Fan Damper Selection Fe 2600

Diunggah oleh

Guilherme AugustoHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Fan Damper Selection Fe 2600

Diunggah oleh

Guilherme AugustoHak Cipta:

Format Tersedia

FAN ENGINEERING

Information and Recommendations for the Engineer FE-2600

Fan Damper Selection

Introduction

Dampers offer a low cost, low maintenance alternative fans. This is not to imply that the various dampers can-

for controlling airflow in a fan system when compared not be used interchangeably. The concepts still hold true

to inverter drives or “in-flight” adjustable blade fans. In for all fans and systems, and use would only be limited

some types of fans, such as roof ventilators, dampers by choice or ruggedness of construction.

are standard, but in most instances they are sold as an

optional accessory tailored to meet the requirements of Automatic Dampers

individual applications. Automatic or backdraft dampers are commonly associ-

A variety of damper types are offered that can be ated with wall exhaust or roof ventilator applications.

installed on either the fan inlet, outlet or at some remote Designed to open automatically when the fan is ener-

location in the fan system. There are automatic dampers, gized and to close by gravity when power is turned off,

manually operated dampers, motor operated dampers these parallel blade, end pivoted dampers provide a

and modulated control dampers. There are varied mechanism which prevents the air from back flowing

degrees of construction from light to heavy, different through the system while also serving to exclude outside

blade shapes, end or center pivoted blades and parallel elements such as rain and snow. Typical wall and roof

or opposed blade arrangements, all uniquely configured installations are shown in Figure 1.

for specific applications. Another type of automatic backdraft damper is

The first part of this article will cover dampers and referred to as a stack cap or a discharge cap. Stack

concepts associated with lower pressure systems incor- caps are simply two opposed blade dampers mounted

porating panel fans, tubeaxial fans, vaneaxial fans and atop a roof fan, complete with a protective wind band

centrifugal vent set fans. Starting with “Volume Control that allows air to be exhausted while excluding the ele-

Dampers” the discussion will favor the medium to high ments when not operating (see Figure 2).

pressure systems commonly associated with centrifugal

Figure 1. Automatic Dampers

Wall Type: Designed for

horizontal airflow – grav-

OW

ity close. Optional bird AIR

FL

screen shown. AIRFLOW

Ceiling Type: Designed for vertical airflow.

Automatic gravity close. Exhaust only.

Figure 2. Stack Caps

DAMPER STOP

STACK CAP

DAMPER AIRFLOW

WINDBAND

BRONZE BUSHING

DAMPER ROD

BULB SEAL

CURB BASE

BEARING SUPPORT

WINDBAND BRACKET

DRAIN CHANNEL

DISCONNECT

SWITCH BRACKET

©2004 Twin City Fan Companies, Ltd.

In addition to exhaust applications, square, rectangular The electric actuators for these dampers are provided

and circular automatic backdraft dampers are also used with end switches that allow the damper to open before

in certain duct systems to function as check valves to the fan motor is energized. And like the two-position

prevent reverse airflow through a fan during shut down. actuator supplied on end pivoted dampers, when power

This is of particular importance in parallel fan systems, is off the spring return insures positive closing of the

where the fans are cycled independently, to prevent damper blades.

“windmilling” of the fan that is not in operation. System characteristics are altered only by the resis-

These dampers are not intended for capacity control tance to airflow with fully opened blades.

and therefore the system characteristics are altered only

by the resistance required to fully open the blades. Volume Control Dampers

Fan or system capacity can be altered over a finite

Motor Operated range through gradual damper blade adjustments. These

dampers can be located on the fan discharge (outlet

End Pivoted Dampers dampers), the fan intake (inlet dampers) or any place in

The function of these dampers is similar to that previ- the system. These dampers may be manually controlled

ously described for automatic dampers. The difference or controlled with sophisticated automatic systems.

is that they are usually furnished with a two-position

electric actuator (Figure 3) that powers the blades open Outlet Control Dampers

rather than relying on the velocity pressure of the air- Outlet control dampers are normally center pivoted with

flow. This is of particular importance in low flow condi- either “parallel” or “opposed” blade configuration (see

tions that might otherwise only partially open the auto- Figure 5).

matic damper blades creating blade flutter and poten-

tially more noise. Figure 5. Outlet Control Dampers

Figure 3. Motor Operated, End Pivoted Damper

AIRFLOW

Outlet Damper-Parallel Blade

Best suited to applications

For vertical or horizontal airflow. Exhaust only. requiring accurate air volume

control from wide open to Outlet Damper-Opposed Blade

75% wide open. Best suited for control over

Another advantage of the motor operated damper is broad range of air volume.

that when power is off the spring return insures positive

closing of the blades and is not influenced by stray

eddies or air currents. They can be mounted horizontally as shown, with the

Like the automatic damper, the two-position motor blades parallel to the fan shaft, or they can be mount-

operated damper is not intended for capacity control ed with the blades perpendicular to the fan shaft.

and therefore the system characteristics are altered only Perpendicular blade orientation may require special bear-

by the resistance to airflow of the fully opened blades. ing considerations.

As the blades are closed on the “parallel” blade

Motor Operated damper the air tends to pile up on one side creating

uneven airflow in the duct. This can lead to airflow dis-

Center Pivoted Dampers tribution problems in branch ducts located too close to

The motor operated center pivoted damper (see Figure the damper. It can also lead to a system effect on fan

4) can be used in either supply or exhaust applications. performance when the damper is too close to the inlet

These dampers are used primarily in reversing airflow of the fan.

fans and in air handling systems that require the damp-

ers to be open before the fan is energized. Figure 6. Damper Airflow Characteristics

Figure 4. Motor Operated, Center Pivoted Damper

AIRFLOW

Parallel Blade Damper Opposed Blade Damper

Illustrating Diverted Flow Illustrating Non-Diverting

Flow

“Opposed” blade dampers are the preferred selection

when it is necessary to maintain an even distribution of

airflow immediately downstream of the dampers. The

Designed for supply and exhaust. airflow characteristics of both the “parallel” blade and the

“opposed” blade dampers are illustrated in Figure 6.

2 Fan Engineering FE-2600

Also note in Figure 6, that as the damper lever arm centrifugal fan and outlet damper combination can be

is closed on the “parallel” blade damper, there is only seen in Figure 7.

a small reduction of area between the blades. Now The outlet damper controls the airflow after it passes

compare this to the “opposed” blade damper, where for through the fan by changing the resistance the airflow

the same amount of lever arm travel there is a propor- is working against.

tional reduction of area between blades. For example, a Point 1 on the curve represents the fan system with

30 degree closing of the lever arm on a “parallel” blade a full open blade setting. As the damper blades are

damper results in a capacity reduction of approximately closed off the damper resistance increases, driving the

10 percent while the same degree of closing on an operating point to the left along the fan’s static pressure

“opposed” blade damper will result in a capacity reduc- curve. Points 2, 3, 4 and 5 represent the fan system for

tion of approximately 30 percent. several different settings of damper blade closure. Note

The small reduction in capacity for a relatively large that as the damper resistance is increased, it moves the

lever arm travel makes the “parallel” blade damper the brake horsepower to the left along its curve, as noted

preferred choice where sensitive control of airflow by points 1a, 2a, 3a, 4a and 5a. On backward inclined

between wide open and 75 percent of wide open is centrifugal fans, as the damper is closed, the brake

required. The “opposed” blade damper is selected when horsepower can be more or less than the “wide open”

proportional control is desired. damper horsepower, but on forward curve and radial

The operating characteristics of a backward inclined blade centrifugal fans, the brake horsepower will always

be less than with the wide open setting.

Figure 7. Operating Characteristics of a Backward Inclined Centrifugal Fan With Outlet Dampers

5

4

3 2a

3a 1a

4a BHP

2

5a

BRAKE HORSEPOWER

STATIC PRESSURE

SYSTEM

CURVES

1

CFM

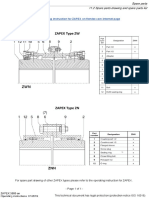

Inlet Box Dampers Figure 8. Inlet Box Damper

Inlet box dampers are used when volume control is

required with a fan inlet box in lieu of a variable inlet

vane. The performance of the inlet box damper is simi-

lar to the variable inlet vane, but allows for an easier

means of control when an inlet box is used.

Inlet box dampers are typically constructed with rug-

ged, two piece parallel blades that run along the narrow

axis of the damper to preswirl the air as it enters the

fan inlet. See the illustration below. The standard mate-

rial of construction for the inlet box damper is mild steel,

but special materials can be used based on airstream

requirements. The dampers are constructed with relubri-

cable bearings. When airstream temperatures are over

300°F, or system pressure dictates, the bearings are

mounted on Typestuffing boxes

I Blades that Position

in Closed protect the bearings

from the harsh airstream.

Type II Blades in Closed Position

3 Fan Engineering FE-2600

Inlet Control Dampers Figure 9. Inlet Control Dampers

Inlet box dampers, external inlet vane dampers and

internal vane dampers are the most common forms of

inlet control dampers. The inlet box damper (positioned

properly) and both types of inlet vane dampers pre-spin

the air in the direction of fan rotation. By creating spin

in the direction of fan rotation, the airflow, pressure and

horsepower of the fan are reduced, resulting in a new

fan performance curve.

The inlet box damper is similar to the parallel blade

outlet damper shown in Figure 5. Both types of inlet

vane dampers are shown in Figure 9.

The external inlet vane damper is normally attached

directly to the fan inlet flange. The vanes are center External Type Internal (Nested) Type

pivoted and operate parallel to each other. This damper

is configured with a center hub, which allows the vanes both a resistance and flow modifying effect by pre-

to be supported on each end through pivot bearings. spinning the air before it enters the fan wheel, generat-

This type of construction makes the external vane ing a new performance curve for each vane position.

damper capable of handling higher velocities and pres- The performance curve reacts very similar to a fan

sures than is possible with the internal inlet vane damp- equipped with speed control.

ers. It also makes them more expensive. Another advan- Point 1 on the curve represents a fan system with a

tage of the external vane damper is that the control fully opened (90 degree) vane setting. Points 2, 3 and

linkage is outside the air stream and easier to service. 4, and 2a, 3a and 4a show the reduction in airflow and

The internal (nested) vane damper is constructed with horsepower for different angles of vane closing.

the vanes assembled in the throat of the fan inlet cone. Predicting the exact airflow and horsepower reductions

Because of this they are subject to much higher veloc- varies with damper and fan type.

ities than the equivalent external vane damper, resulting

in higher pressure losses. For this reason the center hub Conclusion

is omitted in this design. This requires the center piv- While certain systems involving temperature, corrosives,

oted parallel vanes to be cantilevered off the inlet cone airborne particulate, control sensitivity, etc., can limit the

throat resulting in a construction that is better suited to use of dampers, they still can offer impressive savings

lower pressures and velocities than the external vane for most systems. They provide the system designer with

damper. The internal vane damper is lower cost, more a low cost and effective method to control system air-

compact and easier to install than the external type. flow. Although the power savings with outlet dampers

Figure 10 shows potential performance curves of a may be substantial, even greater savings can be realized

fan with variable inlet vanes. The inlet damper produces using inlet dampers.

Figure 10. Performance Curves of a Fan With Variable Inlet Vanes

SP

1a

BHP

2a

90°

STATIC PRESSURE

70°

BRAKE HORSEPOWER

3a SYSTEM

CURVE

1

50°

2

4a

30°

3

4

90°

70°

50°

30°

CFM

Twin city fan & blower | www.tcf.com

5959 Trenton Lane N | Minneapolis, MN 55442 | Phone: 763-551-7600 | Fax: 763-551-7601

Anda mungkin juga menyukai

- Ngineering ATA: Fan Damper SelectionDokumen4 halamanNgineering ATA: Fan Damper SelectionMohamed TahounBelum ada peringkat

- Airbus Flight Control Laws: The Reconfiguration LawsDari EverandAirbus Flight Control Laws: The Reconfiguration LawsPenilaian: 4.5 dari 5 bintang4.5/5 (16)

- Centrifugal Damper Cat PDFDokumen8 halamanCentrifugal Damper Cat PDFcassindromeBelum ada peringkat

- Fans Blowers and CompressorsDokumen7 halamanFans Blowers and CompressorsChristina SignioBelum ada peringkat

- A330 Normal Law: Putting Fly-by-Wire Into PerspectiveDari EverandA330 Normal Law: Putting Fly-by-Wire Into PerspectivePenilaian: 5 dari 5 bintang5/5 (2)

- Parallel Blade Damper: Air Distribution 135Dokumen2 halamanParallel Blade Damper: Air Distribution 135Rohit ShresthaBelum ada peringkat

- Centrifugal Damper CatDokumen8 halamanCentrifugal Damper CatAdil Shahzad100% (2)

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGDari EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGBelum ada peringkat

- Selection Criteria For DampersDokumen4 halamanSelection Criteria For Dampersmarlon168Belum ada peringkat

- Prevention of Actuator Emissions in the Oil and Gas IndustryDari EverandPrevention of Actuator Emissions in the Oil and Gas IndustryBelum ada peringkat

- Aerolab Tunel de Viento PDFDokumen22 halamanAerolab Tunel de Viento PDFedgarBelum ada peringkat

- Product Application Guide: Multiple Fan Systems - Fans in Series and ParallelDokumen4 halamanProduct Application Guide: Multiple Fan Systems - Fans in Series and Parallelasl20105945Belum ada peringkat

- Oral and Practical Review: Reflections on the Part 147 CourseDari EverandOral and Practical Review: Reflections on the Part 147 CourseBelum ada peringkat

- Fans and BlowersDokumen3 halamanFans and BlowersLurking RogueBelum ada peringkat

- Introduction to Fly-by-Wire Flight Control Systems: The professional pilot’s guide to understanding modern aircraft controlsDari EverandIntroduction to Fly-by-Wire Flight Control Systems: The professional pilot’s guide to understanding modern aircraft controlsBelum ada peringkat

- All You Need To Know About Fans - Electronics CoolingDokumen5 halamanAll You Need To Know About Fans - Electronics Coolingany oneBelum ada peringkat

- Marvel Carbureter and Heat Control As Used on Series 691 Nash Sixes Booklet SDari EverandMarvel Carbureter and Heat Control As Used on Series 691 Nash Sixes Booklet SBelum ada peringkat

- Ed 2300Dokumen4 halamanEd 2300rlam17Belum ada peringkat

- Hydraulics and Pneumatics: A Technician's and Engineer's GuideDari EverandHydraulics and Pneumatics: A Technician's and Engineer's GuidePenilaian: 4 dari 5 bintang4/5 (8)

- Adding The Control, Rigidity and Power of Hydraulics To A Pneumatic MachineDokumen5 halamanAdding The Control, Rigidity and Power of Hydraulics To A Pneumatic MachineSoro FoxBelum ada peringkat

- Introduction to Fly-By-Wire Flight Control SystemsDari EverandIntroduction to Fly-By-Wire Flight Control SystemsPenilaian: 5 dari 5 bintang5/5 (1)

- Cooling Fan CalculationsDokumen13 halamanCooling Fan CalculationsF. A AhmedBelum ada peringkat

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitDari EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitBelum ada peringkat

- Selecting A Cooling Fan: Device CharacteristicsDokumen4 halamanSelecting A Cooling Fan: Device CharacteristicsGary KerrBelum ada peringkat

- Influence of System Parameters Using Fuse Protection of Regenerative DC DrivesDari EverandInfluence of System Parameters Using Fuse Protection of Regenerative DC DrivesBelum ada peringkat

- 21 - Fans and BlowersDokumen8 halaman21 - Fans and Blowersyusuf.yuzuakBelum ada peringkat

- FansDokumen20 halamanFansMohammed AhmedBelum ada peringkat

- Delco Radio Owner's Manual Model 633; Delcotron Generator InstallationDari EverandDelco Radio Owner's Manual Model 633; Delcotron Generator InstallationBelum ada peringkat

- Types of DampersDokumen7 halamanTypes of DampersOA Aoo0% (1)

- About Control ValvesDokumen17 halamanAbout Control ValvesSaurabh BarangeBelum ada peringkat

- Pneumatic For BTMTDokumen192 halamanPneumatic For BTMTron Joshua QuirapBelum ada peringkat

- FactFile AD15 EN Reva Cement Clinker Fan LowresDokumen2 halamanFactFile AD15 EN Reva Cement Clinker Fan Lowresمهندس فهمي عبدالعزيزBelum ada peringkat

- Delco Manuals: Radio Model 633, Delcotron Generator Delco Radio Owner's Manual Model 633, Delcotron Generator InstallationDari EverandDelco Manuals: Radio Model 633, Delcotron Generator Delco Radio Owner's Manual Model 633, Delcotron Generator InstallationBelum ada peringkat

- Understanding BlowersDokumen11 halamanUnderstanding BlowersJam BabBelum ada peringkat

- Mine Ventilation - Fans and Flow DevicesDokumen45 halamanMine Ventilation - Fans and Flow DevicesKudo ShinichiBelum ada peringkat

- 6 System Surge Fan Surge Paralleling PDFDokumen5 halaman6 System Surge Fan Surge Paralleling PDFAnonymous n6D3JhBelum ada peringkat

- HVAC Handbook Part 6 Air Handling EquipmentDokumen75 halamanHVAC Handbook Part 6 Air Handling EquipmentTanveerBelum ada peringkat

- TB-2008-002 Fan Selection Guide: Basic Fan Technology OverviewDokumen24 halamanTB-2008-002 Fan Selection Guide: Basic Fan Technology OverviewRsn786Belum ada peringkat

- Fans. BlowersDokumen57 halamanFans. BlowersShubham SenBelum ada peringkat

- Fan Surge Information Tbn006 PDFDokumen4 halamanFan Surge Information Tbn006 PDFShellFugateBelum ada peringkat

- Anti-Stall Fans For The Mining IndustryDokumen4 halamanAnti-Stall Fans For The Mining IndustryJuan TunasBelum ada peringkat

- HVAC Handbook New Edition Part 6 Air Handling EquipmentDokumen75 halamanHVAC Handbook New Edition Part 6 Air Handling EquipmentAbdul Nabi100% (9)

- Kelair Dampers 101Dokumen3 halamanKelair Dampers 101harishcsharmaBelum ada peringkat

- Ejector Working PrincipleDokumen11 halamanEjector Working Principleanuram66100% (3)

- Fans & Blowers-Calculation of PowerDokumen20 halamanFans & Blowers-Calculation of PowerPramod B.Wankhade92% (24)

- Control Valve Training MaterialDokumen36 halamanControl Valve Training MaterialSanjoy Kr. DeyBelum ada peringkat

- Greenheck Damper GuideDokumen2 halamanGreenheck Damper GuideStefan WeissBelum ada peringkat

- 8.1 Mechanical Ventilation - Fans For Ventilation Underground MinesDokumen7 halaman8.1 Mechanical Ventilation - Fans For Ventilation Underground MinesDeepakKattimaniBelum ada peringkat

- Incoloy Alloy 825Dokumen4 halamanIncoloy Alloy 825Roman PaduaBelum ada peringkat

- Avoiding Short Term Overheat Failures of Recovery Boiler Superheater TubesDokumen27 halamanAvoiding Short Term Overheat Failures of Recovery Boiler Superheater TubesGuilherme AugustoBelum ada peringkat

- Safe Firing of Black Liquor (February 2012) PDFDokumen94 halamanSafe Firing of Black Liquor (February 2012) PDFGuilherme AugustoBelum ada peringkat

- Mechanicalsealforpumps 150921014002 Lva1 App6892Dokumen50 halamanMechanicalsealforpumps 150921014002 Lva1 App6892Buddy EkoBelum ada peringkat

- Zapex Type ZW: For Spare Part Drawing of Other ZAPEX Types Please Refer To The Operating Instruction For ZAPEXDokumen1 halamanZapex Type ZW: For Spare Part Drawing of Other ZAPEX Types Please Refer To The Operating Instruction For ZAPEXGuilherme AugustoBelum ada peringkat

- Installation and Maintenance Instructions Reverse Acting Rupture Disc AssembliesDokumen5 halamanInstallation and Maintenance Instructions Reverse Acting Rupture Disc AssembliesGuilherme AugustoBelum ada peringkat

- BE Seal Pack With MaxPack PDFDokumen2 halamanBE Seal Pack With MaxPack PDFGuilherme AugustoBelum ada peringkat

- Hydraulic Thrust DeviceDokumen2 halamanHydraulic Thrust DeviceGuilherme Augusto100% (1)

- Steam and Gas Turbines Laboratory TestsDokumen8 halamanSteam and Gas Turbines Laboratory TestsGuilherme AugustoBelum ada peringkat

- PDFDokumen8 halamanPDFGuilherme AugustoBelum ada peringkat

- Rotary Kiln PDFDokumen49 halamanRotary Kiln PDFVictor Maruli100% (1)

- 253 MA Flux-Cored Wire: Alloy Description and ApplicationDokumen1 halaman253 MA Flux-Cored Wire: Alloy Description and ApplicationGuilherme AugustoBelum ada peringkat

- Velocity Measurements of Particles in The Impeller of A Centrifugal Slurry PumpDokumen11 halamanVelocity Measurements of Particles in The Impeller of A Centrifugal Slurry PumpGuilherme AugustoBelum ada peringkat

- Process ControlDokumen6 halamanProcess ControlGuilherme AugustoBelum ada peringkat

- Product Data Sheet LT 80P: Siegling - Total Belting SolutionsDokumen2 halamanProduct Data Sheet LT 80P: Siegling - Total Belting SolutionsGuilherme AugustoBelum ada peringkat

- 192 eDokumen4 halaman192 eGuilherme AugustoBelum ada peringkat

- 216 0Dokumen12 halaman216 0Guilherme AugustoBelum ada peringkat

- 333 Extremultus-Compendium 02-2017 enDokumen108 halaman333 Extremultus-Compendium 02-2017 enGuilherme Augusto100% (1)

- Md-17 Shaft DesignDokumen7 halamanMd-17 Shaft DesignHenry OoiBelum ada peringkat

- Md-17 Shaft DesignDokumen7 halamanMd-17 Shaft DesignHenry OoiBelum ada peringkat

- Simulação 1Dokumen7 halamanSimulação 1Guilherme AugustoBelum ada peringkat

- Md-17 Shaft DesignDokumen7 halamanMd-17 Shaft DesignHenry OoiBelum ada peringkat

- Lab Final SolutionDokumen18 halamanLab Final SolutionZeeBelum ada peringkat

- Effect of Heater Geometry On The High Temperature Distribution On A MEMS Micro-HotplateDokumen6 halamanEffect of Heater Geometry On The High Temperature Distribution On A MEMS Micro-HotplateJorge GuerreroBelum ada peringkat

- Course Outline Principles of MarketingDokumen3 halamanCourse Outline Principles of MarketingKhate Tria De LeonBelum ada peringkat

- Frequency Polygons pdf3Dokumen7 halamanFrequency Polygons pdf3Nevine El shendidyBelum ada peringkat

- Soil Liquefaction Analysis of Banasree Residential Area, Dhaka Using NovoliqDokumen7 halamanSoil Liquefaction Analysis of Banasree Residential Area, Dhaka Using NovoliqPicasso DebnathBelum ada peringkat

- Feasibility and Optimization of Dissimilar Laser Welding ComponentsDokumen366 halamanFeasibility and Optimization of Dissimilar Laser Welding Componentskaliappan45490Belum ada peringkat

- Kazi Shafikull IslamDokumen3 halamanKazi Shafikull IslamKazi Shafikull IslamBelum ada peringkat

- Abstract Cohort 1 Clin Psych FZ 20220323Dokumen31 halamanAbstract Cohort 1 Clin Psych FZ 20220323Azizah OthmanBelum ada peringkat

- DC Motor: F Bli NewtonDokumen35 halamanDC Motor: F Bli NewtonMuhammad TausiqueBelum ada peringkat

- Machine Design REE 302: CH 1: Introduction To Mechanical Engineering DesignDokumen26 halamanMachine Design REE 302: CH 1: Introduction To Mechanical Engineering DesignDull PersonBelum ada peringkat

- Analysis and Design of Well FoundationDokumen40 halamanAnalysis and Design of Well Foundationdhanabal100% (1)

- ARCASIA Students Design Competition TORDokumen4 halamanARCASIA Students Design Competition TORDeena McgeeBelum ada peringkat

- EE 8602 - Protection and Switchgear Unit I - MCQ BankDokumen11 halamanEE 8602 - Protection and Switchgear Unit I - MCQ Bankpoonam yadavBelum ada peringkat

- Design Calculation FOR Rigid Pavement/RoadDokumen5 halamanDesign Calculation FOR Rigid Pavement/RoadghansaBelum ada peringkat

- Introduction To SCRDokumen19 halamanIntroduction To SCRAlbin RobinBelum ada peringkat

- 4.1 Hydrostatic Force On Curved Surfaces - CE 309-CE22S2 - Fluid MechanicsDokumen4 halaman4.1 Hydrostatic Force On Curved Surfaces - CE 309-CE22S2 - Fluid MechanicsRUSSELBelum ada peringkat

- Student Workbook: Advance 3Dokumen31 halamanStudent Workbook: Advance 3Damaris VegaBelum ada peringkat

- Report Painter GR55Dokumen17 halamanReport Painter GR55Islam EldeebBelum ada peringkat

- Native Instruments Sibelius Sound Sets - The Sound Set ProjectDokumen3 halamanNative Instruments Sibelius Sound Sets - The Sound Set ProjectNicolas P.Belum ada peringkat

- Creative LibrarianDokumen13 halamanCreative LibrarianulorBelum ada peringkat

- Aquinas Five Ways To Prove That God Exists - The ArgumentsDokumen2 halamanAquinas Five Ways To Prove That God Exists - The ArgumentsAbhinav AnandBelum ada peringkat

- Backward Forward PropogationDokumen19 halamanBackward Forward PropogationConrad WaluddeBelum ada peringkat

- Electronics 12 00811Dokumen11 halamanElectronics 12 00811Amber MishraBelum ada peringkat

- Assistant Bookkeeper Resume Sample - Best Format - Great Sample ResumeDokumen4 halamanAssistant Bookkeeper Resume Sample - Best Format - Great Sample ResumedrustagiBelum ada peringkat

- A. Premise Vs Conclusion NotesDokumen8 halamanA. Premise Vs Conclusion NotesEmma PreciousBelum ada peringkat

- Business Logic Module 1Dokumen5 halamanBusiness Logic Module 1Cassandra VenecarioBelum ada peringkat

- Research Paper On N Queen ProblemDokumen7 halamanResearch Paper On N Queen Problemxvrdskrif100% (1)

- ANSI AAMI ST63 2002 - Sterilization of Healthcare Products - Dry HeatDokumen54 halamanANSI AAMI ST63 2002 - Sterilization of Healthcare Products - Dry HeatGraciane TagliettiBelum ada peringkat

- SL 4001Dokumen2 halamanSL 4001ardiBelum ada peringkat

- Assignment 5 WarehousingDokumen4 halamanAssignment 5 WarehousingabbasBelum ada peringkat

- Power of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesDari EverandPower of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesPenilaian: 4.5 dari 5 bintang4.5/5 (21)

- Solar Power Demystified: The Beginners Guide To Solar Power, Energy Independence And Lower BillsDari EverandSolar Power Demystified: The Beginners Guide To Solar Power, Energy Independence And Lower BillsPenilaian: 4.5 dari 5 bintang4.5/5 (2)

- Nuclear Energy in the 21st Century: World Nuclear University PressDari EverandNuclear Energy in the 21st Century: World Nuclear University PressPenilaian: 4.5 dari 5 bintang4.5/5 (3)

- Introduction to Power System ProtectionDari EverandIntroduction to Power System ProtectionPenilaian: 5 dari 5 bintang5/5 (1)

- The Permaculture City: Regenerative Design for Urban, Suburban, and Town ResilienceDari EverandThe Permaculture City: Regenerative Design for Urban, Suburban, and Town ResilienceBelum ada peringkat

- Fire on the Horizon: The Untold Story of the Gulf Oil DisasterDari EverandFire on the Horizon: The Untold Story of the Gulf Oil DisasterBelum ada peringkat

- Shorting the Grid: The Hidden Fragility of Our Electric GridDari EverandShorting the Grid: The Hidden Fragility of Our Electric GridPenilaian: 4.5 dari 5 bintang4.5/5 (2)

- Practical Power Distribution for IndustryDari EverandPractical Power Distribution for IndustryPenilaian: 2.5 dari 5 bintang2.5/5 (2)

- Renewable Energy: A Very Short IntroductionDari EverandRenewable Energy: A Very Short IntroductionPenilaian: 4.5 dari 5 bintang4.5/5 (12)

- A Pathway to Decarbonise the Shipping Sector by 2050Dari EverandA Pathway to Decarbonise the Shipping Sector by 2050Belum ada peringkat

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialDari EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialBelum ada peringkat

- Heat Transfer Engineering: Fundamentals and TechniquesDari EverandHeat Transfer Engineering: Fundamentals and TechniquesPenilaian: 4 dari 5 bintang4/5 (1)

- Handbook on Battery Energy Storage SystemDari EverandHandbook on Battery Energy Storage SystemPenilaian: 4.5 dari 5 bintang4.5/5 (2)

- Photovoltaic Solar Energy: From Fundamentals to ApplicationsDari EverandPhotovoltaic Solar Energy: From Fundamentals to ApplicationsBelum ada peringkat

- Offshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsDari EverandOffshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsBelum ada peringkat

- Practical Reservoir Engineering and CharacterizationDari EverandPractical Reservoir Engineering and CharacterizationPenilaian: 4.5 dari 5 bintang4.5/5 (3)

- Live Off Grid: Escape The City, Learn How To Travel Intelligently Using Solar PowerDari EverandLive Off Grid: Escape The City, Learn How To Travel Intelligently Using Solar PowerBelum ada peringkat

- Fundamentals of Hydrogen Production and Utilization in Fuel Cell SystemsDari EverandFundamentals of Hydrogen Production and Utilization in Fuel Cell SystemsBelum ada peringkat

- Idaho Falls: The Untold Story of America's First Nuclear AccidentDari EverandIdaho Falls: The Untold Story of America's First Nuclear AccidentPenilaian: 4.5 dari 5 bintang4.5/5 (21)

- VSC-FACTS-HVDC: Analysis, Modelling and Simulation in Power GridsDari EverandVSC-FACTS-HVDC: Analysis, Modelling and Simulation in Power GridsBelum ada peringkat

- Electrical Load-Curve Coverage: Proceedings of the Symposium on Load-Curve Coverage in Future Electric Power Generating Systems, Organized by the Committee on Electric Power, United Nations Economic Commission for Europe, Rome, Italy, 24 – 28 October 1977Dari EverandElectrical Load-Curve Coverage: Proceedings of the Symposium on Load-Curve Coverage in Future Electric Power Generating Systems, Organized by the Committee on Electric Power, United Nations Economic Commission for Europe, Rome, Italy, 24 – 28 October 1977Belum ada peringkat

- An Introduction to Renewable Energy Sources : Environment Books for Kids | Children's Environment BooksDari EverandAn Introduction to Renewable Energy Sources : Environment Books for Kids | Children's Environment BooksBelum ada peringkat

- RV Living Collection: RV living for beginners, RV travel for the whole family, RV repair and RV mobile solar power: Experience Freedom on the roads alone or with your family with this collection. Learn how to repair your motorhome while using renewable energy!Dari EverandRV Living Collection: RV living for beginners, RV travel for the whole family, RV repair and RV mobile solar power: Experience Freedom on the roads alone or with your family with this collection. Learn how to repair your motorhome while using renewable energy!Belum ada peringkat

- Global Landscape of Renewable Energy FinanceDari EverandGlobal Landscape of Renewable Energy FinanceBelum ada peringkat

- Simulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetDari EverandSimulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetPenilaian: 2 dari 5 bintang2/5 (1)