Conditions and Instructions For Valves

Diunggah oleh

Mauricio Ariel H. OrellanaDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Conditions and Instructions For Valves

Diunggah oleh

Mauricio Ariel H. OrellanaHak Cipta:

Format Tersedia

CONDITIONS AND 4. AMBIENT TEMPERATURE RANGE 7.

CONTAMINATION LEVEL

The ambient temperature has a direct (FILTRATION)

INSTRUCTIONS FOR VALVES

effect on the used materials in the valve, Filtration and the associated particle size

e.g. their mech. strength. Generally, of contaminants in the hydraulic oil is

In general there are different conditions the maximum temperature depends the most important point in the operation

existing under which HYDAC valves primarily on the sealing materials. of a hydraulic system. Exceeding the

could be used in hydraulics. HYDAC defines here: specified particle size in the filtration

These conditions are depending on the zz NBR: from -30°C to +60°C classes 21/19/16 to 18/16/13 may cause

corresponding valve and described on (solenoid valves - 20°C) immediate failure of the parts in the

the depending datasheet in detail. hydraulic system when these particles

zz FPM: from -20°C to +80°C

These conditions are: are accumulated in critical areas.

(sometimes up to +100°C)

1. Pressure There are also deep temperature valves

2. Flow rate (TT), where the seals are specially 8. NOMINAL TENSION AND VOLTAGE

3. Type of hydraulic fluid designed for low temperatures. In solenoid valves coils are used

Other influences of temperature: which are designed to operate safely

4. Ambient temperature range

zz brittle fracture of steel at low in the voltage range of +/- 15% of

5. Media operating temperature range nominal voltage at max. 60 ° ambient

temperatures

6. Viscosity of the fluid temperature. The combination of steady

zz relaxation of springs made of spring surge and very hot temperatures can

7. Contamination level (filtration) of the steel at higher temperatures

operating fluid result in extreme cases to failure of the

zz fusing of coils at continous operation solenoid. Therefore always a good heat

8. Nominal current and voltage under high current and at high dissipation and voltage level has to be

(proportional and solenoid operated temperatures assured.

valves)

9. MTTFd values

5. MEDIA OPERATIONG 9. MTTFd VALUES

TEMPERATURE RANGE We confirm the usage of basically

1. PRESSURE

Like the ambient temperature the media and approved safety principals to

Each valve is designed for a certain temp. range has a direct effect on the ISO 13849‑2:2003; charts C.1 and C.2

maximum pressure at which it can be used materials in the valve, e.g. their for the design of our hydraulic valves.

operated without risk to the environment mech. strength. Generally, the maximum (Confirmation in each datasheet of the

and life. For this value, we assume the temperature depends primarily on the valve)

warranty, as we have demonstrated in sealing materials. HYDAC defines here: The customer is responsible for the

tests. It varies from valve to valve.

zz NBR: from -30°C to +100°C implementation and the operation of

(solenoid valves - 20°C) our valves due to th a.m. standard as

2. FLOW RATE zz FPM: from -20°C to +120°C well as the adherence of the operation

Each valve is designed for a certain (all other influences see point 4) conditions under „Specifications“ of each

maximum flow - due to its nominal size. datasheet.

At ths flow it is still reasonable to operate

6. VISCOSITY

the valve. An operation above this value

will boost the power dissipation. This HYDAC valves may be used generally

value also varies from valve to valve. only in specific viscosity ranges, as in

too thin or thick liquids, the assured

features can not be fulfilled. These

3. TYPE OF HYDRAULIC FLUID viscosities are also different for the

The type of operating fluid is closely different valves, but in average in the

linked to its viscosity. HYDAC can only range of 10 mm² /s to 420 mm²/ s.

recommend hydraulic fluids according to

DIN 51524 Part 1 and 2. For these fluids

the function of the valves is warranted.

E 53.000.0/10.14

75

Anda mungkin juga menyukai

- EN53000 Einsatzbedingungen Ventile PDFDokumen1 halamanEN53000 Einsatzbedingungen Ventile PDFPritesh KoratBelum ada peringkat

- Conditions and Instructions For ValvesDokumen1 halamanConditions and Instructions For ValveshelderfgmBelum ada peringkat

- EN53000 Einsatzbedingungen Ventile PDFDokumen1 halamanEN53000 Einsatzbedingungen Ventile PDFPritesh KoratBelum ada peringkat

- PRD Doc Pro 530001-00001 Sen Ain V2Dokumen1 halamanPRD Doc Pro 530001-00001 Sen Ain V2Mahesh NanayakkaraBelum ada peringkat

- NRZ28 DC FuseDokumen4 halamanNRZ28 DC FuseAndres LarachBelum ada peringkat

- General / Power TransmissionDokumen7 halamanGeneral / Power TransmissionJako MishyBelum ada peringkat

- Ansi C57.12&iec 76 PDFDokumen8 halamanAnsi C57.12&iec 76 PDFfreddy vargas100% (1)

- TES-P-119-39-R0-Transformer Overloading & Life SpanDokumen20 halamanTES-P-119-39-R0-Transformer Overloading & Life SpanZain-Ul- AbdeenBelum ada peringkat

- Diaphragm Accumulators: 1. DescriptionDokumen8 halamanDiaphragm Accumulators: 1. DescriptionFelipe Pisklevits LaubeBelum ada peringkat

- Reference Specification: 175 C Operation Leaded MLCC For Automotive With AEC-Q200 RHS SeriesDokumen17 halamanReference Specification: 175 C Operation Leaded MLCC For Automotive With AEC-Q200 RHS SeriesDanish Ur RahmanBelum ada peringkat

- Diaphragm Valve, Metal: ConstructionDokumen10 halamanDiaphragm Valve, Metal: ConstructionChemikal EngineerBelum ada peringkat

- Diaphragm Accumulators: 1. DescriptionDokumen8 halamanDiaphragm Accumulators: 1. DescriptionDAHMOUCHE Fatma ZohraBelum ada peringkat

- NGR Technical InformationDokumen6 halamanNGR Technical InformationPrabakar PBelum ada peringkat

- 9.1.13.5 Dry Type Transformer User ManualDokumen6 halaman9.1.13.5 Dry Type Transformer User ManualDindie GarvidaBelum ada peringkat

- LO 15PTB英文说明书Dokumen26 halamanLO 15PTB英文说明书Fernando Cesar MarachBelum ada peringkat

- Drift Calculation For Thin Film ResistorsDokumen3 halamanDrift Calculation For Thin Film ResistorsDamian Huitzil CedilloBelum ada peringkat

- Motor Protector Determination For Single Phase Hermetic CompressorsDokumen2 halamanMotor Protector Determination For Single Phase Hermetic CompressorsrayBelum ada peringkat

- Press SW IndfossDokumen2 halamanPress SW IndfossSting DâuBelum ada peringkat

- Capacitor Information (PT 2) PDFDokumen18 halamanCapacitor Information (PT 2) PDFwillchamBelum ada peringkat

- Murata MLCC RDE - C0G - 50V - 100VDokumen26 halamanMurata MLCC RDE - C0G - 50V - 100VTzouralas TheodorosBelum ada peringkat

- Jedec Standard No. 22-A110 Test Method A110 Highly-Accelerated Temperature and Humidity Stress Test (Hast) 1.0 PurposeDokumen5 halamanJedec Standard No. 22-A110 Test Method A110 Highly-Accelerated Temperature and Humidity Stress Test (Hast) 1.0 PurposeAylia RizviBelum ada peringkat

- Honeywell Px2Dokumen10 halamanHoneywell Px2UTOPIA TECHNOLOGYBelum ada peringkat

- Murata KH SpecDokumen20 halamanMurata KH SpecDino KaoBelum ada peringkat

- ASTM D2669-06 Apparent Viscosity of Petroleum Waxes Compounded PDFDokumen5 halamanASTM D2669-06 Apparent Viscosity of Petroleum Waxes Compounded PDFLluís FontBelum ada peringkat

- DPSPDFDokumen6 halamanDPSPDFNavneet SinghBelum ada peringkat

- Refrigeration and Air ConditioningDokumen4 halamanRefrigeration and Air ConditioningAleksandar Sasa SeferovicBelum ada peringkat

- Badotherm Diaphragm Seal Solution HTDSDokumen4 halamanBadotherm Diaphragm Seal Solution HTDSNathanBelum ada peringkat

- 2d - Guidance On Safe Use of TelehandlersDokumen5 halaman2d - Guidance On Safe Use of TelehandlersmohammudpBelum ada peringkat

- DE2E3SA472MN2AT01FDokumen24 halamanDE2E3SA472MN2AT01FDeepakBelum ada peringkat

- Oil-Filled Melt Pressure Transducers W3 Series: MV/V OutputDokumen4 halamanOil-Filled Melt Pressure Transducers W3 Series: MV/V OutputGopal HegdeBelum ada peringkat

- Akumulatori Sa DiafragmomDokumen6 halamanAkumulatori Sa Diafragmombhstudent_537083349Belum ada peringkat

- Number of Main Circuits Rated Diversity Factor To IEC / EN 61439-2 To IEC / EN 61439-3Dokumen6 halamanNumber of Main Circuits Rated Diversity Factor To IEC / EN 61439-2 To IEC / EN 61439-3Erick MoraBelum ada peringkat

- DB GB DS21Dokumen4 halamanDB GB DS21cadhoaBelum ada peringkat

- Olympus Thickness GagesDokumen8 halamanOlympus Thickness GagessukimeBelum ada peringkat

- Dry TRDokumen39 halamanDry TRahmed tareqBelum ada peringkat

- Cpe Xomox XLB Iom en A4 2016-11-30 WebDokumen10 halamanCpe Xomox XLB Iom en A4 2016-11-30 Webchida mohaBelum ada peringkat

- Hbe Montageanleitung Einschraubheizkoerper en 0715Dokumen2 halamanHbe Montageanleitung Einschraubheizkoerper en 0715words2zhigang_612545Belum ada peringkat

- Atvus PRVDokumen6 halamanAtvus PRVvipulpanchotiyaBelum ada peringkat

- Neutral Grounding ResistorDokumen4 halamanNeutral Grounding ResistorViswanathan VBelum ada peringkat

- Pressure Switches BrochureDokumen38 halamanPressure Switches BrochurearavindBelum ada peringkat

- Slide 1 - There Are Many Different Types of Circuit Breakers and Many Different System Conditions Where They May Be AppliedDokumen7 halamanSlide 1 - There Are Many Different Types of Circuit Breakers and Many Different System Conditions Where They May Be AppliedHüseyin AkdoğanBelum ada peringkat

- Elec Fuse Temp DeratingDokumen1 halamanElec Fuse Temp DeratingVaibhav ChouguleBelum ada peringkat

- Pressure Switch CatalogueDokumen0 halamanPressure Switch CatalogueMilosglBelum ada peringkat

- Winding and InsulationDokumen6 halamanWinding and InsulationRatilal M JadavBelum ada peringkat

- 3/2-Way Solenoid Valve, Direct-Acting: Type 743Dokumen4 halaman3/2-Way Solenoid Valve, Direct-Acting: Type 743Francisco Mones RuizBelum ada peringkat

- High Temperature Ultrasonic TestingDokumen3 halamanHigh Temperature Ultrasonic TestingCarlos Bustamante100% (1)

- Manual RTD Thermocouple General ImDokumen2 halamanManual RTD Thermocouple General ImAdhitya ReBelum ada peringkat

- Section 5 T: RansformersDokumen2 halamanSection 5 T: RansformersJon LopezBelum ada peringkat

- 28 - Ficha Tecnica ElectrovalvulaDokumen12 halaman28 - Ficha Tecnica ElectrovalvulaStephany Rueda YnocheaBelum ada peringkat

- Additional Pressure and Temperature Switch Application InformationDokumen2 halamanAdditional Pressure and Temperature Switch Application InformationJean GonzalezBelum ada peringkat

- Techrite Fenwal Fenwal 17000 & 18000 Series Thermoswitch Temperature Controllers 2013050684Dokumen8 halamanTechrite Fenwal Fenwal 17000 & 18000 Series Thermoswitch Temperature Controllers 2013050684jesusBelum ada peringkat

- LoadingGuideComparison IEEE IEC R1Dokumen22 halamanLoadingGuideComparison IEEE IEC R1Ali AhmedBelum ada peringkat

- Integrated Safety Detector Comem RIS2: Bunch of Accessories in One Single DeviceDokumen2 halamanIntegrated Safety Detector Comem RIS2: Bunch of Accessories in One Single Devicebellato rangerBelum ada peringkat

- Dsorption Efrigeration: Ahmed Rezk, Ahmed Elsayed, Saad Mahmoud, and Raya AL-DadahDokumen59 halamanDsorption Efrigeration: Ahmed Rezk, Ahmed Elsayed, Saad Mahmoud, and Raya AL-DadahTechnoKittyKittyBelum ada peringkat

- Hard Natural Rubber: Technical Data SheetDokumen2 halamanHard Natural Rubber: Technical Data SheetBruno MiguelBelum ada peringkat

- E3302 0 02 05 - SK HochdruckDokumen3 halamanE3302 0 02 05 - SK Hochdruckcesar_aros_provosteBelum ada peringkat

- Control Panel Section - 10426-2000!13!17Dokumen17 halamanControl Panel Section - 10426-2000!13!17hhBelum ada peringkat

- 137 Amot 8253 Product Document - AshxDokumen4 halaman137 Amot 8253 Product Document - AshxEliecer DiazBelum ada peringkat

- Top Gun CUT-40MDokumen9 halamanTop Gun CUT-40MTom PleysierBelum ada peringkat

- Influence of System Parameters Using Fuse Protection of Regenerative DC DrivesDari EverandInfluence of System Parameters Using Fuse Protection of Regenerative DC DrivesBelum ada peringkat

- Hedland Catalog 2015 FebDokumen80 halamanHedland Catalog 2015 FebMauricio Ariel H. OrellanaBelum ada peringkat

- MN 022311FTRDokumen6 halamanMN 022311FTRMauricio Ariel H. OrellanaBelum ada peringkat

- Presostato de PresionDokumen4 halamanPresostato de PresionMauricio Ariel H. OrellanaBelum ada peringkat

- Hedland Petroleum Flowmeter DatasheetDokumen8 halamanHedland Petroleum Flowmeter DatasheetMauricio Ariel H. OrellanaBelum ada peringkat

- Conectores TuberiasDokumen98 halamanConectores TuberiasMauricio Ariel H. OrellanaBelum ada peringkat

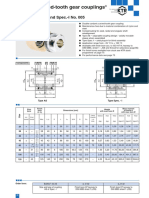

- Bowex Curved-Tooth Gear Couplings: Type As No. 004 and Spec.-I No. 005Dokumen1 halamanBowex Curved-Tooth Gear Couplings: Type As No. 004 and Spec.-I No. 005Mauricio Ariel H. OrellanaBelum ada peringkat

- T100 VDokumen2 halamanT100 VMauricio Ariel H. OrellanaBelum ada peringkat

- Installation and Operating Manual: Air OnlyDokumen11 halamanInstallation and Operating Manual: Air OnlyMauricio Ariel H. OrellanaBelum ada peringkat

- Installation and Operating Manual: Engine Air StartersDokumen17 halamanInstallation and Operating Manual: Engine Air StartersMauricio Ariel H. OrellanaBelum ada peringkat

- Installation and Operating Manual: From Tech Development IncDokumen6 halamanInstallation and Operating Manual: From Tech Development IncMauricio Ariel H. OrellanaBelum ada peringkat

- Prince Valves PDFDokumen82 halamanPrince Valves PDFMauricio Ariel H. OrellanaBelum ada peringkat

- Installation and Operating Manual: Publication T1-728 Dated: April 15, 2002Dokumen10 halamanInstallation and Operating Manual: Publication T1-728 Dated: April 15, 2002Mauricio Ariel H. OrellanaBelum ada peringkat

- Installation and Operating Manual: Publication T30-706, Rev. 1 Dated: May 9, 2001Dokumen10 halamanInstallation and Operating Manual: Publication T30-706, Rev. 1 Dated: May 9, 2001Mauricio Ariel H. OrellanaBelum ada peringkat

- Tas 85 Manual 1Dokumen4 halamanTas 85 Manual 1Mauricio Ariel H. OrellanaBelum ada peringkat

- Service Procedure #THP-100: Commercial Steering SystemsDokumen2 halamanService Procedure #THP-100: Commercial Steering SystemsMauricio Ariel H. OrellanaBelum ada peringkat

- Directional Control Valves: Log Splitter Control ValveDokumen4 halamanDirectional Control Valves: Log Splitter Control ValveMauricio Ariel H. OrellanaBelum ada peringkat

- Ficha MartilloDokumen5 halamanFicha MartilloMauricio Ariel H. OrellanaBelum ada peringkat

- Mounting Subplates BA: Single and ModularDokumen3 halamanMounting Subplates BA: Single and ModularMauricio Ariel H. OrellanaBelum ada peringkat

- RDH Hy08-M1320-1 Na PDFDokumen64 halamanRDH Hy08-M1320-1 Na PDFMauricio Ariel H. OrellanaBelum ada peringkat

- HyvaDokumen4 halamanHyvaMauricio Ariel H. OrellanaBelum ada peringkat

- Session 2 - 01 (Energy Efficiency Potential Assessment of Chandrapura TPS, DVC)Dokumen52 halamanSession 2 - 01 (Energy Efficiency Potential Assessment of Chandrapura TPS, DVC)pkumarBelum ada peringkat

- Ems Accounting Term 2Dokumen39 halamanEms Accounting Term 2Paballo KoopediBelum ada peringkat

- Natural GeotextilesDokumen27 halamanNatural GeotextilesDr Muhammad Mushtaq Mangat100% (1)

- Part 04 - Plumbing, Mechanical & Firefighting SpecificationsDokumen210 halamanPart 04 - Plumbing, Mechanical & Firefighting Specificationsvtalex100% (1)

- Suplayer Metal Working Sipil and Fabrication: Company ProfileDokumen10 halamanSuplayer Metal Working Sipil and Fabrication: Company ProfileRuntian TeaBelum ada peringkat

- Cost Estimate, RevisedDokumen6 halamanCost Estimate, RevisedUdit AmatBelum ada peringkat

- Leadership Assesment ToolDokumen5 halamanLeadership Assesment ToolJayeeta DebnathBelum ada peringkat

- Project On Brand Awareness of ICICI Prudential by SajadDokumen99 halamanProject On Brand Awareness of ICICI Prudential by SajadSajadul Ashraf71% (7)

- Technical Writing PDFDokumen129 halamanTechnical Writing PDFKundan Kumar100% (1)

- 3 CBLSF 50 HDokumen6 halaman3 CBLSF 50 HNaz LunBelum ada peringkat

- 3rd Term s1 Agricultural Science 1Dokumen41 halaman3rd Term s1 Agricultural Science 1Adelowo DanielBelum ada peringkat

- Ten Rules of NetiquetteDokumen11 halamanTen Rules of NetiquetteAriel CancinoBelum ada peringkat

- Peir Nts Section 8 BeDokumen14 halamanPeir Nts Section 8 BethamestunnelBelum ada peringkat

- SQA Plan TemplateDokumen105 halamanSQA Plan Templatestudent1291Belum ada peringkat

- St10 Flasher DLL: Stmicroelectronics ConfidentialDokumen10 halamanSt10 Flasher DLL: Stmicroelectronics Confidentialeshwarp sysargusBelum ada peringkat

- Crude Palm OilDokumen4 halamanCrude Palm OilpalmoilanalyticsBelum ada peringkat

- Adaptation Fom Squirrels GamesDokumen2 halamanAdaptation Fom Squirrels GamesDenny Boy MochranBelum ada peringkat

- Piping Tie in Procedure Rev A PDFDokumen15 halamanPiping Tie in Procedure Rev A PDFMohammed Sibghatulla100% (1)

- Dahua Video Conferencing SolutionDokumen16 halamanDahua Video Conferencing SolutionDennis DubeBelum ada peringkat

- Midterm Fin Oo4Dokumen82 halamanMidterm Fin Oo4patricia gunio100% (1)

- Pecson Vs CADokumen3 halamanPecson Vs CASophiaFrancescaEspinosaBelum ada peringkat

- Namma Kalvi 12th Maths Chapter 4 Study Material em 213434Dokumen17 halamanNamma Kalvi 12th Maths Chapter 4 Study Material em 213434TSG gaming 12Belum ada peringkat

- Management of HondaDokumen8 halamanManagement of HondafarhansufiyanBelum ada peringkat

- A Study On Impact of Acne Vulgaris On Quality of LifeDokumen7 halamanA Study On Impact of Acne Vulgaris On Quality of LifeIJAR JOURNALBelum ada peringkat

- Exp.1 (Screening) Group1Dokumen16 halamanExp.1 (Screening) Group1itokki otoyaBelum ada peringkat

- PCIB Vs Escolin DigestDokumen3 halamanPCIB Vs Escolin DigestsamontedianneBelum ada peringkat

- Remedies FlowDokumen44 halamanRemedies Flowzeebeelo100% (1)

- 2.how To Boost Your Coating SalesDokumen23 halaman2.how To Boost Your Coating SalesAjaz Noor KhattakBelum ada peringkat

- Picasso OperatingInstructions Manual 211018 WEBDokumen27 halamanPicasso OperatingInstructions Manual 211018 WEBBill McFarlandBelum ada peringkat

- Conext Battery Monitor Quick Start Guide 975 0690-03-01 Rev B SPA1Dokumen2 halamanConext Battery Monitor Quick Start Guide 975 0690-03-01 Rev B SPA1xray123zzzBelum ada peringkat