LUXATHANE 5160 Polyurethane Finish Product Details

Diunggah oleh

shameelDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

LUXATHANE 5160 Polyurethane Finish Product Details

Diunggah oleh

shameelHak Cipta:

Format Tersedia

LUXATHANE 5160

Polyurethane Finish

PRODUCT A two component acrylic polyurethane giving a high performance finish in new construction and

maintenance industries.

DESCRIPTION • Long term recoatable properties

• Excellent gloss and colour retention

• Resistance to large number of chemicals and water.

• Can be applied to a wide range of substrates

• High build application in a single coat.

• Confirms to BS 5493-KF2A

DESIGNED USE • As a topcoat for the exterior of chemical storage tanks, pipelines.

• Suitable for application on structural steel, tanks and piping for onshore and offshore facilities

• Suitable as topcoat for upto C5 Environment as per ISO12944 Part 2.

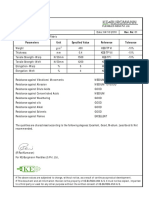

PHYSICAL DATA VOLUME SOLIDS

63 % + 2 %

(Based on ASTM D2697)

TYPICAL DRY FILM THICKNESS 75 microns

WET FILM THICKNESS 125 microns

THEORETICAL COVERAGE 8.4 m2/litre @ 75 microns DFT

VOC “As Supplied”

370 gms/ltr

(Based on ASTM D3960)

COLOUR As per RAL / BS shade cards

FINISH Gloss

APPLICATION METHOD OF APPLICATION:

This is the recommended method of application:

DETAILS Maximum 5% Thinner may be added.

AIRLESS SPRAY

Tip Size: 0.43 - 0.53 mm (0.017 - 0.021 in)

Pressure: 110 - 150 kg/cm2 (1600 - 2100 psi)

This is also a suitable method of application. Maximum

CONVENTIONAL SPRAY 20% Thinner may be added

Tip Size: 1.80 - 2.20 mm (0.071 - 0.087 in)

Pressure: 2.75 - 3.45 kg/cm2 (40-50 psi)

May be used for difficult shapes or touch-up.

BRUSH OR ROLLER However, additional coats may be required to achieve

the recommended film thickness.

NOTE: LUXATHANE 5160 is supplied in two separate containers. Contents must be thoroughly

intermixed before use. Once mixed allow to stand for 5 – 10 minutes, this allows any aeration to settle.

Unopened tins should be stored in a warm dry atmosphere away from moisture.

DRYING TIME:

Surface Re coating Interval

Touch Dry Hard Dry Pot Life

Temperature Minimum Maximum

15°C 3 Hrs 24 Hrs 12 Hrs Indefinite 6 Hrs

25°C 2 Hrs 12 Hrs 6 Hrs Indefinite 3 Hrs

35°C ½ Hr 6 Hrs 3 Hrs Indefinite 2 Hrs

45°C 20 mins 4 Hrs 2 Hrs Indefinite 1 Hr

NO. OF COMPONENTS Two

Mixing Ratio 7 parts Base to 1 Part Hardener (by volume)

Do not apply this product if the Relative Humidity exceeds

Application Conditions 85% or if the substrate temperature is within 3°C of the dew

point

ADDITIONAL Thinner / Cleaning solvent Solvalux 7-73

Storage Instruction Store in a cool shaded dry area

INFORMATION Flash Point Mixed 27°C

Packaging 5 liters & 20 liters

Shelf Life 12 months from the date of manufacture.

March 2014 Version 0 Protective Coatings Sales & Service Dubai Tel 04- 3391000 Fax 04-3391322 Abu Dhabi Tel 02-6798202 Fax 02-6713774

LUXATHANE 5160

Polyurethane Finish

SURFACE STEEL:

• For Maximum performance, this product should be applied to a surface that has been blast cleaned

PREPARATION and suitably primed (eg., with EPILUX or ZINCANODE or EPIMASTIC range of products).

• A build coat should be applied e.g., EPILUX or EPIMASTIC range of build / Intermediate coats

• The underlying system should be sound and undamaged.

• All surfaces to be over coated must be dry and free from surface contaminants.

• All wax, oil and grease should be removed by solvent cleaning in accordance with guidelines given

in SSPC – SPI.

• Soluble salts, dirt and dust must be removed prior to applying the coating. Dry brushing should be

sufficient. A fresh water wash must followed to remove all soluble salts.

• Always ensure maximum over coating time for the primer/ build coat has not been exceeded prior

to application.

ALUMINIUM, COPPER, ZINC SPRAYED STEEL, GALVAINISED METAL:

• Degrease with Berger Tool Cleaner and where practical, abrade lightly to form key.

• Pre treat with one coat of LUXAPRIME 1500 followed by one coat of EPILUX range of primers.

Then apply LUXATHANE 5160 as specified.

NEW WOOD, PLYWOOD, CHIPBOARD, HARDBOARD, SHUTTERING ETC.:

• Sand paper smooth and dust down.

• Fill holes, cracks etc. with EPILUX 829

• Prime with 1 or 2 coats of EPILUX 610. Then apply LUXATHANE 5160 as specified.

CONCRETE, PLASTER, BRICK, SIPORES BLOCKS ETC.:

• Dust down, remove all splashes of plaster, concrete, cement etc.

• Fill holes, cracks etc. with EPILUX 829

• Apply 1 or 2 coats of EPILUX CONCRETE PRIMER thinned 20-25% as priming coat.

• Then apply LUXATHANE 5160 as specified.

PRODUCT USE • This product is not suitable for use in immersed conditions.

• Do not apply this product if the pot life has been exceeded even if the paint still appears to liquid.

RESTRICTIONS • Dry heat resistance up to 120o C.

• May also be applied between 50 and 75 Microns DFT.

• Contact Berger Representative for suggesting suitable paint system

SAFETY • Avoid contact with the skin and eyes. Wear suitable protective clothing such as overalls, goggles, dust

masks and gloves. Use a barrier cream.

PRECAUTIONS • Ensure that there is adequate ventilation in the area where the product is being applied. Do not breathe

vapor or spray.

• This product is flammable. Keep away from sources of ignition. Do not smoke. Take precautionary

measures against static discharge. In case of fire – blanket flames with foam, carbon dioxide or dry

chemicals

• Refer to MSDS for further information.

FIRST AID • Eyes: In the event of accidental splashes, flush eyes with water immediately and obtain medical advice

• Skin: Wash skin thoroughly with soap and water or approved industrial cleaner.

• DO NOT USE solvent or thinners.

• Inhalation: Remove to fresh air, loosen collar and keep patient rested.

• Ingestion: In case of accidental ingestion, DO NOT INDUCE VOMITING.

Obtain immediate medical attention

The information provided on this data sheet is not intended to be complete and is provided as general advice only. It is the responsibility

DISCLAIMER of the user to ensure that the product is suitable for the purpose for which he wishes to use it. As we have no control over the treatment of

the product, the standard of surface preparation of the substrate, or other factors affecting the use of this product, we are not responsible

for its performance nor would we accept any liability whatsoever or howsoever arising from the use of this product unless specifically

agreed to in writing by us. The information contained in this data sheet may be modified by us from time to time, and without notice, in

the light of our experience and continuous product development.

March 2014 Version 0 Protective Coatings Sales & Service Dubai Tel 04- 3391000 Fax 04-3391322 Abu Dhabi Tel 02-6798202 Fax 02-6713774

Anda mungkin juga menyukai

- Epoxy Primer for Corrosion ProtectionDokumen2 halamanEpoxy Primer for Corrosion ProtectionsreeBelum ada peringkat

- HEMPADUR ZINC 15360 15360 en-GB PDFDokumen2 halamanHEMPADUR ZINC 15360 15360 en-GB PDFErwin MalmsteinBelum ada peringkat

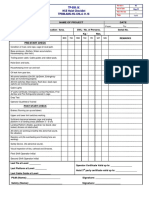

- Borang Pemeriksaan Air KompressorDokumen1 halamanBorang Pemeriksaan Air KompressorAndara Asifa YudianaBelum ada peringkat

- Chklist HEXDokumen3 halamanChklist HEXluisBelum ada peringkat

- Vaultex CatelogDokumen218 halamanVaultex Catelogprabu prasad0% (1)

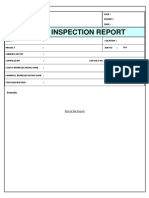

- 00-Material Submission FormDokumen4 halaman00-Material Submission FormHafiz AbdullahBelum ada peringkat

- Earth Compactor Daily Check ListDokumen2 halamanEarth Compactor Daily Check ListpjosesmBelum ada peringkat

- Part Submission WarrantDokumen4 halamanPart Submission WarrantSam AnuBelum ada peringkat

- F - OPN - 05 R1 Assessment Form - Earthmoving EquipmentDokumen1 halamanF - OPN - 05 R1 Assessment Form - Earthmoving EquipmentJanaoo. comBelum ada peringkat

- Check ListDokumen88 halamanCheck ListRaafat SaadBelum ada peringkat

- Foam InductorDokumen6 halamanFoam InductorDipanjan Chakrabarti100% (1)

- F.e.& Scba InspectionDokumen5 halamanF.e.& Scba InspectionAviects Avie JaroBelum ada peringkat

- Dumper Truck Daily ChecklistDokumen1 halamanDumper Truck Daily ChecklistAbdus SamadBelum ada peringkat

- OISD - Contarctor SafetyDokumen55 halamanOISD - Contarctor SafetyVarun AroraBelum ada peringkat

- Corroseal TE 321 Rev 01Dokumen1 halamanCorroseal TE 321 Rev 01Ashif AkhtarBelum ada peringkat

- Contractor EHS Statistics: Contractor Company Name: Month: July - 2022Dokumen4 halamanContractor EHS Statistics: Contractor Company Name: Month: July - 2022fasilBelum ada peringkat

- Form-I-010 Welding Machine Inspection Form: Carry-In CertificateDokumen1 halamanForm-I-010 Welding Machine Inspection Form: Carry-In CertificateAdhy DarmawanBelum ada peringkat

- Sop Changing A Toner CartridgeDokumen2 halamanSop Changing A Toner CartridgezaheerBelum ada peringkat

- JOB SAFETY ANALYSIS FORMDokumen7 halamanJOB SAFETY ANALYSIS FORMIulian Costin IonBelum ada peringkat

- StyreneDokumen2 halamanStyreneBiju_PottayilBelum ada peringkat

- MS Working at HeightsDokumen15 halamanMS Working at HeightsNauval FadliBelum ada peringkat

- Towed Scraper Checklist V0810.1 PDFDokumen1 halamanTowed Scraper Checklist V0810.1 PDFcherifBelum ada peringkat

- Pds Project SetupDokumen3 halamanPds Project SetupSRIKANTHBelum ada peringkat

- DAR Vol1-2013Dokumen744 halamanDAR Vol1-2013chitransh2002Belum ada peringkat

- Hoist Checklist ReviewDokumen1 halamanHoist Checklist ReviewNavdeep Singh GrewalBelum ada peringkat

- Machinery Inspection Checklist - Wah FungDokumen4 halamanMachinery Inspection Checklist - Wah FungMKhairulMDBelum ada peringkat

- Lifting PlanDokumen12 halamanLifting Plangeriaxavier2022Belum ada peringkat

- GD380A-L ListDokumen6 halamanGD380A-L ListNam Won HongBelum ada peringkat

- LDIP-P1-Site Daily Report-SECM&E-June 24 2013Dokumen3 halamanLDIP-P1-Site Daily Report-SECM&E-June 24 2013Giang Cao Tho100% (1)

- Checklist For Equipment Inspection BikeDokumen1 halamanChecklist For Equipment Inspection BikeHung HoangBelum ada peringkat

- Equipment Maintenance and Measuring Equipment ProcedureDokumen2 halamanEquipment Maintenance and Measuring Equipment ProcedureRaja Mani100% (1)

- Safety 2Dokumen15 halamanSafety 2hyde2520015754Belum ada peringkat

- Quiz For TT DriverDokumen8 halamanQuiz For TT DriverGulbarga DepotBelum ada peringkat

- Equipment Register - Pat Testing Original CertificateDokumen3 halamanEquipment Register - Pat Testing Original CertificateSayed AbbasBelum ada peringkat

- 07 - TDS - Masterflow 520Dokumen3 halaman07 - TDS - Masterflow 520Alexi ALfred H. TagoBelum ada peringkat

- QATAR Pin Braze pdfr1Dokumen14 halamanQATAR Pin Braze pdfr1Karunanithi NagarajanBelum ada peringkat

- Fire Water TankDokumen1 halamanFire Water TankAnonymous yCpjZF1rFBelum ada peringkat

- SOP For Hydra RepairingDokumen13 halamanSOP For Hydra RepairingMD AbdullahBelum ada peringkat

- Scaffold Inspection Report-Master ListDokumen2 halamanScaffold Inspection Report-Master ListMobin Thomas AbrahamBelum ada peringkat

- Ind Swift Limited (Gbu) : Manpower Summary of (Company Name) As On 31.05.2010 (Permanent)Dokumen14 halamanInd Swift Limited (Gbu) : Manpower Summary of (Company Name) As On 31.05.2010 (Permanent)tarique1189040Belum ada peringkat

- Sop Installing PumpDokumen4 halamanSop Installing PumpilhamBelum ada peringkat

- Middle East Welding Safety ProceduresDokumen6 halamanMiddle East Welding Safety ProceduresyahiyaBelum ada peringkat

- Statement For Routine Lifting: (XXX Room For Your Own Numbering System)Dokumen3 halamanStatement For Routine Lifting: (XXX Room For Your Own Numbering System)Mark Julius CabasanBelum ada peringkat

- KAP Power Plant Work Permit FormDokumen1 halamanKAP Power Plant Work Permit FormMuhammad SajidBelum ada peringkat

- Name: SignDokumen1 halamanName: SignAdel AlKhedawyBelum ada peringkat

- SCOPE OF WORK For Cooling Tower Sump CLEANINGDokumen10 halamanSCOPE OF WORK For Cooling Tower Sump CLEANINGAbhinav PradhanBelum ada peringkat

- Mobile Scaffold Inspection ChecklistDokumen3 halamanMobile Scaffold Inspection Checklistanthony murphyBelum ada peringkat

- M/S Kapoor Enterprises Vendor Code: K635: Mechanized Rock Breaker ChecklistDokumen2 halamanM/S Kapoor Enterprises Vendor Code: K635: Mechanized Rock Breaker Checklistprojit basu100% (1)

- Basra Multipurpose Terminal Construction Method StatementDokumen26 halamanBasra Multipurpose Terminal Construction Method StatementMahmoud FakhereddinBelum ada peringkat

- Wfp291338 For Quality and Quantity Inspection of FoodsDokumen14 halamanWfp291338 For Quality and Quantity Inspection of FoodsOzlem MepBelum ada peringkat

- 10 Percent Acid Washing SOP TemplateDokumen5 halaman10 Percent Acid Washing SOP TemplatekofinyameBelum ada peringkat

- QUSAHWIRA FIELD DEVELOPMENTDokumen1 halamanQUSAHWIRA FIELD DEVELOPMENTJayaprakasan Koyadan KorothBelum ada peringkat

- MDLZ-RBIPL-MS-01-SITE MOBILIZATION WORK - UptdDokumen21 halamanMDLZ-RBIPL-MS-01-SITE MOBILIZATION WORK - Uptdshamshad ahamedBelum ada peringkat

- SK Assoicates Authorized DealerDokumen1 halamanSK Assoicates Authorized DealerKamalesh KumarBelum ada peringkat

- Jsa GRIT BLASTINGDokumen3 halamanJsa GRIT BLASTINGPrajnay ShettyBelum ada peringkat

- Verifiable Contractor Hse Questionnaire: Please Answer The Following QuestionsDokumen4 halamanVerifiable Contractor Hse Questionnaire: Please Answer The Following QuestionsDanny SolvanBelum ada peringkat

- Safe Use of Lifting Machines and Lifting TackleDokumen59 halamanSafe Use of Lifting Machines and Lifting TackleJakesBelum ada peringkat

- JOB Description: Position Title Department Position Reports To Job Class Job SummaryDokumen2 halamanJOB Description: Position Title Department Position Reports To Job Class Job SummaryVijay RajaindranBelum ada peringkat

- TDS-PDF-Interchar 1290 Eng A4 20170228Dokumen4 halamanTDS-PDF-Interchar 1290 Eng A4 20170228shameelBelum ada peringkat

- Steel Master 1200 WF PDSDokumen5 halamanSteel Master 1200 WF PDSshameelBelum ada peringkat

- Interchar 973 (Ac) TdsEngDokumen4 halamanInterchar 973 (Ac) TdsEngshameelBelum ada peringkat

- Steel Master 1200 WFDokumen4 halamanSteel Master 1200 WFshameelBelum ada peringkat

- Product Data Sheet - 370-120Dokumen4 halamanProduct Data Sheet - 370-120shameelBelum ada peringkat

- MSDS 370-120H Rev 0 (2017-01-27)Dokumen14 halamanMSDS 370-120H Rev 0 (2017-01-27)shameelBelum ada peringkat

- MSDS 370-90Dokumen6 halamanMSDS 370-90shameelBelum ada peringkat

- Interbond 808Dokumen4 halamanInterbond 808shameelBelum ada peringkat

- Hardtop OptimaDokumen4 halamanHardtop OptimashameelBelum ada peringkat

- Surface Preparation Standards Comparison ChartDokumen2 halamanSurface Preparation Standards Comparison ChartajuhaseenBelum ada peringkat

- Product Data Sheet - 700-60Dokumen5 halamanProduct Data Sheet - 700-60shameelBelum ada peringkat

- Chemflake Special)Dokumen5 halamanChemflake Special)shameelBelum ada peringkat

- TDS - Barrier - English (Uk) - Issued.30.11.2011 PDFDokumen4 halamanTDS - Barrier - English (Uk) - Issued.30.11.2011 PDFRedzuanBelum ada peringkat

- Interzinc 2280Dokumen4 halamanInterzinc 2280shameelBelum ada peringkat

- Steel Master 60 WBDokumen4 halamanSteel Master 60 WBshameelBelum ada peringkat

- Paint Spread Rate CalculationDokumen12 halamanPaint Spread Rate CalculationshameelBelum ada peringkat

- Steel Master 1200 WFDokumen4 halamanSteel Master 1200 WFshameelBelum ada peringkat

- Tankguard StorageDokumen4 halamanTankguard StorageshameelBelum ada peringkat

- Interline 850Dokumen4 halamanInterline 850shameelBelum ada peringkat

- Muki Z 2001 - TDSDokumen4 halamanMuki Z 2001 - TDSshameelBelum ada peringkat

- Tankguard SFDokumen4 halamanTankguard SFshameelBelum ada peringkat

- RIG STATUSDokumen7 halamanRIG STATUSshameelBelum ada peringkat

- Intershield 300Dokumen4 halamanIntershield 300shameelBelum ada peringkat

- Area Survey ReportDokumen1 halamanArea Survey ReportshameelBelum ada peringkat

- Interline 850Dokumen4 halamanInterline 850shameelBelum ada peringkat

- Re in StatementDokumen2 halamanRe in StatementshameelBelum ada peringkat

- Katalog Collection 2013-BenzDokumen172 halamanKatalog Collection 2013-Benzవెంకట్ వెంకిBelum ada peringkat

- Churches of RevelationDokumen11 halamanChurches of RevelationmaymorganBelum ada peringkat

- Pisces Man Secrets How To Text A Pisces Man by Anna Kovach 2022 EditionDokumen58 halamanPisces Man Secrets How To Text A Pisces Man by Anna Kovach 2022 EditionNatalie RichardsonBelum ada peringkat

- How I Fell in Love With My Stepbrother. Book OneDokumen7 halamanHow I Fell in Love With My Stepbrother. Book Onekelly.Belum ada peringkat

- Styleguide - US Spring Summer 2013 Lia Sophia CatalogDokumen51 halamanStyleguide - US Spring Summer 2013 Lia Sophia CatalogJillian WhiteBelum ada peringkat

- Physical Activity Frequency of Activity Estimated Time (In Minute) Risk Factor Rating (RFR) Safety Checklists IncludedDokumen4 halamanPhysical Activity Frequency of Activity Estimated Time (In Minute) Risk Factor Rating (RFR) Safety Checklists IncludedavinmanzanoBelum ada peringkat

- Acetone MSDS PDFDokumen5 halamanAcetone MSDS PDFYan Lean DollisonBelum ada peringkat

- Employee Safety Performance SheetDokumen40 halamanEmployee Safety Performance SheetAbdul MueedBelum ada peringkat

- The Reggaeton Style of FashionDokumen4 halamanThe Reggaeton Style of FashionKaren AguilarBelum ada peringkat

- Play 03: Pyramids: by Joseph FrostDokumen5 halamanPlay 03: Pyramids: by Joseph FrostJoe FrostBelum ada peringkat

- Grey's Anatomy Quotes - Season 3Dokumen27 halamanGrey's Anatomy Quotes - Season 3tinuBelum ada peringkat

- Vertical Roller Mill Process DetailsDokumen49 halamanVertical Roller Mill Process Detailsrecai100% (3)

- Clothes and WDokumen1 halamanClothes and WMorales Ximena PaulaBelum ada peringkat

- Inter Organizational Relations in The Business Model of BenettonDokumen19 halamanInter Organizational Relations in The Business Model of BenettonMohit MehtaBelum ada peringkat

- House On The HillDokumen5 halamanHouse On The HillHugo ChávezBelum ada peringkat

- Isobutanol PDFDokumen11 halamanIsobutanol PDFElías VillegasBelum ada peringkat

- Winnie and FriendsDokumen21 halamanWinnie and FriendsClarissa Garcia98% (92)

- Unit 2Dokumen1 halamanUnit 2Чыонг ТанBelum ada peringkat

- Steps in English 2 - Workbook (PDFDrive)Dokumen97 halamanSteps in English 2 - Workbook (PDFDrive)Ana TasicBelum ada peringkat

- Baby/Infant Bath-Is A Procedure of Cleaning The Skin of The Baby For Promoting Hygiene and ComfortDokumen3 halamanBaby/Infant Bath-Is A Procedure of Cleaning The Skin of The Baby For Promoting Hygiene and ComfortHoney VargasBelum ada peringkat

- Modeling and Simulating Bodies and GarmentsDokumen203 halamanModeling and Simulating Bodies and GarmentsShoaib AzizBelum ada peringkat

- Standing Post ExercisesDokumen11 halamanStanding Post Exercisesrappa84100% (2)

- Beyond The Barriers The Book of WorldsDokumen202 halamanBeyond The Barriers The Book of WorldsShalashaskka88% (8)

- Beadwork Books: Best-Seller! Addresses The Most CommonDokumen3 halamanBeadwork Books: Best-Seller! Addresses The Most CommonDini Amalia Fauziah0% (1)

- Blanca Nieves en InglesDokumen9 halamanBlanca Nieves en InglesBrillo Xghj0% (1)

- F073 BatikElementsAccessoriesDokumen4 halamanF073 BatikElementsAccessoriesnata westBelum ada peringkat

- Holy Symbol: A G Item Cost Weight Item Cost WeightDokumen5 halamanHoly Symbol: A G Item Cost Weight Item Cost WeightGeorgeBelum ada peringkat

- The Levi's StoryDokumen5 halamanThe Levi's StoryFitto PriestazaBelum ada peringkat

- Market MayhemCase StudyDokumen5 halamanMarket MayhemCase StudyAnurag SahaBelum ada peringkat

- Fabric SpecDokumen15 halamanFabric Specpanduranganraghurama100% (1)