Aquaculture and Geothermal Heat Pump Systems

Diunggah oleh

shubhiJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Aquaculture and Geothermal Heat Pump Systems

Diunggah oleh

shubhiHak Cipta:

Format Tersedia

AQUACULTURE AND GEOTHERMAL

HEAP PUMP SYSTEMS

Andrew Chiasson, P.E.

Geo-Heat Center

ABSTRACT AQUACULTURE TANK HEATING SYSTEMS

The objective of this study is to examine the In a comparison study of this type, assumptions need

feasibility of aquaculture tank heating with geothermal heat to be made about the fish tank heating system that is being

pump (GHP) systems. Both closed- and open-loop GHP displaced by the GHP system. It was assumed that a con-

systems are examined for heating uncovered and greenhouse- ventional system would consist of a number of above-ground

covered tanks at three locations across the U.S. A net present tanks; where, water is heated by a natural gas-fired boiler

value analysis is conducted for a 20-year life-cycle for various system. The alternative is a water-to-water GHP system.

GHP base-load fractions with natural gas-fired boiler peaking.

The fraction of GHP capacity to the peak load yielding the AQUACULTURE TANK HEATING LOADS

lowest life-cycle cost is plotted at various GHP installation Hourly heating loads were calculated for above-

costs and natural gas rates. ground aquaculture tanks with a total surface area of 10,000

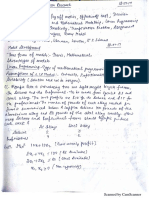

Heating load calculations show that covering ft2 (930 m2) and a depth of 5 ft (1.5 m). Typical

aquaculture tanks with a greenhouse-type structure reduces the meteorological year (TMY) data for Boston, MA; Dallas, TX,

heating requirements by over 50%. Economic analyses for and Denver, CO, were used to compute loads for two

closed-loop GHP systems show that, the lowest life-cycle cost scenarios: (1) tanks uncovered and (2) tanks covered by a

at natural gas rates of $1.00/therm ($0.35/m3) is observed greenhouse structure. Heat transfer processes included in the

when the GHP system is sized for 10-20% of the peak load. calculations are shown in Figure 1. The tank set point

At that fraction, 30-55% of the total annual heating load could temperature was 80oF (27oC).

be handled. At low loop installation costs of $4/ft-$6/ft (a) uncovered tank

($13/m-$20/m), approximately 55-70% of the annual heating

load could be handled.

Open-loop GHP systems show considerably more SOLAR

RADIATION

favorable economics than closed-loop systems. In all

situations examined, at natural gas prices of $1.00/therm CONVECTION

THERMAL

RADIATION

($0.35/m3), the lowest life-cycle cost is observed when the wind

EVAPORATION

open-loop system is sized for about 40% of the peak load. At

that size, the GHP system can handle over 80% of the annual CONDUCTION

TANK

heating requirements. At low-to-moderate installation costs of +

CONVECTION

$200-$700/ton ($57/kW-$200/kW), over 90% of the annual

heating load could be handled. Of course, open-loop systems CONDUCTION

would need to be sited at locations with sufficient groundwater TO GROUND

supply. (b) covered tank

INTRODUCTION

SOLAR

RADIATION

The success and economic benefits of aquaculture

operations with low-temperature geothermal resources (i.e., GREENHOUSE

STRUCTURE

groundwater temperatures >140oF (60oC) has lead to the HEAT AND HUMIDITY

HUMIDITY

BUILDUP DUE TO

GREENHOUSE EFFECT

question of whether or not lower temperature resources could

be exploited with the aid of geothermal heat pumps (GHPs). CONVECTION

THERMAL

RADIATION

EVAPORATION

This study seeks to answer that question, and therefore, the wind

+

RE- CONDENSATION

objective is to determine the feasibility of heating fish tanks

with GHP systems. Both closed- and open-loop systems are HEAT LOSSES

AND GAINS

by

TANK

CONDUCTION

+

CONVECTION

examined at three locations across the United States: Boston, INFILTRATION,

CONDUCTION,

CONVECTION

MA; Dallas, TX, and Denver, CO. A number of GHP base- CONDUCTION

load combinations are examined for the three locations to find TO GROUND

the lowest 20-year life-cycle cost at various natural gas rates

and GHP installation costs. Figure 1. Heat transfer processes in covered and

uncovered aquaculture tanks.

6 GHC BULLETIN, MARCH 2005

Hourly heating loads for the year are shown in

Figures 2 and 3. As might be expected, Boston and Denver

show more extreme heating loads than Dallas. In all cases,

covering the tanks with a greenhouse structure results in

approximately a 50% reduction in heating load. An

interesting and important result is shown in Figure 4, which

Figure 3. Hourly heating loads on an annual basis

for covered aquaculture tanks.

is a plot of the fraction of total annual heating demands versus

the fraction of the peak load that a base-load system would be

designed to handle. This is significant since a base-load

system (the GHP system in this case) sized at 50% of the peak

Figure 2. Hourly heating loads on an annual basis load could meet about 92% of the total annual heating

for uncovered aquaculture tanks. requirements.

GHC BULLETIN, MARCH 2005 7

Figure 4. Fraction of total annual heating load actually handled versus design fraction of peak load for a base-load

system.

8 GHC BULLETIN, MARCH 2005

ECONOMIC ANALYSIS Results of the closed-loop economic analysis are

Closed-Loop GHP System presented in the form of contour plots in Figure 5 for

The hourly loads shown in Figures 2 and 3 were uncovered tanks and in Figure 6 for greenhouse-covered

converted to monthly total and peak loads, and using a tanks. Results were similar for all three cities examined. The

software program, ground loops were sized for each location plot shows contours of the GHP fraction of the total heating

for several GHP part load cases (100%, 75%, 50%, 33%, 25%, system that yields the lowest NPV at various natural gas rates

10%, and 0%). The remainder of the load is handled by a and ground-loop installation costs.

natural gas-fired-boiler system. The loop-sizing software also A review of Figures 5 and 6 reveals that at natural

computes heat pump power consumption. gas prices above about $0.50-$0.60/therm ($0.18/m3-

A net present value (NPV) analysis of a 20-year life- $0.21/m3), it would be economically justifiable to heat a

cycle was used to compare alternatives for the various part portion of aquaculture tanks with a closed-loop GHP system,

load cases. Equipment costs for natural gas-fired boiler depending on the installation costs. For uncovered tanks at

systems were taken from R.S. Means Mechanical Cost Data natural gas costs of $1.00/therm ($0.35/m3), for example, the

and water-to-water heat pump material and installation costs lowest life-cycle cost is seen to range from a GHP sized at

were assumed at $1000/ton ($284/kW) of heat pump capacity. about 7% of the peak load at installation costs of $12/ft

Ground-loop installation costs are commonly reported per foot ($39/m) to about 22% of the peak load at installation costs of

of vertical bore, and for this study, a range of $4/ft to $12/ft $4/ft ($13/m). At these sizes, the GHP system could handle

($13/m to $39/m) was examined, which is representative of from about 25% to about 65% of the total annual load,

the widely varying values observed across the U.S. respectively. For covered tanks under the same conditions,

Annual operating costs included fuel and the lowest life cycle cost is seen to range from a GHP sized at

maintenance costs. A range of natural gas costs from $0.50 about 12% of the peak load at installation costs of $12/ft

to $2.00 per therm ($0.18/m3 to $0.70/m3) was examined. ($39/m) to about 25% of the peak load at installation costs of

Electricity cost was fixed at $0.10/kW-hr. Annual boiler $4/ft ($13/m).

maintenance costs were assumed at 2% of capital cost. A

discount rate of 6% was assumed.

Figure 5. Closed-loop GHP system fraction providing lowest net present value of a 20-year life-cycle at various

natural gas costs and closed-loop installation costs used to heat uncovered aquaculture tanks (Results

derived from Boston, Dallas and Denver climate data).

GHC BULLETIN, MARCH 2005 9

Figure 6. Closed-loop GHP system fraction providing lowest net present value of a 20-year life-cycle at various

natural gas costs and closed-loop installation costs used to heat covered aquaculture tanks (Results derived

from Boston, Dallas and Denver climate data).

Open-Loop GHP System

The same overall approach was taken in the economic

analysis of the open-loop systems as for the closed-loop

systems with the following differences. The capital cost range

of the open-loop systems were taken from Outside the Loop

Newsletter (Vol. 1, No.1, 1998). These costs, shown in Figure

7, are expressed per ton (and kW) of delivered capacity for

various well configurations and include costs of production

and injection wells, well tests, pumps, piping to the building,

heat exchangers, controls, and 15% contingency.

For the operating costs, additional electrical loads were

included to account for a submersible pump operating under

an assumed vertical head of 100 ft (30.48 m).

Results of the open-loop economic analysis are

presented in Figure 8 for uncovered tanks and in Figure 9 for

greenhouse-covered tanks. The plots show contours of the

GHP fraction of the total heating system that yields the lowest

NPV at various natural gas rates and open loop installation

costs. A review of Figures 8 and 9 shows greater feasibility

of aquaculture tank heating with open-loop GHP systems over

closed-loop systems. The lowest life-cycle cost at natural gas

rates of $1.00/therm ($0.35/m3), is seen for the GHP system Figure 7. Open-loop system costs for 60 o F

sized at about 40% of the peak load, being capable of handling groundwater (Source: Outside the Loop

over 90% of the annual heating load, at installation costs up to Newsletter, Vol. 1, No. 1, 1998).

10 GHC BULLETIN, MARCH 2005

Figure 8. Open-loop GHP system fraction providing lowest net present value of a 20-year life-cycle at various

natural gas costs and closed-loop installation costs used to heat uncovered aquaculture tanks (Results

derived from Boston, Dallas and Denver climate data).

$700/ton ($200/kW) for uncovered tanks and up to about has shown that the feasibility of heating aquaculture tanks

$875/ton ($250/kW) for covered tanks. Above these costs per with closed-loop GHP systems is strongly dependent on the

ton (kW), an open-loop system could still be installed to natural gas cost and the ground-loop installation cost. The

handle 80-90% of the annual load for either covered or lowest life-cycle cost was observed when the closed-loop GHP

uncovered tanks. Note also the relative “flatness” of the 0.1 system handles only a portion of the total annual heating

to 0.4 curves in Figures 8 and 9. This reflects the economies requirement. At natural gas rates of $1.00/therm ($0.35/m3),

of scale with open loop systems; only two to four wells are depending on loop installation costs and whether or not the

needed if enough ground water is present. Thus, a greenhouse aquaculture tanks are covered, a closed-loop GHP system

would need to be sited at a location where there is sufficient sized at 7-25% of the peak load could be installed to handle

groundwater supply. from about 25-70% of the annual load.

The economics of open-loop systems for the cases

CONCLUDING SUMMARY examined, as may be expected, are more attractive than

This study has examined the feasibility of closed-loop systems. In all situations examined, at natural gas

aquaculture tank heating with closed- and open-loop GHP prices of $1.00/therm ($0.35/m3), the lowest life-cycle cost

systems. Heating loads were computed for three climates was observed at the GHP system sized at about 40% of the

across the U.S. The net present value of a 20-year life-cycle peak load. At that size, an open-loop system could handle

was determined for various GHP base-load fractions. over 80% of the annual heating load. At low-to-moderate

The results of this study show that the practice of installation costs of $200-$700/ton ($57/kW-$200/kW), over

covering aquaculture tanks with greenhouse-type structures 90% of the annual heating load could be handled.

can reduce heating demands by 55%. The economic analysis

GHC BULLETIN, MARCH 2005 11

Figure 9. Open-loop GHP system fraction providing lowest net present value of a 20-year life-cycle at various

natural gas costs and closed-loop installation costs used to heat covered aquaculture tanks (Results derived

from Boston, Dallas and Denver climate data).

12 GHC BULLETIN, MARCH 2005

Anda mungkin juga menyukai

- Advanced Engineering Thermodynamics: Thermodynamics and Fluid Mechanics SeriesDari EverandAdvanced Engineering Thermodynamics: Thermodynamics and Fluid Mechanics SeriesPenilaian: 4 dari 5 bintang4/5 (9)

- Performance and Risks of Advanced Pulverized-Coal Plants: Herminé Nalbandian IEA Coal ResearchDokumen6 halamanPerformance and Risks of Advanced Pulverized-Coal Plants: Herminé Nalbandian IEA Coal ResearchRAM KrishanBelum ada peringkat

- Theoretical and Experimental Investigation On A GAX Based NH3 H2O - 2020 - SolarDokumen13 halamanTheoretical and Experimental Investigation On A GAX Based NH3 H2O - 2020 - SolarLENNART CHRIS BRUNA MUÑOZBelum ada peringkat

- Desalination: V. Samson Packiaraj Raphael, R. Velraj, Purnima JalihalDokumen20 halamanDesalination: V. Samson Packiaraj Raphael, R. Velraj, Purnima JalihalMustafa KaddouraBelum ada peringkat

- 1 s2.0 S1359431121005561 MainDokumen16 halaman1 s2.0 S1359431121005561 Mainmuhammad.arslanBelum ada peringkat

- Ref 1-Simulation and Analysis of Different Adiabatic Compressed Air Energy StorageDokumen8 halamanRef 1-Simulation and Analysis of Different Adiabatic Compressed Air Energy StorageAbhishek DahiyaBelum ada peringkat

- Cascading Vapour Absorption Cycle With Organic Rankine Cycle For Enhancing Geothermal Power Generation PDFDokumen13 halamanCascading Vapour Absorption Cycle With Organic Rankine Cycle For Enhancing Geothermal Power Generation PDFM Rama Yudhanto100% (1)

- Energy Conversion and Management: Rabah GomriDokumen9 halamanEnergy Conversion and Management: Rabah GomriStanley PrimoBelum ada peringkat

- Geothermal Turboden: Smarter Binary Systems DeliveredDokumen21 halamanGeothermal Turboden: Smarter Binary Systems Deliveredthibault martinBelum ada peringkat

- Fluid Selection For The Organic Rankine Cycle (ORC) in Biomass Power and Heat Plants PDFDokumen6 halamanFluid Selection For The Organic Rankine Cycle (ORC) in Biomass Power and Heat Plants PDFChairunnisa NisaBelum ada peringkat

- Basic Hydrodynamic Aspects of A Solar Energy Based Desalination ProcessDokumen10 halamanBasic Hydrodynamic Aspects of A Solar Energy Based Desalination Processagmibrahim5055Belum ada peringkat

- Jten 2016 2 6.1210Dokumen12 halamanJten 2016 2 6.1210danish5aliBelum ada peringkat

- J Apenergy 2010 11 034Dokumen8 halamanJ Apenergy 2010 11 034Gerakan MemberkatiBelum ada peringkat

- Aquaculture and Geothermal Heat Pump SystemsDokumen13 halamanAquaculture and Geothermal Heat Pump SystemsdaebigBelum ada peringkat

- On Mixtures As Working Fluids For Air-Cooled ORC Bottoming Power Plants of Gas TurbinesDokumen12 halamanOn Mixtures As Working Fluids For Air-Cooled ORC Bottoming Power Plants of Gas Turbinescarlo83Belum ada peringkat

- 1 s2.0 S1359431120331288 MainDokumen10 halaman1 s2.0 S1359431120331288 MainSharik DuarteBelum ada peringkat

- 2012 - Thermodynamic Evaluation of Heat Recovery Through A Canopus Heat Exchanger For Vapor Compression Refrigeration (VCRDokumen7 halaman2012 - Thermodynamic Evaluation of Heat Recovery Through A Canopus Heat Exchanger For Vapor Compression Refrigeration (VCRBradley JohnsonBelum ada peringkat

- 1 s2.0 S1359431122001247 MainDokumen14 halaman1 s2.0 S1359431122001247 MainAasia FarrukhBelum ada peringkat

- 1 s2.0 S0017931019312049 Main PDFDokumen11 halaman1 s2.0 S0017931019312049 Main PDFTanvir MahtabBelum ada peringkat

- 13 Space Heating and Cooling: Properties, Production, ApplicationsDokumen1 halaman13 Space Heating and Cooling: Properties, Production, ApplicationsPon lathaBelum ada peringkat

- Handbook of Food PreservationDokumen14 halamanHandbook of Food PreservationEduardo RuedaBelum ada peringkat

- Performance Optimization of A Combined Solar Collector, Geothermal Heat Pump and Thermal Seasonal Storage System For Heating and Cooling GreenhousesDokumen10 halamanPerformance Optimization of A Combined Solar Collector, Geothermal Heat Pump and Thermal Seasonal Storage System For Heating and Cooling GreenhousesAbdelilah HilaliBelum ada peringkat

- Energy Conversion and Management: Dehua Cai, Jingkai Jiang, Guogeng He, Keqiao Li, Lijuan Niu, Ruxi XiaoDokumen12 halamanEnergy Conversion and Management: Dehua Cai, Jingkai Jiang, Guogeng He, Keqiao Li, Lijuan Niu, Ruxi XiaoKArenBelum ada peringkat

- Energy Conversion and Management: Evangelos Bellos, Christos Tzivanidis, Dimitrios TsimpoukisDokumen15 halamanEnergy Conversion and Management: Evangelos Bellos, Christos Tzivanidis, Dimitrios TsimpoukisShafira RiskinaBelum ada peringkat

- CO2 Emissions From Geothermal Power PlantsDokumen9 halamanCO2 Emissions From Geothermal Power Plantsakbar maulanaBelum ada peringkat

- Sustainable Energy Technologies and AssessmentsDokumen13 halamanSustainable Energy Technologies and AssessmentsMuhammadAsimBelum ada peringkat

- Applied Energy: Qiang Liu, Yuanyuan Duan, Zhen YangDokumen6 halamanApplied Energy: Qiang Liu, Yuanyuan Duan, Zhen YangKumbamBelum ada peringkat

- 1 s2.0 S1359431118348919 MainDokumen8 halaman1 s2.0 S1359431118348919 MainLilou MGKBelum ada peringkat

- Thermodynamic and Economic Investigation of A HumidificationDokumen11 halamanThermodynamic and Economic Investigation of A HumidificationDokajanBelum ada peringkat

- Journal of Cleaner Production: Siyu Zhang, Zhenjiao Jiang, Shengsheng Zhang, Qixing Zhang, Guanhong FengDokumen12 halamanJournal of Cleaner Production: Siyu Zhang, Zhenjiao Jiang, Shengsheng Zhang, Qixing Zhang, Guanhong FengCRISTIAN TIBOCHA VELASCOBelum ada peringkat

- Thermal Conductivity in Geothermal ReservoirsDokumen5 halamanThermal Conductivity in Geothermal ReservoirsZedouri AziezBelum ada peringkat

- 1 s2.0 S1359431116341680 MainDokumen15 halaman1 s2.0 S1359431116341680 Mainmuhammad.arslanBelum ada peringkat

- MainDokumen7 halamanMainDiego MaportiBelum ada peringkat

- Ocean Thermal Energy Conversion: UIS EGADokumen33 halamanOcean Thermal Energy Conversion: UIS EGA1341131Belum ada peringkat

- 7 - Performance of Solar-Ice Slurry Systems For Residential Buildings in European ClimatesDokumen14 halaman7 - Performance of Solar-Ice Slurry Systems For Residential Buildings in European ClimatesRicardo ToledoBelum ada peringkat

- Diez - Economic FeasibilityDokumen8 halamanDiez - Economic FeasibilityrvramanBelum ada peringkat

- Design, Fabrication and Performance Analysis of Vapor Absorption Refrigeration System Powered by Solar Using NanofluidDokumen5 halamanDesign, Fabrication and Performance Analysis of Vapor Absorption Refrigeration System Powered by Solar Using NanofluidchilakaprakashBelum ada peringkat

- Parametric and Working Fluid Analysis of A Combined Organic Rankine-Vapor Compression Refrigeration System Activated by Low-Grade Thermal EnergyDokumen10 halamanParametric and Working Fluid Analysis of A Combined Organic Rankine-Vapor Compression Refrigeration System Activated by Low-Grade Thermal EnergyCatalina DobreBelum ada peringkat

- OTECDokumen14 halamanOTECTALLURI LAKSHMI PRASANNABelum ada peringkat

- Applied Thermal Engineering: Jin Luo, Anning Li, Xinning Ma, Kanghui PeiDokumen12 halamanApplied Thermal Engineering: Jin Luo, Anning Li, Xinning Ma, Kanghui PeiJorge CazhoBelum ada peringkat

- A Novel Reverse Flow Strategy For Ethylbenzene Dehydrogenation in A Packed-Bed ReactorDokumen17 halamanA Novel Reverse Flow Strategy For Ethylbenzene Dehydrogenation in A Packed-Bed ReactorMuhammad Akbar FahleviBelum ada peringkat

- Energy Conversion and Management: Latif Aref, Rasoul Fallahzadeh, Vahid Madadi AvarganiDokumen12 halamanEnergy Conversion and Management: Latif Aref, Rasoul Fallahzadeh, Vahid Madadi Avarganiyourladys AcostaBelum ada peringkat

- Energy Conversion and Management: A.H. Mosaffa, L. Garousi Farshi, S. KhaliliDokumen16 halamanEnergy Conversion and Management: A.H. Mosaffa, L. Garousi Farshi, S. Khalililugo aldair cobeñas pereyraBelum ada peringkat

- Automotive Hydrogen Storage System Using Cryo-Adsorption On Activated CarbonDokumen12 halamanAutomotive Hydrogen Storage System Using Cryo-Adsorption On Activated CarbonMartín KunuschBelum ada peringkat

- Energy Conversion and Management: A. Marni Sandid, M. Bassyouni, Driss Nehari, Y. ElhenawyDokumen14 halamanEnergy Conversion and Management: A. Marni Sandid, M. Bassyouni, Driss Nehari, Y. Elhenawymahmoud hassanBelum ada peringkat

- Energy Conversion and Management: Erren Yao, Huanran Wang, Ligang Wang, Guang Xi, François MaréchalDokumen11 halamanEnergy Conversion and Management: Erren Yao, Huanran Wang, Ligang Wang, Guang Xi, François MaréchalrendiBelum ada peringkat

- 1 s2.0 S2214157X1630185X MainDokumen10 halaman1 s2.0 S2214157X1630185X MaindandiBelum ada peringkat

- Wet and Dry Cooling Systems OptimizationDokumen11 halamanWet and Dry Cooling Systems OptimizationlightsonsBelum ada peringkat

- WHRS and PP For Cement Plants - Todays Boiler Spring 2014Dokumen2 halamanWHRS and PP For Cement Plants - Todays Boiler Spring 2014ash22202Belum ada peringkat

- Absorption Refrigeration: Kevin D. Rafferty, P.E. Geo-Heat CenterDokumen4 halamanAbsorption Refrigeration: Kevin D. Rafferty, P.E. Geo-Heat CenterRichard WeimerBelum ada peringkat

- 1 s2.0 S111001681200004X MainDokumen8 halaman1 s2.0 S111001681200004X MainSaiful IslamBelum ada peringkat

- Review of Water Based Vapour Absorption Cooling Systems Using Thermodynamic AnalysisDokumen12 halamanReview of Water Based Vapour Absorption Cooling Systems Using Thermodynamic AnalysisalmadhagiBelum ada peringkat

- Horizontal Ground Heat Exchanger Design For Ground Coupled Heat PumpsDokumen8 halamanHorizontal Ground Heat Exchanger Design For Ground Coupled Heat PumpsOsama YousufBelum ada peringkat

- Steam Generation Thermodynamics: Efficiency Improvements Can Quickly Be Identified With Back-Of-The-Envelope CalculationsDokumen4 halamanSteam Generation Thermodynamics: Efficiency Improvements Can Quickly Be Identified With Back-Of-The-Envelope CalculationsDaniel Puello RodeloBelum ada peringkat

- Steam Generation ThermodynamicsDokumen4 halamanSteam Generation ThermodynamicsBramJanssen76Belum ada peringkat

- Exergy Storage of Compressed Air in Cavern and Cavern Volume Est - 2017 - ApplieDokumen13 halamanExergy Storage of Compressed Air in Cavern and Cavern Volume Est - 2017 - ApplieMelissa ChongBelum ada peringkat

- Biblio 09Dokumen9 halamanBiblio 09Amadou Ousmane OumarouBelum ada peringkat

- Geo Perform XDokumen4 halamanGeo Perform Xthermosol5416Belum ada peringkat

- Calculation Analysis On The Natural Circulation of A Passive Residual Heat Removal System For IPWRDokumen9 halamanCalculation Analysis On The Natural Circulation of A Passive Residual Heat Removal System For IPWRGanjar GilaBelum ada peringkat

- LiberaryDokumen13 halamanLiberaryhesham helalyBelum ada peringkat

- Fundamental of Steam TurbineDokumen50 halamanFundamental of Steam TurbineImam Wahyudi100% (2)

- Fundamental of Steam TurbineDokumen50 halamanFundamental of Steam TurbineImam Wahyudi100% (2)

- Fundamental of Steam TurbineDokumen50 halamanFundamental of Steam TurbineImam Wahyudi100% (2)

- Questions Answers.......... CH (1to 4)Dokumen32 halamanQuestions Answers.......... CH (1to 4)shubhiBelum ada peringkat

- ch3000 PDFDokumen40 halamanch3000 PDFAndika SaputraBelum ada peringkat

- Sem VII ORDokumen11 halamanSem VII ORshubhiBelum ada peringkat

- Steppingstone ModiDokumen3 halamanSteppingstone ModiViren SangwanBelum ada peringkat

- Electrical Phenomena in Rocks and MineralsDokumen3 halamanElectrical Phenomena in Rocks and MineralsshubhiBelum ada peringkat

- Electrical Phenomena in Rocks and MineralsDokumen3 halamanElectrical Phenomena in Rocks and MineralsshubhiBelum ada peringkat

- Use "A" or "An" Use "The" Don't Use "A," "An," or "The": A Movie The Movie A Man The ManDokumen3 halamanUse "A" or "An" Use "The" Don't Use "A," "An," or "The": A Movie The Movie A Man The ManshubhiBelum ada peringkat

- Electric - Motors Work PDFDokumen40 halamanElectric - Motors Work PDFAnonymous L9fB0XUBelum ada peringkat

- Electrical Phenomena in Rocks and MineralsDokumen3 halamanElectrical Phenomena in Rocks and MineralsshubhiBelum ada peringkat

- Silk Road Ensemble in Chapel HillDokumen1 halamanSilk Road Ensemble in Chapel HillEmil KangBelum ada peringkat

- Hot Rolled Coils Plates & SheetsDokumen40 halamanHot Rolled Coils Plates & Sheetssreekanth6959646Belum ada peringkat

- 30 de Thi Hoc Ky 2 Mon Tieng Anh Lop 9 Co Dap An 2023Dokumen64 halaman30 de Thi Hoc Ky 2 Mon Tieng Anh Lop 9 Co Dap An 2023Trần MaiBelum ada peringkat

- Internal Gear Pump: Replaces: 03.08 Material No. R901216585 Type PGH.-3XDokumen36 halamanInternal Gear Pump: Replaces: 03.08 Material No. R901216585 Type PGH.-3XbiabamanbemanBelum ada peringkat

- Chapter 5 - Amino acids and Proteins: Trần Thị Minh ĐứcDokumen59 halamanChapter 5 - Amino acids and Proteins: Trần Thị Minh ĐứcNguyễn SunBelum ada peringkat

- Differential Calculus ExamDokumen6 halamanDifferential Calculus ExamCaro Kan LopezBelum ada peringkat

- Practical Applications of Electrical ConductorsDokumen12 halamanPractical Applications of Electrical ConductorsHans De Keulenaer100% (5)

- TSC M34PV - TSC M48PV - User Manual - CryoMed - General Purpose - Rev A - EnglishDokumen93 halamanTSC M34PV - TSC M48PV - User Manual - CryoMed - General Purpose - Rev A - EnglishMurielle HeuchonBelum ada peringkat

- 762id - Development of Cluster-7 Marginal Field Paper To PetrotechDokumen2 halaman762id - Development of Cluster-7 Marginal Field Paper To PetrotechSATRIOBelum ada peringkat

- EstoqueDokumen56 halamanEstoqueGustavo OliveiraBelum ada peringkat

- Conjunctions in SentencesDokumen8 halamanConjunctions in SentencesPunitha PoppyBelum ada peringkat

- Adhesive Film & TapeDokumen6 halamanAdhesive Film & TapeJothi Vel MuruganBelum ada peringkat

- Mtech Vlsi Lab ManualDokumen38 halamanMtech Vlsi Lab ManualRajesh Aaitha100% (2)

- Fike ECARO-25 Frequently Asked Questions (FAQ)Dokumen8 halamanFike ECARO-25 Frequently Asked Questions (FAQ)Jubert RaymundoBelum ada peringkat

- Demand Determinants EEMDokumen22 halamanDemand Determinants EEMPrabha KaranBelum ada peringkat

- Bloomsbury Fashion Central - Designing Children's WearDokumen16 halamanBloomsbury Fashion Central - Designing Children's WearANURAG JOSEPHBelum ada peringkat

- Mang-May-Tinh - 03a.-Dns1 - (Cuuduongthancong - Com)Dokumen52 halamanMang-May-Tinh - 03a.-Dns1 - (Cuuduongthancong - Com)Anh Quân TrầnBelum ada peringkat

- Javascript NotesDokumen5 halamanJavascript NotesRajashekar PrasadBelum ada peringkat

- Andromeda: Druid 3 Warborn06Dokumen5 halamanAndromeda: Druid 3 Warborn06AlanBelum ada peringkat

- Development of A Small Solar Thermal PowDokumen10 halamanDevelopment of A Small Solar Thermal Powעקיבא אסBelum ada peringkat

- EPSS 627: DescriptionDokumen2 halamanEPSS 627: DescriptionudayakumartBelum ada peringkat

- Plant Vs Filter by Diana WalstadDokumen6 halamanPlant Vs Filter by Diana WalstadaachuBelum ada peringkat

- Grammar Practice #2Dokumen6 halamanGrammar Practice #2Constantin OpreaBelum ada peringkat

- Advanced Statistical Approaches To Quality: INSE 6220 - Week 4Dokumen44 halamanAdvanced Statistical Approaches To Quality: INSE 6220 - Week 4picalaBelum ada peringkat

- El TontoDokumen92 halamanEl TontoRobertBelum ada peringkat

- Human Capital PlanningDokumen27 halamanHuman Capital Planningalokshri25Belum ada peringkat

- M.T Nautica Batu Pahat: Clean Product Tanker 4,497 BHPDokumen1 halamanM.T Nautica Batu Pahat: Clean Product Tanker 4,497 BHPSuper 247Belum ada peringkat

- Datalogic tl46 A Manual - 230104 - 140343Dokumen2 halamanDatalogic tl46 A Manual - 230104 - 140343Emmanuel Baldenegro PadillaBelum ada peringkat

- PDF Synopsis PDFDokumen9 halamanPDF Synopsis PDFAllan D GrtBelum ada peringkat

- Module 4 How To Make Self-Rescue Evacuation Maps?Dokumen85 halamanModule 4 How To Make Self-Rescue Evacuation Maps?RejieBelum ada peringkat