Post Tention 1

Diunggah oleh

assaad006Deskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Post Tention 1

Diunggah oleh

assaad006Hak Cipta:

Format Tersedia

Massaad ghadieh

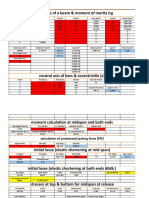

ID : A0710475 note that all the yellow cells are imput

case 1 spalling or bursting

b (cm) = 75 b1<---------- b2 ---------->b3

b1 (cm) = 15 h1

b2 (cm) = 45

b3 (cm) = 15 h

h (cm) = 100 h2

h1 (cm) = 15

h2 (cm) = 65 h3

h3 (cm) = 20 <---------------------- b --------------->

section A (cm 2 ) y(cm) A*Y(cm 3 ) A*y 2 (cm 4 ) Icg(cm 4) Summary (m)

1 1500 50 75000 3750000 1250000 Icg 5190187 0.0519019

2 675 92.5 62437.5 5775468.8 12656.25 Yb 48.401639 0.4840164

3 900 10 9000 90000 30000 Yt 51.598361 0.5159836

4 1500 50 75000 3750000 1250000

∑ 4575 221437.5 13365469 2542656.3 Ac 4575 0.4575

L 20 m

1. section properties

Area 0.4575 m2 perimeter 3.5 m

Ybot 0.484 m 7 strands spacing area

Ytop 0.516 m 12.7 mm 5 cm 99 mm2 9.9E-05 m2

Icg 0.05190187 m4 15.2 mm 6 cm 140 mm2 0.00014 m2

2. Jacking force:

Aps: 0.0027 m2

Fpj 3766.5 kN name of duct area of strands

using 2 ducts with 9 strands each 9 C 15 1350 mm2

3. strands eccentricity

4. Moments

at 0.5L

Msw 571.875 kn-m

Msdl 500 kn-m 10 kN/m

Mll 375 kn-m 7.5 kN/m

at 0.4L

Msw 549 kn-m

Msdl 480 kn-m 10 kN/m

Mll 360 kn-m 7.5 kN/m

at 0.3L

Msw 480.375 kn-m

Msdl 420 kn-m 10 kN/m

Mll 315 kn-m 7.5 kN/m

at 0.25L

Msw 428.90625 kn-m

Msdl 375 kn-m 10 kN/m

Mll 281.25 kn-m 7.5 kN/m

at 0.2L

Msw 366 kn-m

Msdl 320 kn-m 10 kN/m

Mll 240 kn-m 7.5 kN/m

at 0.1L

Msw 205.875 kn-m

Msdl 180 kn-m 10 kN/m

Mll 135 kn-m 7.5 kN/m

at 0L

Msw 0 kn-m

Msdl 0 kn-m

Mll 0 kn-m

5 . initial stage

(max of 27 strands per duct )

Friction loss:

e ax^2+bx+c take the largest value if no data mentioned

condition 1 : at x = 0 e = 0 c = 0

condition 2 : at x = L e = 0 b = - a*L CL

condition 3 : at x = L/2 de/dx = 0 =>> 2aL/2 + b = 0 = > b = -a*L

2 equations 2 unknowns :

b = - a/L =>a = - 4emax/L^2

x = L/2 =>(aL^2)/4 + bL/2 = emax b = 4emax/L x

e (-4emax/L^2)*x^2 + (4emax/L)*x

diam of duct = 7 cm e=emax

clear cov= 4 cm stirrup = 1 cm

emax = 0.39901639 (Ybot - (clear cover + stirrup + diam of duct)) e

a -0.00399016 b 0.0798

e -0.00399016 x^2 + 0.0798 x

at jacking x = 0

Lpx =(dist from jacking end to the specified point ) = 0m

μpx =(friction coeff) = 0.0066

K (wobble coeff) = 0.25

de/dx at x = 0 de/dx = 0.0798 rad

αpx =(angle change with respect to jacking end)= 0

ΔfFr = 0 Pj = 0

at anchoring end x = 20 m

Lpx =(dist from jacking end to the specified point ) = 20 m

μpx =(friction coeff) = 0.0066

K (wobble coeff) = 0.25

de/dx at x = L de/dx = -0.0798 rad

αpx =(angle change with respect to jacking end)= 0.159607 rad

ΔfFr = 0.15793801 Pj = 594.873

f'c = 40 Mpa

f'ci = 32 Mpa

0.6*f'ci = -19.2 Mpa

initial losses at mid-span : at x = 0.5L = 10 m

friction losses

at x = L/2= 10 m

Lpx =(dist from jacking end to the specified point ) = 10 m

μpx =(friction coeff) = 0.0066

K (wobble coeff) = 0.25

de/dx at x = 0.5L de/dx = 0 rad

αpx =(angle change with respect to jacking end)= 0.079803 rad

ΔfFr = 0.08236064 Pj = 310.211

anchor set losses : (slippage)

1/4 " to 3/8" => 0.63cm to 0.8 cm

ΔfAs =(ΔL/L)Eps 80 Mpa

maximum at jacking end and 0 at the anchor end

elastic losses

e -0.00399016 x^2 + 0.0798 x 0.39902 m

N= 2

n 7.52241257

fcir 15390.3776 kN/m2

ES 57886.3848 kN/m2 57.8864 Mpa

Fpi = 3393.36919 kN 9.90657 %

stresses :

Ѵbot = -Fpi/A - [(Fpi*e)*Ybot]/Icg + [Msw*Ybot]/Icg

=> Ѵbot -14711.0827 kN/m2 =>> -14.711 Mpa

Ѵtop = -Fpi/A + [(Fpi*e)*Ytop]/Icg - [Msw*Ytop]/Icg

=> Ѵtop 358.411638 kN/m2 =>> 0.35841 Mpa

allowable stresses that we need to comply with

ACI code chap 18 section 18.4.1

check : ok for compression

max (+) allowable for tension :

0.25*sqrt(f'ci) = 1.41421 Mpa

check : ok

initial losses at 0.4L ==> x = 8m

friction losses

at x =0.4L 8m

Lpx =(dist from jacking end to the specified point ) = 8m

μpx =(friction coeff) = 0.0066

K (wobble coeff) = 0.25

de/dx at x = 0.4L de/dx = 0.01596 rad

αpx =(angle change with respect to jacking end)= 0.063843 rad

ΔfFr = 0.06644991 Pj = 250.284

anchor set losses : (slippage)

1/4 " to 3/8" => 0.63cm to 0.8 cm

ΔfAs =(ΔL/L)Eps 80 Mpa

maximum at jacking end and 0 at the anchor end

elastic losses

e -0.00399016 x^2 + 0.0798 x 0.38306 m

fcir 14660.3962 kN/m2

ES 55140.7742 kN/m2 55.1408 Mpa

Fpi = 3400.94414 kN 9.70545 %

stresses :

Ѵbot = -Fpi/A - [(Fpi*e)*Ybot]/Icg + [Msw*Ybot]/Icg

=> Ѵbot -14462.9442 kN/m2 =>> -14.463 Mpa

Ѵtop = -Fpi/A + [(Fpi*e)*Ytop]/Icg - [Msw*Ytop]/Icg

=> Ѵtop 59.676495 kN/m2 =>> 0.05968 Mpa

allowable stresses that we need to comply with

ACI code chap 18 section 18.4.1

check : ok for compression

max (+) allowable for tension :

0.25*sqrt(f'ci) = 1.41421 Mpa

check : ok

initial losses at 0.3L ==> x = 6m

friction losses

at x =0.3L 6m

Lpx =(dist from jacking end to the specified point ) = 6m

μpx =(friction coeff) = 0.0066

K (wobble coeff) = 0.25

de/dx at x = 0.3L de/dx = 0.03192 rad

αpx =(angle change with respect to jacking end)= 0.047882 rad

ΔfFr = 0.0502633 Pj = 189.317

anchor set losses : (slippage)

1/4 " to 3/8" => 0.63cm to 0.8 cm

ΔfAs =(ΔL/L)Eps 80 Mpa

maximum at jacking end and 0 at the anchor end

elastic losses

e -0.00399016 x^2 + 0.0798 x 0.33517 m

fcir 13283.1829 kN/m2

ES 49960.7909 kN/m2 49.9608 Mpa

Fpi = 3415.09471 kN 9.32976 %

stresses :

Ѵbot = -Fpi/A - [(Fpi*e)*Ybot]/Icg + [Msw*Ybot]/Icg

=> Ѵbot -13659.4565 kN/m2 =>> -13.659 Mpa

Ѵtop = -Fpi/A + [(Fpi*e)*Ytop]/Icg - [Msw*Ytop]/Icg

=> Ѵtop -860.781345 kN/m2 =>> -0.8608 Mpa

allowable stresses that we need to comply with

ACI code chap 18 section 18.4.1

check : ok for compression

max (+) allowable for tension :

0.25*sqrt(f'ci) = 1.41421 Mpa

check : ok

initial losses at 0.25L ==> x = 5m

friction losses

at x =0.25 5m

Lpx =(dist from jacking end to the specified point ) = 5m

μpx =(friction coeff) = 0.0066

K (wobble coeff) = 0.25

de/dx at x = 0.25L de/dx = 0.0399 rad

αpx =(angle change with respect to jacking end)= 0.039902 rad

ΔfFr = 0.04206505 Pj = 158.438

anchor set losses : (slippage)

1/4 " to 3/8" => 0.63cm to 0.8 cm

ΔfAs =(ΔL/L)Eps 80 Mpa

maximum at jacking end and 0 at the anchor end

elastic losses

e -0.00399016 x^2 + 0.0798 x 0.29926 m

fcir 12258.9316 kN/m2

ES 46108.3707 kN/m2 46.1084 Mpa

Fpi = 3425.57962 kN 9.05138 %

stresses :

Ѵbot = -Fpi/A - [(Fpi*e)*Ybot]/Icg + [Msw*Ybot]/Icg

=> Ѵbot -13047.9104 kN/m2 =>> -13.048 Mpa

Ѵtop = -Fpi/A + [(Fpi*e)*Ytop]/Icg - [Msw*Ytop]/Icg

=> Ѵtop -1560.0667 kN/m2 =>> -1.5601 Mpa

allowable stresses that we need to comply with

ACI code chap 18 section 18.4.1

check : ok for compression

max (+) allowable for tension :

0.25*sqrt(f'ci) = 1.41421 Mpa

check : ok

initial losses at 0.2L ==> x = 4m

friction losses

at x =0.2L 4m

Lpx =(dist from jacking end to the specified point ) = 4m

μpx =(friction coeff) = 0.0066

K (wobble coeff) = 0.25

de/dx at x = 0.2L de/dx = 0.04788 rad

αpx =(angle change with respect to jacking end)= 0.031921 rad

ΔfFr = 0.03379604 Pj = 127.293

anchor set losses : (slippage)

1/4 " to 3/8" => 0.63cm to 0.8 cm

ΔfAs =(ΔL/L)Eps 80 Mpa

maximum at jacking end and 0 at the anchor end

elastic losses

e -0.00399016 x^2 + 0.0798 x 0.25537 m

fcir 11164.536 kN/m2

ES 41992.1231 kN/m2 41.9921 Mpa

Fpi = 3436.77758 kN 8.75408 %

stresses :

Ѵbot = -Fpi/A - [(Fpi*e)*Ybot]/Icg + [Msw*Ybot]/Icg

=> Ѵbot -12283.5432 kN/m2 =>> -12.284 Mpa

Ѵtop = -Fpi/A + [(Fpi*e)*Ytop]/Icg - [Msw*Ytop]/Icg

=> Ѵtop -2425.48645 kN/m2 =>> -2.4255 Mpa

allowable stresses that we need to comply with

ACI code chap 18 section 18.4.1

check : ok for compression

max (+) allowable for tension :

0.25*sqrt(f'ci) = 1.41421 Mpa

check : ok

initial losses at 0.1L ==> x = 2m

friction losses

at x =0.1L 2m

Lpx =(dist from jacking end to the specified point ) = 2m

μpx =(friction coeff) = 0.0066

K (wobble coeff) = 0.25

de/dx at x = 0.1L de/dx = 0.06384 rad

αpx =(angle change with respect to jacking end)= 0.015961 rad

ΔfFr = 0.01704326 Pj = 64.1934

anchor set losses : (slippage)

1/4 " to 3/8" => 0.63cm to 0.8 cm

ΔfAs =(ΔL/L)Eps 80 Mpa

maximum at jacking end and 0 at the anchor end

elastic losses

e -0.00399016 x^2 + 0.0798 x 0.14365 m

fcir 9160.41064 kN/m2

ES 34454.194 kN/m2 34.4542 Mpa

Fpi = 3457.30035 kN 8.2092 %

stresses :

Ѵbot = -Fpi/A - [(Fpi*e)*Ybot]/Icg + [Msw*Ybot]/Icg

=> Ѵbot -10268.3795 kN/m2 =>> -10.268 Mpa

Ѵtop = -Fpi/A + [(Fpi*e)*Ytop]/Icg - [Msw*Ytop]/Icg

=> Ѵtop -4666.42285 kN/m2 =>> -4.6664 Mpa

allowable stresses that we need to comply with

ACI code chap 18 section 18.4.1

check : ok for compression

max (+) allowable for tension :

0.25*sqrt(f'ci) = 1.41421 Mpa

check : ok

initial losses at 0L ==> x = 0m

friction losses

at x =0L= 0m

Lpx =(dist from jacking end to the specified point ) = 0m

μpx =(friction coeff) = 0.0066

K (wobble coeff) = 0.25

de/dx at x = 0.1L de/dx = 0.0798 rad

αpx =(angle change with respect to jacking end)= 0 rad

ΔfFr = 0 Pj = 0

anchor set losses : (slippage)

1/4 " to 3/8" => 0.63cm to 0.8 cm

ΔfAs =(ΔL/L)Eps 80 Mpa

maximum at jacking end and 0 at the anchor end

elastic losses

e -0.00399016 x^2 + 0.0798 x 0m

fcir 8232.78689 kN/m2

ES 30965.2098 kN/m2 30.9652 Mpa

Fpi = 3466.89393 kN 7.9545 %

stresses :

Ѵbot = -Fpi/A - [(Fpi*e)*Ybot]/Icg

=> Ѵbot -7577.91024 kN/m2 =>> -7.5779 Mpa

Ѵtop = -Fpi/A + [(Fpi*e)*Ytop]/Icg

=> Ѵtop -7577.91024 kN/m2 =>> -7.5779 Mpa

allowable stresses that we need to comply with

ACI code chap 18 section 18.4.1

check : ok for compression

max (+) allowable for tension :

0.5*sqrt(f'ci) = 2.82843 Mpa

check : ok

6 . final stage

Final losses at 0.5L

Kcr 1.6

Es/Ec 6.72825034

fcir 13430.1757

fcds 3843.95008

CR 103197.641 kN/m2 103.198 Mpa

Ksh = 0.85 for 3days

V/S 0.13071429 m

SH 41492.0117 kN/m2 41.492 Mpa

Kre 5000 psi

Kre 34475 kN/m2

J 0.04 for low relaxation wire 270 ksi or 1860 Mpa

Fpi/fpu 0.67570075

C 0.75 from table 3

RE 19778.9689

total 164468.622

Fpf 2949.30391 kN 21.6964 %

Ѵbot = -Fpf/A - [(Fpf*e)*Ybot]/Icg + [(Msw + Mdl + Mll)*Ybot]/Icg = -3928.1

=> Ѵbot -3928.14506 kN/m2 =>> -3.9281 Mpa

Ѵtop = -Fpf/A + [(Fpf*e)*Ytop]/Icg - [(Msw + Mdl + Mll)*Ytop]/Icg = -9131.3

=> Ѵtop -9131.31772 kN/m2 =>> -9.1313 Mpa

allowable stresses that we need to comply with

ACI code chap 18 section 18.4.2 (b)

for compression : (-)

Pre + DL + LL = -3.9281 Mpa bot

0.6*f'c = -24 Mpa it is greater , ok

Pre + DL + LL = -9.1313 Mpa top

0.6*f'c = -24 Mpa it is greater , ok

for tension : (+)

Pre + DL + LL = -3.9281 Mpa

0.5*sqrt(f'c) = 3.16228 Mpa (normal environmental condition)

0.25*sqrt(f'c) = 1.58114 Mpa (aggressive environmental condition) near sea

0 = 0 Mpa (extremly aggressive environmental condition) poluted area

Final losses at 0.4L

Kcr 1.6

Es/Ec 6.72825034

fcir 12996.7309

fcds 3542.58439

CR 101775.783 kN/m2 101.776 Mpa

Ksh = 0.85 for 3days

V/S 0.13071429 m

SH 41492.0117 kN/m2 41.492 Mpa

Kre 5000 psi

Kre 34475 kN/m2

J 0.04 for low relaxation wire 270 ksi or 1860 Mpa

Fpi/fpu 0.67720911

C 0.75 from table 3

RE 19903.9929

total 163171.787

Fpf 2960.38032 kN 21.4024 %

Ѵbot = -Fpf/A - [(Fpf*e)*Ybot]/Icg + [(Msw + Mdl + Mll)*Ybot]/Icg = -4092.7

=> Ѵbot -4092.66006 kN/m2 =>> -4.0927 Mpa

Ѵtop = -Fpf/A + [(Fpf*e)*Ytop]/Icg - [(Msw + Mdl + Mll)*Ytop]/Icg = -9006

=> Ѵtop -9005.95767 kN/m2 =>> -9.006 Mpa

allowable stresses that we need to comply with

ACI code chap 18 section 18.4.2 (b)

for compression : (-)

Pre + DL + LL = -4.0927 Mpa bot

0.6*f'c = -24 Mpa it is greater , ok

Pre + DL + LL = -9.006 Mpa top

0.6*f'c = -24 Mpa it is greater , ok

for tension : (+)

Pre + DL + LL = -4.0927 Mpa

0.5*sqrt(f'c) = 3.16228 Mpa (normal environmental condition)

0.25*sqrt(f'c) = 1.58114 Mpa (aggressive environmental condition) near sea

0 = 0 Mpa (extremly aggressive environmental condition) poluted area

Final losses at 0.3L

Kcr 1.6

Es/Ec 6.72825034

fcir 11754.4681

fcds 2712.29117

CR 97340.8478 kN/m2 97.3408 Mpa

Ksh = 0.85 for 3days

V/S 0.13071429 m

SH 41492.0117 kN/m2 41.492 Mpa

Kre 5000 psi

Kre 34475 kN/m2

J 0.04 for low relaxation wire 270 ksi or 1860 Mpa

Fpi/fpu 0.68002682

C 0.75 from table 3

RE 20192.4405

total 159025.3

Fpf 2985.7264 kN 20.7294 %

Ѵbot = -Fpf/A - [(Fpf*e)*Ybot]/Icg + [(Msw + Mdl + Mll)*Ybot]/Icg = -4524.6

=> Ѵbot -4524.55012 kN/m2 =>> -4.5246 Mpa

Ѵtop = -Fpf/A + [(Fpf*e)*Ytop]/Icg - [(Msw + Mdl + Mll)*Ytop]/Icg = -8660

=> Ѵtop -8660.00469 kN/m2 =>> -8.66 Mpa

allowable stresses that we need to comply with

ACI code chap 18 section 18.4.2 (b)

for compression : (-)

Pre + DL + LL = -4.5246 Mpa bot

0.6*f'c = -24 Mpa it is greater , ok

Pre + DL + LL = -8.66 Mpa top

0.6*f'c = -24 Mpa it is greater , ok

for tension : (+)

Pre + DL + LL = -4.5246 Mpa

0.5*sqrt(f'c) = 3.16228 Mpa (normal environmental condition)

0.25*sqrt(f'c) = 1.58114 Mpa (aggressive environmental condition) near sea

0 = 0 Mpa (extremly aggressive environmental condition) poluted area

Final losses at 0.25L

Kcr 1.6

Es/Ec 6.72825034

fcir 10925.4842

fcds 2162.22192

CR 94338.2757 kN/m2 94.3383 Mpa

Ksh = 0.85 for 3days

V/S 0.13071429 m

SH 41492.0117 kN/m2 41.492 Mpa

Kre 5000 psi

Kre 34475 kN/m2

J 0.04 for low relaxation wire 270 ksi or 1860 Mpa

Fpi/fpu 0.68211462

C 0.75 from table 3

RE 20398.0903

total 156228.378

Fpf 3003.763 kN 20.2506 %

Ѵbot = -Fpf/A - [(Fpf*e)*Ybot]/Icg + [(Msw + Mdl + Mll)*Ybot]/Icg = -4828.8

=> Ѵbot -4828.77107 kN/m2 =>> -4.8288 Mpa

Ѵtop = -Fpf/A + [(Fpf*e)*Ytop]/Icg - [(Msw + Mdl + Mll)*Ytop]/Icg = -8417.1

=> Ѵtop -8417.14355 kN/m2 =>> -8.4171 Mpa

allowable stresses that we need to comply with

ACI code chap 18 section 18.4.2 (b)

for compression : (-)

Pre + DL + LL = -4.8288 Mpa bot

0.6*f'c = -24 Mpa it is greater , ok

Pre + DL + LL = -8.4171 Mpa top

0.6*f'c = -24 Mpa it is greater , ok

for tension : (+)

Pre + DL + LL = -4.8288 Mpa

0.5*sqrt(f'c) = 3.16228 Mpa (normal environmental condition)

0.25*sqrt(f'c) = 1.58114 Mpa (aggressive environmental condition) near sea

0 = 0 Mpa (extremly aggressive environmental condition) poluted area

Final losses at 0.2L

Kcr 1.6

Es/Ec 6.72825034

fcir 10029.5389

fcds 1574.48195

CR 91020.3841 kN/m2 91.0204 Mpa

Ksh = 0.85 for 3days

V/S 0.13071429 m

SH 41492.0117 kN/m2 41.492 Mpa

Kre 5000 psi

Kre 34475 kN/m2

J 0.04 for low relaxation wire 270 ksi or 1860 Mpa

Fpi/fpu 0.6843444

C 0.75 from table 3

RE 20621.1144

total 153133.51

Fpf 3023.3171 kN 19.7314 %

Ѵbot = -Fpf/A - [(Fpf*e)*Ybot]/Icg + [(Msw + Mdl + Mll)*Ybot]/Icg = -5172.8

=> Ѵbot -5172.8153 kN/m2 =>> -5.1728 Mpa

Ѵtop = -Fpf/A + [(Fpf*e)*Ytop]/Icg - [(Msw + Mdl + Mll)*Ytop]/Icg = -8138.7

=> Ѵtop -8138.68196 kN/m2 =>> -8.1387 Mpa

allowable stresses that we need to comply with

ACI code chap 18 section 18.4.2 (b)

for compression : (-)

Pre + DL + LL = -5.1728 Mpa bot

0.6*f'c = -24 Mpa it is greater , ok

Pre + DL + LL = -8.1387 Mpa top

0.6*f'c = -24 Mpa it is greater , ok

for tension : (+)

Pre + DL + LL = -5.1728 Mpa

0.5*sqrt(f'c) = 3.16228 Mpa (normal environmental condition)

0.25*sqrt(f'c) = 1.58114 Mpa (aggressive environmental condition) near sea

0 = 0 Mpa (extremly aggressive environmental condition) poluted area

Final losses at 0.1L

Kcr 1.6

Es/Ec 6.72825034

fcir 7556.94066

fcds 498.17593

CR 75989.018 kN/m2 75.989 Mpa

Ksh = 0.85 for 3days

V/S 0.13071429 m

SH 41492.0117 kN/m2 41.492 Mpa

Kre 5000 psi

Kre 34475 kN/m2

J 0.04 for low relaxation wire 270 ksi or 1860 Mpa

Fpi/fpu 0.68843097

C 0.75 from table 3

RE 21298.1933

total 138779.223

Fpf 3082.59645 kN 18.1575 %

Ѵbot = -Fpf/A - [(Fpf*e)*Ybot]/Icg + [(Msw + Mdl + Mll)*Ybot]/Icg = -6009.8

=> Ѵbot -6009.84093 kN/m2 =>> -6.0098 Mpa

Ѵtop = -Fpf/A + [(Fpf*e)*Ytop]/Icg - [(Msw + Mdl + Mll)*Ytop]/Icg = -7514.1

=> Ѵtop -7514.07678 kN/m2 =>> -7.5141 Mpa

allowable stresses that we need to comply with

ACI code chap 18 section 18.4.2 (b)

for compression : (-)

Pre + DL + LL = -6.0098 Mpa bot

0.6*f'c = -24 Mpa it is greater , ok

Pre + DL + LL = -7.5141 Mpa top

0.6*f'c = -24 Mpa it is greater , ok

for tension : (+)

Pre + DL + LL = -6.0098 Mpa

0.5*sqrt(f'c) = 3.16228 Mpa (normal environmental condition)

0.25*sqrt(f'c) = 1.58114 Mpa (aggressive environmental condition) near sea

0 = 0 Mpa (extremly aggressive environmental condition) poluted area

Final losses at 0L

Kcr 1.6

Es/Ec 6.72825034

fcir 7577.91024

fcds 0

CR 81577.7234 kN/m2 81.5777 Mpa

Ksh = 0.85 for 3days

V/S 0.13071429 m

SH 41492.0117 kN/m2 41.492 Mpa

Kre 5000 psi

Kre 34475 kN/m2

J 0.04 for low relaxation wire 270 ksi or 1860 Mpa

Fpi/fpu 0

C 0.75 from table 3

RE 22479.962

total 104057.685

Fpf 3185.93818 kN 15.4138 %

Ѵbot = -Fpf/A - [(Fpf*e)*Ybot]/Icg + [(Msw + Mdl + Mll)*Ybot]/Icg = -6963.8

=> Ѵbot -6963.79931 kN/m2 =>> -6.9638 Mpa

Ѵtop = -Fpf/A + [(Fpf*e)*Ytop]/Icg - [(Msw + Mdl + Mll)*Ytop]/Icg = -6963.8

=> Ѵtop -6963.79931 kN/m2 =>> -6.9638 Mpa

allowable stresses that we need to comply with

ACI code chap 18 section 18.4.2 (b)

for compression : (-)

Pre + DL + LL = -6.9638 Mpa bot

0.6*f'c = -24 Mpa it is greater , ok

Pre + DL + LL = -6.9638 Mpa top

0.6*f'c = -24 Mpa it is greater , ok

for tension : (+)

Pre + DL + LL = -6.9638 Mpa

0.5*sqrt(f'c) = 3.16228 Mpa (normal environmental condition)

0.25*sqrt(f'c) = 1.58114 Mpa (aggressive environmental condition) near sea

0 = 0 Mpa (extremly aggressive environmental condition) poluted area

Anda mungkin juga menyukai

- Foundations Ch4Dokumen62 halamanFoundations Ch4stevehuppertBelum ada peringkat

- RC18 Column02Dokumen8 halamanRC18 Column02assaad006Belum ada peringkat

- Neutral Axis of A Beam & Moment of Inertia IcgDokumen8 halamanNeutral Axis of A Beam & Moment of Inertia Icgassaad006Belum ada peringkat

- Staade Print HelpDokumen6 halamanStaade Print Helpassaad006Belum ada peringkat

- Military BuildingsDokumen5 halamanMilitary Buildingsassaad006100% (1)

- Show Daily 2Dokumen37 halamanShow Daily 2assaad006100% (2)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Einhell BC-BG 43 AsDokumen16 halamanEinhell BC-BG 43 AsCristiana LaviniaBelum ada peringkat

- A Model Curriculum For K-12 Computer ScienceDokumen45 halamanA Model Curriculum For K-12 Computer ScienceRini SandeepBelum ada peringkat

- Automine For Trucks Brochure EnglishDokumen4 halamanAutomine For Trucks Brochure EnglishJH Miguel AngelBelum ada peringkat

- Project Report DemoDokumen6 halamanProject Report DemoSangeeta TarkasbandBelum ada peringkat

- Oracle Advisor Webcast: What's New in Financial Reporting 11.1.2.4.900Dokumen33 halamanOracle Advisor Webcast: What's New in Financial Reporting 11.1.2.4.900huyhnBelum ada peringkat

- EnglishDokumen6 halamanEnglishDiep NgocBelum ada peringkat

- Computer Communication Networks CS-418: Lecture 8 - 1 Network Layer - Routing ProtocolsDokumen19 halamanComputer Communication Networks CS-418: Lecture 8 - 1 Network Layer - Routing ProtocolsAli MemonBelum ada peringkat

- MagPi108, MagPi Magazine August 2021Dokumen100 halamanMagPi108, MagPi Magazine August 2021Benjamin DoverBelum ada peringkat

- Coursera - Data Analytics - Course 1Dokumen8 halamanCoursera - Data Analytics - Course 1UtjaleBelum ada peringkat

- Buyer Seller RelationDokumen16 halamanBuyer Seller RelationMirza Sher Afgan BabarBelum ada peringkat

- Programming in Infobasic: ObjectivesDokumen22 halamanProgramming in Infobasic: Objectiveslolitaferoz100% (1)

- Lectra Fashion Brochure - pdf898Dokumen8 halamanLectra Fashion Brochure - pdf898Kanti ModhwadiaBelum ada peringkat

- AePDS MaharashtraDokumen1 halamanAePDS MaharashtraJuber ChausBelum ada peringkat

- Software Requirements Specification: Version 1.0 ApprovedDokumen20 halamanSoftware Requirements Specification: Version 1.0 ApprovedygtBelum ada peringkat

- Easy Start Guide: WEG CFW300 Frequency InverterDokumen15 halamanEasy Start Guide: WEG CFW300 Frequency InverterJoel Borges BrasilBelum ada peringkat

- Spectradaq-200 Is A Precision Data Acquisition Sound Card Optimized For Test and MeasurementDokumen2 halamanSpectradaq-200 Is A Precision Data Acquisition Sound Card Optimized For Test and MeasurementMounicaRasagyaPallaBelum ada peringkat

- Online Examination System, Use Case ProjectDokumen32 halamanOnline Examination System, Use Case ProjectMohit Sharma100% (23)

- HPGL2-RTL ReferenceGuide 5961-3526 540pages Sep96Dokumen540 halamanHPGL2-RTL ReferenceGuide 5961-3526 540pages Sep96pappu khanBelum ada peringkat

- Absolute Beginner Guide NanoVNA v1 6Dokumen75 halamanAbsolute Beginner Guide NanoVNA v1 6fox7878100% (1)

- Waves and Transmission LinesDokumen8 halamanWaves and Transmission LinesetitahBelum ada peringkat

- A Review On BIM-based Automated Code Compliance Checking SystemDokumen1 halamanA Review On BIM-based Automated Code Compliance Checking SystemAsad AhmedBelum ada peringkat

- Avaya Aura Communication Manager Special Application Features R10.2.x Dec2023Dokumen45 halamanAvaya Aura Communication Manager Special Application Features R10.2.x Dec2023Vinod M SBelum ada peringkat

- Solid Programming AbilitiesDokumen4 halamanSolid Programming AbilitiesScribe.coBelum ada peringkat

- PHARMACY MANAGEMENT PROJECT Ahmad IbitoyDokumen116 halamanPHARMACY MANAGEMENT PROJECT Ahmad IbitoyHamna BadarBelum ada peringkat

- Seatel 1898 Quick Start and Specs PDFDokumen6 halamanSeatel 1898 Quick Start and Specs PDFIonut NeamtuBelum ada peringkat

- nanoVNA-Applications - Rudiswiki9Dokumen18 halamannanoVNA-Applications - Rudiswiki9mariorossi5555550% (2)

- Networking AssignmentDokumen53 halamanNetworking AssignmentManish SahBelum ada peringkat

- Resource Allocation Failure Service Degraded PDFDokumen11 halamanResource Allocation Failure Service Degraded PDFyacine bouazniBelum ada peringkat

- Math Texas TAKS With Answers 2009Dokumen51 halamanMath Texas TAKS With Answers 2009aehsgo2collegeBelum ada peringkat

- Electronics 1 - Laboratory ExercisesDokumen63 halamanElectronics 1 - Laboratory Exercisesneo_rajaBelum ada peringkat