Crosby 2130 2150

Diunggah oleh

Sumner TingJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Crosby 2130 2150

Diunggah oleh

Sumner TingHak Cipta:

Format Tersedia

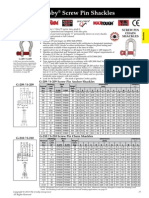

Crosby® Bolt Type Shackles

• Capacities 1/3 thru 150 metric tons, grade 6.

• Working Load Limit and grade “6” permanently shown on every shackle.

BOLT TYPE • Forged — Quenched and Tempered, with alloy pins. BOLT TYPE

• Hot Dip galvanized or Self Colored. (85, 120, and 150-metric ton shackles CHAIN

ANCHOR are all hot dip galvanized bows and the bolts are Dimetcoted® and painted red)

Shackles

SHACKLES • Fatigue rated (1/3t - 55t). SHACKLES

• Shackles 25t and larger are RFID EQUIPPED.

• Approved for use at -40 degree C (-40 degree F) to 204 degree C (400 degree F).

• 2t through 25t bow and bolt are Certified to meet charpy impact testing of 42

joules (31 ft-Ibs.) min. ave. at -20 degree C (-4 degree F)

• Meets or exceeds all requirements of ASME B30.26.

• Sizes 1/2t-25t meet the performance requirements of EN13889:2003.

• Shackles 55 metric tons and smaller can be furnished proof tested with certificates to

designated standards, such as ABS, DNV, Lloyds, or other certification when requested

at time of order.

• Shackles 120 metric tons and larger are proof tested, Magnetic Particle Inspected and

provided with Serialized Pin and Bow.

G-2130 / S-2130 • Type Approval and certification in accordance with ABS 2006 Steel Vessel Rules 1-1-

17.7, and ABS Guide for Certification of Cranes. G-2150 / S-2150

G-2130 Bolt Type Anchor • 3.1 Certification as standard available for charpy and statistical proof test for pg 79 only G-2150 Bolt Type Chain shackles.

shackles with thin head bolt -

nut with cotter pin. Meets the

up to 25 tons to DNV2.7-1 and EN13889. Thin hex head bolt - nut with

• Crosby 2t through 25t G2130 anchor shackles are type approved to DNV Certification cotter pin. Meets the performance

performance requirements of requirements of Federal

Federal Specification RR-C-271F Notes 2.7-1- Offshore Containers. These Crosby shackles are statistical proof and impact

Specification RR-C-271F Type

Type IVA, Grade A, Class 3, except tested. The tests are conducted by Crosby and 3.1 test certification is available upon IVB, Grade A, Class 3, except

for those provisions required of request. Refer to page 76 for Crosby COLD TUFF® shackles that meet the additional for those provisions required of

the contractor. For additional requirements of DNV rules for certification of lifting applications - Loose Gear. the contractors. For additional

information, see page 468. • All other 2130 and all 2150 shackles can meet charpy requirements of 42 joules information, see page 444.

(31 ft-Lbs) avg at -20 degree C (-4 degree F) upon special request.

• Look for the Red Pin® . . . the mark of genuine Crosby quality.

Working Stock Dimensions Tolerance

Nominal Load No. Weight (mm) +/-

G-2130 / S-2130 Size Limit Each

(in.) (t)* G-2130 S-2130 (kg) A B C D E F H L N C A

3/16 1/3 ‡ 1019464 – .03 9.65 6.35 22.4 4.85 15.2 14.2 37.3 24.9 4.85 1.50 1.50

1/4 1/2 1019466 – .05 11.9 7.85 28.7 6.35 19.8 15.5 46.7 32.5 6.35 1.50 1.50

5/16 3/4 1019468 – .10 13.5 9.65 31.0 7.85 21.3 19.1 53.0 37.3 7.85 1.50 1.50

3/8 1 1019470 – .15 16.8 11.2 36.6 9.65 26.2 23.1 63.0 45.2 9.65 3.30 1.50

7/16 1-1/2 1019471 – .22 19.1 12.7 42.9 11.2 29.5 26.9 74.0 51.5 11.2 3.30 1.50

1/2 2 1019472 1019481 .36 20.6 16.0 47.8 12.7 33.3 30.2 83.5 58.5 12.7 3.30 1.50

5/8 3-1/4 1019490 1019506 .62 26.9 19.1 60.5 16.0 42.9 38.1 106 74.5 17.5 3.30 1.50

3/4 4-3/4 1019515 1019524 1.23 31.8 22.4 71.5 19.1 51.0 46.0 126 89.0 20.6 6.35 1.50

7/8 6-1/2 1019533 1019542 1.79 36.6 25.4 84.0 22.4 58.0 53.0 148 102 24.6 6.35 1.50

1 8-1/2 1019551 1019560 2.28 42.9 28.7 95.5 25.4 68.5 60.5 167 119 26.9 6.35 1.50

1-1/8 9-1/2 1019579 1019588 3.75 46.0 31.8 108 28.7 74.0 68.5 190 131 31.8 6.35 1.50

1-1/4 12 1019597 1019604 5.31 51.5 35.1 119 31.8 82.5 76.0 210 146 35.1 6.35 1.50

1-3/8 13-1/2 1019613 1019622 7.18 57.0 38.1 133 35.1 92.0 84.0 233 162 38.1 6.35 3.30

1-1/2 17 1019631 1019640 8.62 60.5 41.4 146 38.1 98.5 92.0 254 175 41.1 6.35 3.30

1-3/4 25 1019659 1019668 15.4 73.0 51.0 178 44.5 127 106 313 225 57.0 6.35 3.30

2 35 1019677 1019686 23.7 82.5 57.0 197 51.0 146 122 348 253 61.0 6.35 3.30

2-1/2 55 1019695 1019702 44.6 105 70.0 267 66.5 184 145 453 327 79.5 6.35 6.35

3 † 85 1019711 – 70 127 82.5 330 76.0 200 165 546 365 92.0 6.35 6.35

3-1/2 † 120 ‡ 1019739 – 120 133 95.5 372 92.0 229 203 626 419 105 6.35 6.35

4 † 150 ‡ 1019757 – 153 140 108 368 104 254 229 653 468 116 6.35 6.35

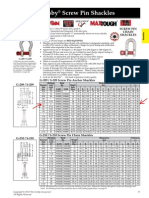

Working Stock Dimensions Tolerance

Nominal Load No. Weight (mm) +/-

G-2150 / S-2150 Size Limit Each

(in.) (t)* G-2150 S-2150 (kg) A B D F G K M P R G A

1/4 1/2 1019768 – .06 11.9 7.85 6.35 15.5 19.1 40.4 24.6 39.6 6.35 1.50 1.50

5/16 3/4 1019770 – .10 13.5 9.65 7.85 19.1 25.4 48.5 29.5 46.2 7.85 1.50 1.50

3/8 1 1019772 – .15 16.8 11.2 9.65 23.1 31.0 58.5 35.8 55.0 9.65 3.30 1.50

7/16 1-1/2 1019774 – .22 19.1 12.7 11.2 26.9 36.1 67.5 41.1 63.5 11.2 3.30 1.50

1/2 2 1019775 1019784 .34 20.6 16.0 12.7 30.2 41.4 77.0 46.0 71.0 12.7 3.30 1.50

5/8 3-1/4 1019793 1019800 .67 26.9 19.1 16.0 38.1 51.0 95.5 58.5 89.5 16.0 3.30 1.50

3/4 4-3/4 1019819 1019828 1.14 31.8 22.4 19.1 46.0 60.5 115 70.0 103 20.6 6.35 1.50

7/8 6-1/2 1019837 1019846 1.74 36.6 25.4 22.4 53.0 71.5 135 81.0 120 24.6 6.35 1.50

1 8-1/2 1019855 1019864 2.52 42.9 28.7 25.4 60.5 81.0 151 93.5 135 25.4 6.35 1.50

1-1/8 9-1/2 1019873 1019882 3.45 46.0 31.8 28.7 68.5 91.0 172 103 150 31.8 6.35 1.50

1-1/4 12 1019891 1019908 4.90 51.5 35.1 31.8 76.0 100 191 115 165 35.1 6.35 1.50

1-3/8 13-1/2 1019917 1019926 6.24 57.0 38.1 35.1 84.0 111 210 127 183 38.1 6.35 3.30

1-1/2 17 1019935 1019944 8.39 60.5 41.4 38.1 92.0 122 230 137 196 41.1 6.35 3.30

1-3/4 25 1019953 1019962 14.2 73.0 51.0 44.5 106 146 279 162 230 54.0 6.35 3.30

2 35 1019971 1019980 21.2 82.5 57.0 51.0 122 172 312 184 264 60.0 6.35 3.30

2-1/2 55 1019999 1020004 38.6 105 70.0 66.5 145 203 377 238 344 66.5 6.35 6.35

3 † 85 1020013 – 56 127 82.5 76.0 165 216 429 279 419 89.0 6.35 6.35

* NOTE: Maximum Proof Load is 2.0 times the Working Load Limit. Minimum Ultimate Strength is 6 times the Working Load

Limit. For Working Load Limit reduction due to side loading applications, see page 91.

† Individually Proof Tested with certification.

‡ Furnished in Anchor style only and furnished with Round Head Bolts with welded handles.

Copyright © 2013 The Crosby Group LLC 79

All Rights Reserved

Anda mungkin juga menyukai

- Drilling Fluids Processing HandbookDari EverandDrilling Fluids Processing HandbookPenilaian: 4.5 dari 5 bintang4.5/5 (4)

- G-2130 / S-2130 Bolt Type Anchor ShacklesDokumen1 halamanG-2130 / S-2130 Bolt Type Anchor ShacklesRaul GutierrezBelum ada peringkat

- Crossby Shackles Catalog G-2130 PDFDokumen1 halamanCrossby Shackles Catalog G-2130 PDFSam LowBelum ada peringkat

- Crosby G-2130 Shackle Data Sheet PDFDokumen1 halamanCrosby G-2130 Shackle Data Sheet PDFdavidandrewleggBelum ada peringkat

- cROSBY LINKSDokumen1 halamancROSBY LINKSTheo van der BergBelum ada peringkat

- G-2130 / S-2130 Bolt Type Anchor ShacklesDokumen1 halamanG-2130 / S-2130 Bolt Type Anchor Shacklesramy abazaBelum ada peringkat

- Screw Pin Anchor Shackles Screw Pin Chain ShacklesDokumen1 halamanScrew Pin Anchor Shackles Screw Pin Chain ShacklesJulius HendraBelum ada peringkat

- Crosby Bolt Type Shackles: Testing The LimitsDokumen1 halamanCrosby Bolt Type Shackles: Testing The LimitsStephen KokoBelum ada peringkat

- Crosby 2140 Shackle DatasheetDokumen1 halamanCrosby 2140 Shackle DatasheetKikitornado 22Belum ada peringkat

- Screw Pin Anchor ShacklesDokumen1 halamanScrew Pin Anchor Shacklesnikka2012Belum ada peringkat

- Crosby ShacklesDokumen1 halamanCrosby Shacklesroy sihalohoBelum ada peringkat

- CROSBY Shackle Anchor 1Dokumen1 halamanCROSBY Shackle Anchor 1Tapan MehtaBelum ada peringkat

- Assymetrical WedgeDokumen1 halamanAssymetrical WedgeNurettin IsikBelum ada peringkat

- G-2140 / S-2140 Crosby Alloy Bolt Type Anchor ShacklesDokumen1 halamanG-2140 / S-2140 Crosby Alloy Bolt Type Anchor ShacklessaurabhsubhuBelum ada peringkat

- Bolt Type Anchor Shackles Bolt Type Chain ShacklesDokumen1 halamanBolt Type Anchor Shackles Bolt Type Chain ShacklesMikiBelum ada peringkat

- 82Dokumen1 halaman82Drajat DarmawanBelum ada peringkat

- Bolt Type Anchor Shackles Bolt Type Chain ShacklesDokumen1 halamanBolt Type Anchor Shackles Bolt Type Chain ShacklesdanamuanBelum ada peringkat

- FT Eslabon Maestro A342Dokumen1 halamanFT Eslabon Maestro A342fernando.solarBelum ada peringkat

- Crosby G2140 ShackleDokumen1 halamanCrosby G2140 Shacklepgarrett775814233Belum ada peringkat

- Catalogue - Crosby G-2130 Bolt Type Shackle PDFDokumen1 halamanCatalogue - Crosby G-2130 Bolt Type Shackle PDFAnindya SaputraBelum ada peringkat

- Grilletes G-2140, S-2140 CrosbyDokumen1 halamanGrilletes G-2140, S-2140 CrosbyLuis Manuel Montoya RiveraBelum ada peringkat

- Crosby Wide Body ShacklesDokumen1 halamanCrosby Wide Body ShacklesPeter BarabasBelum ada peringkat

- Alloy Screw Pin Shackle G209ADokumen1 halamanAlloy Screw Pin Shackle G209ARony Prayitno SimeonBelum ada peringkat

- Angular Contact Bearing SwivelsDokumen1 halamanAngular Contact Bearing SwivelsmeromikhaBelum ada peringkat

- Wide ShackleDokumen1 halamanWide ShacklerahulBelum ada peringkat

- G2130, G2140, G2150 Crosby Bolt Anchor Safety Shackles PDFDokumen2 halamanG2130, G2140, G2150 Crosby Bolt Anchor Safety Shackles PDFSonhaji11Belum ada peringkat

- Crosby L322 TDSDokumen1 halamanCrosby L322 TDSKonstantinos SynodinosBelum ada peringkat

- Manilhas Crosby G2130Dokumen1 halamanManilhas Crosby G2130Álamo NatividadeBelum ada peringkat

- Invalco Product GuideDokumen24 halamanInvalco Product GuideyeisonBelum ada peringkat

- Crosby Swivels: S-1 Jaw & HookDokumen1 halamanCrosby Swivels: S-1 Jaw & HookZeckBelum ada peringkat

- Crosby ShacklesDokumen6 halamanCrosby Shacklessabah8800Belum ada peringkat

- Crosby Shackles G-2130 PDFDokumen2 halamanCrosby Shackles G-2130 PDFBolarinwaBelum ada peringkat

- CM CatalogueDokumen88 halamanCM CatalogueTang Hong ChiangBelum ada peringkat

- SCI GroovedDokumen56 halamanSCI GroovedVeer GangjiBelum ada peringkat

- Load Swivel CrosbyDokumen1 halamanLoad Swivel CrosbyDwiki RamadhaniBelum ada peringkat

- Crosby Grade 100 Chain FittingsDokumen1 halamanCrosby Grade 100 Chain FittingsKonstantinos SynodinosBelum ada peringkat

- S G209 CrosbyDokumen1 halamanS G209 CrosbyJS168Belum ada peringkat

- Crosby Grade 100 Clevis Sling Hooks: J AA R LDokumen1 halamanCrosby Grade 100 Clevis Sling Hooks: J AA R LKonstantinos SynodinosBelum ada peringkat

- Latch Kit CrosbyDokumen1 halamanLatch Kit CrosbyRodolfo Garduño ColínBelum ada peringkat

- Crosby ShackleDokumen1 halamanCrosby ShacklevrandyBelum ada peringkat

- Shackel PDF Crosby in MMDokumen1 halamanShackel PDF Crosby in MMkanchanabalajiBelum ada peringkat

- Crosby Wide Body Metric For ReferenceDokumen1 halamanCrosby Wide Body Metric For ReferenceshazanBelum ada peringkat

- Crosby Grade 100 Clevis Sling Hooks: J AA R LDokumen1 halamanCrosby Grade 100 Clevis Sling Hooks: J AA R LYOGESH GOPALBelum ada peringkat

- Crosby G-2140 Alloy Shackle Product SheetDokumen1 halamanCrosby G-2140 Alloy Shackle Product Sheetmihai_serban13Belum ada peringkat

- Tas00002f8 1Dokumen4 halamanTas00002f8 1Johnson Chng Hou KiatBelum ada peringkat

- Crosby ShackleDokumen1 halamanCrosby Shacklecaner_kurtoglu-1Belum ada peringkat

- Cold Tuff Fittings: Master LinksDokumen1 halamanCold Tuff Fittings: Master LinksYOGESH GOPALBelum ada peringkat

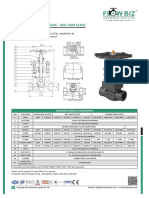

- Technical Information Series BVMM General Description: Ball ValvesDokumen6 halamanTechnical Information Series BVMM General Description: Ball ValvesAliArababadiBelum ada peringkat

- CI5000ENGDokumen7 halamanCI5000ENGKaliya PerumalBelum ada peringkat

- Jorgensen Steel Reference Book - Aug2010Dokumen456 halamanJorgensen Steel Reference Book - Aug2010polumathesBelum ada peringkat

- Crosby G-209R ROV ShackleDokumen1 halamanCrosby G-209R ROV ShacklenatBelum ada peringkat

- Catalogo Marazzi Rev04 09 04Dokumen2 halamanCatalogo Marazzi Rev04 09 04nexus41Belum ada peringkat

- Compliant To Tia Eia 222 F and Tia Eia 2Dokumen57 halamanCompliant To Tia Eia 222 F and Tia Eia 2santiago canoBelum ada peringkat

- Working Guide to Drilling Equipment and OperationsDari EverandWorking Guide to Drilling Equipment and OperationsPenilaian: 5 dari 5 bintang5/5 (9)

- Newnes Workshop Engineer's Pocket BookDari EverandNewnes Workshop Engineer's Pocket BookPenilaian: 4.5 dari 5 bintang4.5/5 (2)

- Materials Data for Cyclic Loading: Low-Alloy SteelsDari EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsPenilaian: 5 dari 5 bintang5/5 (2)

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsDari EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsPenilaian: 4.5 dari 5 bintang4.5/5 (10)

- Pressure Seal Bolted Bonnet Valves (Velan) PDFDokumen56 halamanPressure Seal Bolted Bonnet Valves (Velan) PDFUtku KepcenBelum ada peringkat

- Malaysia-Tapis CPP Topside PDFDokumen2 halamanMalaysia-Tapis CPP Topside PDFSumner TingBelum ada peringkat

- SteamDokumen1 halamanSteamSumner TingBelum ada peringkat

- Fgru RFC PDFDokumen1 halamanFgru RFC PDFSumner TingBelum ada peringkat

- Shale Oil & Gas: Overview of Shale HC Potential in Onshore East MalaysiaDokumen15 halamanShale Oil & Gas: Overview of Shale HC Potential in Onshore East MalaysiaSumner TingBelum ada peringkat

- P9 ClampDokumen1 halamanP9 ClampSumner TingBelum ada peringkat

- Pressure Test Procedure Rev.cDokumen8 halamanPressure Test Procedure Rev.cSumner TingBelum ada peringkat

- Pengerang Integrated Petroleum Complex (PIPC) : Malaysia ThematicDokumen44 halamanPengerang Integrated Petroleum Complex (PIPC) : Malaysia ThematicSumner TingBelum ada peringkat

- Shale Oil & Gas: Overview of Shale HC Potential in Onshore East MalaysiaDokumen15 halamanShale Oil & Gas: Overview of Shale HC Potential in Onshore East MalaysiaSumner TingBelum ada peringkat

- Petronas Vendor Approved List Jan 2018Dokumen50 halamanPetronas Vendor Approved List Jan 2018Sumner Ting60% (5)

- ASME B31.3-2016 Postweld Heat Treatment TableDokumen1 halamanASME B31.3-2016 Postweld Heat Treatment TableSumner TingBelum ada peringkat

- P9 ClampDokumen1 halamanP9 ClampSumner TingBelum ada peringkat

- Structural Gratings Standard Drawing Type 1Dokumen1 halamanStructural Gratings Standard Drawing Type 1Sumner TingBelum ada peringkat

- Spring HangerDokumen1 halamanSpring HangerSumner TingBelum ada peringkat

- Pipe Sizes ThreadsDokumen2 halamanPipe Sizes ThreadsSumner TingBelum ada peringkat

- Mesh CalculationDokumen1 halamanMesh CalculationSumner TingBelum ada peringkat

- Stencil WP03Dokumen18 halamanStencil WP03Sumner TingBelum ada peringkat

- 6" to 3Dokumen1 halaman6" to 3Sumner TingBelum ada peringkat

- B3200 2017-Catalogue LRDokumen508 halamanB3200 2017-Catalogue LRSumner TingBelum ada peringkat

- Baumann Actuator Type32 Instr D1099Dokumen8 halamanBaumann Actuator Type32 Instr D1099Sumner TingBelum ada peringkat

- Pig Weight Vs TimeDokumen4 halamanPig Weight Vs TimeSumner TingBelum ada peringkat

- DNV RP D101 October 2008Dokumen42 halamanDNV RP D101 October 2008aop10468100% (1)

- Off-Campus Programmes Offered Semester I 2012/2013Dokumen2 halamanOff-Campus Programmes Offered Semester I 2012/2013Sumner TingBelum ada peringkat

- CY Comment Response Sheet - TH LT1 XX GENP INT PRC 1203 Rev C1Dokumen3 halamanCY Comment Response Sheet - TH LT1 XX GENP INT PRC 1203 Rev C1Sumner TingBelum ada peringkat

- Quickly analyze risks in Excel with @RISK in under 20 minutesDokumen3 halamanQuickly analyze risks in Excel with @RISK in under 20 minutesSumner TingBelum ada peringkat

- CorrosionDokumen3 halamanCorrosionSumner TingBelum ada peringkat

- Control ValveDokumen10 halamanControl ValveSumner TingBelum ada peringkat

- Convo HotelDokumen1 halamanConvo HotelSumner TingBelum ada peringkat

- Convo HotelDokumen1 halamanConvo HotelSumner TingBelum ada peringkat

- Hughes Brothers PDFDokumen52 halamanHughes Brothers PDFJavier MaldonadoBelum ada peringkat

- AL - CU - Integration - Preso - v7 24 Jul 08 ZipDokumen80 halamanAL - CU - Integration - Preso - v7 24 Jul 08 ZipFreddy CadenaBelum ada peringkat

- Structural Behaviour of Bolted Moment Connections in Cold-Formed Steel Beam-Column Sub-FramesDokumen22 halamanStructural Behaviour of Bolted Moment Connections in Cold-Formed Steel Beam-Column Sub-FramesAniket DubeBelum ada peringkat

- Indian Boiler Regulations: (Xiii)Dokumen1 halamanIndian Boiler Regulations: (Xiii)Vishal SoniBelum ada peringkat

- Presperse Catalog - Europe Asia 12-2011 PDFDokumen13 halamanPresperse Catalog - Europe Asia 12-2011 PDFponian9338Belum ada peringkat

- Carbon Steel 1030 Availability from North American SuppliersDokumen4 halamanCarbon Steel 1030 Availability from North American SuppliersShailendra SharmaBelum ada peringkat

- Pulp Paper Industry PDFDokumen2 halamanPulp Paper Industry PDFX800XLBelum ada peringkat

- 3Cr2W8V PDFDokumen2 halaman3Cr2W8V PDFFARID MIFTAHUL ANWARBelum ada peringkat

- Chemical Composition of Portland Cement 9Dokumen2 halamanChemical Composition of Portland Cement 9Jorge CabreraBelum ada peringkat

- Die CastingDokumen9 halamanDie CastingBhushan SalunkeBelum ada peringkat

- Deformation of Solids: 1-Nov 01-Q/5Dokumen3 halamanDeformation of Solids: 1-Nov 01-Q/5Coolman PoonBelum ada peringkat

- Soal Senyawa Kimia PDFDokumen4 halamanSoal Senyawa Kimia PDFLewi Petrik HorayosBelum ada peringkat

- Materials and Processes PDFDokumen28 halamanMaterials and Processes PDFBala SundaramBelum ada peringkat

- MBN 10105 2014-10Dokumen7 halamanMBN 10105 2014-10조준장Belum ada peringkat

- Astm A 888 2013 PDFDokumen58 halamanAstm A 888 2013 PDFjoao carlos protzBelum ada peringkat

- Heat Resistant Alloy HN Data SheetDokumen2 halamanHeat Resistant Alloy HN Data SheetAzize RazamBelum ada peringkat

- Seismic Design Coefficients From ASCE 7-10-2Dokumen5 halamanSeismic Design Coefficients From ASCE 7-10-2Bunkun15Belum ada peringkat

- MHS Griber Parallel 2-3-4 Finger PDFDokumen80 halamanMHS Griber Parallel 2-3-4 Finger PDFVitor PereiraBelum ada peringkat

- Shackles: 5150 - Nut & Bolt Bow ShackleDokumen1 halamanShackles: 5150 - Nut & Bolt Bow ShackleAlthaf R100% (1)

- AntiSegregation HopperDokumen5 halamanAntiSegregation Hoppermecaunidos7771Belum ada peringkat

- FlowBiz Forged Steel Globe Valve 1500 ClassDokumen2 halamanFlowBiz Forged Steel Globe Valve 1500 ClassFlowBiz Exports Pvt. Ltd.Belum ada peringkat

- ASME V Liquid Penentrant ExaminationDokumen10 halamanASME V Liquid Penentrant ExaminationAlejandroBelum ada peringkat

- G61-86R03E1.1207958-1 (Polarização)Dokumen5 halamanG61-86R03E1.1207958-1 (Polarização)Fabricio Benedito DestroBelum ada peringkat

- Series FBV-3C-SS, FBVS-3C-SS Specification SheetDokumen2 halamanSeries FBV-3C-SS, FBVS-3C-SS Specification SheetWattsBelum ada peringkat

- 3.1 Casting ProcessDokumen4 halaman3.1 Casting Processزينب عبد الخالق كاملBelum ada peringkat

- En 1982 Copper and Copper Alloy Ingots and Castings - Compositions, Uses and Typical Properties-Table11Dokumen1 halamanEn 1982 Copper and Copper Alloy Ingots and Castings - Compositions, Uses and Typical Properties-Table11yw_oulalaBelum ada peringkat

- Model FCDokumen23 halamanModel FCLeandroBelum ada peringkat

- Analyze A Sample of Brass QualitativelyDokumen4 halamanAnalyze A Sample of Brass QualitativelyMEGHNA MATHURBelum ada peringkat

- Broom Manufacture Machine: StartDokumen62 halamanBroom Manufacture Machine: StartHaziq PazliBelum ada peringkat