4.0/4.1

HF32/22 410/420 4.10/4.20 215/225 2.70/2.83 220/230 2.76/2.89 32.0/33.0 4.0/4.1

HF32/25 410/420 4.10/4.20 240/250 3.01/3.14 250/260 3.14/3.27 32.0/33.0 4.0/4.1

A world leader in magnetic technology

Tolerances

Tolerances:− +/−3% is common. +/−0.25mm is also commonly

used. The tolerance available will depend on the size and shape of

the magnet.

Corrosion Resistance

Corrosion resistance is excellent. Ferrite magnets are essentially

made from oxides of iron and Strontium and Barium.

They cannot corrode in water. They are sometimes regarded as be-

ing ’magnetic rust’.

Maximum and Minimum Working

Temperatures

(Please note − your application will affect the performance available)

The maximum recommended operating temperature is +250 to

+300 degrees C.

The minimum operating temperature varies with the magnet shape

and magnetic circuit.

It could be as low as −60 degrees C but may be as high as 0 (zero)

degrees C.

Temperature coefficients

Rev. Temp. Coef. of Induction (Br), α, %/°C Rev. Temp. Coef. of Intrinsic Coercivity (Hci), β,

%/°C

−0.2 (+) 0.27

Physical Characteristics (Typical)

Characteristic Symbol Unit Value

Density D g/cc 4.9 to 5.1

Vickers Hardness Hv D.P.N 400 to 700

Compression Strength C.S N/mm2 680−720

Coefficient of Thermal Expansion C// 10-6/°C 15

Τ

C 10-6/°C 10

Specific Heat Capacity c J/kg°C 795−855

Electrical Resistivity ρ μ Ω.cm 1x1010

Thermal Conductivity k W/cm°C 0.029

Modulus of Elasticity λ/E Pa 1.8x1011

Compression Strength C.S. Pa 895x106

Tensile Strength σUTS or S U Pa 34x106

Flexural Strength σ Pa 62x106

Hardness Mohs 7

Poisson’s Ratio ν 0.28

Curie Temperature Tc °C 450

A world leader in magnetic technology

Additional Notes

Ferrite / Ceramic magnets are permanent magnets. They have no relationship to soft magnetic ferrites.

Ferrite Magnets, termed Hard ferrites, are not the same as soft ferrites as would be used in transformers.

The term Hard relates to the fact that when the Ferrite magnet is exposed to a short external magnetic field, the Ferrite magnets retains magnetism due

to it having a high coercivity, Hc.

Soft ferrite material (as used in transformer cores) does not retain magnetism after exposure to the same short magnetic field due to soft ferrite materials

having low coercivity, Hc.

The high coercive force of Ferrite magnets means they are classified as hard materials, like all the other permanent magnets.

The Ferrite magnets has a more complete name of Hard Hexagonal Ferrite permanent magnets.

The magnet shape, its environment, and the actual application affect how the Ferrite magnet will perform.

When determining suitability, you should always assess the Intrinsic curve rather than the Normal curve.

Maximum performance is possible by keeping the intrinsic working point above the ’knee’ and ideally at the BHmax working point.

In Ferrite magnets the Hci actually increases with rising temperature (a benefit in electric motors).

At higher temperatures the resistance to demagnetising increases in Ferrite magnets.

Demagnetisation is possible in colder temperatures (e.g. freezing conditions) − a higher working point reduces the risk.

Ferrite magnets have excellent corrosion resistance − they do not rust or degrade when in water.

Anisotropic grades (direction of magnetisation locked in structure) are stronger than isotropic grades.

Isotropic (unoriented) grade example:− C1; Anisotropic (oriented) grade examples:− C5, C7, C8.

If you have any more questions, require technical assistance or would like a quotation, simply contact us.

If you have any more questions, require technical assistance and would like a quotation, simply contact us.

www.eclipsemagnetics.com

Eclipse Magnetics Ltd, Atlas Way, Sheffield, S4 7QQ, England

T +44 (0)114 225 0600 F +44 (0)114 225 0525 E info@eclipsemagnetics.com W www.eclipsemagnetics.com

While every effort has been made to ensure the accuracy of the information in this publication please note that specifications may change without notice.

A world leader in magnetic technology

Anda mungkin juga menyukai

- Read First InstructionsDokumen2 halamanRead First InstructionsClovis Kitenge0% (1)

- SupportServices Motors PDFDokumen92 halamanSupportServices Motors PDFMarKusELNBelum ada peringkat

- RADAR BRIDGE MASTER ''E'' Series Radar Ship's ManualDokumen161 halamanRADAR BRIDGE MASTER ''E'' Series Radar Ship's Manualtoumassis_p100% (11)

- Design of Electrical Machine Unit 1 2 MarksDokumen6 halamanDesign of Electrical Machine Unit 1 2 MarksVel MuruganBelum ada peringkat

- ABB Motor CatalogueDokumen6 halamanABB Motor CatalogueJeremy LandryBelum ada peringkat

- Cable Reel Leroy Somer - enDokumen16 halamanCable Reel Leroy Somer - enEmerson BatistaBelum ada peringkat

- Chint Contactor NC1 PDFDokumen13 halamanChint Contactor NC1 PDFmahmudBelum ada peringkat

- Amplifier: Electronics & SoftwareDokumen3 halamanAmplifier: Electronics & SoftwareJose M. RodriguezBelum ada peringkat

- Magnet - PMSM AnalysisDokumen26 halamanMagnet - PMSM Analysispcg_liveBelum ada peringkat

- High Performance Cooling of Traction BrushlessDokumen96 halamanHigh Performance Cooling of Traction BrushlessdftghsBelum ada peringkat

- Design of Synchronous MachinesDokumen17 halamanDesign of Synchronous MachinesNiteshNarukaBelum ada peringkat

- ABB Catalogue For LT MotorDokumen6 halamanABB Catalogue For LT MotorNavneet Singh0% (1)

- Project 1 Synchronous MachineDokumen34 halamanProject 1 Synchronous MachineDivya Kumar SharmaBelum ada peringkat

- 4411 Motor3D v13Dokumen78 halaman4411 Motor3D v13Roberto Eduardo Quintal PalomoBelum ada peringkat

- PhasesDokumen74 halamanPhasesRuth Velasquez QuirozBelum ada peringkat

- A Three-Phase Induction Motor ProblemDokumen26 halamanA Three-Phase Induction Motor ProblemmehmetBelum ada peringkat

- Fuses in Parallel Fuses in Parallel: ConfidentialDokumen10 halamanFuses in Parallel Fuses in Parallel: ConfidentialJonny Cristhian Otero Baca100% (1)

- Documentare ElectroeroziuneDokumen7 halamanDocumentare Electroeroziuneprofanu1Belum ada peringkat

- Treo Treo Yaari Charging Cable ChangedDokumen2 halamanTreo Treo Yaari Charging Cable ChangedCotech2 KNRBelum ada peringkat

- Project THESISDokumen58 halamanProject THESISnithinBelum ada peringkat

- A Three-Phase Induction Motor ProblemDokumen26 halamanA Three-Phase Induction Motor Problemowen674s100% (2)

- Catalogue Multi 9 Merlin Gerin PDFDokumen2 halamanCatalogue Multi 9 Merlin Gerin PDFOrlando VilladiegoBelum ada peringkat

- Sensored Field Oriented Control of A Permanent Magnet Synchronous Motor (PMSM)Dokumen35 halamanSensored Field Oriented Control of A Permanent Magnet Synchronous Motor (PMSM)Muhammad Waseem AnwarBelum ada peringkat

- Electromagnetic Force Couplingin - ANSYS PDFDokumen48 halamanElectromagnetic Force Couplingin - ANSYS PDFrahulbqaBelum ada peringkat

- Adaptive Headlight System For AutomobilesDokumen6 halamanAdaptive Headlight System For AutomobilesInternational Journal of Innovative Science and Research TechnologyBelum ada peringkat

- A Review On Hybrid Renewable Energy SystemsDokumen10 halamanA Review On Hybrid Renewable Energy SystemsChristhy Vanessa Ruiz MadroñeroBelum ada peringkat

- Cogging Torque MeasurementDokumen3 halamanCogging Torque MeasurementIon TrifuBelum ada peringkat

- Maxwell 15 - 2D PDFDokumen628 halamanMaxwell 15 - 2D PDFCata0% (1)

- Analyzing Power Electronics & Control System On Matlab/SimulinkDokumen18 halamanAnalyzing Power Electronics & Control System On Matlab/SimulinkMOHIT JAINBelum ada peringkat

- Power Genius Meters PDFDokumen2 halamanPower Genius Meters PDFAritheertham SaravananBelum ada peringkat

- Theory of Vector ControlDokumen26 halamanTheory of Vector ControlKuna MarndiBelum ada peringkat

- Reluctance MotorDokumen16 halamanReluctance Motorapi-382713280% (5)

- Lab MachineDokumen9 halamanLab MachineAnonymous ryvoPIDBelum ada peringkat

- A Permanent Magnet DC Motor ProblemDokumen32 halamanA Permanent Magnet DC Motor ProblemVladimir Kuznetsov100% (1)

- Reostate Pape&OlbertzDokumen14 halamanReostate Pape&Olbertzsoryn_25Belum ada peringkat

- Tutorial On How To Create An Op-Amp in CadenceDokumen9 halamanTutorial On How To Create An Op-Amp in Cadencecharlie charlieBelum ada peringkat

- Sew EncoderDokumen24 halamanSew EncodersanatikalaBelum ada peringkat

- RMXPRT OnlinehelpDokumen533 halamanRMXPRT Onlinehelpluchoteves100% (1)

- BEG1K075G - User Manual (V1.4)Dokumen20 halamanBEG1K075G - User Manual (V1.4)fantum10% (1)

- Hydraulic Pumps: BY Abeesh Kiran A M-Tech Design and Precision Engineering Nitk Surathkal, KarnatakaDokumen62 halamanHydraulic Pumps: BY Abeesh Kiran A M-Tech Design and Precision Engineering Nitk Surathkal, KarnatakaFaisal Rafique100% (1)

- Library List 7-28-06Dokumen3 halamanLibrary List 7-28-06Ola FondaBelum ada peringkat

- 6520-3902004РТ ENGL. (ЕВРО -2, 3, 4)Dokumen1.445 halaman6520-3902004РТ ENGL. (ЕВРО -2, 3, 4)kiên HoangBelum ada peringkat

- Simulate Variable Speed Motor Control - MATLAB & Simulink PDFDokumen9 halamanSimulate Variable Speed Motor Control - MATLAB & Simulink PDFLanAnhThịNguyễnBelum ada peringkat

- ACPLDokumen47 halamanACPLAmit BiswasBelum ada peringkat

- XXXXXXX: ConverterDokumen11 halamanXXXXXXX: ConverterfaisalBelum ada peringkat

- 01 Control Structures PDFDokumen22 halaman01 Control Structures PDFJeff RobertBelum ada peringkat

- Motor Sizing WorksheetDokumen5 halamanMotor Sizing Worksheetapi-3835934Belum ada peringkat

- Synchronous MechineDokumen8 halamanSynchronous MechineNaveen BansalBelum ada peringkat

- smps1000 EltekDokumen2 halamansmps1000 Elteksebax123Belum ada peringkat

- M 01 Motor Drive Link To M2DDokumen19 halamanM 01 Motor Drive Link To M2DSwathi Prasad100% (1)

- 3856 Motor Maxwell2DDokumen95 halaman3856 Motor Maxwell2DRiadh Tarkhani100% (3)

- Speed Control of BLDC Motor Using IPM and Micro 2812 Ver.2.0Dokumen41 halamanSpeed Control of BLDC Motor Using IPM and Micro 2812 Ver.2.0subbanna100% (1)

- Chapter 1 Digital Systems and Binary NumbersDokumen40 halamanChapter 1 Digital Systems and Binary NumbersDesyilalBelum ada peringkat

- Electrical Machines DiagramDokumen22 halamanElectrical Machines DiagramArivumani100% (1)

- Electrical Machine DesignDokumen8 halamanElectrical Machine DesignArvin TorrenteBelum ada peringkat

- Ferrite / Ceramic Data Sheet: American Standard - Also Used in UKDokumen1 halamanFerrite / Ceramic Data Sheet: American Standard - Also Used in UKsmailinatorBelum ada peringkat

- Galvanized Wire PDFDokumen10 halamanGalvanized Wire PDFAbdullah Al AsikBelum ada peringkat

- Type S Starco™: Pressed Seamless Steel / Stainless Steel / GalvanisedDokumen1 halamanType S Starco™: Pressed Seamless Steel / Stainless Steel / GalvanisedCristian Vicente Irigoyen AlvaradoBelum ada peringkat

- Kolver Usa CatalogoDokumen24 halamanKolver Usa CatalogoMartin DavilaBelum ada peringkat

- Hardware-Standard-Steel StructuresDokumen14 halamanHardware-Standard-Steel Structuresunytrix accountsBelum ada peringkat

- كميات الصخرDokumen5 halamanكميات الصخرalhaythamahmed5Belum ada peringkat

- Mega-Field Developments Require Special Tatics, Risk Management PDFDokumen3 halamanMega-Field Developments Require Special Tatics, Risk Management PDFGILBERTO YOSHIDABelum ada peringkat

- Datasheet Wear PadDokumen3 halamanDatasheet Wear PadGILBERTO YOSHIDABelum ada peringkat

- 3196 I FRAME BulletinDokumen24 halaman3196 I FRAME BulletinGILBERTO YOSHIDABelum ada peringkat

- UNC, UNF, & UNEF Thread ANSI B1,1 PDFDokumen4 halamanUNC, UNF, & UNEF Thread ANSI B1,1 PDFGILBERTO YOSHIDA100% (1)

- Information Handling Services, Wed Jan 29 12:06:09 2003Dokumen544 halamanInformation Handling Services, Wed Jan 29 12:06:09 2003GILBERTO YOSHIDABelum ada peringkat

- GRI Test Method GT12 (B) - ISO VersionDokumen7 halamanGRI Test Method GT12 (B) - ISO VersionGILBERTO YOSHIDABelum ada peringkat

- Canalisations Tubes Matriaux Synthse Eau Chaude Froide Sous Pression Version AnglaiseDokumen11 halamanCanalisations Tubes Matriaux Synthse Eau Chaude Froide Sous Pression Version AnglaiseGILBERTO YOSHIDABelum ada peringkat

- Pages From Aiche - Source ModelsDokumen2 halamanPages From Aiche - Source ModelsGILBERTO YOSHIDABelum ada peringkat

- Polypropylene Pipe Availability - PP-H: Metric Sizes DIN 8077/8078Dokumen4 halamanPolypropylene Pipe Availability - PP-H: Metric Sizes DIN 8077/8078GILBERTO YOSHIDABelum ada peringkat

- Hazards and Risk Assessment: Appendix BDokumen60 halamanHazards and Risk Assessment: Appendix BGILBERTO YOSHIDABelum ada peringkat

- BiotrendDokumen50 halamanBiotrendrobertBelum ada peringkat

- D10T Track-Type Tractor Power Train System: Rjg1-UpDokumen2 halamanD10T Track-Type Tractor Power Train System: Rjg1-UpJHOSMAR_22Belum ada peringkat

- CMOS Means Complementary MOS: NMOS and PMOS Working Together in A CircuitDokumen8 halamanCMOS Means Complementary MOS: NMOS and PMOS Working Together in A Circuitsuresht196Belum ada peringkat

- Techrite Fenwal Fenwal 17000 & 18000 Series Thermoswitch Temperature Controllers 2013050684Dokumen8 halamanTechrite Fenwal Fenwal 17000 & 18000 Series Thermoswitch Temperature Controllers 2013050684jesusBelum ada peringkat

- CJ1M (Brochure) PDFDokumen2 halamanCJ1M (Brochure) PDFDio Ilham Tirta AdiBelum ada peringkat

- Switchyard Earthing Report - AkkareipattuDokumen12 halamanSwitchyard Earthing Report - AkkareipattuManjithaGeethadharaGunarathneBelum ada peringkat

- ZW37 Heag 33 KV DrawingDokumen8 halamanZW37 Heag 33 KV Drawingabu sayedBelum ada peringkat

- DC GeneratorDokumen24 halamanDC GeneratorRahmat Bagus ArdhiansyahBelum ada peringkat

- Polysonics DCT7088 Flow Meter UltrasonicDokumen4 halamanPolysonics DCT7088 Flow Meter UltrasonicAris SetyawanBelum ada peringkat

- EA SERS 495 Presentation PDFDokumen36 halamanEA SERS 495 Presentation PDFAnonymous O9PMnP2FBelum ada peringkat

- TGS 2611C00 (1013)Dokumen2 halamanTGS 2611C00 (1013)R GikiswantoBelum ada peringkat

- Growth and Properties of Stacked Self-Assembled in Ga As Quantum Dots Didik Aryanto, Zulkafli Othaman, Abd. Khamim IsmailDokumen6 halamanGrowth and Properties of Stacked Self-Assembled in Ga As Quantum Dots Didik Aryanto, Zulkafli Othaman, Abd. Khamim IsmailakhmadfadholiBelum ada peringkat

- 10 MM Manifold Mount Solenoid Valve: Product SpecificationsDokumen6 halaman10 MM Manifold Mount Solenoid Valve: Product Specificationshüseyin vururBelum ada peringkat

- FPD 7024 Datasheet Data Sheet enUS 2692360331Dokumen4 halamanFPD 7024 Datasheet Data Sheet enUS 2692360331Danilo BarreraBelum ada peringkat

- HOOSEKI Campur 1Dokumen12 halamanHOOSEKI Campur 1Anugrah Prihantoro Amd T100% (3)

- Lecture 08 - Diffusion in Solids PDFDokumen23 halamanLecture 08 - Diffusion in Solids PDFicagayle VBelum ada peringkat

- ATENA TroubleshootingDokumen63 halamanATENA TroubleshootingAlvaro Hernandez LopezBelum ada peringkat

- Ge 11 Midterm ExamDokumen4 halamanGe 11 Midterm ExamNeil DalanonBelum ada peringkat

- Crystal Tester: Presented By-Sudesha Basu Majumder (19BEE0228) Parichay Singh (19BEE0229)Dokumen16 halamanCrystal Tester: Presented By-Sudesha Basu Majumder (19BEE0228) Parichay Singh (19BEE0229)Sudesha BasuBelum ada peringkat

- 8cef7c4b9cf6dac898a95442dc7c6834(1)Dokumen50 halaman8cef7c4b9cf6dac898a95442dc7c6834(1)Shalin DoshiBelum ada peringkat

- BN68 02589C 00L10 - 0329Dokumen331 halamanBN68 02589C 00L10 - 0329Kiki Riki MikiBelum ada peringkat

- Readme For EbootDokumen1 halamanReadme For EbootNea SpiracheBelum ada peringkat

- Sony ctv-61 Az1k Chassis Training Manual PDFDokumen45 halamanSony ctv-61 Az1k Chassis Training Manual PDFtom bozleyBelum ada peringkat

- E92 Complete VehicleDokumen41 halamanE92 Complete VehicleSilvia RodriguezBelum ada peringkat

- Components:: R1 R2 R3 R4 C1 C2 D1 D2Dokumen3 halamanComponents:: R1 R2 R3 R4 C1 C2 D1 D2Anton Pers100% (1)

- SWOLE o CLOCK MANUAL !!!Dokumen2 halamanSWOLE o CLOCK MANUAL !!!Aleksandar DimovskiBelum ada peringkat

- 950F IiDokumen20 halaman950F Iidico65583% (6)

- VLSI Interview QuestionsDokumen41 halamanVLSI Interview QuestionsKarthik Real Pacifier0% (1)