SP0405R01 Underground Cable JSA

Diunggah oleh

karlHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

SP0405R01 Underground Cable JSA

Diunggah oleh

karlHak Cipta:

Format Tersedia

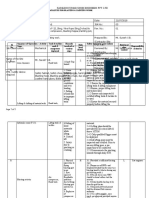

FIELD TEST LV UNDERGROUND CABLE INSTALLATIONS

JOB SAFETY ANALYSIS

Title: Field Test LV Underground Cable Installations

Purpose and Scope: To provide instruction on the field testing of low voltage underground cable installations

Staffing Resources: Cable Jointer or Electrical Mechanic instructed and competent in LV cable testing techniques. Work crew instructed and competent in LV

switchboard rescue and resuscitation techniques, polarity testing, pole top rescue, manual handling. Safety Observer where required..

Documentation/References:

P53 Operate the Network Enterprise Process. P53K55 Manage Low Voltage Switching for De-Energised Access on the Network Procedure. Certificate of Test –

Low Voltage Cable Continuity, Insulation Resistances and Phasing Form. Ergon Energy Underground Construction Manual. Work Health and Safety Regulations

2011 (QLD). Electrical Safety Regulation Section 12, 14(2). Electrical Safety Code of Practice for Electrical Work. Electrical Safety Code of Practice for Working

Near Live Parts. CS000501F115 Daily/Task Risk Management Plan.

Key Tools and Equipment:

Roadway warning signs, barricading. Insulating gloves applicable to task, work gloves, safety headwear where gravitational hazards exist, safety eyewear and

footwear, high visibility clothing, protective clothing, hearing protection, sun protection. Confined space monitoring and rescue equipment (where required). Work

site communication equipment (e.g. 2 way radio, etc), pole top rescue kit, LV Rescue kit. Test equipment shall comply with Code of Practice for Electrical Work

Section 6 and be fitted with fused leads (where applicable). 1.0kV DC insulation resistance tester.

Development Team: Graham Smith, Ken Feltham, Marshall Jones, Don Date Completed: 20 May 2003

McCormack, Keith Weisse, Stuart Traill

Reviewed By: Megan Moncrieff Date Completed: 18 March 2008

Related SWP No.: SP0405 SWP Owner Approval:

Key Stakeholders: Executive Management Team, Senior Management Team, Area Managers, Project Managers, Supervisors, Field Staff. Network Line Standards

Group, Fleet Management

Check this is the latest Process Zone version before use Page 1 of 9 Job Safety Analysis SP0405R01 Ver 4

Ergon Energy Corporation Limited ABN 50 087 646 062

Ergon Energy Queensland Pty Ltd ABN 11 121 177 802

FIELD TEST LV UNDERGROUND CABLE INSTALLATIONS

JOB SAFETY ANALYSIS

Risk Score

Task Most Likely Breakdown Event (Loss Of Most Likely Outcome (Incident Additional/

Task Step Hazard Existing

No. Control) Outcome) Alternate

Controls

Controls

1 Preliminary Step Vehicular and pedestrian Test equipment out of test Plant damage L

Selection of all required test traffic date, out of calibration or Faulty equipment or

equipment for performing Uneven ground surface unserviceable inaccurate readings

earthing resistance, continuity Test equipment operated Sprains, strain

and insulation resistance, incorrectly

voltage, phase rotation and Insufficient staffing resources

polarity tests. assigned to safely complete

Confirm test equipment in test tests

and operational prior to and Encroachment of traffic into

after use work zone

Assessment of staff numbers Trip or slip on uneven ground

required

Confirm licensing and

competency

Ensure ready on site access

to dry chemical fire

extinguisher where a gas

torch is used.

2 Confirm isolation prior to test Proximity to exposed live Contact with or movement Plant damage L L

Check phase rotation where terminals within proximity to energised Flash burns, electric

required Energised cable in work terminals shock

Confirm LV fuse carriers open area Incorrect isolation performed Sprains, strain,

& fuse cartridges removed Energisation from including from secondary musculoskeletal

(where applicable). secondary source of sources of supply injuries, lacerations

Confirm LV cables to be supply Failure to implement fall Loss of supply

tested are de-energised. Live unterminated cable arrest and restraint systems Fall from height

Place DNOB on all LV ends when working at heights Falling objects

isolation points and locked Step and touch potential Working in drop zone

where provision is made. Working at height Encroachment of traffic into

Vehicular and pedestrian work zone

traffic Inaccurate or absent cable

Uneven ground surface identification labelling

Failure to wear all required

Check this is the latest Process Zone version before use Page 2 of 9 Job Safety Analysis SP0405R01 Ver 4

Ergon Energy Corporation Limited ABN 50 087 646 062

Ergon Energy Queensland Pty Ltd ABN 11 121 177 802

FIELD TEST LV UNDERGROUND CABLE INSTALLATIONS

JOB SAFETY ANALYSIS

Risk Score

Task Most Likely Breakdown Event (Loss Of Most Likely Outcome (Incident Additional/

Task Step Hazard Existing

No. Control) Outcome) Alternate

Controls

Controls

PPE including class 00 gloves

Short circuit initiated between

different sources of potential

using test equipment

Failure to ensure all members

of working party sign on LV

Isolation Section of Daily/Task

Risk Management Plan.

3 Prove Mechanical and Proximity to exposed live Failure to confirm phasing Sprains, strain, L L

Electrical Integrity of LV Cable terminals Short circuit initiated between musculoskeletal

Installations Energised cable in work different sources of potential injuries

Confirm by sample (at area using test equipment Plant damage

intervals no greater than 6 Energisation from Failure to control access to Flashover, electric

pillars apart) that cable secondary source of work zone shock, burns

terminations at pillars and supply Incorrect isolation performed Explosion

poles are tight and phase Live unterminated cable including from secondary Falling objects

colours correct. ends sources of supply Fall from heights

Disconnect all Multiple Earth Working at height Contact with or movement Loss of supply

Neutral connections of cable Falling objects within proximity to energised

section under test. Vehicular and pedestrian terminals

Remove street light fuses and traffic Failure to implement fall

disconnect neutrals at street Uneven ground surface arrest and restraint systems

light poles. High fault level when working at heights

Conduct earth tests and Encroachment of public Working in drop zone

record results into work zone Failure to wear all required

Perform continuity test PPE including class 00 gloves

between each phase and Failure to confirm LV system

neutral conductor neutral correct

combinations with a bridge Failure to reinstate neutral

connected between conductors after polarity tests

applicable conductors at Failure to remove street light

cable end and confirm similar fuses and disconnect neutrals

resistance values between at street light poles.

tests (e.g. A-B, B-C, A-C, -

N).

Check this is the latest Process Zone version before use Page 3 of 9 Job Safety Analysis SP0405R01 Ver 4

Ergon Energy Corporation Limited ABN 50 087 646 062

Ergon Energy Queensland Pty Ltd ABN 11 121 177 802

FIELD TEST LV UNDERGROUND CABLE INSTALLATIONS

JOB SAFETY ANALYSIS

Risk Score

Task Most Likely Breakdown Event (Loss Of Most Likely Outcome (Incident Additional/

Task Step Hazard Existing

No. Control) Outcome) Alternate

Controls

Controls

Perform insulation resistance

test between each phase and

neutral conductors to earth

and record insulation

resistance reading.

4 Energise Cable and Confirm Proximity to exposed live Failure to confirm phasing Sprains, strain, L

Polarity terminals Short circuit initiated between musculoskeletal

Remove DNOB from LV cable Energised cable in work different sources of potential injuries

isolation point area using test equipment Plant damage

Replace fuse cartridges and Energisation from Encroachment of public into Flashover, electric

close. secondary source of work zone shock, burns

At last pillar of each circuit supply Incorrect isolation performed Explosion

and at sample locations (at Live unterminated cable including from secondary Falling objects

intervals no greater than 6 ends sources of supply Fall from heights

pillars apart): Working at height Contact with or movement Loss of supply

Check polarity and record Falling objects within proximity to energised

(Phase to phase, phase Vehicular and pedestrian terminals

to neutral, phase to traffic Failure to implement fall

independent earth) Uneven ground surface arrest and restraint systems

Check phase rotation. High fault level when working at heights

Phase out to other supply Working in drop zone

across existing LV open point Failure to wear all required

(where applicable) PPE including class 00 gloves

Conduct polarity test at street Failure to confirm LV system

lights and reconnect neutral correct

streetlight neutrals Failure to reinstate neutral

Reconnect all Multiple Earth conductors after polarity tests

Neutral connections of cable

section under test.

5 Final checks Proximity to exposed live Contact with or movement Flashover, electric L

terminals within proximity to energised shock, burns

Energised cable in work terminals Explosion

Check this is the latest Process Zone version before use Page 4 of 9 Job Safety Analysis SP0405R01 Ver 4

Ergon Energy Corporation Limited ABN 50 087 646 062

Ergon Energy Queensland Pty Ltd ABN 11 121 177 802

FIELD TEST LV UNDERGROUND CABLE INSTALLATIONS

JOB SAFETY ANALYSIS

Risk Score

Task Most Likely Breakdown Event (Loss Of Most Likely Outcome (Incident Additional/

Task Step Hazard Existing

No. Control) Outcome) Alternate

Controls

Controls

area Failure to confirm LV system Loss of supply

Live unterminated cable neutral correct Plant damage

ends Failure to reinstate neutral

High fault level conductors after polarity tests

Check this is the latest Process Zone version before use Page 5 of 9 Job Safety Analysis SP0405R01 Ver 4

Ergon Energy Corporation Limited ABN 50 087 646 062

Ergon Energy Queensland Pty Ltd ABN 11 121 177 802

FIELD TEST LV UNDERGROUND CABLE INSTALLATIONS

JOB SAFETY ANALYSIS

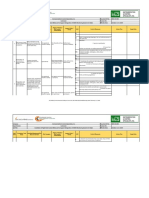

Existing Control Measures

Risk Ranking

Personal C = Consequences E = Exposure P =

Task Elimination Substitution Engineering Administration Protective Probability

No. Equipment C E P Risk

Score

1 As constructed drawing supplied to work 1 3 5 L

crew along with construction folder.

Confirm all test equipment within current

test date, calibration and operational.

Ensure all persons required to use test

equipment are competent in its operation.

Assign adequate staffing resources with

required competencies to safely complete

tests.

Use roadway warning signs/ barricading to

control vehicle and pedestrian traffic around

work zone and relevant exclusion zones

around live parts.

Ground conditions and potential slip/fall

hazards in travel path considered in

Daily/Task Risk Management plan.

Reinforce requirement to wear all required

PPE including applicable class of gloves.

Identify locations defined as confined

spaces and ensure compliance with

confined space entry requirements.

2 Reinforce requirement to wear all required 2 3 4 L

PPE including applicable class of gloves.

Ensure class 00 gloves, and insulated mats

are used while working on or near exposed

live parts.

Isolate LV cable to be tested from all

sources of supply and tagged, and locked

where provision is made, in accordance with

LV isolation requirements.

Ensure all members of working party sign

on and understand requirements of LV

Check this is the latest Process Zone version before use Page 6 of 9 Job Safety Analysis SP0405R01 Ver 4

Ergon Energy Corporation Limited ABN 50 087 646 062

Ergon Energy Queensland Pty Ltd ABN 11 121 177 802

FIELD TEST LV UNDERGROUND CABLE INSTALLATIONS

JOB SAFETY ANALYSIS

Risk Ranking

Personal C = Consequences E = Exposure P =

Task Elimination Substitution Engineering Administration Protective Probability

No. Equipment C E P Risk

Score

Isolation Section of Daily/Task Risk

Management Plan.

Comply with Work Health and Safety

Regulations 2011 (QLD), “Falling Objects”,

“Falls”.

Ensure ground based persons are clear of

drop zone while work is performed aloft.

3 Position Safety Observer where testing is 2 3 4 L

performed in vicinity of exposed live parts.

Test to confirm LV system neutral correct at

last pillar of each LV cable run, MEN

locations and at sample locations.

Confirm street light fuses removed and

neutrals at street light poles disconnected.

Confirm phasing to other LV system at all

open points.

4 Confirm all neutral and MEN conductors are 1 3 4 L

reinstated after polarity tests.

5 Ensure all final tests have been carried out 2 3 4 L

and completed works have been built to the

design plan &/ construction standards.

Check that the cabinet / padmount is locked,

or the pillar lid is replaced and securely

bolted down, where work has been carried

in these areas.

Make the site electrically and mechanically

safe and tidy the area before leaving.

Check this is the latest Process Zone version before use Page 7 of 9 Job Safety Analysis SP0405R01 Ver 4

Ergon Energy Corporation Limited ABN 50 087 646 062

Ergon Energy Queensland Pty Ltd ABN 11 121 177 802

FIELD TEST LV UNDERGROUND CABLE INSTALLATIONS

JOB SAFETY ANALYSIS

Additional/Alternative Control Measures

Risk Ranking

Personal C = Consequences E = Exposure P =

Task Elimination Substitution Engineering Administration Protective Probability

No. Equipment C E P Risk

Score

2 Ensure insulated tools are used while 2 3 4 L

working on or near exposed energised

terminals.

Ensure test equipment suitable for task.

Live work on LV including testing is only to

be performed where a documented safe

system of work is implemented.

Persons performing electrical testing must

ensure electrical equipment is tested to

confirm electrical work performed is

electrically safe and all persons not

necessary for testing are electrically safe.

3 Perform continuity test between each phase 2 3 4 L

and neutral conductor combinations with a

bridge connected between applicable

conductors at cable end and confirm similar

resistance values between tests (e.g. A-B,

B-C, A-C, -N) – a maximum variation of

10% between readings.

Apply 1.0kV phase to neutral insulation

resistance test on all LV cables until a

steady value is achieved (minimum

allowable resistance on new cables is

100M, minimum allowable resistance prior

to energisation of aged cables is 1M) and

record readings.

Check this is the latest Process Zone version before use Page 8 of 9 Job Safety Analysis SP0405R01 Ver 4

Ergon Energy Corporation Limited ABN 50 087 646 062

Ergon Energy Queensland Pty Ltd ABN 11 121 177 802

FIELD TEST LV UNDERGROUND CABLE INSTALLATIONS

JOB SAFETY ANALYSIS

1: DETERMINE CONSEQUENCE: - The most likely outcome of a potential incident resulting from 4: RISK ASSESSMENT MATRIX

exposure to the identified hazard.

Probability x Exposure

Level Descriptor Definition

5 Disaster Fatality; toxic release off-site with detrimental effect; financial loss (>$1,000,000). 1 to 2 3 to 5 6 to 10 11 to 23 24 to 36

Extensive injuries (e.g. permanent disability, amputation) requiring medical treatment, hospitalisation

4 Very Serious and long term rehabilitation; off-site release with no detrimental effects loss of production capability; Likelihood (How often?)

financial loss ($500,000 to $1,000,000).

Almost Quite

Disabling injuries requiring medical treatment and rehabilitation (e.g. broken limbs, hospitalisation); on- Unlikely but Extremely

3 Serious Consequences certain will possible Possible

site release contained with outside assistance; financial loss ($50,000 to $500,000). possible unlikely

(How Bad?) occur could occur

Medical treatment required (e.g. stitches, removal of foreign body); on-site release immediately

2 Substantial

contained; financial loss ($5,000 to $50,000). 5. Disaster Extreme Extreme Extreme High Moderate

1 Minor First aid treatment; negligible environmental damage; financial loss (<$5,000).

4. Very Serious Extreme Extreme High Moderate Low

2: DETERMINE EXPOSURE: - How often a person interacts with a hazard.

Level Descriptor Definition 3. Serious Extreme High High Moderate Low

1 Continuous Many times a day.

2 Frequent Daily. 2. Substantial High Moderate Moderate Low Low

3 Occasional Weekly.

1. Minor High Moderate Low Low Low

4 Infrequent Between weekly and monthly.

5 Rare Between monthly and yearly.

5: RISK TREATMENT STRATEGY

6 Very Rare Less than once a year.

Risk Score Required Actions

3: DETERMINE PROBABILITY

The likelihood of the breakdown event and nominated consequences occurring once the person is Low Implement control measures and verify compliance by routine monitoring.

exposed to the hazard.

Level Descriptor Definition Moderate Action required within agreed timeframe to minimise risk to “As Low As Reasonably

Practicable” (ALARP). Further action may be required and management responsibility

1 Almost Certain Breakdown event will almost certainly occur from exposure to hazard. specified to take this action. The ALARP principle implies that controls have been

determined such that the level of risk-reducing action is in proportion to the benefit

2 Quite Possible Not unusual for breakdown event occurring, even 50/50 chance. obtained.

Unusual but Action as soon as possible to minimise risk to acceptable level. Requires attention by

3 Unusual for breakdown event to occur but possible. High

Possible senior management and measures should be put in place to reduce the probability,

Remotely exposure and/or consequence of the outcome occurring to ALARP.

4 Remote possibility of breakdown event occurring but history of occurrence exists within industry.

Possible

Extreme Same treatment as for high risks however immediate action required to minimise risk to

Conceivable but acceptable level.

5 No known history of breakdown event occurring after years of exposure but is conceivably possible.

Unlikely

(Adapted from AS/NZS 4360:1999 Risk Management and NSCA Risk Score Calculator, 2001)

Practically Practically impossible for breakdown event to occur. Has never occurred before and is not likely to

6

Impossible occur.

Check this is the latest Process Zone version before use Page 9 of 9 Job Safety Analysis SP0405R01 Ver 4

Ergon Energy Corporation Limited ABN 50 087 646 062

Ergon Energy Queensland Pty Ltd ABN 11 121 177 802

Anda mungkin juga menyukai

- Risk Assesment Installation Testing For Fire Fighting Piping System and AccessoriesDokumen8 halamanRisk Assesment Installation Testing For Fire Fighting Piping System and AccessoriesGopinath SekarBelum ada peringkat

- Jsa - Cable Termination: Job Step No. Step Description Hazards Control Measure(s) Responsible PersonDokumen7 halamanJsa - Cable Termination: Job Step No. Step Description Hazards Control Measure(s) Responsible PersonMon Trang NguyễnBelum ada peringkat

- JSA Formet New Blasting & PaintingDokumen5 halamanJSA Formet New Blasting & Paintingsakthi venkatBelum ada peringkat

- JSA Fitting and Welding Work For Pipe Trench InstalationDokumen6 halamanJSA Fitting and Welding Work For Pipe Trench InstalationVishnu VijayanBelum ada peringkat

- Job Safety Analysis Sheet: KOC Emergency-160 90030980 (PIL)Dokumen3 halamanJob Safety Analysis Sheet: KOC Emergency-160 90030980 (PIL)Sreeraj Reghunathan Nair VanmazhyBelum ada peringkat

- 002 11KV Switchgear JHA Work SheetDokumen4 halaman002 11KV Switchgear JHA Work SheetWaseem Ahmad100% (1)

- Employee Remote Work Policy TemplateDokumen3 halamanEmployee Remote Work Policy Templatekarl100% (1)

- GN12 WTIA Comparison of Welding Inspector Qualifications and CertificationsDokumen4 halamanGN12 WTIA Comparison of Welding Inspector Qualifications and Certificationskarl0% (1)

- Checklist & Guideline ISO 22000Dokumen14 halamanChecklist & Guideline ISO 22000Documentos Tecnicos75% (4)

- RSA - Brand - Guidelines - 2019 2Dokumen79 halamanRSA - Brand - Guidelines - 2019 2Gigi's DelightBelum ada peringkat

- Job Safety Analysis (JSA) : Electronics (Cleaning + Servicing)Dokumen2 halamanJob Safety Analysis (JSA) : Electronics (Cleaning + Servicing)Nishad MuhammedBelum ada peringkat

- Jsa D. G. INSTALLATIONDokumen5 halamanJsa D. G. INSTALLATIONRavi thokalBelum ada peringkat

- JSA - For Trays ErectionDokumen1 halamanJSA - For Trays ErectionAvinash RaiBelum ada peringkat

- SRB-02-2011 - (Welding of Pipes) For Thrust BoringDokumen4 halamanSRB-02-2011 - (Welding of Pipes) For Thrust BoringkkalviBelum ada peringkat

- Al-Khafji Joint Operation (Kjo) Upgrade of Kjo'S Public Address and General Alarm System Contract# Gt629It19Dokumen7 halamanAl-Khafji Joint Operation (Kjo) Upgrade of Kjo'S Public Address and General Alarm System Contract# Gt629It19Numan SaleemBelum ada peringkat

- Risk Assessment On Demolition Work - CompressDokumen8 halamanRisk Assessment On Demolition Work - CompressAbegail Manuel GatusBelum ada peringkat

- RA For Installation of Earthing & Bonding SystemDokumen10 halamanRA For Installation of Earthing & Bonding SystemProjects INTSBelum ada peringkat

- WMS For Fire Fighting Line and SupportsDokumen4 halamanWMS For Fire Fighting Line and SupportsAbdul Rehman Sheikh100% (1)

- Safety Campaign-Working at Height Final (May-2022)Dokumen6 halamanSafety Campaign-Working at Height Final (May-2022)HSE99 BHDC100% (1)

- Job Hazard Analysis: Format For JHA WorksheetDokumen3 halamanJob Hazard Analysis: Format For JHA WorksheetWaseem AhmadBelum ada peringkat

- Rock Breaker Self ChecklistDokumen1 halamanRock Breaker Self ChecklistNair R RakeshBelum ada peringkat

- Jha - de Spading Activities For N2 PurgingDokumen4 halamanJha - de Spading Activities For N2 PurgingNasrullah100% (1)

- JSA Format Erection of Column 903-C-02,03Dokumen5 halamanJSA Format Erection of Column 903-C-02,03sakthi venkat100% (1)

- 2640.011SWP - Excavations and TrenchesDokumen7 halaman2640.011SWP - Excavations and TrenchesHasanuddin HAMIDBelum ada peringkat

- Aj Infratech: Job Hazard AnalysisDokumen5 halamanAj Infratech: Job Hazard AnalysisDwitikrushna RoutBelum ada peringkat

- The University of Faisalabad: Commercial Electrical Inspection Checklists (2008 Nec)Dokumen1 halamanThe University of Faisalabad: Commercial Electrical Inspection Checklists (2008 Nec)Rao UmarBelum ada peringkat

- JSA Erection StructureDokumen11 halamanJSA Erection StructureJAYESH JOSHIBelum ada peringkat

- One Direct Method Statement: Preventative MeasuresDokumen4 halamanOne Direct Method Statement: Preventative MeasuresAyu Wanda SaraswatiBelum ada peringkat

- Jsa Bearing Replacement-OverhaulingDokumen2 halamanJsa Bearing Replacement-Overhaulingashish engineeringBelum ada peringkat

- Accident Investigation FormDokumen8 halamanAccident Investigation FormagusnurcahyoBelum ada peringkat

- 011 Duct Lifter SWMSDokumen2 halaman011 Duct Lifter SWMSJ JohnsonBelum ada peringkat

- JSA - 015 - Concrete Breaking With Hydraulic BreakerDokumen2 halamanJSA - 015 - Concrete Breaking With Hydraulic BreakerAhmed AlderbiBelum ada peringkat

- SS JSP - 063 Testing and Pre-Commissioning WorksDokumen9 halamanSS JSP - 063 Testing and Pre-Commissioning WorksBarkat UllahBelum ada peringkat

- 2F 5 Radiation Risk AssessmentDokumen1 halaman2F 5 Radiation Risk AssessmentNurul SyaheerahBelum ada peringkat

- Job Risk Assessment Design and Installation of New Scada SystemDokumen17 halamanJob Risk Assessment Design and Installation of New Scada Systemzee khanBelum ada peringkat

- Risk Assessment of Cable Tray InstallationDokumen10 halamanRisk Assessment of Cable Tray Installationfayaz fayazhotmail.comBelum ada peringkat

- SWMS 1 Loading, Unloading & ShiftingDokumen8 halamanSWMS 1 Loading, Unloading & ShiftingJ.j.JijoBelum ada peringkat

- RAPID-P0027-0005-CON-JHA-3215-0005 - Rev. A JHA of Blasting and PaintingDokumen4 halamanRAPID-P0027-0005-CON-JHA-3215-0005 - Rev. A JHA of Blasting and Paintingshaiful annuarBelum ada peringkat

- EXCAVATION BY HAND (Live Electrical) (Known & Unknown) : Job Safety AnalysisDokumen2 halamanEXCAVATION BY HAND (Live Electrical) (Known & Unknown) : Job Safety Analysisfrancis100% (1)

- WHS 2016 Working at Heights SWMSDokumen14 halamanWHS 2016 Working at Heights SWMSlupiBelum ada peringkat

- JSA Concereting and PaintingDokumen4 halamanJSA Concereting and PaintingHow Chin Engineering Sdn BhdBelum ada peringkat

- Demolition JhaDokumen2 halamanDemolition JhaElvyn Fabellore HerreraBelum ada peringkat

- JSEA-ICS-002-Installation of Rigid Steel Conduit (RSC)Dokumen11 halamanJSEA-ICS-002-Installation of Rigid Steel Conduit (RSC)Jayson EscamillanBelum ada peringkat

- 18 SOP CBL Trench DiggingDokumen10 halaman18 SOP CBL Trench DiggingMd Gulam SafiBelum ada peringkat

- Precast Erection JSWDokumen6 halamanPrecast Erection JSWPrabhakaran GurunathanBelum ada peringkat

- OCP Confined Space ShahiDokumen4 halamanOCP Confined Space ShahiVishal SrivastavaBelum ada peringkat

- Jsa CompressorDokumen9 halamanJsa CompressorRavi thokalBelum ada peringkat

- Welding Procedure - Arc Welding Machine - Method Statement HQDokumen8 halamanWelding Procedure - Arc Welding Machine - Method Statement HQSaaed EllalaBelum ada peringkat

- 2020 06 17 JSA For AC Servicing-Server RoomDokumen12 halaman2020 06 17 JSA For AC Servicing-Server RoomDarren OscarBelum ada peringkat

- Window CleaningDokumen1 halamanWindow CleaningSanthoshKumarBelum ada peringkat

- S07 Tank Project - JSA - Erection of Scaffolding 2nd LevelDokumen6 halamanS07 Tank Project - JSA - Erection of Scaffolding 2nd LevelKrishVy KumærBelum ada peringkat

- JSA For Hydrotesting PDFDokumen6 halamanJSA For Hydrotesting PDFMohammed Minhaj100% (1)

- SWMS HYD VAYUCON 04 Marking & Installation of DuctsDokumen9 halamanSWMS HYD VAYUCON 04 Marking & Installation of DuctsBodakunta Ajay VarmaBelum ada peringkat

- Confined Spaces Standard Operating Procedure and Permit CombinedDokumen8 halamanConfined Spaces Standard Operating Procedure and Permit CombinedRaza Muhammad SoomroBelum ada peringkat

- Environmental, Health and Safety Risks AnalysisDokumen3 halamanEnvironmental, Health and Safety Risks AnalysisKrishna PatilBelum ada peringkat

- JSA For Dewatering PumpDokumen1 halamanJSA For Dewatering Pumpwahyu nugrohoBelum ada peringkat

- JSA-Site Acceptance Test of 33 KV Feeders After Replacing Existing Relay by IEC61850 Facility RelayDokumen9 halamanJSA-Site Acceptance Test of 33 KV Feeders After Replacing Existing Relay by IEC61850 Facility Relayfrancis_e_tan100% (2)

- Jsa For Site EstablishmentDokumen8 halamanJsa For Site EstablishmentBenasher IbrahimBelum ada peringkat

- CTRA TK 64 003 Scaffolding Inside OutsideDokumen6 halamanCTRA TK 64 003 Scaffolding Inside OutsideMohamed RizwanBelum ada peringkat

- Bar Bending Checklist: Contractor NameDokumen1 halamanBar Bending Checklist: Contractor NameAfroz AlamBelum ada peringkat

- Procedures For Safe Working and Testing of Energized Electrical EquipmentDokumen25 halamanProcedures For Safe Working and Testing of Energized Electrical EquipmentSelvn SubramanianBelum ada peringkat

- Substation Earth Testing Job Safety AnalysisDokumen5 halamanSubstation Earth Testing Job Safety Analysispartho banerjeeBelum ada peringkat

- Substation Earth Testing Job Safety AnalysisDokumen5 halamanSubstation Earth Testing Job Safety AnalysishkaruvathilBelum ada peringkat

- Commissioning Ground Mounted Distribution SubstationsDokumen6 halamanCommissioning Ground Mounted Distribution SubstationsSergio Henrique F. CArniettoBelum ada peringkat

- Electromagnetic Field Calculation of Transformer Station 400/110 KV Ernestinovo Using The Cdegs SoftwareDokumen7 halamanElectromagnetic Field Calculation of Transformer Station 400/110 KV Ernestinovo Using The Cdegs SoftwarekarlBelum ada peringkat

- Lightning Protection of PV SystemsDokumen15 halamanLightning Protection of PV SystemskarlBelum ada peringkat

- Comparison of Oman Seismic Code For Buildings With International CounterpartsDokumen12 halamanComparison of Oman Seismic Code For Buildings With International CounterpartskarlBelum ada peringkat

- OilFilledPowerCable CatalogDokumen24 halamanOilFilledPowerCable CatalogkarlBelum ada peringkat

- En JV Catalogue 2Dokumen56 halamanEn JV Catalogue 2Yudhi Tri IndrawanBelum ada peringkat

- MSDS PetrolUnleaded PDFDokumen13 halamanMSDS PetrolUnleaded PDFkarlBelum ada peringkat

- Powerlink - Asset Management Plan - Volume 3 PUBLIC - January 2016Dokumen186 halamanPowerlink - Asset Management Plan - Volume 3 PUBLIC - January 2016karlBelum ada peringkat

- M5 U5 Traceability RecordDokumen13 halamanM5 U5 Traceability RecordkarlBelum ada peringkat

- MDG43 Technical Standard For The Design of Diesel Engine Systems For Use in Underground Coal MinesDokumen21 halamanMDG43 Technical Standard For The Design of Diesel Engine Systems For Use in Underground Coal Mineskarl100% (1)

- Te 1120 PRNDokumen183 halamanTe 1120 PRNkarlBelum ada peringkat

- EES005 Electrical Protection and Earthing Guideline PDFDokumen37 halamanEES005 Electrical Protection and Earthing Guideline PDFkarl100% (1)

- Linguistics Is Descriptive, Not Prescriptive.: Prescriptive Grammar. Prescriptive Rules Tell You HowDokumen2 halamanLinguistics Is Descriptive, Not Prescriptive.: Prescriptive Grammar. Prescriptive Rules Tell You HowMonette Rivera Villanueva100% (1)

- Obesity - The Health Time Bomb: ©LTPHN 2008Dokumen36 halamanObesity - The Health Time Bomb: ©LTPHN 2008EVA PUTRANTO100% (2)

- BNF Pos - StockmockDokumen14 halamanBNF Pos - StockmockSatish KumarBelum ada peringkat

- Anatomy Anal CanalDokumen14 halamanAnatomy Anal CanalBela Ronaldoe100% (1)

- MASONRYDokumen8 halamanMASONRYJowelyn MaderalBelum ada peringkat

- User Manual For Speed Control of BLDC Motor Using DspicDokumen12 halamanUser Manual For Speed Control of BLDC Motor Using DspicTrung TrựcBelum ada peringkat

- Ito Na Talaga Yung FinalDokumen22 halamanIto Na Talaga Yung FinalJonas Gian Miguel MadarangBelum ada peringkat

- DQ Vibro SifterDokumen13 halamanDQ Vibro SifterDhaval Chapla67% (3)

- Ricoh IM C2000 IM C2500: Full Colour Multi Function PrinterDokumen4 halamanRicoh IM C2000 IM C2500: Full Colour Multi Function PrinterKothapalli ChiranjeeviBelum ada peringkat

- History of The Sikhs by Major Henry Cour PDFDokumen338 halamanHistory of The Sikhs by Major Henry Cour PDFDr. Kamalroop SinghBelum ada peringkat

- Chapter 2 ProblemsDokumen6 halamanChapter 2 ProblemsYour MaterialsBelum ada peringkat

- Hdfs Default XML ParametersDokumen14 halamanHdfs Default XML ParametersVinod BihalBelum ada peringkat

- Prelim Examination MaternalDokumen23 halamanPrelim Examination MaternalAaron ConstantinoBelum ada peringkat

- Shostack ModSec08 Experiences Threat Modeling at MicrosoftDokumen11 halamanShostack ModSec08 Experiences Threat Modeling at MicrosoftwolfenicBelum ada peringkat

- On Derridean Différance - UsiefDokumen16 halamanOn Derridean Différance - UsiefS JEROME 2070505Belum ada peringkat

- DPSD ProjectDokumen30 halamanDPSD ProjectSri NidhiBelum ada peringkat

- Decision Making and The Role of Manageme PDFDokumen20 halamanDecision Making and The Role of Manageme PDFRaadmaan RadBelum ada peringkat

- 2021-03 Trophy LagerDokumen11 halaman2021-03 Trophy LagerAderayo OnipedeBelum ada peringkat

- C C C C: "P P P P PDokumen25 halamanC C C C: "P P P P PShalu Dua KatyalBelum ada peringkat

- Log Building News - Issue No. 76Dokumen32 halamanLog Building News - Issue No. 76ursindBelum ada peringkat

- Presentation 11Dokumen14 halamanPresentation 11stellabrown535Belum ada peringkat

- Negotiating Skills Negotiating Skills: To Provide You With The Skills To Plan & Implement Successful NegotiationDokumen32 halamanNegotiating Skills Negotiating Skills: To Provide You With The Skills To Plan & Implement Successful NegotiationKanimozhi.SBelum ada peringkat

- Salads: 300 Salad Recipes For Rapid Weight Loss & Clean Eating (PDFDrive) PDFDokumen1.092 halamanSalads: 300 Salad Recipes For Rapid Weight Loss & Clean Eating (PDFDrive) PDFDebora PanzarellaBelum ada peringkat

- Leak Detection ReportDokumen29 halamanLeak Detection ReportAnnMarie KathleenBelum ada peringkat

- Roleplayer: The Accused Enchanted ItemsDokumen68 halamanRoleplayer: The Accused Enchanted ItemsBarbie Turic100% (1)

- Application of Graph Theory in Operations ResearchDokumen3 halamanApplication of Graph Theory in Operations ResearchInternational Journal of Innovative Science and Research Technology100% (2)

- Principals' Leadership Styles and Student Academic Performance in Secondary Schools in Ekiti State, NigeriaDokumen12 halamanPrincipals' Leadership Styles and Student Academic Performance in Secondary Schools in Ekiti State, NigeriaiqraBelum ada peringkat

- Bana LingaDokumen9 halamanBana LingaNimai Pandita Raja DasaBelum ada peringkat