Packinox Xylene Isomerization

Diunggah oleh

CorneliuPopaJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Packinox Xylene Isomerization

Diunggah oleh

CorneliuPopaHak Cipta:

Format Tersedia

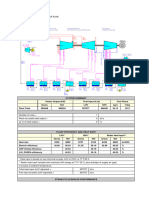

Alfa Laval Packinox for xylene isomerization

Standard combined feed/effluent heat exchanger

Alfa Laval Packinox

heat exchanger

Recycled hydrogen

Mixed xylene

Paraxylene

Alfa Laval Packinox Standard Combined Feed/Effluent Heat

Exchangers began service in xylene isomerization units

in the mid-1990s. By 2000, some 35 Alfa Laval Packinox

Standard Combined Feed/Effluent Heat Exchangers had

been installed in paraxylene production plants.

For xylene isomerization, Alfa Laval Packinox offers against

S&Ts the advantage of capital savings on installation, trans-

port, foundation and piping, in addition to economizing fuel

on associated process equipment in operation.

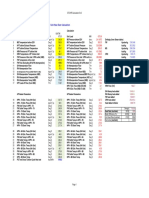

New unit case study

ALFA LAVAL PACKINOX SHELL & TUBE

Hot End Approach HEA = 28°C HEA = 50°C

Number of shells 1 2

Duty MW 90 83

MM Btu/h 307.1 283.2

Heat recovery MW 7

MM Btu/h 23.9

Estimated dry weight kg 128,000.00 220,000.00

CAPEX

Estimated equipment cost $US 2,800,000 2,600,000

Estimated installation cost $US 1,120,000 1,820,000

Estimated installed cost $US 3,920,000 4,420,000

CAPEX Savings on installed heat exchanger $US 500,000

CAPEX Savings on other installed equipment (Heater, Cooler) 350,000

TOTAL CAPEX SAVINGS $US 850,000

OPEX

ENERGY SAVINGS PER YEAR:

CHARGE HEATER,COMPRESSOR,… $US 3,150,000

EMISSIONS SAVINGS PER YEAR: Nox, Sox, GHG $US 560,000

assuming: 10.5 $US/ MM BTU, 1 Euro = 1,2 $US, GHG = 20 $US/Ton, Nox = 0,5 $US/Lb, Sox = 0,5 $US/Lb

PPI00203EN 0705 Alfa Laval reserves the right to change specifications without prior notification.

How to contact Alfa Laval

Up-to-date Alfa Laval contact details for

all countries are always available on our

website at www.alfalaval.com

Anda mungkin juga menyukai

- Packinox For Catalytic Reforming PDFDokumen2 halamanPackinox For Catalytic Reforming PDFRebekah SchmidtBelum ada peringkat

- On Geothermal Net ZeroDokumen65 halamanOn Geothermal Net Zerosandesh negiBelum ada peringkat

- DME Reactor ChemCADDokumen19 halamanDME Reactor ChemCADKayBelum ada peringkat

- Main Activities in University of Perugia About Technologies For Greenhouse Gases MitigationDokumen16 halamanMain Activities in University of Perugia About Technologies For Greenhouse Gases MitigationbharathimanjulaBelum ada peringkat

- Mitsubishi Electric PUHY-RP YJM-A Data Book EngDokumen293 halamanMitsubishi Electric PUHY-RP YJM-A Data Book EngFelixBelum ada peringkat

- Multi V Water IV Outside Unit Service Manual Exploded View Model Arwb Las4Dokumen33 halamanMulti V Water IV Outside Unit Service Manual Exploded View Model Arwb Las4Jose CuevasBelum ada peringkat

- Economic Benefits of High Temperature Ammonia Heat Pumps (Two Case Stories) (Two Case Stories)Dokumen13 halamanEconomic Benefits of High Temperature Ammonia Heat Pumps (Two Case Stories) (Two Case Stories)Sebastian Matías AguillónBelum ada peringkat

- Optimizing DME reactor design using ChemCAD Sensitivity and Hand resultsDokumen19 halamanOptimizing DME reactor design using ChemCAD Sensitivity and Hand resultsKayBelum ada peringkat

- Specification Sheet WXCDokumen3 halamanSpecification Sheet WXCVarga SzabolcsBelum ada peringkat

- Alfa Laval Packinox For Catalytic Reforming: Combined Feed/effluent Heat ExchangerDokumen3 halamanAlfa Laval Packinox For Catalytic Reforming: Combined Feed/effluent Heat Exchangerrizwan khan100% (1)

- Advance 25CDokumen2 halamanAdvance 25CImran zahoorBelum ada peringkat

- Che 455 Fall 2009 Major 1 Phthalic Anhydride Production: BackgroundDokumen20 halamanChe 455 Fall 2009 Major 1 Phthalic Anhydride Production: Backgroundاحمد الدلالBelum ada peringkat

- C30 PerformanceDokumen14 halamanC30 PerformanceLoy RiveroBelum ada peringkat

- Low Temperature Air/water Evi Heat Pump - Split: Model Zluaw-10Sh Zluaw-12ShDokumen1 halamanLow Temperature Air/water Evi Heat Pump - Split: Model Zluaw-10Sh Zluaw-12ShHumberto GarciaBelum ada peringkat

- Self-Contained Packaged Gas/Electric System: Model RG 024 To 120 (2 To 10 Tons) Model RE 090 To 120 (7 To 10 Tons)Dokumen34 halamanSelf-Contained Packaged Gas/Electric System: Model RG 024 To 120 (2 To 10 Tons) Model RE 090 To 120 (7 To 10 Tons)Michael MartinBelum ada peringkat

- 3.1.2 Indoor Unitswaesetghuio ' (Poiuytrfghbml, .'Dokumen1 halaman3.1.2 Indoor Unitswaesetghuio ' (Poiuytrfghbml, .'kabuBelum ada peringkat

- Fuel Value CalculatorDokumen3 halamanFuel Value CalculatorShafiBelum ada peringkat

- Indoor Units Specifications for 3 Capacity ModelsDokumen1 halamanIndoor Units Specifications for 3 Capacity ModelskabuBelum ada peringkat

- Indoor Units Specifications for 3 Capacity ModelsDokumen1 halamanIndoor Units Specifications for 3 Capacity ModelskabuBelum ada peringkat

- TCL Air Conditioner Service Manual SEODokumen138 halamanTCL Air Conditioner Service Manual SEOPedro Pablo GonzalezBelum ada peringkat

- Triplex BoilerDokumen53 halamanTriplex Boilershahroze mustafaBelum ada peringkat

- Specifications and technical data for 3 air conditioning unit modelsDokumen4 halamanSpecifications and technical data for 3 air conditioning unit modelsGABRIELA ALEXANDRA GAITAN TUSELLBelum ada peringkat

- MRCE - 3 - (Biomass-Fired Thermal Plant)Dokumen2 halamanMRCE - 3 - (Biomass-Fired Thermal Plant)Pablo PiquêBelum ada peringkat

- Packinox Catalytic ReformingDokumen2 halamanPackinox Catalytic Reformingzohaib_farooqBelum ada peringkat

- AKsugar lm2500 R2 PEACE ReportDokumen72 halamanAKsugar lm2500 R2 PEACE Reportshameer_sanju1049Belum ada peringkat

- 6-3 - ODU CatalogueDokumen61 halaman6-3 - ODU CatalogueFareethAbdullahBelum ada peringkat

- Split Type Wall Mounted ERA Series - KoppelDokumen2 halamanSplit Type Wall Mounted ERA Series - KoppelLeomark RespondeBelum ada peringkat

- 14ENTDMV0042Dokumen13 halaman14ENTDMV0042jraimundoBelum ada peringkat

- Case 2 - Tank Heat LossDokumen84 halamanCase 2 - Tank Heat Lossahmad santosoBelum ada peringkat

- Exhaust and Jacket Water Heat Recovery From GeneratorDokumen8 halamanExhaust and Jacket Water Heat Recovery From GeneratorMuhammad Abdul Samad50% (2)

- Deutz, TBG 616 K (323 - 700 KW)Dokumen4 halamanDeutz, TBG 616 K (323 - 700 KW)Dexterous EngineeringBelum ada peringkat

- Inter Cambiado RDokumen2 halamanInter Cambiado RmilenarixBelum ada peringkat

- Rooftop Package ClimaCreator Tropical R410A 50Hz (Brochure)Dokumen2 halamanRooftop Package ClimaCreator Tropical R410A 50Hz (Brochure)rodrigobenitez754Belum ada peringkat

- Regular Paper 3 - Set A: Section - Iii: Long Descriptive Questions Marks: 6 X 10 60Dokumen32 halamanRegular Paper 3 - Set A: Section - Iii: Long Descriptive Questions Marks: 6 X 10 60YogaAnandBelum ada peringkat

- Chiller Estimator 4.0Dokumen25 halamanChiller Estimator 4.0Prince RajaBelum ada peringkat

- Tu Macc Data Requirements TemplateDokumen49 halamanTu Macc Data Requirements TemplateNikhil MohiteBelum ada peringkat

- Manufacturing cost per year analysisDokumen7 halamanManufacturing cost per year analysisMadiha ZaimuriBelum ada peringkat

- RTAF - Air-Cooled Series R (TM) Product ReportDokumen2 halamanRTAF - Air-Cooled Series R (TM) Product ReportRafaelDutraBelum ada peringkat

- Simplified Approach to Comparing Operating Costs of Absorption and Electric Chiller TechnologiesDokumen24 halamanSimplified Approach to Comparing Operating Costs of Absorption and Electric Chiller Technologiesnurochman bpBelum ada peringkat

- Celanova Faza 2 Chilleri: Selection: Compact Screw Compressors CS // CSVDokumen3 halamanCelanova Faza 2 Chilleri: Selection: Compact Screw Compressors CS // CSVSladjan UgrenovicBelum ada peringkat

- EPRA014-018DV Data Books EEDEN22 EnglishDokumen103 halamanEPRA014-018DV Data Books EEDEN22 Englishchrdue1Belum ada peringkat

- Aleyna Ceyhan, İpek Erdinç, Nijat Tarverdiyev, Elif Toprak, İlayda Nur GüzelDokumen2 halamanAleyna Ceyhan, İpek Erdinç, Nijat Tarverdiyev, Elif Toprak, İlayda Nur Güzelilayda güzelBelum ada peringkat

- GPB15D Gas Turbine: A Closer LookDokumen2 halamanGPB15D Gas Turbine: A Closer LookMorgen GumpBelum ada peringkat

- Example - Coal Fire Power PlantDokumen17 halamanExample - Coal Fire Power PlantChristian DelfinBelum ada peringkat

- Tac07csk (1) UnlockedDokumen43 halamanTac07csk (1) UnlockedJuan AlbertoBelum ada peringkat

- Compact Rooftop Heat Pump Technical SpecificationsDokumen10 halamanCompact Rooftop Heat Pump Technical SpecificationsRonald MonzónBelum ada peringkat

- Evaporative Cooling & Wet Compression Technologies Boost Power OutputDokumen4 halamanEvaporative Cooling & Wet Compression Technologies Boost Power OutputRobert RafyanBelum ada peringkat

- Greenstar Danesmoor System 12 18 ErP DatasheetDokumen1 halamanGreenstar Danesmoor System 12 18 ErP DatasheetUcef AcyBelum ada peringkat

- GTCGR & Boiler Efficiciency During Trial Opn Tanda U#5Dokumen1 halamanGTCGR & Boiler Efficiciency During Trial Opn Tanda U#5om prakash pathakBelum ada peringkat

- Riello r40 G Ts0024uk04 Rev1Dokumen24 halamanRiello r40 G Ts0024uk04 Rev1Patricio Fernandez BarbaBelum ada peringkat

- Outside Unit: Service ManualDokumen35 halamanOutside Unit: Service ManualHeitor Prudente CorreaBelum ada peringkat

- Skikda Training CDU (Goal Content)Dokumen26 halamanSkikda Training CDU (Goal Content)Mohamed OuichaouiBelum ada peringkat

- Esercizi Tipo Esame 13-01-2022Dokumen15 halamanEsercizi Tipo Esame 13-01-2022armanjeffryBelum ada peringkat

- Natural Gas Boiler CalcDokumen18 halamanNatural Gas Boiler CalcopiratsBelum ada peringkat

- Solution To Mid Term ExamDokumen9 halamanSolution To Mid Term ExamMariel MirafloresBelum ada peringkat

- Pinch Analysis - Project Work 1 Grass-Roots Design of Organics Distillation PlantDokumen3 halamanPinch Analysis - Project Work 1 Grass-Roots Design of Organics Distillation Plantmohsen ranjbarBelum ada peringkat

- Air Conditioner Service Manual Models LV-C3621CL/HL/AL LV-D4821CL/HL/AL LV-D6021CL/HL/ALDokumen43 halamanAir Conditioner Service Manual Models LV-C3621CL/HL/AL LV-D4821CL/HL/AL LV-D6021CL/HL/ALCesar Calderon GrBelum ada peringkat

- VPS Gensets FinalDokumen2 halamanVPS Gensets FinalMarianoBarbagalloBelum ada peringkat

- IDEA StatiCa System RequirementsDokumen1 halamanIDEA StatiCa System RequirementsCorneliuPopaBelum ada peringkat

- Packinox Methanol SynthesisDokumen2 halamanPackinox Methanol SynthesisCorneliuPopaBelum ada peringkat

- 04 - Steam TrapsDokumen108 halaman04 - Steam TrapsCorneliuPopaBelum ada peringkat

- 03 - Condensate GuidelinesDokumen56 halaman03 - Condensate GuidelinesCorneliuPopaBelum ada peringkat

- Packinox Hydrotreating PDFDokumen4 halamanPackinox Hydrotreating PDFzubair195Belum ada peringkat

- Packinox Pyrolysis Gasoline HydrogenationDokumen2 halamanPackinox Pyrolysis Gasoline HydrogenationCorneliuPopaBelum ada peringkat

- Woman UK - 20 January 2020 PDFDokumen66 halamanWoman UK - 20 January 2020 PDFCorneliuPopaBelum ada peringkat

- Handloading Ruger M77 Compact Handloading Ruger M77 CompactDokumen84 halamanHandloading Ruger M77 Compact Handloading Ruger M77 CompactCorneliuPopa100% (2)

- Handloading Ruger M77 Compact Handloading Ruger M77 CompactDokumen84 halamanHandloading Ruger M77 Compact Handloading Ruger M77 CompactCorneliuPopa100% (2)

- Packinox Pyrolysis Gasoline HydrogenationDokumen2 halamanPackinox Pyrolysis Gasoline HydrogenationCorneliuPopaBelum ada peringkat

- Animal Scene - January 2020 PDFDokumen106 halamanAnimal Scene - January 2020 PDFCorneliuPopaBelum ada peringkat

- Customer Story Oil Refinery Russia PPI00399ENDokumen2 halamanCustomer Story Oil Refinery Russia PPI00399ENCorneliuPopaBelum ada peringkat

- Agrement Tehnic Fibre Carbon (Compressed)Dokumen45 halamanAgrement Tehnic Fibre Carbon (Compressed)CorneliuPopaBelum ada peringkat

- Packinox Paraffin DehydrogenationDokumen2 halamanPackinox Paraffin DehydrogenationCorneliuPopaBelum ada peringkat

- Packinox Multistream ServiceDokumen2 halamanPackinox Multistream ServiceCorneliuPopaBelum ada peringkat

- Packinox Catalytic ReformingDokumen2 halamanPackinox Catalytic Reformingzohaib_farooqBelum ada peringkat

- Site-Ul General IsoDokumen1 halamanSite-Ul General IsoCorneliuPopaBelum ada peringkat

- SyzranDokumen2 halamanSyzranCorneliuPopaBelum ada peringkat

- LayoDokumen3 halamanLayoCorneliuPopaBelum ada peringkat

- Feb26 StopStau SUSY WithTausDokumen19 halamanFeb26 StopStau SUSY WithTausCorneliuPopaBelum ada peringkat

- CP LeftletDokumen4 halamanCP LeftletSiang LingBelum ada peringkat

- Customer Story Oil Refinery Russia PPI00399ENDokumen2 halamanCustomer Story Oil Refinery Russia PPI00399ENCorneliuPopaBelum ada peringkat

- TrigEff PDFDokumen4 halamanTrigEff PDFCorneliuPopaBelum ada peringkat

- Howtoreferee ImtDokumen33 halamanHowtoreferee ImtCorneliuPopaBelum ada peringkat

- Process Plant Piping Maintenance RepairDokumen73 halamanProcess Plant Piping Maintenance RepairMiguel Cárdenas JaramilloBelum ada peringkat

- Petrom OMV - Norm - J - 2201 - Rom - Eng - Rev.1 - 2007-04-18Dokumen52 halamanPetrom OMV - Norm - J - 2201 - Rom - Eng - Rev.1 - 2007-04-18lucianduBelum ada peringkat

- Gas SolubilityDokumen59 halamanGas SolubilityAustine Ameh0% (1)

- TTC Pneumatic CYLINDER PDFDokumen30 halamanTTC Pneumatic CYLINDER PDFwienna1987Belum ada peringkat

- Installation Instructions For Axial Fans For Bathroom, Toilets, Utility Rooms and KitchensDokumen2 halamanInstallation Instructions For Axial Fans For Bathroom, Toilets, Utility Rooms and KitchenstylerdurdaneBelum ada peringkat

- CS6K-260|265|270|275 P Canadian Solar Module SpecificationsDokumen2 halamanCS6K-260|265|270|275 P Canadian Solar Module SpecificationsagnieszkaBelum ada peringkat

- User Manual: FeaturesDokumen1 halamanUser Manual: Featureskunal royBelum ada peringkat

- Mantenimiento 6466 PDFDokumen3 halamanMantenimiento 6466 PDFmarcosluna680% (3)

- Effect of Change in Frequency On Operation and Performance of Three Phase Induction MotorDokumen4 halamanEffect of Change in Frequency On Operation and Performance of Three Phase Induction MotorIDES100% (1)

- Sundyne LMV BMP 311 Centrifugal Pump Data SheetDokumen2 halamanSundyne LMV BMP 311 Centrifugal Pump Data Sheetmasoud67aBelum ada peringkat

- Gas Turbine Technologies For Electric GenerationDokumen54 halamanGas Turbine Technologies For Electric GenerationFabbrox100% (3)

- Sr. Activity Car PortBus Port RCC RooTotal ProgressDokumen8 halamanSr. Activity Car PortBus Port RCC RooTotal Progressaks2205Belum ada peringkat

- 8 Markscheme SL Paper2Dokumen61 halaman8 Markscheme SL Paper2Su ÇAĞLARBelum ada peringkat

- ACCC Conductors PDFDokumen6 halamanACCC Conductors PDFYayan RnsBelum ada peringkat

- tp6255 Generator Sets Service ManualDokumen116 halamantp6255 Generator Sets Service Manualjpin1968100% (6)

- Project ProposalDokumen13 halamanProject ProposalSyed Mustafa NajeebBelum ada peringkat

- Testing A Metalenclosed Bus PDFDokumen10 halamanTesting A Metalenclosed Bus PDFTunoNegro1Belum ada peringkat

- Mcqwind and SolarDokumen9 halamanMcqwind and SolarhananwarBelum ada peringkat

- Flexible ElectronicsDokumen17 halamanFlexible Electronicspulastya100% (3)

- Physics SPMDokumen26 halamanPhysics SPMMiztaDushanBelum ada peringkat

- GSR 2019 Full Report enDokumen336 halamanGSR 2019 Full Report enedgarmerchanBelum ada peringkat

- Solana Generating Station Project (Concentrating Solar Power Project) in ArizonaDokumen2 halamanSolana Generating Station Project (Concentrating Solar Power Project) in ArizonarijoiBelum ada peringkat

- EE8703 - SOLAR PV AND THERMAL SYSTEMS EXAM REVIEWDokumen8 halamanEE8703 - SOLAR PV AND THERMAL SYSTEMS EXAM REVIEWsayantikaBelum ada peringkat

- Physical ScienceDokumen4 halamanPhysical ScienceDaisuke Inoue100% (1)

- Visco MeterDokumen1 halamanVisco MetercellBelum ada peringkat

- Garrett Catalog of 2Dokumen42 halamanGarrett Catalog of 2Djabir Kodra100% (1)

- 800MW TG O&M Manual YeramarusDokumen321 halaman800MW TG O&M Manual YeramarusArvind Shukla100% (5)

- Island Mode Operation - 8feb08Dokumen9 halamanIsland Mode Operation - 8feb08Ezequiel Juarez BenítezBelum ada peringkat

- CASA CPL GK Jan 2004Dokumen173 halamanCASA CPL GK Jan 2004Allen Cheng100% (3)

- Soft Switching Boost Converter with MPPT for Solar Home LightingDokumen29 halamanSoft Switching Boost Converter with MPPT for Solar Home Lightingsatheesh_240Belum ada peringkat

- GroupDokumen8 halamanGroupMyles QuinteroBelum ada peringkat