6S Audit Checklist

Diunggah oleh

Pramod AthiyarathuDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

6S Audit Checklist

Diunggah oleh

Pramod AthiyarathuHak Cipta:

Format Tersedia

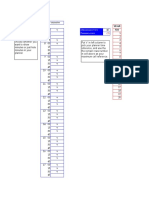

6S Audit Checklist form

Area of study: Audit date:

6S Incharge for area: Auditors:

Score

6S Checklist item Checklist item description 0 1 2 3 4Comments/Observations Recommendation Sub total

Are there any unused jigs, tools dies, furniture or similar items in the area?

Jigs, Tools etc.

Are ther machines or equipment which are unused around in the area?

Machines and equipment

Sort Materials or parts

Are there unneeded or excess materials or parts available in the area?

Are frequently used tools,materials placed in a more approcable manner and rarely used material kept in a storage area?

Storage spots as per useage

Is there aneffective usage or red tag practice?

Red Tagging

Location indicators

Are Shelves, racks, draws marked with labels or any other location indicators?

Item indicators

is there item labelling available within shelf or racks?

Set in Order Over populating shelf,racks etc

Do the shelf or racks in area look over populated?

Walkways and sign boards

Are there marker lines indicating walkways and necessary sign boards?

Placement of tools

Are tools and parts located in a user friendly yet time saving way?

cleanliness of over all area

Is the environment free of hazards and kept clean including floors and shelves, worktable etc?

Cleaning stations

Is there required amount of cleaning supplies to fullfil 3S? Is it available at the point of use?

Shine Maintainance of machine/Equipment

Are the machines/Equipment kept tidy with periodic maintainance when required?

Cleaning operations responsibility

Is there a person responsible for the cleaning operations soley?

Frequency of cleaning

Is cleaning being done periodically?

Communication and understanding of first 3S

Are the first 3S clearly understood and communicated accordingly?

Maintainance of 3S culture

Are the asscociates maintaining first 3S culture in work place?

Standardize Continous Improvement plan

Is there any improvement plan inplace? if so, are there any standards mentioned for this?

Performance of Area

Are area incharges upto date regarding their ares 6S performances?

As per standard procedure

Do all the activities follow standards mentioned?

Understanding and knowledge of 6S

Is everyone aware of 6S culture and its benefits?

6S questionnaire

Is there evidence of monthly 6S questionnaire conducted?

Sustain Weekly update to managers

Make sure there is record of weekly update to managers

Communication boards

Are 6S communication boards upto date and reviewd periodically?

Procedure followed for 6S overall

Are procedures mentioned follow 6S and are up to date?

Walkways, access to safety equipment is clearly identified and unobstructed (hazards, obstacles)

Hazards

Are appropriate signs and/or controls in place to identify potential hazards, PPE need, safety warnings etc.?

Signs & Identification

Safety Safety equipments

Is all safety equipment identified, unobstructed and accessible?

Are necessary good quality PPE of sufficient quantity available in the area?

PPE

Additional notes :

0 - Very Poor, 1-Poor, 2- Average, 3 - good, 4 -

Very good Overall score

*SCORES*

Anda mungkin juga menyukai

- 1S2S3S - Check SheetDokumen1 halaman1S2S3S - Check SheetManoj KaushikBelum ada peringkat

- 5S - Levels of ExcellenceDokumen2 halaman5S - Levels of ExcellenceHartoyo SwiBelum ada peringkat

- 5S Audit Checklist and Report PDFDokumen2 halaman5S Audit Checklist and Report PDFshahiraBelum ada peringkat

- 5s Audit Check SheetDokumen2 halaman5s Audit Check SheetElizabethMayMendiolaSabando100% (2)

- 6s AuditchecklistDokumen14 halaman6s Auditchecklisthasan_waqar20040% (1)

- 6S Audit Draft)Dokumen3 halaman6S Audit Draft)pikeman666100% (3)

- 5S Checklist OkDokumen2 halaman5S Checklist Okmichelle ann100% (1)

- 6s AuditchecklistDokumen7 halaman6s Auditchecklistpremrrs0% (1)

- MMI Industries 6S Audit ChecklistDokumen2 halamanMMI Industries 6S Audit ChecklistAisyah Nabilah Johary100% (7)

- 6S Levels of Achievement Matrix Self AssessmentDokumen3 halaman6S Levels of Achievement Matrix Self AssessmentAnbalagan Ravichandran100% (1)

- 5S Audit FormDokumen2 halaman5S Audit Formmounirs719883Belum ada peringkat

- 5s Checklist OperationDokumen1 halaman5s Checklist OperationallanbatiancilaBelum ada peringkat

- 5S Audit SheetDokumen3 halaman5S Audit Sheetleansensei67% (3)

- 5S Audit FormDokumen1 halaman5S Audit FormViorel IosubBelum ada peringkat

- Implement 5S ManagementDokumen3 halamanImplement 5S ManagementSivakumaar Nagarajan100% (2)

- 5S Audit Scorecard ResultsDokumen5 halaman5S Audit Scorecard ResultsGauravBelum ada peringkat

- 5 S Check ListDokumen6 halaman5 S Check ListWaqar LatifBelum ada peringkat

- Karla Melissa Martinez Medina. Vanessa Margarita Duran Aguilera. Leticia Serrano Wong. Dariela Zuñiga TreviñoDokumen12 halamanKarla Melissa Martinez Medina. Vanessa Margarita Duran Aguilera. Leticia Serrano Wong. Dariela Zuñiga TreviñoKarla Martinez100% (1)

- 5S Audit ChecklistDokumen12 halaman5S Audit Checklistmogul_hunkBelum ada peringkat

- Presentation 6 S STARTER TrainingDokumen96 halamanPresentation 6 S STARTER Trainingm_ramas2001Belum ada peringkat

- 5s CSRDokumen69 halaman5s CSRFadzilahMohamadBelum ada peringkat

- 5S Monthly Audit ChecklistDokumen6 halaman5S Monthly Audit ChecklistZahid Hussain50% (2)

- 5S Productivity ManagementDokumen28 halaman5S Productivity Managementloryn_dungca2031Belum ada peringkat

- 5S ManualDokumen23 halaman5S ManualBittuBelum ada peringkat

- 5S Audit Scorecard: Organizing for Safety and ProductivityDokumen4 halaman5S Audit Scorecard: Organizing for Safety and ProductivityTarunaiBelum ada peringkat

- 6S CourseDokumen25 halaman6S Coursem_ramas2001100% (2)

- 5S Audit Checklist FactoryDokumen2 halaman5S Audit Checklist FactoryGaneshBelum ada peringkat

- 5S Guidelines, Checklist, Rules & ResponsibilityDokumen14 halaman5S Guidelines, Checklist, Rules & ResponsibilityNurin Afzani Makrai71% (7)

- 1S, 2S & 6S Audit ChecklistDokumen46 halaman1S, 2S & 6S Audit ChecklistSudhagarBelum ada peringkat

- 5S Roles and ResponsibilitiesDokumen5 halaman5S Roles and Responsibilitiessenk197100% (1)

- 5S Audit FormDokumen1 halaman5S Audit FormStephi S. MontesdeocaBelum ada peringkat

- 5S Audit ChecklistDokumen4 halaman5S Audit ChecklistAjay Krishnan100% (3)

- 6S Implementation in Foundry ShopDokumen4 halaman6S Implementation in Foundry ShopSaad JamilBelum ada peringkat

- 5S ImplementationDokumen37 halaman5S ImplementationPakshal Shah0% (1)

- 5S Audit FormDokumen2 halaman5S Audit Formsigmasundar100% (1)

- Production Audit ChecklistDokumen1 halamanProduction Audit ChecklistAnton MymrikovBelum ada peringkat

- 5S Audit Checklist Documents Standardization and Continuous ImprovementDokumen10 halaman5S Audit Checklist Documents Standardization and Continuous ImprovementJamal AbdullahBelum ada peringkat

- 5S Audit ChecklistDokumen5 halaman5S Audit ChecklistDaniel2116Belum ada peringkat

- Optimized 5S Office AuditDokumen2 halamanOptimized 5S Office AuditWaqar DarBelum ada peringkat

- 6s Audit ChecklistDokumen3 halaman6s Audit ChecklistMahesh NakawalaBelum ada peringkat

- Seiri Audit ChecklistDokumen4 halamanSeiri Audit Checklistthephaiduong100% (1)

- Welcome Everyone To Our: N.Mohan RaajDokumen22 halamanWelcome Everyone To Our: N.Mohan RaajMohan Raaj100% (1)

- Advance 5S AuditsDokumen21 halamanAdvance 5S AuditsPhạm Thanh VấnBelum ada peringkat

- 5's TemplateDokumen5 halaman5's TemplatealamtareqBelum ada peringkat

- 5S Implementation Plan at Work PlaceDokumen18 halaman5S Implementation Plan at Work PlacemanishlmehtaBelum ada peringkat

- 5 S Presentation Basic TrainingDokumen82 halaman5 S Presentation Basic TrainingEmman Bosito100% (1)

- 5S/TPM Meeting Summary and Audit ToolsDokumen5 halaman5S/TPM Meeting Summary and Audit ToolsChatnoir NoirBelum ada peringkat

- 5S Diagnostic ChecklistDokumen6 halaman5S Diagnostic Checklistvikkasverma.in50% (2)

- 6S Audit FormDokumen5 halaman6S Audit Formhasan_waqar2004Belum ada peringkat

- 5S Check SheetDokumen8 halaman5S Check SheetDONBelum ada peringkat

- 5S - Final PPDokumen71 halaman5S - Final PPSiti Sara Rahim100% (1)

- 5S Audit Report - V3Dokumen1 halaman5S Audit Report - V3Rachmat Boerhan100% (1)

- QE (5S) Responsibilities and RolesDokumen3 halamanQE (5S) Responsibilities and RolesAdie Caberte0% (1)

- Visual Management Checklist & ReportDokumen4 halamanVisual Management Checklist & ReportBasyeer SuhaimiBelum ada peringkat

- 5S Audit ChecksheetDokumen1 halaman5S Audit ChecksheetIB Ismady68% (19)

- 5S Routine Audit Form: SO RTDokumen1 halaman5S Routine Audit Form: SO RTShahid RazaBelum ada peringkat

- 5s Audit Check SheetDokumen4 halaman5s Audit Check SheetLAI WEI SINGBelum ada peringkat

- 5S Audit SheetDokumen1 halaman5S Audit SheetSiddharth GuptaBelum ada peringkat

- Thing We Can DoDokumen4 halamanThing We Can DoDewan HasanBelum ada peringkat

- 5S Audit Checklist and Report 1663039107Dokumen2 halaman5S Audit Checklist and Report 1663039107Ashish R. SinghBelum ada peringkat

- This Document Has Been Supplied Under License by Shell To:: Replaced Not ReplacDokumen2 halamanThis Document Has Been Supplied Under License by Shell To:: Replaced Not ReplacPramod Athiyarathu100% (1)

- S 705v2020 06 Supplementary Specification To API Recommended Practice 582 For Welding of Pressure Containing Equipment and PipingDokumen58 halamanS 705v2020 06 Supplementary Specification To API Recommended Practice 582 For Welding of Pressure Containing Equipment and PipingandyBelum ada peringkat

- As ISO 10002 Guiding Principles-Bill DeeDokumen12 halamanAs ISO 10002 Guiding Principles-Bill DeeDarren TanBelum ada peringkat

- Improvement Projects - Selection: YearDokumen3 halamanImprovement Projects - Selection: YearPramod AthiyarathuBelum ada peringkat

- Complying With ISO 17025 A Practical GuidebookDokumen122 halamanComplying With ISO 17025 A Practical Guidebookyes17025100% (8)

- Guide to ASME's CA Connect Customer User SystemDokumen258 halamanGuide to ASME's CA Connect Customer User SystemPramod AthiyarathuBelum ada peringkat

- ISO 9001:2000 - Control of RecordsDokumen2 halamanISO 9001:2000 - Control of RecordsPramod AthiyarathuBelum ada peringkat

- Implementing ISO 10002 To Handle Customer ComplaintsDokumen14 halamanImplementing ISO 10002 To Handle Customer ComplaintsPramod AthiyarathuBelum ada peringkat

- Pure Savings On Your New Mashreq Credit Card!: Offer DetailsDokumen2 halamanPure Savings On Your New Mashreq Credit Card!: Offer DetailsPramod AthiyarathuBelum ada peringkat

- Kaizen Report ExampleDokumen1 halamanKaizen Report ExamplePramod AthiyarathuBelum ada peringkat

- Accreditation or CertificationDokumen8 halamanAccreditation or CertificationOsman AitaBelum ada peringkat

- To Do List V1.0Dokumen1 halamanTo Do List V1.0Pramod AthiyarathuBelum ada peringkat

- Enclosure Standards PDFDokumen8 halamanEnclosure Standards PDFnecmettinsengunBelum ada peringkat

- SP010 2 Corrective Action ProcedureDokumen3 halamanSP010 2 Corrective Action ProcedurePramod AthiyarathuBelum ada peringkat

- PREN Calculator Rev Feb 2011Dokumen2 halamanPREN Calculator Rev Feb 2011Sales HBS SolutionsBelum ada peringkat

- Monthly Planner V1.2Dokumen10 halamanMonthly Planner V1.2Pramod AthiyarathuBelum ada peringkat

- Information Requirements For Welding of Pressure Containing Equipment and PipingDokumen20 halamanInformation Requirements For Welding of Pressure Containing Equipment and PipingPramod Athiyarathu100% (1)

- Schedule minutes showDokumen9 halamanSchedule minutes show_Hennet_Belum ada peringkat

- Credit Card Pay Off Calculator V1.11Dokumen2 halamanCredit Card Pay Off Calculator V1.11Pramod AthiyarathuBelum ada peringkat

- HR Policies Required by Law - First Ref - 2018 PDFDokumen33 halamanHR Policies Required by Law - First Ref - 2018 PDFImran AkbarBelum ada peringkat

- Efqm Self AssessmentDokumen60 halamanEfqm Self AssessmentPramod AthiyarathuBelum ada peringkat

- Data Sheet For Welding of Pressure Containing Equipment and PipingDokumen9 halamanData Sheet For Welding of Pressure Containing Equipment and PipingPramod AthiyarathuBelum ada peringkat

- NCPWBBulletin 2010-07 Flange AssemblyDokumen4 halamanNCPWBBulletin 2010-07 Flange AssemblyPramod AthiyarathuBelum ada peringkat

- 1define The Problem 2 Identify The Team 4determine The Root Causes 5look Across 7verify The SolutionDokumen8 halaman1define The Problem 2 Identify The Team 4determine The Root Causes 5look Across 7verify The SolutionALFA ENGINEERINGBelum ada peringkat

- What Is LeanDokumen16 halamanWhat Is LeanPramod AthiyarathuBelum ada peringkat

- Quality in Outsourcing ISO9001 2015 PerspectiveDokumen14 halamanQuality in Outsourcing ISO9001 2015 PerspectivePramod AthiyarathuBelum ada peringkat

- 2019s PDFDokumen156 halaman2019s PDFvladkulBelum ada peringkat

- Six Sigma Applied To Reduce Patients' Waiting Time in A Cancer PharmacyDokumen21 halamanSix Sigma Applied To Reduce Patients' Waiting Time in A Cancer PharmacyPramod AthiyarathuBelum ada peringkat

- Basics of LeanDokumen21 halamanBasics of LeanPiter KiiroBelum ada peringkat

- Lecture 2 Overview Lean Waste EliminationDokumen29 halamanLecture 2 Overview Lean Waste EliminationLucianBelum ada peringkat

- Aachi Masale Case StudyDokumen4 halamanAachi Masale Case StudySHRUTI VBelum ada peringkat

- Detailed Report About Coir IndustryDokumen35 halamanDetailed Report About Coir IndustryParthasarathi PBelum ada peringkat

- Livestock in Bangladesh: Distribution, Growth and PotentialDokumen27 halamanLivestock in Bangladesh: Distribution, Growth and PotentialPranoy ChakrabortyBelum ada peringkat

- SY500H Excavator Warranty GuideDokumen12 halamanSY500H Excavator Warranty GuideGuillermo Herrera100% (2)

- Required For Each of The Following Fraudulent Acts Describe One orDokumen1 halamanRequired For Each of The Following Fraudulent Acts Describe One orAmit PandeyBelum ada peringkat

- Create A Mood Board For (And Name of The Collection!) That Will Give Justice To The Edgy and Sensual Look of The Brand. 1Dokumen3 halamanCreate A Mood Board For (And Name of The Collection!) That Will Give Justice To The Edgy and Sensual Look of The Brand. 1Nicole MirandaBelum ada peringkat

- Procedure For Equipment Calibration and MaintenanceDokumen9 halamanProcedure For Equipment Calibration and MaintenanceAli HadiBelum ada peringkat

- Tanzania High Court Ruling on Company Lawsuit ObjectionsDokumen15 halamanTanzania High Court Ruling on Company Lawsuit ObjectionsdavidBelum ada peringkat

- (Prelim 3RD Lesson) Customers' Meal Experience and Desired Attributes of Food and Beverage Service PersonnelDokumen26 halaman(Prelim 3RD Lesson) Customers' Meal Experience and Desired Attributes of Food and Beverage Service PersonnelLiza MaryBelum ada peringkat

- Cover Sheet: Company NameDokumen4 halamanCover Sheet: Company NamePeter MallorcaBelum ada peringkat

- Business English Present Simple and Continuous Tricky Questions Side by Side 3 Unit 1 CONVDokumen5 halamanBusiness English Present Simple and Continuous Tricky Questions Side by Side 3 Unit 1 CONVazeneth santosBelum ada peringkat

- Localisation of Ev Component Supply Chain in IndiaDokumen8 halamanLocalisation of Ev Component Supply Chain in Indiasoham98kshirsagarBelum ada peringkat

- Recommended Courses & Certifications - 230604 - 002211-1Dokumen10 halamanRecommended Courses & Certifications - 230604 - 002211-1Abcdefgh IjklmnopBelum ada peringkat

- Industrial Management Course at Addis Ababa UniversityDokumen2 halamanIndustrial Management Course at Addis Ababa UniversityAman KemalBelum ada peringkat

- Sharekhan Morning Tiger (Pre Market Insight) 05 Dec 2022Dokumen9 halamanSharekhan Morning Tiger (Pre Market Insight) 05 Dec 2022MADSADBBelum ada peringkat

- Tax Invoice: Original For RecipientDokumen3 halamanTax Invoice: Original For RecipientKuheli Rakhi RoyBelum ada peringkat

- InvoiceDokumen1 halamanInvoiceUsmanBelum ada peringkat

- Introduction To Lux SoapDokumen2 halamanIntroduction To Lux SoapBeerla RajenderBelum ada peringkat

- Economics Grade 10 Sudents Textbook Final VersionDokumen193 halamanEconomics Grade 10 Sudents Textbook Final VersionkasuBelum ada peringkat

- The Bully Episode - A Concise Outline of EventsDokumen6 halamanThe Bully Episode - A Concise Outline of EventsCloyd Uyson100% (3)

- ATP2022Dokumen60 halamanATP2022Muhd ShafiqBelum ada peringkat

- Week 4: Sto. Tomas College of Agriculture, Sciences and TechnologyDokumen12 halamanWeek 4: Sto. Tomas College of Agriculture, Sciences and TechnologyHannah Jean Lapenid LemorenasBelum ada peringkat

- To Build Working Together: Global Annual Review 2020Dokumen59 halamanTo Build Working Together: Global Annual Review 2020Bảo Châuu100% (1)

- Strength Based LeadershipDokumen7 halamanStrength Based Leadershipde_ghaywats100% (1)

- Teaching Note - Customer Analytics at FlipkartDokumen12 halamanTeaching Note - Customer Analytics at FlipkartARPAN100% (1)

- Talent AcquisitionDokumen10 halamanTalent AcquisitionSweety AghiBelum ada peringkat

- Postpaid Bill Anchal Jul 2022-1Dokumen1 halamanPostpaid Bill Anchal Jul 2022-1Mandhir BudhirajaBelum ada peringkat

- Accounting For Merchandising Operations ExercisesDokumen4 halamanAccounting For Merchandising Operations ExercisesthachuuuBelum ada peringkat

- International Student Exchange Programme Indicative Grade Point Average (iGPA) Fall 2021Dokumen3 halamanInternational Student Exchange Programme Indicative Grade Point Average (iGPA) Fall 2021Koh Zi YangBelum ada peringkat

- Chapter 3 ExercisesDokumen6 halamanChapter 3 ExercisesZaffirBelum ada peringkat