Camshaft Housing and Assembly

Diunggah oleh

Hamilton MirandaHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Camshaft Housing and Assembly

Diunggah oleh

Hamilton MirandaHak Cipta:

Format Tersedia

8 03-15

1 8 03-15

SUBJECT DATE

Camshaft Housing and Assembly August 2015

Additions, Revisions, or Updates

Publication Number / Title Platform Section Title Change

Added note regarding usage on specific vehicles.

Step 8 - Added step for windshield wiper linkage removal.

Removal of the

DD Platform Step 18 - Added step to discard seal.

DDC-SVC-MAN-0081 Camshaft Housing

Euro IV DD Step 19 - Added step to place camshaft housing on a clean and flat

DDC-SVC-MAN-0181 surface.

Platform

Removal of the Added note regarding usage on specific vehicles.

Camshaft Housing Step 19 - Re-organized steps for finding TDC.

All information subject to change without notice. 3

8 03-15 Copyright © 2015 DETROIT DIESEL CORPORATION

2 Removal of the Camshaft Housing

2 Removal of the Camshaft Housing

Remove as follows:

NOTE: This procedure applies to vehicles with a Bumper-to-Back of Cab (BBC) measurement under 120 inches.

The camshaft housing can be removed as an assembly on vehicles with over a 120-inch BBC. Refer to section

"Removal of the Camshaft Housing Assembly" for those vehicles.

1. Shut off the engine, apply the parking brake, chock the wheels, and perform any other applicable safety steps.

2. Disconnect the battery power to the engine. Refer to OEM procedures.

3. Open the hood.

WARNING: FIRE HAZARD

Do not power wash or steam clean the engine bay in the area of vehicle electrical components,

unless specified by vehicle manuals or service literature. Power washing/steam cleaning can

permanently damage these components, which could result in fire, personal injury, or property

damage.

4. Steam clean the engine.

5. If necessary, remove the bumper. Refer to OEM procedures.

6. If necessary, remove the rain tray. Refer to OEM procedures.

7. If necessary, remove the windshield wiper linkage. Refer to the OEM procedure.

8. Remove the rocker shaft assemblies and both camshafts. Refer to section "Removal of Camshaft and Rocker Shaft/

Engine Brake Assembly".

WARNING: PERSONAL INJURY

To prevent the escape of high pressure fuel that can penetrate skin, ensure the engine has been

shut down for a minimum of 10 minutes before servicing any component within the high pressure

circuit. Residual high fuel pressure may be present within the circuit.

WARNING: PERSONAL INJURY

All parts provided within this kit must be installed in the proper locations, and MUST be fastened to

the specified torque. Failure to properly torque hardware/components will result in failure of a high

pressure fuel feed line, resulting in possible fire and/or personal injury.

NOTICE: The high pressure fuel rail feed lines, P-clips, vibration dampers, mounting bracket and hardware are

one-time-use components and MUST be replaced any time they are loosened or removed.

NOTICE: Engine size/model year specific service kits, containing all of the necessary parts to replace the high

pressure fuel rail feed lines have been released. Refer to TS letter 12 TS-9 for the high pressure fuel line kit

numbers to repair these engines.

9. Remove and discard the high pressure fuel rail feed lines.

For the three-filter fuel system, Refer to section "Removal of the High Pressure Fuel Rail Feed Lines - Three-Filter

System".

For the two-filter fuel system, Refer to section "Removal of the High Pressure Fuel Rail Feed Lines - Two-Filter

System".

10. Remove the high pressure fuel injector lines.

For the three-filter fuel system, Refer to section "Removal of the High Pressure Fuel Injector Lines - Three-Filter

System".

4 All information subject to change without notice.

Copyright © 2015 DETROIT DIESEL CORPORATION 8 03-15

8 03-15

For the two-filter fuel system, Refer to section "Removal of the High Pressure Fuel Injector Lines - Two-Filter

System".

11. Remove the Pressure Limiting Valve (PLV) banjo bolt from the fuel rail. Discard the PLV banjo bolt sealing washers.

12. Disconnect the fuel rail pressure sensor, Intake Manifold Temperature (IMT) sensor and Camshaft Position (CMP)

sensor.

13. Unclip all of the electrical wiring harness attaching points from the camshaft housing.

14. Unbolt the air compressor inlet pipe from the camshaft housing and the flywheel housing.

15. Remove the bolt and the P-clip securing the doser coolant line to the camshaft housing.

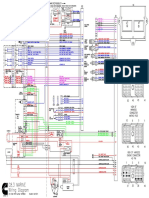

16. Remove the remaining two bolts (29) and (30), if equipped, securing the camshaft housing to the cylinder head. See

illustration below.

WARNING: PERSONAL INJURY

To avoid injury when removing or installing a heavy engine component, ensure the component is

properly supported and securely attached to an adequate lifting device to prevent the component

from falling.

17. Attach a suitable lifting device to the camshaft housing and lift the camshaft housing off the cylinder head.

18. Remove and discard the camshaft housing seal.

19. Place the camshaft housing on a clean and flat surface to avoid damage.

All information subject to change without notice. 5

8 03-15 Copyright © 2015 DETROIT DIESEL CORPORATION

3 Removal of the Camshaft Housing Assembly

3 Removal of the Camshaft Housing Assembly

NOTE: This procedure applies to vehicles with a Bumper-to-Back of Cab (BBC) measurement over 120 inches.

For vehicles with less than a 120-inch BBC, Refer to section "Removal of the Camshaft Housing".

Table 1.

Service Tools Used in the Procedure

Tool Number Tool Name and Engine Tool Graphic

W470589034000 Camshaft Timing Tool - EPA07 DD13 Only

W470589114000 Camshaft Timing Tool - EPA07/EPA10/GHG14 DD13

W470589054000 Camshaft Timing Tool - EPA07 DD15/DD16 Only

W470589104000 Camshaft Timing Tool - EPA07/EPA10/GHG14 DD15/16

J-46392 or W904589046300 Engine Barring Tool - DD Platform

W470589001500 Top Dead Center Locating Pin - DD Platform

Remove as follows:

6 All information subject to change without notice.

Copyright © 2015 DETROIT DIESEL CORPORATION 8 03-15

8 03-15

WARNING: PERSONAL INJURY

To avoid injury, never remove any engine component while the engine is running.

1. Shut off the engine, apply the parking brake, chock the wheels, and perform any other applicable safety steps.

2. Disconnect the batteries. Refer to OEM procedures.

3. Open the hood.

WARNING: FIRE HAZARD

Do not power wash or steam clean the engine bay in the area of vehicle electrical components,

unless specified by vehicle manuals or service literature. Power washing/steam cleaning can

permanently damage these components, which could result in fire, personal injury, or property

damage.

4. Steam clean the engine.

5. If necessary, remove the bumper. Refer to OEM procedures.

6. If necessary, remove the rain tray. Refer to OEM procedures.

7. Remove the air filter housing. Refer to OEM procedures.

8. Unbolt the doser coolant supply line P-clip from the camshaft housing.

9. Remove the high pressure fuel rail feed lines.

Refer to section "Removal of the High Pressure Fuel Rail Feed Lines - Two-Filter System".

Refer to section "Removal of the High Pressure Fuel Rail Feed Lines - Three-Filter System".

10. Remove the high pressure fuel injector lines.

Refer to section "Removal of the High Pressure Fuel Injector Lines - Two-Filter System".

Refer to section "Removal of the High Pressure Fuel Injector Lines - Three-Filter System".

11. Remove the Pressure Limiting Valve (PLV) banjo bolt and discard sealing washers.

12. Disconnect the two 14-pin fuel injector harness connectors from the camshaft housing.

13. Disconnect the fuel rail pressure sensor, Intake Manifold Temperature (IMT) sensor and Camshaft Position (CMP)

sensor.

14. Unclip all of the electrical wiring harness attaching points on to the camshaft housing.

15. Remove the rocker cover. Refer to section "Removal of the Rocker Cover".

16. Unbolt the air compressor inlet pipe from the camshaft housing and the flywheel housing.

17. Remove the fuel injector wiring harness.

Refer to section "Removal of the Two-Piece Fuel Injector Wiring Harness - Two-Filter System".

Refer to section "Removal of the Two-Piece Fuel Injector Wiring Harness - Three-Filter System".

18. Remove the two rear bolts (22 and 23), if equipped, from the camshaft housing.

All information subject to change without notice. 7

8 03-15 Copyright © 2015 DETROIT DIESEL CORPORATION

3 Removal of the Camshaft Housing Assembly

19. Rotate the engine to Top Dead Center (TDC) on cylinder No. 1. Rotate the engine using barring tool (J-46392 or

W904589046300) until the TDC dot (3) is between two teeth on the flywheel and aligns with the edge of the pointer (2)

on the flywheel housing (1).

20. Remove the Crankshaft Position (CKP) sensor from the left (driver) side of the flywheel housing. Install the flywheel

housing crankshaft TDC locating pin (W470589001500) into the CKP sensor hole to verify TDC.

21. Install the proper camshaft timing tool onto the rear of the camshaft housing to verify TDC on cylinder No. 1. Do not

remove the camshaft timing tool until instructed to do so.

22. Fully loosen the overhead lash adjusters for the intake and exhaust rocker arms.

NOTICE: Loosen the camshaft housing bolts in the correct sequence to prevent damage.

NOTE: Do not remove the camshaft mounting bolts completely from the assembly.

23. Loosen the camshaft housing mounting bolts using the following instructions. Fully loosen the center bolts from the

camshaft housing (bolts 1 through 7).

8 All information subject to change without notice.

Copyright © 2015 DETROIT DIESEL CORPORATION 8 03-15

8 03-15

24. Fully loosen the bolts on the exhaust side, excluding bolts 14 and 16.

25. Fully loosen the bolts on the intake side, excluding bolts 15 and 17.

26. Loosen the four remaining bolts (14, 15, 16, and 17) a single turn at a time, using a crisscross pattern until fully

loosened.

27. Install four lifting eyes into the rocker cover mounting holes.

NOTICE: Ensure that no debris falls into the oil galleries on the cylinder head when the camshaft housing

assembly is removed or severe engine damage can occur.

28. Connect a suitable lifting device to the lifting eyes.

NOTE: Because of the pressure on cylinder No. 2 and No. 3 rocker arms, the housing may be stuck on the rear

alignment dowel. If it is stuck, it can be broken free by rocking down on the front of the housing. If that does not

help, a pry bar may be needed to help break it loose from the dowel.

29. Lift and remove the camshaft housing assembly.

NOTICE: No abrasive cleaning pads should be used on the gasket sealing surface.

30. Remove and discard the camshaft housing seal.

NOTICE: Do not rest the camshaft housing assembly on the camshaft gears or damage can occur.

31. Place the camshaft housing assembly on a suitable surface on its side.

All information subject to change without notice. 9

8 03-15 Copyright © 2015 DETROIT DIESEL CORPORATION

Anda mungkin juga menyukai

- Additions, Revisions, or Updates: Subject DateDokumen10 halamanAdditions, Revisions, or Updates: Subject DateEduardo TorresBelum ada peringkat

- Trucks Mechanic Only: Additions, Revisions, or UpdatesDokumen8 halamanTrucks Mechanic Only: Additions, Revisions, or UpdatesLUIS CONDORIBelum ada peringkat

- DD Unable Complete RegenDokumen6 halamanDD Unable Complete RegenJOHN Wright100% (3)

- Identificacion de Modelos DD15 DD13Dokumen6 halamanIdentificacion de Modelos DD15 DD13Ricardo LoredoBelum ada peringkat

- Installation Instruction: Fuel Pump Short Block Service Kit Installation InstructionsDokumen4 halamanInstallation Instruction: Fuel Pump Short Block Service Kit Installation InstructionsSean DuncanBelum ada peringkat

- 505 10Dokumen28 halaman505 10carlos maradiagaBelum ada peringkat

- Detroit 3-3 PDFDokumen307 halamanDetroit 3-3 PDFAlbert SteinBelum ada peringkat

- Detroit™ Transmissions Electronic Application and Installation ManualDokumen80 halamanDetroit™ Transmissions Electronic Application and Installation ManualSonder B50% (2)

- Tmo 1043Dokumen43 halamanTmo 1043Jose Renny PenaBelum ada peringkat

- Troubleshooting Freightliner HVAC BlowerDokumen1 halamanTroubleshooting Freightliner HVAC BlowerCopyMaster2100% (2)

- GHG17 Heavy Duty Troubleshooting Manual (DDC-SVC-MAN-0191)Dokumen17 halamanGHG17 Heavy Duty Troubleshooting Manual (DDC-SVC-MAN-0191)Octavio Hernandez RodriguezBelum ada peringkat

- Internal or External Leakage of The High Pressure Fuel System 2Dokumen11 halamanInternal or External Leakage of The High Pressure Fuel System 2SatooAtheiBelum ada peringkat

- Engine Brake ControlsDokumen9 halamanEngine Brake Controlsalejandro sanchezBelum ada peringkat

- New Cascadia Driver's Manual2 PDFDokumen203 halamanNew Cascadia Driver's Manual2 PDFjesus silvaBelum ada peringkat

- ISX15 Product Enhancements 20132016Dokumen73 halamanISX15 Product Enhancements 20132016TahirBelum ada peringkat

- TT00041 - Injector Sleeve Installation On 2008 - 2017 Detroit DieselDokumen2 halamanTT00041 - Injector Sleeve Installation On 2008 - 2017 Detroit DieselIonut-alexandru Iordache100% (1)

- DDCT Password Removal - EnglishDokumen10 halamanDDCT Password Removal - EnglishJOHN Wright100% (1)

- Detroit DD15 Engine: Horsepower LB-FT Torque LitersDokumen10 halamanDetroit DD15 Engine: Horsepower LB-FT Torque Litersramsi17100% (1)

- 2016 and Newer International Prostar Engine Data: Option 1 Backbone Connection Below The Fuse PanelDokumen6 halaman2016 and Newer International Prostar Engine Data: Option 1 Backbone Connection Below The Fuse PanelCarlosEnriqueRuizPedreraBelum ada peringkat

- P94-2062 EoaDokumen3 halamanP94-2062 EoaGonzalo GalvezBelum ada peringkat

- GHG17 Medium Duty Workshop (DDC-SVC-MAN-0194)Dokumen22 halamanGHG17 Medium Duty Workshop (DDC-SVC-MAN-0194)Namsa LABORATORIO100% (1)

- Gen 5 DD15 Platform Workshop Manual (DDC-SVC-MAN-0215)Dokumen7 halamanGen 5 DD15 Platform Workshop Manual (DDC-SVC-MAN-0215)freddy100% (1)

- 1127 Mid Stop Counterbore CuttingDokumen7 halaman1127 Mid Stop Counterbore Cuttingralph arisBelum ada peringkat

- SS 2688 e PDFDokumen9 halamanSS 2688 e PDFDaniel Castillo PeñaBelum ada peringkat

- Engineering Installation Bulletin: Cooling SystemDokumen43 halamanEngineering Installation Bulletin: Cooling SystemmxnoxnBelum ada peringkat

- Mbe900ts PDFDokumen673 halamanMbe900ts PDFalejandro sanchez100% (1)

- 2009-11!24!135132 ISX Troubleshooting TreeDokumen34 halaman2009-11!24!135132 ISX Troubleshooting TreeHarold PolkaBelum ada peringkat

- Tmo 963 PDFDokumen112 halamanTmo 963 PDFAlex Parra100% (3)

- DD Exhast Egr After Treat Ddc-Svc-Man-0083Dokumen393 halamanDD Exhast Egr After Treat Ddc-Svc-Man-0083directorBelum ada peringkat

- 2010 Maxxforce DT, 9, & 10 Engine To Chassis Interface: Study Guide Tmt-121011Dokumen24 halaman2010 Maxxforce DT, 9, & 10 Engine To Chassis Interface: Study Guide Tmt-121011Henry MorenoBelum ada peringkat

- Dd15 FaultDokumen19 halamanDd15 FaultSs100% (1)

- Diamond Logic Sistema ElectricoDokumen22 halamanDiamond Logic Sistema ElectricoFranciscoBelum ada peringkat

- 18speed FullerDokumen100 halaman18speed FullerPieter Coetzer100% (4)

- Supplemental Manuals - Peterbilt Conventional Trucks Operator's Manual After 1-07 PDFDokumen225 halamanSupplemental Manuals - Peterbilt Conventional Trucks Operator's Manual After 1-07 PDFLuis Reinaldo Ramirez ContrerasBelum ada peringkat

- Coach & Bus EngineDokumen2 halamanCoach & Bus EngineClegivaldoBelum ada peringkat

- Serie 60 Informacion AdicionalDokumen51 halamanSerie 60 Informacion AdicionalMauricio Campos QuirosBelum ada peringkat

- Freightliner Coronado SD: SectionDokumen23 halamanFreightliner Coronado SD: SectionhoangnhuphuocBelum ada peringkat

- Pressure Testing The Intake & Exhaust Sys at One TimeDokumen2 halamanPressure Testing The Intake & Exhaust Sys at One Timejaime roblesBelum ada peringkat

- Air BrakeDokumen56 halamanAir BrakeAlexanderBelum ada peringkat

- DDEC 10 InputsDokumen18 halamanDDEC 10 Inputsalejandro sanchez100% (1)

- On-Board Diagnostics (OBD) : A Vehicle's Self-Diagnostic and Reporting CapabilitiesDokumen13 halamanOn-Board Diagnostics (OBD) : A Vehicle's Self-Diagnostic and Reporting CapabilitiesHerrera AnthonyBelum ada peringkat

- Engine Brake DD15Dokumen7 halamanEngine Brake DD15Hamilton miranda100% (1)

- P94-2044 AbsDokumen5 halamanP94-2044 AbsGonzalo GalvezBelum ada peringkat

- ® ™ Bendix EC 80 ATC Controller Bendix EC 80 ABS ControllerDokumen44 halaman® ™ Bendix EC 80 ATC Controller Bendix EC 80 ABS ControllerIrvin RojasBelum ada peringkat

- CPC Veh Int PDFDokumen1 halamanCPC Veh Int PDFHạcLãoBelum ada peringkat

- DDC SVC MAN 0054.ch5Dokumen188 halamanDDC SVC MAN 0054.ch5aldo jesus100% (1)

- DDEC VI - Reference Guide PDFDokumen98 halamanDDEC VI - Reference Guide PDFMike BBelum ada peringkat

- Actuador VGT Motor PaccarDokumen4 halamanActuador VGT Motor PaccarJESUS ARAIZABelum ada peringkat

- Detroit DD15 Engine Demand DetroitDokumen1 halamanDetroit DD15 Engine Demand Detroitziad khalilBelum ada peringkat

- DD15 Engine Torque SpecificationsDokumen5 halamanDD15 Engine Torque SpecificationsJoser Roberto Magana67% (3)

- Coronado Maintenance ManualDokumen124 halamanCoronado Maintenance Manualssmith6582100% (1)

- Paccar GHG17 EAS 4 Emulator Installation Manual 2Dokumen2 halamanPaccar GHG17 EAS 4 Emulator Installation Manual 2Melvin ZepedaBelum ada peringkat

- EPA10 DD PLATFORM OPERATORS MANUAL For DDC ENGINESDokumen157 halamanEPA10 DD PLATFORM OPERATORS MANUAL For DDC ENGINESfiloktimonBelum ada peringkat

- Newsletter Sam ChassisDokumen14 halamanNewsletter Sam ChassisErik Shelber Calcina CalcinaBelum ada peringkat

- Century Class Trucks Maintenance ManualDokumen137 halamanCentury Class Trucks Maintenance ManualJorge Gregorio Segura100% (5)

- ESA Update AnnouncementDokumen5 halamanESA Update Announcementedin cabreraBelum ada peringkat

- MCM - 120-Pin Connector: All Information Subject To Change Without NoticeDokumen1 halamanMCM - 120-Pin Connector: All Information Subject To Change Without NoticeLuis Eduardo Corzo EnriquezBelum ada peringkat

- Detroit Diesel DD 13 - 15 Fuel SystemDokumen15 halamanDetroit Diesel DD 13 - 15 Fuel SystemAhmetCan YüzükçüBelum ada peringkat

- CLSM0200 0512aDokumen68 halamanCLSM0200 0512amds9185Belum ada peringkat

- Fuel Injection Pump - RemoveDokumen6 halamanFuel Injection Pump - RemoveedwinBelum ada peringkat

- PV776-20 012758Dokumen2 halamanPV776-20 012758Hamilton MirandaBelum ada peringkat

- Wastegate Turbocharger Operation DiagnosticDokumen6 halamanWastegate Turbocharger Operation DiagnosticHamilton MirandaBelum ada peringkat

- VECU and Transmission ECU Wire Harness Rub-Through - CX, CH and CV Models Equipped WithDokumen2 halamanVECU and Transmission ECU Wire Harness Rub-Through - CX, CH and CV Models Equipped WithHamilton MirandaBelum ada peringkat

- Cylinder Balancing, Fault TracingDokumen8 halamanCylinder Balancing, Fault TracingIzz BaharBelum ada peringkat

- Electric Fuel Pump, Fault TracingDokumen11 halamanElectric Fuel Pump, Fault TracingIzz Bahar100% (1)

- J-Tech™ Engine Brake Slave Lash Adjustment ChangeDokumen1 halamanJ-Tech™ Engine Brake Slave Lash Adjustment ChangeHamilton MirandaBelum ada peringkat

- V-MAC® IV Vehicle Interface ConnectorDokumen1 halamanV-MAC® IV Vehicle Interface ConnectorHamilton MirandaBelum ada peringkat

- Air Conditioning Base M2 PDFDokumen1 halamanAir Conditioning Base M2 PDFHamilton MirandaBelum ada peringkat

- Retaining Engine Brake PistonsDokumen1 halamanRetaining Engine Brake PistonsHamilton MirandaBelum ada peringkat

- Variable Turbine Geometry (VTG)Dokumen12 halamanVariable Turbine Geometry (VTG)Hamilton MirandaBelum ada peringkat

- Air Conditioning Base M2 PDFDokumen1 halamanAir Conditioning Base M2 PDFHamilton MirandaBelum ada peringkat

- Body Builder Transmission InterfacesDokumen5 halamanBody Builder Transmission InterfacesHamilton MirandaBelum ada peringkat

- Rear-Mounted Range Shift Cylinder Rebuild T300Dokumen20 halamanRear-Mounted Range Shift Cylinder Rebuild T300Hamilton MirandaBelum ada peringkat

- Addendum 1 (Marker Lights)Dokumen2 halamanAddendum 1 (Marker Lights)Hamilton MirandaBelum ada peringkat

- ABS Module 2Dokumen1 halamanABS Module 2Hamilton MirandaBelum ada peringkat

- Camshaft Wear InspectionDokumen2 halamanCamshaft Wear InspectionHamilton MirandaBelum ada peringkat

- 3 Ddecv 06 PDFDokumen2 halaman3 Ddecv 06 PDFHamilton MirandaBelum ada peringkat

- Diagrama de Cableado ISX Con Bomba de Levante1Dokumen1 halamanDiagrama de Cableado ISX Con Bomba de Levante1Leonel HernandezBelum ada peringkat

- ABS Module 2Dokumen1 halamanABS Module 2Hamilton MirandaBelum ada peringkat

- Allison TechdataFileDokumen10 halamanAllison TechdataFileSergio NavaBelum ada peringkat

- CELECT PLUS Industrial - 3666348 PDFDokumen1 halamanCELECT PLUS Industrial - 3666348 PDFHamilton MirandaBelum ada peringkat

- ISX-07 Final Wiring Diagram - 4021575 - GDokumen1 halamanISX-07 Final Wiring Diagram - 4021575 - GHamilton MirandaBelum ada peringkat

- Cummins ISB 23 Pines 01Dokumen1 halamanCummins ISB 23 Pines 01Hamilton Miranda100% (3)

- AS07-047 WTech3 Vehicle Syst DiagramDokumen1 halamanAS07-047 WTech3 Vehicle Syst DiagramHamilton MirandaBelum ada peringkat

- (Oneil)Dokumen4 halaman(Oneil)Hamilton MirandaBelum ada peringkat

- UP-IV Pocket CardDokumen2 halamanUP-IV Pocket Cardfelix3189100% (1)

- ISM-07 Final Wiring Diagram - 4021574 - GDokumen1 halamanISM-07 Final Wiring Diagram - 4021574 - GHamilton MirandaBelum ada peringkat

- Allison TechdataFileDokumen10 halamanAllison TechdataFileSergio NavaBelum ada peringkat

- Cummins QSB 2 de 2 PDFDokumen1 halamanCummins QSB 2 de 2 PDFHamilton MirandaBelum ada peringkat

- L Gas Plus - 4021503-01 - G PDFDokumen1 halamanL Gas Plus - 4021503-01 - G PDFHamilton MirandaBelum ada peringkat

- F9 Smart Study NotesDokumen97 halamanF9 Smart Study NotesSteven Lino100% (5)

- Hi 3 Yt 318201Dokumen3 halamanHi 3 Yt 318201partha khatuaBelum ada peringkat

- Kolodin Agreement For Discipline by ConsentDokumen21 halamanKolodin Agreement For Discipline by ConsentJordan ConradsonBelum ada peringkat

- Intel Server RoadmapDokumen19 halamanIntel Server Roadmapjinish.K.GBelum ada peringkat

- Add New Question (Download - PHP? SC Mecon&id 50911)Dokumen9 halamanAdd New Question (Download - PHP? SC Mecon&id 50911)AnbarasanBelum ada peringkat

- Power Dense and Robust Traction Power Inverter For The Second Generation Chevrolet Volt Extended Range EDokumen8 halamanPower Dense and Robust Traction Power Inverter For The Second Generation Chevrolet Volt Extended Range Ejrz000Belum ada peringkat

- E Rpms Portfolio Design 3 1Dokumen52 halamanE Rpms Portfolio Design 3 1jebBelum ada peringkat

- Kilifi HRH Strategic Plan 2018-2021Dokumen106 halamanKilifi HRH Strategic Plan 2018-2021Philip OlesitauBelum ada peringkat

- Project Guidelines (Issued by CBSE) : CA. (DR.) G.S. GrewalDokumen51 halamanProject Guidelines (Issued by CBSE) : CA. (DR.) G.S. GrewalShruti Yadav0% (1)

- (1895) Indianapolis Police ManualDokumen122 halaman(1895) Indianapolis Police ManualHerbert Hillary Booker 2ndBelum ada peringkat

- Aug 2020 Builders Line Tamil MonthlyDokumen48 halamanAug 2020 Builders Line Tamil MonthlyBuildersLineMonthlyBelum ada peringkat

- Transportation and Academic Performance of Students in The Academic TrackDokumen3 halamanTransportation and Academic Performance of Students in The Academic TrackMary-Jay TolentinoBelum ada peringkat

- Psychological Attitude Towards SafetyDokumen17 halamanPsychological Attitude Towards SafetyAMOL RASTOGI 19BCM0012Belum ada peringkat

- Imp121 1isDokumen6 halamanImp121 1isErnesto AyzenbergBelum ada peringkat

- Application Letters To Apply For A Job - OdtDokumen2 halamanApplication Letters To Apply For A Job - OdtRita NourBelum ada peringkat

- Mobile Fire Extinguishers. Characteristics, Performance and Test MethodsDokumen28 halamanMobile Fire Extinguishers. Characteristics, Performance and Test MethodsSawita LertsupochavanichBelum ada peringkat

- Orthopanton Villa System MedicalDokumen61 halamanOrthopanton Villa System MedicalOscarOcañaHernándezBelum ada peringkat

- Organization of Brigada Eskwela Steering and Working CommitteesDokumen2 halamanOrganization of Brigada Eskwela Steering and Working CommitteesCherry Lou RiofrirBelum ada peringkat

- NGOs in Satkhira PresentationDokumen17 halamanNGOs in Satkhira PresentationRubayet KhundokerBelum ada peringkat

- 15.910 Draft SyllabusDokumen10 halaman15.910 Draft SyllabusSaharBelum ada peringkat

- Group Tour Operators in Pune - Best Tours and Travels in PuneDokumen10 halamanGroup Tour Operators in Pune - Best Tours and Travels in PuneGargi ToursBelum ada peringkat

- Enabling Trade Report 2013, World Trade ForumDokumen52 halamanEnabling Trade Report 2013, World Trade ForumNancy Islam100% (1)

- BSDC CCOE DRAWING FOR 2x6 KL R-1Dokumen1 halamanBSDC CCOE DRAWING FOR 2x6 KL R-1best viedosBelum ada peringkat

- Guide On Multiple RegressionDokumen29 halamanGuide On Multiple RegressionLucyl MendozaBelum ada peringkat

- Visa Requirements Austrian EmbassyDokumen2 halamanVisa Requirements Austrian Embassyadalcayde2514Belum ada peringkat

- San Francisco Chinese Christian Union, Et Al. v. City and County of San Francisco, Et Al. ComplaintDokumen25 halamanSan Francisco Chinese Christian Union, Et Al. v. City and County of San Francisco, Et Al. ComplaintFindLawBelum ada peringkat

- DTDC Rate Quotation-4Dokumen3 halamanDTDC Rate Quotation-4Ujjwal Sen100% (1)

- Techgig Open Round CompetitionDokumen6 halamanTechgig Open Round CompetitionAnil Kumar GodishalaBelum ada peringkat

- WTO & MFA AnalysisDokumen17 halamanWTO & MFA Analysisarun1974Belum ada peringkat

- Descriptive Na Ly TicsDokumen112 halamanDescriptive Na Ly TicsJay Mart AvanceñaBelum ada peringkat