Hira PDF

Diunggah oleh

Rafki Ismed GhifariJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Hira PDF

Diunggah oleh

Rafki Ismed GhifariHak Cipta:

Format Tersedia

Document Title

The Tata Power Company Ltd Hazard Identification & Risk

Assessment (HIRA) Procedure

Document No.

Date of Issue: 01/09/2016

TPSMS/GSP/HIRA/005 REV 01

Hazard Identification and Risk Assessment (HIRA)

Procedure

Rev No. Reason for Revision Prepared By Checked By Approval by

Rev No. R&P Sub-

First release D R Kamath Vijay Chourey

00 committee

Rev No. Standardization of

01 procedure Navendra Singh Rajesh Sharma

Vijay Chourey

(Group Head – P & ( Head – Corp Safety

(Chief – Corp Safety)

CB; Corp Safety.) Operation)

Note: Uncontrolled once printed Page 1 of 16

Document Title

The Tata Power Company Ltd Hazard Identification & Risk

Assessment (HIRA) Procedure

Document No.

Date of Issue: 01/09/2016

TPSMS/GSP/HIRA/005 REV 01

Contents

Section Description Page No.

1.0 OBJECTIVE 3

2.0 SCOPE 3

3.0 EXPECTED RESULTS 3

4.0 ACCOUNTABILITY & RESPONSIBILTIY 3

5.0 GLOSSARY/ DEFINITIONS 3

6.0 PROCEDURE 4

7.0 RECORDS 8

8.0 TRAINING & COMMUNICATION 8

9.0 VERIFICATION 8

10.0 EXCEPTIONS 9

11.0 REFERENCES 9

12.0 REVIEW 10

13.0 ATTACHMENTS/APPENDIX 10

-- Annexure – 1: Risk Priority Number (RPN) Matrix 10

-- Annexure – 2: Table for Frequency 12

-- Annexure – 3: Table for Severity 13

-- Annexure – 4: Risk Based Control Plan 14

-- Annexure – 5: Types of controls and their effectiveness 15

-- Annexure – 6: HIRA Format (GSP/HIRA/005/FORM/01) 16

Note: Uncontrolled once printed Page 2 of 16

Document Title

The Tata Power Company Ltd Hazard Identification & Risk

Assessment (HIRA) Procedure

Document No.

Date of Issue: 01/09/2016

TPSMS/GSP/HIRA/005 REV 01

1. OBJECTIVE:

Objective of this procedure is to define guidelines for Hazard identification, Risk

assessment and determination of controls.

2. SCOPE:

This procedure applies to all operating plants and project sites of Tata Power Group

companies.

3. EXPECTED RESULTS:

3.1. Manage activities with reduction of risk involved with acceptable risk and safely.

4. ACCOUNTABILITY & RESPONSIBILITY:

4.1. ACCOUNTABILITY: Concerned Division’s Heads/Assets Custodian.

4.2. RESPONSIBILITY: Respective Core team members / Head of Departments - HODs

(Unless otherwise specified).

5. GLOSSARY/ DEFINITIONS:

BC – Business Concern: Any hazard and Risk which will result in Fatal accidents /

severe damage to human health and safety, Damage to property resulting in loss of

Production, huge financial implications etc. (Example - major fire, gas leak, explosion,

toxic release etc.)

Controls: Methods used to manage safety risks. Controls can be Elimination, Substitution,

Isolation/ separation, Engineering controls, signage/warnings and /or administrative

controls, PPE.

Hazard Identification & Risk Assessment: Hazard Identification & Risk Assessment is to

identify and evaluate the hazards, Risk and put controls measures for safe execution of

activities.

Hazard: Source or situation with potential for harm, something that can cause body injury /

occupational illness, damage property.

IPC – Interested Party Concern: The hazard / Risk having a concern expressed by

Employees, Neighbours, local residents etc.(Example –excavation on public road for cable

laying job which involve traffic interface, erection of transmission tower at community area

etc.)

Job Safety Analysis: Job safety analysis (JSA) is a procedure which helps integrate

accepted safety and health principles and practices into a particular job. In a JSA, for each

basic step of the job, it is to identify potential hazards and to recommend the safest way to

do the job.

Job: A piece of physical work defined by time or other limits and that has a clear start and

end point

Note: Uncontrolled once printed Page 3 of 16

Document Title

The Tata Power Company Ltd Hazard Identification & Risk

Assessment (HIRA) Procedure

Document No.

Date of Issue: 01/09/2016

TPSMS/GSP/HIRA/005 REV 01

(Note: The head of the department conducts the risk assessment for any complaint

received by any employee or interested party and if he is convinced with complaint then

the same is considered as interested party concern and the risk is treated as significant.

Proper control measures are to be taken to manage the risk)

LC – Legal Concern: The hazard or risk is addressed by applicable legal requirements

such as Indian Factory act / State factory rules, Indian electricity Act & rules etc. (Example

- use of uncertified lifting tools & cranes, operation of unguarded machines etc.)

Non Routine Job / Task: Where an SOP / SMP is not available or the conditions of the

SOP / SMP have changed.

Non-Significant Risk: Any risk less than RPN 6 and not falling under any of qualitative

risk category (Legal Concern, Business Concern and Interested Party Concern).

OCP: Operational Control Plan

Risk: The likelihood (probability) which can lead to potential negative consequences.

Risk Assessment: A systematic and structured process whereby hazards present in a

workplace, or arising from workplace activity, are identified, risks assessed / evaluated,

and decisions prioritized in order to reduce risks to acceptable levels.

Severity: The level of consequence / harm of an event that could occur due to exposure

to the hazard present.

Significant risk: Any activity falling either under any of qualitative risk category (Legal

Concern, Business Concern and Interested Party Concern) or having Risk Priority Number

(RPN) 6 and above.

Shall: Mandatory requirement

Should: Optional requirement

Statutory requirements: Laws, regulations applicable at the location of plant /work.

SOP: Standard Operating Procedure

SMP: Standard Maintenance Procedure

Task / Activity: A sequence of steps taken to conduct a job. A task is a sub element of a

Job.

Unacceptable Risk: Any activity having Risk Priority Number (RPN) 10 and above.

WI: Work Instructions

6. PROCEDURE:

6.1. General:

6.1.1. All Tata Power Divisions/JVs/Subsidiary shall maintained updated list of all

Activities of significant risk (qualitative) and having Risk Priority Number (RPN) 6

and above, which include Medium Risk, High Risk and Very High Risk (refer

Annexure – 1: Risk Priority Number (RPN) Matrix and Annexure – 4 : Risk Based

Control Plan).

6.1.2. All Tata Power Divisions/JVs/Subsidiary shall develop, maintained and

implement updated HIRA (Hazard Identification & Risk Assessment) register for all

Note: Uncontrolled once printed Page 4 of 16

Document Title

The Tata Power Company Ltd Hazard Identification & Risk

Assessment (HIRA) Procedure

Document No.

Date of Issue: 01/09/2016

TPSMS/GSP/HIRA/005 REV 01

significant risk (qualitative) and having Risk Priority Number (RPN) 6 and above,

which include Medium Risk, High Risk and Very High Risk Activities. The

Procedure for Hazard identification and Risk assessment is defined below.

6.2. Methodology for Preparation of HIRA. Following methodology shall be followed for

preparation of HIRA (Hazard Identification & Risk Assessment).

6.2.1. Key Requisites:

6.2.1.1. Classify the work activities

6.2.1.2. Identify the Hazards & determine Risks.

6.2.1.3. Determine existing control measures.

6.2.1.4. Assess the Risk considering the probable failures in the existing risk

control measures (i.e. Effectiveness of existing risk control measures).

6.2.1.5. Decide whether the risk is acceptable.

6.2.1.6. Decide the additional Risk Control Plan to bring risk to acceptable level.

6.2.2. Composition of Team: The HIRA is generally carried out by a team comprising

of -

6.2.2.1. Employees supervising the job

6.2.2.2. Employees with safety knowledge

6.2.2.3. Employees with technical knowledge of the activity/Job

6.2.2.4. The number of team members will depend on and vary with the complexity

of the Activity/job.

6.3. Steps of preparation of HIRA:

6.3.1. Step -1: Collection of information: Team shall collect the following information

wherever possible, for each work activity.

i. Activities to be carried out, its duration and frequency.

ii. Location/s where the activities to be carried out.

iii. Persons involved in the activities?

iv. Other persons who may be affected by the work (e.g. visitors, contractors, the

public)

v. Training of persons involved in the activities.

vi. Type of activities – Routine/non-routine activities

vii. Availability of Standard Operating Procedure (SOP)/Standard Maintenance

Procedure (SMP) for Routine Activities.

viii. Availability of Permit-To-Work (PTW) for Non-Routine Activities.

ix. Size, shape, surface conditions, weight of materials that might be handled.

x. Utility services such as compressed air/steam.

xi. Other materials to be used or encountered during the work

xii. Physical form of materials to be used and its recommendations as per Material

Safety Data Sheet (MSDS).

xiii. Legal and other requirements applicable for the activities.

xiv. Records of past incident/s and analysis pertaining to activities.

Note: Uncontrolled once printed Page 5 of 16

Document Title

The Tata Power Company Ltd Hazard Identification & Risk

Assessment (HIRA) Procedure

Document No.

Date of Issue: 01/09/2016

TPSMS/GSP/HIRA/005 REV 01

xv. Communications from employees and other interested parties (if any).

xvi. Work place monitoring data.

xvii. Existing Control measures to be in place.

xviii. Safety committee reports

6.4. Step – 2: Hazard Identification: Identify hazards and determine risks. Hazard

identification and risk assessment to be pro-active rather than reactive.

The broad categories of hazards are:

i. Mechanical (Example: Fall / slip due to slippery floor, Exposure to moving /

rotating parts of machine etc.)

ii. Electrical (Example: Electric shocks / electrocution)

iii. Chemicals (Example: acids / alkali /salts etc.).

iv. Fire and Explosion.

v. Radiation (Example: Exposure to X-rays/ Radiography during Non-Destructive

Testing (NDT) etc.)

vi. Toxic release (Example: Leakage of chlorine, ammonia etc)

vii. Natural calamities.(Earth quake, Floods, Severe wind storm, lightening etc)

viii. Biological hazards (Example: Sources of biological hazards include bacteria,

viruses, insects, plants, birds, animals, and humans. These sources can cause

a variety of health effects ranging from skin irritation and allergies to infections

(e.g., Tuberculosis, AIDS, Cancer etc.)

6.4.1. Following three questions to be explored and recorded during hazard

identification

i. Is there a source of harm?

ii. Who (or what) could be harmed?

iii. How could harm occur?

6.4.2. Following factors shall be considered while identifying the hazards and

determining the risks-

i. Human behaviour, capabilities and other human factors.

ii. Hazards originating “outside the workplace” capable of adversely affecting

the health and safety of personnel under the control of the organization within

the workplace.

iii. Hazards created in the vicinity “inside the workplace” by work related

activities under the control of the organization.

iv. Infrastructure, equipment and materials at the workplace, whether provided

by the organization or others.

v. Changes or proposed changes in the organization, it’s activities and

materials.

vi. Applicable legal obligations relating to risk assessment and implementation of

necessary controls.

Note: Uncontrolled once printed Page 6 of 16

Document Title

The Tata Power Company Ltd Hazard Identification & Risk

Assessment (HIRA) Procedure

Document No.

Date of Issue: 01/09/2016

TPSMS/GSP/HIRA/005 REV 01

vii. Design of workplace, processes installations, machinery / equipment,

operating procedures and work organization, including their adaptation to

human capabilities.

6.5. Step – 3: Review of Existing Control Measures: Team shall carry out review of

adequacy of existing control measures and based upon review of the adequacy of

existing control measures qualitative and quantitative risk assessment shall be done as

below.

6.5.1. QUALITATIVE ASSESSMENT OF RISKS:

6.5.1.1.Legal Concern (LC): The hazard or risk is addressed by applicable legal

requirements such as Indian Factory act / State factory rules, Indian

electricity Act & rules etc. (Example - use of uncertified lifting tools & cranes,

operation of unguarded machines etc.)

6.5.1.2. Interested Party Concern (IPC): The hazard / Risk having a concern

expressed by Employees, Neighbours, local residents etc.(Example –

excavation on public road for cable laying job which involve traffic interface,

erection of transmission tower at community area etc.)

(Note: The head of the department should conducts the risk assessment

for any complaint received by any employee or interested party and if he is

convinced with complaint then the same is considered as interested party

concern and the risk is treated as significant. Proper control measures are

to be taken to manage the risk)

6.5.1.3. BC – Business Concern (BC): Any hazard and Risk which will result in:

Fatal accidents / severe damage to human health and safety. Damage to

property resulting in loss of Production, huge financial implications etc.

(Example - major fire, gas leak, explosion, toxic release etc.)

6.5.1.4. Potential Emergency (PE): Situations which result in loss or damage to

humans / property / environment. Any situation, such as arising out of

major fire, gas leak, explosion, toxic release, flooding which is likely to go

out of control and requires controlling by a pre-determined team. The

situation may result in injury/ill health to group of employees and/or general

public and/or, property damage which require mitigation of losses. All such

potential emergencies shall be assessed and considered in any of LC, IPC

or BC category as appropriate.

6.5.1.5.Any Hazard / Risk which is associated with a Legal Concern (LC),

Interested Party Concern (IPC), and Business Concern (BC) are

considered as Significant Risks by default irrespective of its subsequent

Risk Priority Number (RPN) as per Quantitative Risk Assessment and

necessary control measures shall be taken address all such concerns..

Note: Uncontrolled once printed Page 7 of 16

Document Title

The Tata Power Company Ltd Hazard Identification & Risk

Assessment (HIRA) Procedure

Document No.

Date of Issue: 01/09/2016

TPSMS/GSP/HIRA/005 REV 01

6.5.2. QUANTITATIVE ASSESSMENT OF RISKS: After identifying the hazards and

determination of risks, carrying out risk assessment and classify the risks based on

the risk priority number (RPN) refer Annexure - 1.

6.5.2.1. RISK PRIORITY NUMBER (RPN) is obtained by multiplying the following

factors: RPN = F x S. Where;

F - Frequency: likelihood of the occurrence on Incident

S - Severity of harm: The risk from the hazard is determined by estimating

the potential severity of the harm.

Refer to Annexure- 2 & 3 for allocating values for Frequency (F) &

Severity (S)

6.5.2.2. While assigning Frequency (F) & Severity (S) ratings, consider the

adequacy and effectiveness of existing risk control measures (probable

failures in existing risk control measures).Some Examples of probable failures

in control measures.

i. Supervision / Human intervention is must for Controls.

ii. People not wearing PPE, / PPEs not available,

iii. People not aware of control measures / untrained personnel,

iv. Damaged PPEs etc.

6.5.2.3. Additional control measures shall be recommended to reduce the Risk as

per Risk Control Plan mentioned in Annexure – 4.

6.5.2.4. Hierarchy of Risk Control measures: While determining risk controls or

considering changes to existing controls, consideration shall be given to

reducing the risks according to the following hierarchy:

i. ELIMINATE (REMOVE) / SUBSTITUTION

(Example - If practicable, Eliminate the hazards altogether, or

combat the risk at source, for example Use Hypo-chloride in place of

Chlorine, Use tools instead of handling with bare hands, Use trolley

and truck instead of hand carrying, Use man lift instead of Ladder)

ii. ENGINEERING CONTROLS

(Example - Fully automate process, Application of interlocks,

Installation of Safety Valve, Alarm & Detection System etc.)

iii. ADMINISTRATIVE CONTROLS.

(Example- Good housekeeping, Safe systems at work, Training and

information, Welfare, Monitoring, Training, supervision etc.)

iv. PERSONAL PROTECTIVE EQUIPMENTS (PPEs - Last resort).

However PPEs are mandatory for all jobs.

6.6. Step- 4: HIRA Format (GSP/HIRA/005/FORM/01) as per Annexure - 6 should be used

for recording Hazard Identification and Risk Assessment (HIRA).

Note: Uncontrolled once printed Page 8 of 16

Document Title

The Tata Power Company Ltd Hazard Identification & Risk

Assessment (HIRA) Procedure

Document No.

Date of Issue: 01/09/2016

TPSMS/GSP/HIRA/005 REV 01

6.6.1. Hazard Identification and Risk Assessment (HIRA) shall be approved by Division

Chief.

6.7. Step – 5: Hazard identification and Risk assessment shall be reviewed at least once in

two (02) years to keep this information up-to-date. However, Hazard identification and

Risk assessment shall be reviewed before implementing changes to the activity /

process / equipment / existing risk control measures. Review of Risk assessment shall

be carried out during the following situations.

i. During changes from normal operation,

ii. New or modified process/ installation,

iii. Changes in raw materials, chemicals etc,

iv. During expansion, contraction, restructuring

v. New or modified legislation etc.

vi. New information/inputs from interested parties

7. Records:

1.1. HIRA Register as per HIRA Format (GSP/HIRA/005/FORM/01) - Retention period five

(05) years

1.2. List of Unacceptable (High & Very High) Risks activities/Jobs (RPN 6 and above) -

Retention period five (05) years

8. Training & Communication:

1.3. Training of Hazard Identification & Risk Assessment (HIRA) shall be included and

covered in Safety Training Calendar as per Safety Training needs.

1.4. Initial Communication to be done through Corporate Communication, Email and

subsequently shall be made available at safety portal at Sangam.

9. VERIFICATION

1.5. Verification of implementation shall be done during Safety audit, field safety visit and

site inspections.

10. Exceptions: Any Exception to this procedure shall only be done as per Document

Control .Procedure (TPSMS/GSP/DC/014).

11. REFERENCES

Tata Power Safety Management System (TPSMS) Manual

OHSAS 18001:2007

Tata Power Document Control Procedure (TPSMS/GSP/DC/014).

Tata Power Safety Capability Building procedure(TPSMS/SCB/DC/016)

Note: Uncontrolled once printed Page 9 of 16

Document Title

The Tata Power Company Ltd Hazard Identification & Risk

Assessment (HIRA) Procedure

Document No.

Date of Issue: 01/09/2016

TPSMS/GSP/HIRA/005 REV 01

12. Review: Review of this procedure shall be done as and when but not later than once in

every three (03) years. Typical Factors like Changes in legislation, Review of Incident Reports,

Inspection & Audit findings, Feedback from users, Recommendations in Incident investigation

reports may be inputs for the review and revision of the procedure.

13. ATTACHMENTS/APPENDIX :

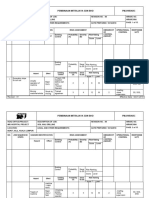

Annexure – 1: Risk Priority Number (RPN) Matrix

Annexure – 2: Table for Frequency

Annexure – 3: Table for Severity

Annexure – 4: Risk Based Control Plan

Annexure – 5: Types of controls and their effectiveness

Annexure – 6: HIRA Format (GSP/HIRA/005/FORM/01)

Note: Uncontrolled once printed Page 10 of 16

Document Title

The Tata Power Company Ltd Hazard Identification & Risk

Assessment (HIRA) Procedure

Document No.

Date of Issue: 01/09/2016

TPSMS/GSP/HIRA/005 REV 01

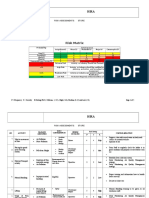

Annexure – 1

Risk Priority Number (RPN) Matrix

5 5 10 15 20 25

(Very High - Has (Low) (High) (High) (Very (Very

happened more than High) High)

once per year in the

Divisions)

4 4 8 12 16 20

(High - Has happened in (Low) (Medium) (High) (Very (Very

Frequency

the Division and more High) High)

than once per year in

Company)

3 3 6 9 12 15

(Medium- Has happened (Low) (Medium) (Medium) (High) (High)

in the Company)

2 2 4 6 8 10

(Low- Happened in The (Very (Low) (Medium) (Medium) (High)

Power Industries globally

last 20 Years)

Low)

1 1 2 3 4 5

(Very Low- (Very (Very Low) (Low) (Low) (Low)

Happened in the

Industries globally last

Low)

10 years )

1 2 3 4 5

(Very (Low) (Medium) (High) (Very High)

Low)

Severity

Annexure – 2

Note: Uncontrolled once printed Page 11 of 16

Document Title

The Tata Power Company Ltd Hazard Identification & Risk

Assessment (HIRA) Procedure

Document No.

Date of Issue: 01/09/2016

TPSMS/GSP/HIRA/005 REV 01

Table for Frequency

Rating Level Description

5 Very High Has happened once during last one year in the

Division

4 High Has happened in the Division or once during last

one year in Company

3 Medium Has happened in the Company

2 Low Happened in The Power Industries globally during

last 20 years.

1 Very Low Happened in the Industries globally during last 10

years.

Annexure – 3

Note: Uncontrolled once printed Page 12 of 16

Document Title

The Tata Power Company Ltd Hazard Identification & Risk

Assessment (HIRA) Procedure

Document No.

Date of Issue: 01/09/2016

TPSMS/GSP/HIRA/005 REV 01

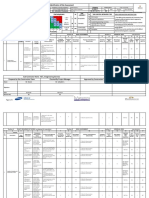

Table for Severity

Very Low Low Medium High Very High

1 2 3 4 5

Consequence Severity Increases

People Physical Noticeable Temporary Partial Fatal/Total

(Health and discomfort and requiring Disability Permanent Permanent

Safety First Aid or (MTC/ Disability/ Disability

slight health RWDC) or Lost work (TPD) or

problem health Day case severe health

problem (LWDC) or problem

causing major health causing

MTC/RWDC problem Fatal/TPD

causing

LWDC

Environment Negligible Minor effects Localize Major Massive

al effect neighbours release makes release make damage

confined to adjacent to local TV national TV makes

within plant plant coverage / coverage / International

grounds / complain newspaper news paper TV coverage

environment / new paper

Product or Some product Several Several Important / Loss of

Service or service costumer customer major substantial

Quality fails to meet complain complain in customer marked share

standards verbally writing cancelled due problem

orders

Asset or Slight damage Noticeable Large damage Major Severe

financial loss is upto Rs. damage 1 Lakh to 10 damage 10 damage more

10,000/- between Rs. Lakhs Lakhs to 1 than 1 crore

10,000 to 1 crore

Lakh

Reputation Slight to Loss of Loss of Loss of Loss of

(Local, moderate reputation at reputation at reputation at reputation at

National, or impact Community State Level National International

International level Level Level

Note: Uncontrolled once printed Page 13 of 16

Document Title

The Tata Power Company Ltd Hazard Identification & Risk

Assessment (HIRA) Procedure

Document No.

Date of Issue: 01/09/2016

TPSMS/GSP/HIRA/005 REV 01

Annexure- 4

Risk Based Control Plan

RPN Risk category (Risk based Control Plan) Decision / What needs to be done?

Control Plan (CP) - 1

<3 Very Low

• Activities having RPN < 3, considered as acceptable risk. No additional controls

Risk ( Non- are necessary other than to ensure that existing controls are maintained &

Significant) implemented.

3–5 Low Risk Control Plan (CP) - 2

• Activities having RPN between 3 -5, considered as acceptable risk.

( Non- • No additional controls are required unless they can be implemented at very

Significant) low cost i.e. improved supervision, enhanced monitoring.

6–9 Medium Control Plan (CP) - 3

• Additional control measures shall be put in place to reduce the RPN to acceptable

Risk level (less than 6).

( Significant) • The risk reduction measures shall be implemented within a defined period.

Arrangements shall be made to ensure that the controls are maintained.

•

10 – High Risks Control Plan (CP) - 4

• Engineering control/Work Instructions (WI) shall be followed to reduce risk to

15 ( Significant & acceptable level (less than 6).

Unacceptable) • In case of absence of Work Instructions (WI), Job/activity specific Operational

Control Plan (OCP) shall be developed and followed

The risk reduction measures shall be implemented within a defined period (before

• start of work).

The work activity should be halted until risk controls are implemented. If it is not

• possible to reduce the risk, the work should remain prohibited.

• Arrangements shall be made to ensure that the controls are maintained.

Control Plan (CP) - 5

16-25 Very High

• It shall incudes all the requirements of Control Plan (CP) - 4 and necessary

Risks changes by Engineering Controls (for example - Fully automate process,

( Significant & Application of interlocks, Installation of Safety Valve, Alarm & Detection System

Unacceptable) etc.) to reduce risk to acceptable level (less than 6).

• The work activity shall be halted until risk controls are implemented as Control

Plan (CP) - 5. If it is not possible to reduce the risk, the work shall remain

prohibited.

• Arrangements shall be made to ensure that the controls are maintained.

Note: Uncontrolled once printed Page 14 of 16

Document Title

The Tata Power Company Ltd Hazard Identification & Risk

Assessment (HIRA) Procedure

Document No.

Date of Issue: 01/09/2016

TPSMS/GSP/HIRA/005 REV 01

Annexure- 5

Types of Controls and their effectiveness

Type of Controls Effectiveness

1. Eliminate the hazard completely. 100%

2. Engineering Controls: Create a barrier between

the person and the hazard.

40–99%

3. Administrative Controls: by use & implementation

of regulation, law, SOP/SMP/WI/OCP, safety procedures,

etc. 20–40%

4. Provide personal protective equipment.

1- 20%

Note: Uncontrolled once printed Page 15 of 16

Document Title

The Tata Power Company Ltd Hazard Identification & Risk

Assessment (HIRA) Procedure

Document No.

Date of Issue: 01/09/2016

TPSMS/GSP/HIRA/005 REV 01

GSP/HIRA/005/FORM/01 Annexure – 6

Note: Uncontrolled once printed Page 16 of 16

Anda mungkin juga menyukai

- 9.hazard Identification & Risk AssessmentDokumen10 halaman9.hazard Identification & Risk AssessmentMuhammad Javed100% (3)

- 08 Permit To Work ProcedureDokumen24 halaman08 Permit To Work Procedureniteshsh31100% (1)

- Scaffold Safety ProcedureDokumen24 halamanScaffold Safety ProcedureAlif Rahmat Febrianto100% (1)

- Hira WordDokumen69 halamanHira WordGokul p100% (2)

- LOTO Procedure PDFDokumen17 halamanLOTO Procedure PDFSatyadip Teraiya50% (2)

- 12 - Tata Power Hazard Identification & Risk Assessment (HIRA) ProcedureDokumen16 halaman12 - Tata Power Hazard Identification & Risk Assessment (HIRA) Procedurehse bsj50% (2)

- 03 Confined Space Entry PDFDokumen18 halaman03 Confined Space Entry PDFBudi SantonyBelum ada peringkat

- Hira PDFDokumen69 halamanHira PDFChíld Çhïññæ Çøôl100% (2)

- Scaffold Safety ProcedureDokumen24 halamanScaffold Safety ProcedureRajib MondalBelum ada peringkat

- 02 - Tata Power Excavation Safety ProcedureDokumen21 halaman02 - Tata Power Excavation Safety Procedurehse bsj100% (1)

- Final HIRA - GBLDokumen49 halamanFinal HIRA - GBLAbdul Rasheed MangrioBelum ada peringkat

- EHS Plan - SiemensDokumen15 halamanEHS Plan - Siemensabbas100% (1)

- HIRADokumen57 halamanHIRAAnonymous Uc25fP83% (6)

- Hazard Identification and Risk Assessment VirtualDokumen33 halamanHazard Identification and Risk Assessment VirtualGyanendra Narayan Nayak100% (1)

- Tata Projects Limited: Hazard Identification and Risk Assessment (HIRA)Dokumen7 halamanTata Projects Limited: Hazard Identification and Risk Assessment (HIRA)Venugopal100% (3)

- Hazrd Identification & Risk Assessment: Mmf100 Nov 2009 - Pm/105/01 © Mott Macdonald 2009Dokumen2 halamanHazrd Identification & Risk Assessment: Mmf100 Nov 2009 - Pm/105/01 © Mott Macdonald 2009SuperuserAsadhussainBelum ada peringkat

- Hazard Identification & Risk Assessment TrainingDokumen64 halamanHazard Identification & Risk Assessment Trainingdhir.ankurBelum ada peringkat

- 7 Hand Held Power ToolsDokumen4 halaman7 Hand Held Power ToolsGilmar MonteiroBelum ada peringkat

- Procedure: Hazard Identification, Risk Assessment and Risk ManagementDokumen45 halamanProcedure: Hazard Identification, Risk Assessment and Risk ManagementWasim ShaikBelum ada peringkat

- Electrical Safety ProcedureDokumen33 halamanElectrical Safety ProcedurePraful E. Pawar100% (1)

- Master Hazards Risks RegisterDokumen113 halamanMaster Hazards Risks RegisterIvanBelum ada peringkat

- HTG Engineering Pvt. Ltd. 2 800 MW Adani Power Jharkhand LTD Hira RegisterDokumen7 halamanHTG Engineering Pvt. Ltd. 2 800 MW Adani Power Jharkhand LTD Hira Registeruttam mishra0% (1)

- Hira DineshDokumen11 halamanHira DineshDurai GunasekaranBelum ada peringkat

- Hira FormatDokumen6 halamanHira FormatMOJIB33% (6)

- Risk AssessmentDokumen10 halamanRisk AssessmentKyaw Kyaw Aung89% (9)

- Site Emerg Response PlanDokumen58 halamanSite Emerg Response PlanErica Lindsey100% (4)

- HIRA for Loading, Unloading, Handling, Lifting & Shifting at Tata SmartFoodzDokumen47 halamanHIRA for Loading, Unloading, Handling, Lifting & Shifting at Tata SmartFoodzNaresh Kumar83% (6)

- Proj - HiraDokumen17 halamanProj - HiraVishal TiwariBelum ada peringkat

- Ppe Policy PDFDokumen22 halamanPpe Policy PDFash100% (1)

- HIRA For TATA Project - Tool RoomDokumen124 halamanHIRA For TATA Project - Tool Roomvivek vjBelum ada peringkat

- Hazard identification and risk assessment formDokumen8 halamanHazard identification and risk assessment formRaghulal ThalappalaBelum ada peringkat

- All HiraDokumen40 halamanAll Hirarameese muhammed100% (1)

- HIRA risk assessments: StoreDokumen5 halamanHIRA risk assessments: Storederwaishjee1100% (1)

- Hira Register: Grasim Industries Limited, Vilayat Bharuch (Gujarat)Dokumen3 halamanHira Register: Grasim Industries Limited, Vilayat Bharuch (Gujarat)Mithlesh Singh75% (4)

- Risk assessment of lifting LCO2 tank from horizontal to vertical using cranesDokumen4 halamanRisk assessment of lifting LCO2 tank from horizontal to vertical using cranesYawar QureshiBelum ada peringkat

- All Hira 2-1Dokumen156 halamanAll Hira 2-1Mojib. AhmadBelum ada peringkat

- HIRA For Stores ActivityDokumen5 halamanHIRA For Stores ActivityRohit Singh100% (22)

- Jsa For Work at HeightDokumen8 halamanJsa For Work at HeightMuhammad Umar Gondal50% (2)

- Forklift Risk AssessmentDokumen5 halamanForklift Risk AssessmentPajserchina100% (4)

- Plant and Equipment Risk Assessment Checklist1Dokumen9 halamanPlant and Equipment Risk Assessment Checklist1peachykrista100% (1)

- Risk Assessment ProcedureDokumen4 halamanRisk Assessment ProcedureRameeSahiba100% (1)

- Work at Height Rescue PlanDokumen11 halamanWork at Height Rescue PlanSaher100% (3)

- Hazard Identification & Risk Assessment for Petal Installation TheatreDokumen6 halamanHazard Identification & Risk Assessment for Petal Installation Theatresachin vaish100% (1)

- LOTO Permit to WorkDokumen2 halamanLOTO Permit to WorkIonian TribeBelum ada peringkat

- Master HiraDokumen88 halamanMaster Hiravivek vj100% (2)

- Hazard ListDokumen7 halamanHazard ListSudish NairBelum ada peringkat

- Risk Assessment For Material HandlingDokumen15 halamanRisk Assessment For Material Handlingvural100% (5)

- Hazard Identification and Risk Assessment for Roof Top Facility OperationsDokumen7 halamanHazard Identification and Risk Assessment for Roof Top Facility Operationsmadhur chavanBelum ada peringkat

- Register of Aspect Impact - IMSM 4.3.1 R02Dokumen7 halamanRegister of Aspect Impact - IMSM 4.3.1 R02jrpatel18853100% (2)

- 1-Mock Drill Report of Aegis Gas On 16-01-2018Dokumen3 halaman1-Mock Drill Report of Aegis Gas On 16-01-2018Parth PatelBelum ada peringkat

- Ppe Matrix - FTDokumen1 halamanPpe Matrix - FTAkhilesh Pandey100% (2)

- Risk Assessment PROCEDUREDokumen27 halamanRisk Assessment PROCEDURESparrow Green Studios100% (6)

- Toolbox Talks Hand and Portable Power Tools EnglishDokumen1 halamanToolbox Talks Hand and Portable Power Tools EnglishsuhasBelum ada peringkat

- PDISDokumen49 halamanPDISdeba819967% (3)

- Ppe MatrixDokumen5 halamanPpe MatrixchrisBelum ada peringkat

- HIRA Risk AssessmentDokumen25 halamanHIRA Risk AssessmentSuraj PantBelum ada peringkat

- Lift Elevator SafetyDokumen17 halamanLift Elevator SafetyPraful E. PawarBelum ada peringkat

- Batteries Handling & Disposal ProcedureDokumen17 halamanBatteries Handling & Disposal ProcedureBALAJIBelum ada peringkat

- Tata Power LOTO ProcedureDokumen17 halamanTata Power LOTO Procedurehse bsjBelum ada peringkat

- 05 - Tata Power Heavy Equipment Safety ProcedureDokumen24 halaman05 - Tata Power Heavy Equipment Safety Procedurehse bsj100% (1)

- INTERNET STANDARDSDokumen18 halamanINTERNET STANDARDSDawn HaneyBelum ada peringkat

- Is 4682 5 1970Dokumen24 halamanIs 4682 5 1970DivakarBelum ada peringkat

- Is.817.1966 Testing and Training of Welders PDFDokumen59 halamanIs.817.1966 Testing and Training of Welders PDFDivakar100% (1)

- Is 814 2004 PDFDokumen34 halamanIs 814 2004 PDFSantosh Kumar60% (5)

- Is 813Dokumen33 halamanIs 813gurubasavarajakm0% (1)

- Is 812 1957 PDFDokumen96 halamanIs 812 1957 PDFRaviTeja Bhamidi100% (3)

- Is.817.1.1992 - Training of Welders - Code of PracticeDokumen29 halamanIs.817.1.1992 - Training of Welders - Code of PracticeSinan YıldızBelum ada peringkat

- BIS Standards On WeldingDokumen5 halamanBIS Standards On Weldingkislay.shahiBelum ada peringkat

- Samsung WashingMachine ManualDokumen72 halamanSamsung WashingMachine ManualAli KhanBelum ada peringkat

- Schneider Electric ManualDokumen60 halamanSchneider Electric ManualOrxan TalibzadeBelum ada peringkat

- San Juan LDRRM PLAN 2017-2021Dokumen67 halamanSan Juan LDRRM PLAN 2017-2021Roy Bautista100% (4)

- 004-Soil NailingDokumen15 halaman004-Soil NailingDon McleanBelum ada peringkat

- 00 Gac 3eDokumen10 halaman00 Gac 3emrbogey2220% (1)

- Disaster Preparedness and Level of AwareDokumen26 halamanDisaster Preparedness and Level of AwareMerryjoyBelum ada peringkat

- Health, Safety & Environmental Hazard IdentificationDokumen6 halamanHealth, Safety & Environmental Hazard IdentificationImad ChaudharyBelum ada peringkat

- Types of DisasterDokumen22 halamanTypes of DisasterKirstin del CarmenBelum ada peringkat

- F2820-P0019-03 Att-7a SCAT - Chart - EnglishDokumen4 halamanF2820-P0019-03 Att-7a SCAT - Chart - EnglishHSE HerygintingBelum ada peringkat

- Service Guide Christie M - Series ProjectorDokumen95 halamanService Guide Christie M - Series Projectorpeter11Belum ada peringkat

- 182 - GE8076, GE6075 Professional Ethics in Engineering - 2 MarksDokumen17 halaman182 - GE8076, GE6075 Professional Ethics in Engineering - 2 Markssharon sylvia .sBelum ada peringkat

- Hazard and Risk Assessment for Environmental ProtectionDokumen19 halamanHazard and Risk Assessment for Environmental ProtectionriyazaliBelum ada peringkat

- BP USPL Incident Reporting Safety ManualDokumen42 halamanBP USPL Incident Reporting Safety Manualben100% (1)

- Communicable Disease Alert and Response For Mass Gatherings: Key ConsiderationsDokumen119 halamanCommunicable Disease Alert and Response For Mass Gatherings: Key ConsiderationsAbhishek topnoBelum ada peringkat

- Kami Export - ILLEGAL DUMPING OF TOXIC WASTE IN THE KIM KIM RIVERDokumen16 halamanKami Export - ILLEGAL DUMPING OF TOXIC WASTE IN THE KIM KIM RIVERTheresa MarionBelum ada peringkat

- Analysis of Hazards: Nptel - Chemical Engineering - Chemical Engineering Design - IIDokumen2 halamanAnalysis of Hazards: Nptel - Chemical Engineering - Chemical Engineering Design - IIboeiniBelum ada peringkat

- MSDS - Acrylic HomopolymerDokumen3 halamanMSDS - Acrylic HomopolymerBeh Jyh JiunnBelum ada peringkat

- 7.OHS-PR-09-03-F02 HIRA - 30 Hydro Testing of Gas PipelineDokumen5 halaman7.OHS-PR-09-03-F02 HIRA - 30 Hydro Testing of Gas PipelineabbasBelum ada peringkat

- Notes ImmersionDokumen17 halamanNotes ImmersionIrish Kyla HernandezBelum ada peringkat

- HiracDokumen18 halamanHiracshaelBelum ada peringkat

- PHA-What If Analysis SampleDokumen3 halamanPHA-What If Analysis SamplekunalbagulBelum ada peringkat

- Safety - Our Top PriorityDokumen4 halamanSafety - Our Top PrioritysanthoshBelum ada peringkat

- Eaf524 ErpDokumen6 halamanEaf524 ErpMuhammad Azrul Mohd UzidBelum ada peringkat

- Secondary 3 Geography Manual Practice BookDokumen32 halamanSecondary 3 Geography Manual Practice BookKate YatiBelum ada peringkat

- Disaster readiness and risk reductionDokumen5 halamanDisaster readiness and risk reductionRosevie Mae VicenteBelum ada peringkat

- Worksheet DRRR q3 Module 2Dokumen5 halamanWorksheet DRRR q3 Module 2Ghaniella B. JulianBelum ada peringkat

- Role of Local Disaster Risk Reduction and Management Council and FundsDokumen28 halamanRole of Local Disaster Risk Reduction and Management Council and FundsLouray Jean BereberBelum ada peringkat

- Documenting Disasters: How Archivists Can Prepare for and Respond to Natural DisastersDokumen20 halamanDocumenting Disasters: How Archivists Can Prepare for and Respond to Natural DisastersfacuscribdBelum ada peringkat

- Incident Investigation Procedure PDFDokumen25 halamanIncident Investigation Procedure PDFMurtadda MohammedBelum ada peringkat

- Nebosh Element - 1 AnswersDokumen4 halamanNebosh Element - 1 AnswersSatish KumarBelum ada peringkat