Hempadur 15553

Diunggah oleh

EngTamerJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Hempadur 15553

Diunggah oleh

EngTamerHak Cipta:

Format Tersedia

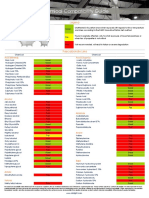

Product Data

HEMPADUR 15553

15553: BASE 15557: CURING AGENT 98021

Description: HEMPADUR 15553 is a two-component epoxy paint. It cures to a flexible, well adhering coating with

good abrasion and impact resistance. Contains zinc phosphate. Cures down to -10°C/14°F.

Recommended use: As a primer for HEMPATEX, HEMPADUR and HEMPATHANE systems on hot dipped galvanized

surfaces, aluminium and stainless steel in moderately corrosive environments. HEMPADUR 15553 is

also suited when roughening of the surface is not possible. Please see surface preparation overleaf.

Service temperature: Maximum, dry exposure only: 140°C/284°F

Certificates/Approvals: Complies with European Fire Standard EN 13501-1; classification B-s1, d0.

Approved as a low flame spread material when used as part of a predefined paint system. Please refer

to “Declaration of Conformity” on www.Hempel.com for further details.

Complies with EU Directive 2004/42/EC: subcategory j.

Availability: Part of Group Assortment. Local availability subject to confirmation.

PHYSICAL CONSTANTS:

Shade nos/Colours: 11630 / Off-white.

Finish: Flat

Volume solids, %: 55 ± 1

Theoretical spreading rate: 11 m2/l [441.1 sq.ft./US gallon] - 50 micron/2 mils

Flash point: 30 °C [86 °F]

Specific gravity: 1.5 kg/litre [12.9 lbs/US gallon]

Surface-dry: 20 minute(s) 20°C/68°F

Through-dry: 1.5 hour(s) 20°C/68°F

Fully cured: 7 day(s) 20°C/68°F

VOC content: 387 g/l [3.2 lbs/US gallon]

Shelf life: 6 months for BASE and 3 years for CURING AGENT (stored in closed container) for the BASE and 2

years for the CURING AGENT (stored in closed container) (25°C/77°F) from time of production.

Shelf life is dependent on storage temperature. Shelf life is reduced at storage temperatures above

25°C/77°F. Do not store above 40°C/104°F.

- The physical constants stated are nominal data according to the HEMPEL Group's approved formulas.

APPLICATION DETAILS:

Version, mixed product: 15553

Mixing ratio: BASE 15557: CURING AGENT 98021

3 : 1 by volume

Application method: Airless spray / Brush

Thinner (max.vol.): 08450 (5%) / 08450 (5%)

Pot life: 2 hour(s) 20°C/68°F

Nozzle orifice: 0.017 - 0.019 "

Nozzle pressure: 175 bar [2537.5 psi]

(Airless spray data are indicative and subject to adjustment)

Cleaning of tools: HEMPEL'S TOOL CLEANER 99610

Indicated film thickness, dry: 50 micron [2 mils]

Indicated film thickness, wet: 100 micron [4 mils]

Overcoat interval, min: see REMARKS overleaf

Overcoat interval, max: see REMARKS overleaf

-

Safety: Handle with care. Before and during use, observe all safety labels on packaging and paint containers,

consult HEMPEL Safety Data Sheets and follow all local or national safety regulations.

Date of issue: January 2016 Page: 1/2

Product Data

HEMPADUR 15553

SURFACE PREPARATION: Stainless steel and aluminium: Remove oil and grease etc. thoroughly with suitable detergent.

Remove salts and other contaminants by high pressure fresh water cleaning. Roughening of the

surface is recommended for optimum adhesion.

Galvanised steel: Remove oil and grease, etc. with suitable detergent. Remove salt and other

contaminants by (high pressure) fresh water cleaning. Zinc salts (white rust) must be removed by high

pressure hosing combined with rubbing with a stiff nylon brush if necessary.

It is recommended to overcoat spray-metallised surfaces as soon as possible to avoid possible

contamination.

APPLICATION CONDITIONS: Apply only on a dry and clean surface with a temperature above the dew point to avoid condensation.

At the freezing point and below be aware of the risk of ice on the surface, which will hinder adhesion.

Use only where application and curing can proceed at temperatures above:-10°C/14°F The

temperature of the surface must also be above these limits.

The temperature of the paint itself should be: 15-25°C/59-77°F In confined spaces provide adequate

ventilation during application and drying.

SUBSEQUENT COAT: According to specification. HEMPADUR, HEMPATHANE, HEMPATEX

REMARKS:

VOC - EU Directive 2004/42/EC:

Not available.

Product As supplied 5 vol. % thinning Limit phase II, 2010

1555311630 387 g/l 410 g/l 500 g/l

For VOC of other shades, please refer to Safety Data Sheet.

Application(s): Ammonium chloride or any other passivation agent should not be present on the surface when coating

the galvanized surface.

Water should not be used for cooling down the steel.

Cleaning of steel should not be initiated unless the steel temperature is below: 30°C/86°F

As the galvanized zinc layer may be porous it is recommended to apply a mist coat of diluted product,

allow air to escape, and then apply a full coat of the product a few minutes later.

Film thicknesses/thinning: May be specified in another film thickness than indicated depending on purpose and area of use. This

will alter spreading rate and may influence drying time and overcoating interval. Normal range dry is:

50-80 micron/2.0-3.2 mils

Overcoating: Overcoating intervals related to later conditions of exposure: If the maximum overcoating interval is

exceeded, roughening of the surface is necessary to ensure intercoat adhesion.

Before overcoating after exposure in contaminated environment, clean the surface thoroughly with high

pressure fresh water hosing and allow drying.

A specification supersedes any guideline overcoat intervals indicated in the table.

Environment Atmospheric, medium

Surface temperature: -10°C (14°F) 0°C (32°F) 20°C (68°F)

Min Max Min Max Min Max

HEMPADUR 27 h Ext. 14 h Ext. 3h Ext.

HEMPATEX 5h 9d 2h 4½ d 30 m 24 h

HEMPATHANE 27 h 90 d 14 h 45 d 3h 10 d

NR = Not Recommended, Ext. = Extended, m = minute(s), h = hour(s), d = day(s)

Overcoating note: In case of overcoating with coating other than HEMPADUR, apply a (thin) additional coat of the product

within the described directions for overcoating.

A completely clean surface is mandatory to ensure intercoat adhesion, especially at long overcoating

intervals. Any dirt, oil, grease, and other foreign matter must be removed with suitable detergent

followed by (high pressure) fresh water cleaning. Salts to be removed by fresh water hosing. Any

degraded surface layer, as a result of a long exposure period, must be removed. Water jetting

may be relevant to remove any degraded surface layer and may also replace the above mentioned

cleaning methods when properly executed. Consult HEMPEL for specific advice if in doubt.

To check whether the quality of the surface cleaning is adequate, a test patch may be relevant.

Note: HEMPADUR 15553 For professional use only.

ISSUED BY: HEMPEL A/S 1555311630

This Product Data Sheet supersedes those previously issued.

For explanations, definitions and scope, see “Explanatory Notes” available on www.hempel.com. Data, specifications, directions and recommendations given in this data sheet

represent only test results or experience obtained under controlled or specially defined circumstances. Their accuracy, completeness or appropriateness under the actual conditions

of any intended use of the Products herein must be determined exclusively by the Buyer and/or User.

The Products are supplied and all technical assistance is given subject to HEMPEL's GENERAL CONDITIONS OF SALES, DELIVERY AND SERVICE, unless otherwise expressly agreed

in writing. The Manufacturer and Seller disclaim, and Buyer and/or User waive all claims involving, any liability, including but not limited to negligence, except as expressed in said

GENERAL CONDITIONS for all results, injury or direct or consequential losses or damages arising from the use of the Products as recommended above, on the overleaf or otherwise.

Product data are subject to change without notice and become void five years from the date of issue.

Date of issue: January 2016 Page: 2/2

Anda mungkin juga menyukai

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitDari EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitBelum ada peringkat

- PDS HEMPADUR 15553 en-GBDokumen2 halamanPDS HEMPADUR 15553 en-GBachusanachuBelum ada peringkat

- Gas Sweetening and Processing Field ManualDari EverandGas Sweetening and Processing Field ManualPenilaian: 4 dari 5 bintang4/5 (7)

- 15553Dokumen2 halaman15553danish100% (1)

- Soldering electronic circuits: Beginner's guideDari EverandSoldering electronic circuits: Beginner's guidePenilaian: 4.5 dari 5 bintang4.5/5 (9)

- HEMPADUR ZINC 15360 15360 en-GB PDFDokumen2 halamanHEMPADUR ZINC 15360 15360 en-GB PDFErwin MalmsteinBelum ada peringkat

- Hempadur Fast Dry 17410 En-GbDokumen2 halamanHempadur Fast Dry 17410 En-GbTrịnh Minh KhoaBelum ada peringkat

- PDS Hempadur Fast Dry 15560 en-GBDokumen2 halamanPDS Hempadur Fast Dry 15560 en-GBErwin MalmsteinBelum ada peringkat

- MS GF 35870 en-GBDokumen2 halamanMS GF 35870 en-GBLinnie McleodBelum ada peringkat

- Detailers Dictionary Volume 2: The Industry StandardDari EverandDetailers Dictionary Volume 2: The Industry StandardBelum ada peringkat

- Hempel - S Zinc Primer 16490Dokumen2 halamanHempel - S Zinc Primer 16490Haryanto RBelum ada peringkat

- Hempadur Multi-Strength GF 35870 PDFDokumen3 halamanHempadur Multi-Strength GF 35870 PDFAnuar SalehBelum ada peringkat

- PDS en-GB 16490Dokumen2 halamanPDS en-GB 16490Anuar SalehBelum ada peringkat

- Hempadur Avantguard 550Dokumen2 halamanHempadur Avantguard 550Anuar SalehBelum ada peringkat

- Hempadur Zinc 17340 17340Dokumen2 halamanHempadur Zinc 17340 17340Sachin NambiarBelum ada peringkat

- PDS Hempaprime Multi 500 Winter en-GBDokumen2 halamanPDS Hempaprime Multi 500 Winter en-GBFreddyBelum ada peringkat

- PDS en-GB 45751Dokumen2 halamanPDS en-GB 45751Anuar SalehBelum ada peringkat

- PDS HEMPATHANE SPEED-DRY TOPCOAT 250 en-GBDokumen2 halamanPDS HEMPATHANE SPEED-DRY TOPCOAT 250 en-GBEli KhawBelum ada peringkat

- PDS Hempadur 85671 en-GBDokumen3 halamanPDS Hempadur 85671 en-GBvitharvanBelum ada peringkat

- PDS Hempadur Multi-Strength 45753 en-GBDokumen2 halamanPDS Hempadur Multi-Strength 45753 en-GBJosip LasanBelum ada peringkat

- Pds Hempadur Speed-Dry ZP 500 En-GbDokumen3 halamanPds Hempadur Speed-Dry ZP 500 En-GbDHANOOPBelum ada peringkat

- Hempadur Primer 15300Dokumen3 halamanHempadur Primer 15300vitharvanBelum ada peringkat

- PDS HEMPADUR 85671 en-GB PDFDokumen2 halamanPDS HEMPADUR 85671 en-GB PDFMohamed Farhan B PositiveBelum ada peringkat

- Hempaprime Multi 500 Summer 45950Dokumen3 halamanHempaprime Multi 500 Summer 45950omar alkarabliehBelum ada peringkat

- Hempadur 85671Dokumen2 halamanHempadur 85671EkoAndriAntoBelum ada peringkat

- Pds Hempadur 85671Dokumen2 halamanPds Hempadur 85671Namta GeorgeBelum ada peringkat

- Pds Hempel's Shopprimer e 15275 En-GbDokumen2 halamanPds Hempel's Shopprimer e 15275 En-GbErwin MalmsteinBelum ada peringkat

- Hempathane Hs 55610 55610 En-GbDokumen2 halamanHempathane Hs 55610 55610 En-GbfaizalBelum ada peringkat

- PDS Hempadur Hi-Build 45200 en-GBDokumen2 halamanPDS Hempadur Hi-Build 45200 en-GBvitharvanBelum ada peringkat

- HEMPADUR MULTI-STRENGTH 35530 BlackDokumen2 halamanHEMPADUR MULTI-STRENGTH 35530 BlackRuby Faith EspinosaBelum ada peringkat

- Product Data: Hempadur Multi-Strength 35530Dokumen2 halamanProduct Data: Hempadur Multi-Strength 35530Vijayaraj KumarBelum ada peringkat

- Hempel'S Vinyl Ester GF 35910: Description: Recommended UseDokumen2 halamanHempel'S Vinyl Ester GF 35910: Description: Recommended UseSurendra KumarBelum ada peringkat

- Hempadur Avantguard 750 1736g - Product DatasheetDokumen2 halamanHempadur Avantguard 750 1736g - Product DatasheetWisnu Wardhana0% (1)

- Product Data: HEMPADUR 85671Dokumen2 halamanProduct Data: HEMPADUR 85671EngTamerBelum ada peringkat

- Hempaline Prepare 130Dokumen2 halamanHempaline Prepare 130CRISTIAN SILVIU IANUCBelum ada peringkat

- PDS Hempatex Hi-Build 46330 en-GBDokumen2 halamanPDS Hempatex Hi-Build 46330 en-GBSARAVANABelum ada peringkat

- Hempadur Zinc 17380Dokumen2 halamanHempadur Zinc 17380sizmaruBelum ada peringkat

- PDS Hempathane HS 55610 en-GBDokumen3 halamanPDS Hempathane HS 55610 en-GBalouisBelum ada peringkat

- PDS HEMPATHANE FAST DRY 55750 en-GBDokumen2 halamanPDS HEMPATHANE FAST DRY 55750 en-GBEli KhawBelum ada peringkat

- Pds Hempel's Shopprimer e 15280 En-GbDokumen2 halamanPds Hempel's Shopprimer e 15280 En-GbErikas Abepa100% (1)

- Hempel'S Vinyl Ester GF 35910: Description: Recommended UseDokumen2 halamanHempel'S Vinyl Ester GF 35910: Description: Recommended UseEngTamerBelum ada peringkat

- PDS HEMPATHANE TOPCOAT 55210 en-GB PDFDokumen2 halamanPDS HEMPATHANE TOPCOAT 55210 en-GB PDFQA QCBelum ada peringkat

- PDS Hempadur 35560 en-GBDokumen2 halamanPDS Hempadur 35560 en-GBErwin MalmsteinBelum ada peringkat

- Hempadur Zinc 17360Dokumen2 halamanHempadur Zinc 17360Bang OchimBelum ada peringkat

- PDS Hempadur 85671 en-GBDokumen2 halamanPDS Hempadur 85671 en-GBfaisalfaiBelum ada peringkat

- Hempadur Quattro InglesDokumen3 halamanHempadur Quattro InglesElizabeth Maria Bazán MoralesBelum ada peringkat

- PDS Hempaprime Multi 500 Summer en-GBDokumen2 halamanPDS Hempaprime Multi 500 Summer en-GBFreddyBelum ada peringkat

- Pds Hempadur 35900 En-GbDokumen2 halamanPds Hempadur 35900 En-Gbluisbarrios104Belum ada peringkat

- PDS Hempathane HS 55610 en-GBDokumen3 halamanPDS Hempathane HS 55610 en-GBAnonymous HPlNDhM6ejBelum ada peringkat

- Pds Hempadur 85671 En-GbDokumen2 halamanPds Hempadur 85671 En-GbPrabath Nilan GunasekaraBelum ada peringkat

- Pds Hempadur 15590 En-GbDokumen2 halamanPds Hempadur 15590 En-Gbyasararafat12010Belum ada peringkat

- APCS-20A HempelDokumen10 halamanAPCS-20A HempelarjunmohananBelum ada peringkat

- Pds Hempathane Topcoat 55210 En-GbDokumen2 halamanPds Hempathane Topcoat 55210 En-GbSachin NambiarBelum ada peringkat

- HempelDokumen2 halamanHempelAnuar SalehBelum ada peringkat

- In 1st-PDS Hempadur 15570 en-GB PDFDokumen3 halamanIn 1st-PDS Hempadur 15570 en-GB PDFdcsamaraweeraBelum ada peringkat

- PDS Hempadur Multi-Strength 35842 en-GBDokumen2 halamanPDS Hempadur Multi-Strength 35842 en-GBIfrahimBelum ada peringkat

- Product Data: Hempel'S 15asgDokumen2 halamanProduct Data: Hempel'S 15asgwahyu0% (1)

- Elcometer 130 SSP Bresle Equivalence Report 2015Dokumen26 halamanElcometer 130 SSP Bresle Equivalence Report 2015EngTamerBelum ada peringkat

- Current SSPC Standards June2019Dokumen7 halamanCurrent SSPC Standards June2019Aleksander Segura Tinoco100% (1)

- 32 Samss 100Dokumen38 halaman32 Samss 100EngTamerBelum ada peringkat

- Asm Stag PDFDokumen1 halamanAsm Stag PDFRajiv SinghBelum ada peringkat

- 32 Samss 100Dokumen38 halaman32 Samss 100EngTamerBelum ada peringkat

- E-17 Model l60-6d Wrought 6d 60o ElbowDokumen4 halamanE-17 Model l60-6d Wrought 6d 60o ElbowEngTamerBelum ada peringkat

- Jotamastic Protective Brochure 2011 Tcm279 1592Dokumen24 halamanJotamastic Protective Brochure 2011 Tcm279 1592EngTamerBelum ada peringkat

- Norpol Accelerator 9802 PDokumen12 halamanNorpol Accelerator 9802 PEngTamerBelum ada peringkat

- Safety Data Sheet: Jotun Peroxide 1Dokumen12 halamanSafety Data Sheet: Jotun Peroxide 1EngTamerBelum ada peringkat

- Integrated Air Control Modules: Instructions-PartsDokumen14 halamanIntegrated Air Control Modules: Instructions-PartsEngTamerBelum ada peringkat

- Norox Mekp-925hDokumen2 halamanNorox Mekp-925hEngTamerBelum ada peringkat

- Butanox M 50Dokumen4 halamanButanox M 50EngTamerBelum ada peringkat

- Norox KP-9Dokumen2 halamanNorox KP-9EngTamerBelum ada peringkat

- Sigma Marine Coatings Manual - Part70Dokumen2 halamanSigma Marine Coatings Manual - Part70EngTamerBelum ada peringkat

- Sigma Marine Coatings Manual - Part64Dokumen2 halamanSigma Marine Coatings Manual - Part64EngTamerBelum ada peringkat

- Integrated Air Control Modules: Instructions-PartsDokumen16 halamanIntegrated Air Control Modules: Instructions-PartsEngTamerBelum ada peringkat

- Sigma Marine Coatings Manual - Part68Dokumen2 halamanSigma Marine Coatings Manual - Part68EngTamerBelum ada peringkat

- Sigma Marine Coatings Manual - Part67Dokumen2 halamanSigma Marine Coatings Manual - Part67EngTamerBelum ada peringkat

- Sigma Marine Coatings Manual - Part59Dokumen2 halamanSigma Marine Coatings Manual - Part59EngTamerBelum ada peringkat

- Sigma Marine Coatings Manual - Part69Dokumen2 halamanSigma Marine Coatings Manual - Part69EngTamerBelum ada peringkat

- Sigma Marine Coatings Manual - Part66Dokumen2 halamanSigma Marine Coatings Manual - Part66EngTamerBelum ada peringkat

- Sigma Marine Coatings Manual - Part61Dokumen2 halamanSigma Marine Coatings Manual - Part61EngTamerBelum ada peringkat

- Sigma Marine Coatings Manual - Part65Dokumen2 halamanSigma Marine Coatings Manual - Part65EngTamerBelum ada peringkat

- Sigma Marine Coatings Manual - Part60Dokumen2 halamanSigma Marine Coatings Manual - Part60EngTamerBelum ada peringkat

- Sigma Marine Coatings Manual - Part56Dokumen2 halamanSigma Marine Coatings Manual - Part56EngTamerBelum ada peringkat

- Sigma Part50Dokumen2 halamanSigma Part50EngTamerBelum ada peringkat

- Sigma Marine Coatings Manual - Part57Dokumen2 halamanSigma Marine Coatings Manual - Part57EngTamerBelum ada peringkat

- Sigma Marine Coatings Manual - Part58Dokumen2 halamanSigma Marine Coatings Manual - Part58EngTamerBelum ada peringkat

- Sigma Marine Coatings Manual - Part55Dokumen2 halamanSigma Marine Coatings Manual - Part55EngTamerBelum ada peringkat

- Sigmacover 525: Description Principal CharacteristicsDokumen2 halamanSigmacover 525: Description Principal CharacteristicsEngTamerBelum ada peringkat

- Theoretical Plate: Unit OperationsDokumen17 halamanTheoretical Plate: Unit OperationsMehari AsratBelum ada peringkat

- Chemsitry Yearly 1Dokumen24 halamanChemsitry Yearly 1Online TeachingBelum ada peringkat

- 1 s2.0 S0272884219306522 MainDokumen16 halaman1 s2.0 S0272884219306522 MainFábio FriolBelum ada peringkat

- Adchem - Biotech PCD Product SheetDokumen4 halamanAdchem - Biotech PCD Product SheetNirbhay SinghBelum ada peringkat

- CHM02 Written Work 2BDokumen9 halamanCHM02 Written Work 2BRonna IturaldeBelum ada peringkat

- Dr. Naitik D Trivedi & Dr. Upama N. Trivedi: Multiple Choice Questions (Analysis and Chemistry)Dokumen35 halamanDr. Naitik D Trivedi & Dr. Upama N. Trivedi: Multiple Choice Questions (Analysis and Chemistry)Seema YadavBelum ada peringkat

- Modul Defra Ting 5 Guru FinalDokumen34 halamanModul Defra Ting 5 Guru FinalWeenaBelum ada peringkat

- D&T FolioDokumen25 halamanD&T FolioYudish PoontaubBelum ada peringkat

- Control of Substances Hazardous To Health (Coshh) Regulations Summary of ChangesDokumen27 halamanControl of Substances Hazardous To Health (Coshh) Regulations Summary of ChangesSoares CardosoBelum ada peringkat

- Experiment No. 5 Preparation of Aspirin (Initial)Dokumen2 halamanExperiment No. 5 Preparation of Aspirin (Initial)Christine MarcellanaBelum ada peringkat

- FLSmidth Key To LubricantsDokumen70 halamanFLSmidth Key To LubricantsMuhammad SaputraBelum ada peringkat

- L32-Diffusion Coating ProcessesDokumen10 halamanL32-Diffusion Coating ProcessesdavidblessleyBelum ada peringkat

- To Study The Digestion of Starch by SaliDokumen12 halamanTo Study The Digestion of Starch by SaliUthaya SurianBelum ada peringkat

- Mariane Rabelo - Artigo QuakerDokumen10 halamanMariane Rabelo - Artigo QuakerTibis GBelum ada peringkat

- Dialight Chemical CompatibilityDokumen16 halamanDialight Chemical CompatibilityJuan AcuñaBelum ada peringkat

- VADOSE ZONE Microbial EcologyDokumen9 halamanVADOSE ZONE Microbial EcologySh MbaBelum ada peringkat

- Strengthening Mechanism-30102017Dokumen18 halamanStrengthening Mechanism-30102017Amina MubasharBelum ada peringkat

- Chemical Kinetic - Dec2016 PDFDokumen137 halamanChemical Kinetic - Dec2016 PDFFaisal AzamBelum ada peringkat

- 2011 Vol 30-31-32 Reprint-Welding Processes, Faults, Defects, Etc ReprintDokumen28 halaman2011 Vol 30-31-32 Reprint-Welding Processes, Faults, Defects, Etc ReprintMuhammad UmairBelum ada peringkat

- C3 ElectrochemistryDokumen39 halamanC3 ElectrochemistryaliesyaBelum ada peringkat

- Draft Fumigation Certificate - SK226485001Dokumen2 halamanDraft Fumigation Certificate - SK226485001Erick TacdolBelum ada peringkat

- Geology and Exploration of Porphyry Copper Deposits: in North Sulawesi, IndonesiaDokumen17 halamanGeology and Exploration of Porphyry Copper Deposits: in North Sulawesi, IndonesiaazizBelum ada peringkat

- Missile TechnologyDokumen52 halamanMissile TechnologySanjay KumarBelum ada peringkat

- OMM SEMINAR Plastic BricksDokumen25 halamanOMM SEMINAR Plastic BricksOm ZakardeBelum ada peringkat

- Zenpure - Filter CatalogueDokumen326 halamanZenpure - Filter CatalogueLU DustinBelum ada peringkat

- Project Report On Oleum: Guided By: Yamini S. PatelDokumen51 halamanProject Report On Oleum: Guided By: Yamini S. PatelPatel RajBelum ada peringkat

- PerfumeDokumen23 halamanPerfumeMeliha Mahamude80% (5)

- JEE Main Sample Question Paper 6Dokumen28 halamanJEE Main Sample Question Paper 6Tanvir ShafalBelum ada peringkat

- 4 Principles and Concepts of Laboratory Design and Ventilation - 4Dokumen93 halaman4 Principles and Concepts of Laboratory Design and Ventilation - 4rizky anandaBelum ada peringkat

- Guava IrshadDokumen14 halamanGuava IrshadPedro de SouzaBelum ada peringkat

- Hacking Electronics: An Illustrated DIY Guide for Makers and HobbyistsDari EverandHacking Electronics: An Illustrated DIY Guide for Makers and HobbyistsPenilaian: 3.5 dari 5 bintang3.5/5 (2)

- Conquering the Electron: The Geniuses, Visionaries, Egomaniacs, and Scoundrels Who Built Our Electronic AgeDari EverandConquering the Electron: The Geniuses, Visionaries, Egomaniacs, and Scoundrels Who Built Our Electronic AgePenilaian: 4.5 dari 5 bintang4.5/5 (9)

- Practical Electrical Wiring: Residential, Farm, Commercial, and IndustrialDari EverandPractical Electrical Wiring: Residential, Farm, Commercial, and IndustrialPenilaian: 3.5 dari 5 bintang3.5/5 (3)

- Teach Yourself Electricity and Electronics, 6th EditionDari EverandTeach Yourself Electricity and Electronics, 6th EditionPenilaian: 3.5 dari 5 bintang3.5/5 (15)

- Electronics All-in-One For Dummies, 3rd EditionDari EverandElectronics All-in-One For Dummies, 3rd EditionPenilaian: 5 dari 5 bintang5/5 (2)

- INCOSE Systems Engineering Handbook: A Guide for System Life Cycle Processes and ActivitiesDari EverandINCOSE Systems Engineering Handbook: A Guide for System Life Cycle Processes and ActivitiesPenilaian: 5 dari 5 bintang5/5 (1)

- Digital Filmmaking: The Ultimate Guide to Web Video Production for Beginners and Non-Professionals, Learn Useful Tips and Advice on How You Can Create, Film and Edit Your VideosDari EverandDigital Filmmaking: The Ultimate Guide to Web Video Production for Beginners and Non-Professionals, Learn Useful Tips and Advice on How You Can Create, Film and Edit Your VideosPenilaian: 5 dari 5 bintang5/5 (1)

- Electrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tDari EverandElectrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tPenilaian: 4.5 dari 5 bintang4.5/5 (27)

- Analog Design and Simulation Using OrCAD Capture and PSpiceDari EverandAnalog Design and Simulation Using OrCAD Capture and PSpiceBelum ada peringkat

- Programming the Raspberry Pi, Third Edition: Getting Started with PythonDari EverandProgramming the Raspberry Pi, Third Edition: Getting Started with PythonPenilaian: 5 dari 5 bintang5/5 (2)

- Practical Power Distribution for IndustryDari EverandPractical Power Distribution for IndustryPenilaian: 2.5 dari 5 bintang2.5/5 (2)

- Upcycled Technology: Clever Projects You Can Do With Your Discarded Tech (Tech gift)Dari EverandUpcycled Technology: Clever Projects You Can Do With Your Discarded Tech (Tech gift)Penilaian: 4.5 dari 5 bintang4.5/5 (2)

- Build Your Own Electronics WorkshopDari EverandBuild Your Own Electronics WorkshopPenilaian: 3.5 dari 5 bintang3.5/5 (3)

- The Phone Fix: The Brain-Focused Guide to Building Healthy Digital Habits and Breaking Bad OnesDari EverandThe Phone Fix: The Brain-Focused Guide to Building Healthy Digital Habits and Breaking Bad OnesPenilaian: 5 dari 5 bintang5/5 (1)

- Current Interruption Transients CalculationDari EverandCurrent Interruption Transients CalculationPenilaian: 4 dari 5 bintang4/5 (1)

- Heat Transfer Engineering: Fundamentals and TechniquesDari EverandHeat Transfer Engineering: Fundamentals and TechniquesPenilaian: 4 dari 5 bintang4/5 (1)

- Wearable Sensors: Fundamentals, Implementation and ApplicationsDari EverandWearable Sensors: Fundamentals, Implementation and ApplicationsEdward SazonovBelum ada peringkat

- The Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionDari EverandThe Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionPenilaian: 4.5 dari 5 bintang4.5/5 (543)

- ARDUINO CODE: Mastering Arduino Programming for Embedded Systems (2024 Guide)Dari EverandARDUINO CODE: Mastering Arduino Programming for Embedded Systems (2024 Guide)Belum ada peringkat