Rope Definition Lubrication

Diunggah oleh

smsobhan0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

76 tayangan2 halaman1. The document defines 9 terms related to the amount and type of lubrication used in rope manufacturing.

2. The terms range from lubricant-free ropes to heavily lubricated ropes and include specifications for the amount of lubricant that should cover individual wires and be present overall in the core and finished rope.

3. Parameters like heating the lubricant, wiping strands, and acceptable lubricant levels in fibre cores are provided for each type of lubrication defined.

Deskripsi Asli:

rope Definition Lubrication

Hak Cipta

© © All Rights Reserved

Format Tersedia

PDF, TXT atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen Ini1. The document defines 9 terms related to the amount and type of lubrication used in rope manufacturing.

2. The terms range from lubricant-free ropes to heavily lubricated ropes and include specifications for the amount of lubricant that should cover individual wires and be present overall in the core and finished rope.

3. Parameters like heating the lubricant, wiping strands, and acceptable lubricant levels in fibre cores are provided for each type of lubrication defined.

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

76 tayangan2 halamanRope Definition Lubrication

Diunggah oleh

smsobhan1. The document defines 9 terms related to the amount and type of lubrication used in rope manufacturing.

2. The terms range from lubricant-free ropes to heavily lubricated ropes and include specifications for the amount of lubricant that should cover individual wires and be present overall in the core and finished rope.

3. Parameters like heating the lubricant, wiping strands, and acceptable lubricant levels in fibre cores are provided for each type of lubrication defined.

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

Anda di halaman 1dari 2

PDF E C:\Handbook

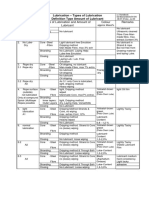

Amount of Lubricant – Terms 02-Bestandteile

HB 04-02-01T2

Definition Lubrication 04-04/06-02.doc

2.4.4.6.1 & 5.1.7.1 Type of Lubrication Dat:06.07.00

Nr. Terms Definition

1 Lube-Free. Ultrasonic No Lubricant is used during stranding or closing. The wires

are delubricated already at drawing. During stranding and

closing only lubricant free Emulsion will be used as “laying

help”. These Emulsions show no remainings afterwards.

Max remainings at testing to DIN Standard:

If a fibre core is requested, only man made fibre cores are

used, which are lubricant free, that means the extracted

content is not allowed to be bigger than 3 %.

The finished rope will be drawn through an Ultra-Sonic

Cleaning Bath.

2 No-Lube – Dry Rope Free of Lubricant but wires still show remainings of drawing

Soap materials and laying-help-material. No lubricant is

used during stranding and closing. During stranding and

closing only lubricant free Emulsion will be used as “laying

help”, which will show no big remainings.

Maximum remainings at testing to DIN:

If a fibre core is requested, only man made fibre cores are

used, which are lubricant free, that means the extracted

content is not allowed to be bigger than 3 %.

3 Rope dry A. The Core is dry, that means without lubricant.

A0 The Batch-Content of Fibre Core has to be chosen in

such a way, that the extracted content is not above 7%.

During stranding and closing only the necessary oildrops

to allow the laying are added. Strands, rope and core are

heavily wiped after the die-stand.

B. Steel Core: only strands lubricated. Otherwise as A.

4 Rope outside not Compound-Construction, Spiral ropes, Multi-Layer-Spiral-

lubricated Ropes, and Multiple Operation –Ropes only the Strand-

Inner-Layers are light lubricated. The Steel-Core is also only

light lubricated. (Heavy wiping) Fibre Cores have a

maximum lubricant content of 12 %

5 Light Lubricated Lubricant is heated up, when applied to strands, to the

A1 maximum allowed Temperature Limit, that means it is very

liquid. A lubricant has to be used, which is, because of its

consistency, suitable. The Lubricant is poured between the

wires at the stranding lay point , before the strand is formed.

Each single wire should be slightly covered with lubricant.

Behind the die and again behind the postformer, (calibration

rollers) etc., the strands and rope are wiped heavily (Double

wiping). Only a light film of lubricant should cover the wires.

The core is only light lubricate. A fibre core should have no

visible outside laying lubricant. The lubricant content of the

fibre core shall not be above 12 %.The total content of

lubricant of the rope should be at approximately 0,8 to 1,2 %

Lubricants: e. g. Nyrosten T 55, A 19/200, Cedrakon,

Elaskon High Tech 2000

Handbook/02-Bestanteile/04-04/06-01.doc/Datum 09.03.06/ Seite 2 von 2

6 Normal Lubrication Lubricant is heated when applied to normal requested

temperature.

A lubricant has to be used, which is, because of its

consistency, suitable.

The Lubricant is poured between the wires at the stranding

lay point , before the strand is formed. Each single wire

should be slightly covered with lubricant. Behind the die and

again behind the postformer, (calibration rollers) etc., the

strands and rope are wiped slightly. A light film of lubricant

should cover the wires.

The core is only light lubricated. A fibre core should have no

visible outside laying lubricant. The lubricant content of the

fibre core shall not be above 16 %.The total content of

lubricant of the rope should be at approximately 1,0 to 1,5 %

Lubricants: e. g. Nyrosten T 55, A 19/200, Cedrakon,

Elaskon High Tech 2000.

6.1 Normal Lubrication As 6.

A2.1 Lubricant Transparent, yellow, brown, green.

Total amount of Lubricant of rope: 1,0 to 2 %.

6.2 Normal Lubrication As 6.

A2.2 Lubricant black, asphaltic or brown/golden N 113

Total amount of Lubricant of rope: 1,5 to 3 %.

7 Heavy Lubrication Lubricant is heated when applied to normal requested

temperature.

A lubricant has to be used, which is, because of its

consistency, suitable.

The Lubricant is poured between the wires at the stranding

lay point , before the strand is formed. Each single wire

should be slightly covered with lubricant. Behind the die and

again behind the postformer, (calibration rollers) etc., the

strands and rope are not wiped . A heavy film of lubricant

should cover the wires.

The core is heavily lubricated. A fibre core may show visible

on the outside laying lubricant. The lubricant content of the

fibre core shall not be between 16 % and 25 %.

The total content of lubricant of the rope should be at

approximately 1,8 to 3,5 %

Lubricants: e. g.

8 Double Lubrication e. g. as corrosion protection when stored for a longer time.

Before rope testing on fatigue cycling machines (University

of Stuttgart: Hot Steam Cylinder Oil, to compare rope quality

without the influence of different lubricant).

Rope lubricated as per 6 or 7 and the finished rope is

lubricated again. Depending of the application with a thin

light lubricant or a very adhesive type of lubricant.

9 Field Lubrication During Service the ropes should be or must be lubricated,

because the original Lubrication in most of the cases will not

be sufficient for the whole service life. The method and the

type of lubricant used, is depending on the type of

application. The lubricant must be compatible with the

original lubricant.

Anda mungkin juga menyukai

- Wire Rope Technical BulletinDokumen2 halamanWire Rope Technical BulletinhandaruBelum ada peringkat

- Wire Rope Lubrication CodeDokumen2 halamanWire Rope Lubrication CodeAli100% (1)

- EA9 Red Oxide PrimerDokumen3 halamanEA9 Red Oxide PrimernkhhhBelum ada peringkat

- Lubricant & LubricationDokumen4 halamanLubricant & LubricationmimBelum ada peringkat

- Basic Chain Lubrication GuideDokumen2 halamanBasic Chain Lubrication GuideRakesh PawarBelum ada peringkat

- Nippon HB Epoxy LinerDokumen3 halamanNippon HB Epoxy LinerRai Hasnain Ahmad DahaBelum ada peringkat

- Basic Carbonate White Lead Pigment: Standard Specification ForDokumen2 halamanBasic Carbonate White Lead Pigment: Standard Specification ForFernando Berrospi GarayBelum ada peringkat

- B680 BulkDokumen3 halamanB680 BulkJM ArcillaBelum ada peringkat

- Unit - 2 Notes by Rama PawarDokumen18 halamanUnit - 2 Notes by Rama PawarKaran ParajapatiBelum ada peringkat

- Dry Moly Fluid - GBDokumen3 halamanDry Moly Fluid - GBVitor GodoyBelum ada peringkat

- Molykote Cabo de AcoDokumen1 halamanMolykote Cabo de AcomarcosBelum ada peringkat

- EA4 Finish MetalDokumen3 halamanEA4 Finish MetalAzmeer YusufBelum ada peringkat

- Lubricant - Mech& MesurmentDokumen5 halamanLubricant - Mech& MesurmentRevanth PolicherlaBelum ada peringkat

- Zinc Rich Primer HSDokumen3 halamanZinc Rich Primer HSthowchinBelum ada peringkat

- CTS DC Lubrication 3Dokumen2 halamanCTS DC Lubrication 3Alson LeeBelum ada peringkat

- Lubrication: Md. Al Amin Hossain Lecturer (ME)Dokumen8 halamanLubrication: Md. Al Amin Hossain Lecturer (ME)SaHaria SajibBelum ada peringkat

- Nippon EA9 Finish HBDokumen3 halamanNippon EA9 Finish HBHamza GhaniBelum ada peringkat

- TI - LubricationDokumen5 halamanTI - LubricationAlex LinsBelum ada peringkat

- Lubrication: Necessity of Lubrication Lubricating PointsDokumen3 halamanLubrication: Necessity of Lubrication Lubricating PointsSiddharth MankarBelum ada peringkat

- Improving Chain LubricationDokumen5 halamanImproving Chain LubricationAhmadreza AminianBelum ada peringkat

- Ar 250Dokumen1 halamanAr 250Yoo KyungsikBelum ada peringkat

- Lubrication: Necessity of Lubrication Lubricating PointsDokumen3 halamanLubrication: Necessity of Lubrication Lubricating PointsrccanarimBelum ada peringkat

- Transpoxy Tankguard 118 ESDokumen5 halamanTranspoxy Tankguard 118 ESFadi MagdyBelum ada peringkat

- UNIT III: Lubricants: Soami P. Satsangee CHM 181 7/10/2015Dokumen46 halamanUNIT III: Lubricants: Soami P. Satsangee CHM 181 7/10/2015anjali sharmaBelum ada peringkat

- Heavy Duty NLGI 00 Grease For Open Gears and Wire RopesDokumen1 halamanHeavy Duty NLGI 00 Grease For Open Gears and Wire RopesProject Sales CorpBelum ada peringkat

- Lubricants 7Dokumen4 halamanLubricants 7chemistrymaster100% (3)

- Mod 7.03d Lubrication Tools SlideshowDokumen24 halamanMod 7.03d Lubrication Tools Slideshowzaidkadiri9Belum ada peringkat

- Function of A Lubricant: Ref To Page 48 Diesel Engines 3rd Edition, A J WhartonDokumen11 halamanFunction of A Lubricant: Ref To Page 48 Diesel Engines 3rd Edition, A J Whartonapi-3701567Belum ada peringkat

- Chapter-5 Minor Auto Body RepairDokumen6 halamanChapter-5 Minor Auto Body RepairAmanuelBelum ada peringkat

- Honda XR50R Service Manual 2000 2003Dokumen197 halamanHonda XR50R Service Manual 2000 2003aurongayBelum ada peringkat

- 2018.11.25 Grease Book FuchsDokumen18 halaman2018.11.25 Grease Book FuchsnghiaBelum ada peringkat

- LubricantsDokumen5 halamanLubricantsengineeringchemistry100% (2)

- Basic Carbonate White Lead Pigment: Standard Specification ForDokumen2 halamanBasic Carbonate White Lead Pigment: Standard Specification ForMohammed KarasnehBelum ada peringkat

- Wire Rope LubricatorDokumen8 halamanWire Rope LubricatorvlmiltonBelum ada peringkat

- Arocoat - Repair Paint Data SheetDokumen3 halamanArocoat - Repair Paint Data SheetIsboBelum ada peringkat

- Lubrication SMBA01 SAMV10Dokumen30 halamanLubrication SMBA01 SAMV10Sadashiva sahooBelum ada peringkat

- Unit7 Lubricants7Dokumen5 halamanUnit7 Lubricants7engineeringchemistryBelum ada peringkat

- Basic Carbonate White Lead Pigment: Standard Specification ForDokumen2 halamanBasic Carbonate White Lead Pigment: Standard Specification ForSdferwste SrqreBelum ada peringkat

- LB Series Asphalt Mixing Plant Repair and Maintenance ManualDokumen38 halamanLB Series Asphalt Mixing Plant Repair and Maintenance ManualLai_Wei_Wah_7018Belum ada peringkat

- Durosan 03 Exterior MattDokumen3 halamanDurosan 03 Exterior Mattمحمد عزتBelum ada peringkat

- 5B Ii LubricantsDokumen25 halaman5B Ii Lubricantsmsk3kiidBelum ada peringkat

- Automatic Lubrication Manual Sandvik PrimaryDokumen10 halamanAutomatic Lubrication Manual Sandvik PrimaryBalaji Kakade100% (1)

- QA NA Lubrication 101Dokumen4 halamanQA NA Lubrication 101usermellaBelum ada peringkat

- Aluminium Paint HR NipponDokumen2 halamanAluminium Paint HR Nipponyarth88Belum ada peringkat

- Nippon ArocoatDokumen3 halamanNippon ArocoatHANIF IZANI ISHAKBelum ada peringkat

- SKF Bearings With Solid Oil - The Third Lubrication ChoiceDokumen8 halamanSKF Bearings With Solid Oil - The Third Lubrication ChoiceLuisSilvaBelum ada peringkat

- Grease BasicsDokumen6 halamanGrease BasicsnagbabuiBelum ada peringkat

- Zinky 13 Inorganic Zinc Rich Primer 85 16042018Dokumen4 halamanZinky 13 Inorganic Zinc Rich Primer 85 16042018ppglBelum ada peringkat

- We Need To Do Better - Metropolitan Jan 2023Dokumen57 halamanWe Need To Do Better - Metropolitan Jan 2023Kenneth John BrownBelum ada peringkat

- NP ArocoatDokumen4 halamanNP ArocoatJohn HaBelum ada peringkat

- Durosan 02 INT MATT (I) : Technical Data SheetDokumen3 halamanDurosan 02 INT MATT (I) : Technical Data Sheetمحمد عزتBelum ada peringkat

- Industrial ChemistryDokumen15 halamanIndustrial Chemistryjhapindra adhikariBelum ada peringkat

- Chemistry Notes On LubricantsDokumen4 halamanChemistry Notes On LubricantsSohamDixit67% (3)

- Apcoline 4100Dokumen2 halamanApcoline 4100Moin AltafBelum ada peringkat

- 12 - Epoxy Zinc Phosphate PrimerDokumen3 halaman12 - Epoxy Zinc Phosphate Primerhello geeBelum ada peringkat

- Preparation For Running TubingDokumen3 halamanPreparation For Running TubingYougchu LuanBelum ada peringkat

- Creative Resin: Easy techniques for contemporary resin artDari EverandCreative Resin: Easy techniques for contemporary resin artBelum ada peringkat

- Machinery Oil Analysis & Condition Monitoring : A Practical Guide to Sampling and Analyzing Oil to Improve Equipment ReliabilityDari EverandMachinery Oil Analysis & Condition Monitoring : A Practical Guide to Sampling and Analyzing Oil to Improve Equipment ReliabilityPenilaian: 3 dari 5 bintang3/5 (4)

- Elevator Control Valves: EN ISO 9001Dokumen6 halamanElevator Control Valves: EN ISO 9001smsobhanBelum ada peringkat

- Confomity Document Otis Belts - 2020-9-23Dokumen3 halamanConfomity Document Otis Belts - 2020-9-23smsobhanBelum ada peringkat

- Blain Service Manual GBDokumen40 halamanBlain Service Manual GBsmsobhanBelum ada peringkat

- Omarlift Brochure - HydraulicDokumen1 halamanOmarlift Brochure - HydraulicsmsobhanBelum ada peringkat

- Calculation of Traction Sheave - محاسبات عالی و کامل WitturDokumen13 halamanCalculation of Traction Sheave - محاسبات عالی و کامل WittursmsobhanBelum ada peringkat

- Thyssen Elevator Certificate 2Dokumen2 halamanThyssen Elevator Certificate 2smsobhanBelum ada peringkat

- Arian Controller DiagramDokumen3 halamanArian Controller DiagramsmsobhanBelum ada peringkat

- WITTUR - Arl 500 Installation Operation Manual WitturDokumen4 halamanWITTUR - Arl 500 Installation Operation Manual WittursmsobhanBelum ada peringkat

- JVF 5000 DriveDokumen120 halamanJVF 5000 DrivesmsobhanBelum ada peringkat

- Weltweit ! Worldwide!: RollenführungDokumen3 halamanWeltweit ! Worldwide!: RollenführungsmsobhanBelum ada peringkat

- Rope BergDokumen16 halamanRope BergsmsobhanBelum ada peringkat

- Drive VVVF GtakeDokumen267 halamanDrive VVVF GtakesmsobhanBelum ada peringkat

- Drive - HpmontDokumen148 halamanDrive - HpmontsmsobhanBelum ada peringkat

- Operador Wittur Hydra Plus: Hidra Plus - Midi / SupraDokumen3 halamanOperador Wittur Hydra Plus: Hidra Plus - Midi / SuprasmsobhanBelum ada peringkat

- 0 Cer ThyssenDokumen1 halaman0 Cer ThyssensmsobhanBelum ada peringkat

- Kone Ecosystem MR Sf2817Dokumen8 halamanKone Ecosystem MR Sf2817smsobhanBelum ada peringkat

- VIEW User V4 Manual - THYSSEN PDFDokumen70 halamanVIEW User V4 Manual - THYSSEN PDFsmsobhanBelum ada peringkat

- UE Guide Directive Machine 2006-42-CEDokumen406 halamanUE Guide Directive Machine 2006-42-CEvoltaredBelum ada peringkat

- L7 UsersManualDokumen299 halamanL7 UsersManualTushar ImranBelum ada peringkat

- 17 +lifts+directiveDokumen24 halaman17 +lifts+directivesmsobhanBelum ada peringkat

- JANUS - ThyssenKrupp Lift Interface Guide 1.0Dokumen22 halamanJANUS - ThyssenKrupp Lift Interface Guide 1.0smsobhan100% (1)

- Seismic Principles: - Chapter 1Dokumen13 halamanSeismic Principles: - Chapter 1Mahardika Aji KurniawanBelum ada peringkat

- Pearson's Classification of Lewis Acids and Lewis Bases Into Hard and Soft - Acids and BasesDokumen5 halamanPearson's Classification of Lewis Acids and Lewis Bases Into Hard and Soft - Acids and BasesThantea ChhakchhuakBelum ada peringkat

- THE TITLE OF EXPERIMENT Ion ExchangeDokumen18 halamanTHE TITLE OF EXPERIMENT Ion Exchangeputri wildanaBelum ada peringkat

- Elvis 4Dokumen9 halamanElvis 4Azhar Ali Zafar0% (1)

- Experiment 2 - Study of Packed Column DistillationDokumen7 halamanExperiment 2 - Study of Packed Column DistillationAdawiyah Az-zahra100% (1)

- 1 - Designing Ultrasonic Flow MetersDokumen183 halaman1 - Designing Ultrasonic Flow Metersmunzii100% (1)

- Kelompok 10 - Metode Optimasi Senyawa PenuntunDokumen36 halamanKelompok 10 - Metode Optimasi Senyawa Penuntunapr_aprililianti100% (1)

- Engineering Piping Design Guide Fiberglass Reinforced Piping SystemsDokumen36 halamanEngineering Piping Design Guide Fiberglass Reinforced Piping Systemsoscarhdef100% (1)

- Molten Salt Storage Systems For Solar Thermal Prower PlantsDokumen8 halamanMolten Salt Storage Systems For Solar Thermal Prower PlantsSaul RamBelum ada peringkat

- Directional Spray Nozzles, Open: Type D3 Protectospray@ - L/2" NPTDokumen6 halamanDirectional Spray Nozzles, Open: Type D3 Protectospray@ - L/2" NPTKrishna N HBelum ada peringkat

- AAK Dairy Fat PDFDokumen20 halamanAAK Dairy Fat PDFa4rarhim100% (2)

- Biology Unit PlanDokumen10 halamanBiology Unit Planapi-246097943Belum ada peringkat

- Environmentally Friendly Cooling With Heat: Ecoo 2.0: The Classic of Adsorption RefrigerationDokumen3 halamanEnvironmentally Friendly Cooling With Heat: Ecoo 2.0: The Classic of Adsorption RefrigerationGokulSubramanianBelum ada peringkat

- Ec 1Dokumen443 halamanEc 1Chaitanya KumarBelum ada peringkat

- Carbohydrate Qualitative AnalysisDokumen9 halamanCarbohydrate Qualitative AnalysisRamesh KandagatlaBelum ada peringkat

- Internship Report On Railway Coach FactoryDokumen39 halamanInternship Report On Railway Coach FactoryJyotiraj ThakuriaBelum ada peringkat

- 80 3689 01 Threaded ConnectionsDokumen12 halaman80 3689 01 Threaded ConnectionsMiguel Alfonso Ruiz MendezBelum ada peringkat

- Butyl Diglycol Acetate ManufacturersDokumen4 halamanButyl Diglycol Acetate ManufacturersSomuSolventsBelum ada peringkat

- Ls Series Washer Extractors: Designed To LastDokumen4 halamanLs Series Washer Extractors: Designed To LastTom DavidcsBelum ada peringkat

- Osmotic Fragility of Red Blood CellsDokumen3 halamanOsmotic Fragility of Red Blood Cellschaudhry umar farooqBelum ada peringkat

- Bc20122lnh-1 Assay Sheet (For Bc-30 Vet Research Use Only)Dokumen1 halamanBc20122lnh-1 Assay Sheet (For Bc-30 Vet Research Use Only)Subodh SahuBelum ada peringkat

- 01 - Ashrae - AerodynamicsDokumen52 halaman01 - Ashrae - AerodynamicsAnonymous A8HV1JiN2TBelum ada peringkat

- ACDpumps Oil Well Pump3Dokumen4 halamanACDpumps Oil Well Pump3mattuiffBelum ada peringkat

- Centrifugal PumpsDokumen26 halamanCentrifugal PumpsromwamaBelum ada peringkat

- OuchterlonyDokumen4 halamanOuchterlonyd_caasi100% (1)

- Brochura PCP TiconaDokumen84 halamanBrochura PCP TiconaFJNovaes454Belum ada peringkat

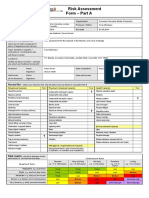

- Risk AssessmentDokumen2 halamanRisk AssessmentFaraiMbudaya0% (1)

- HW3 QM2 Fall2014Dokumen1 halamanHW3 QM2 Fall2014Mena Awan100% (1)

- Measurement System BehaviourDokumen48 halamanMeasurement System BehaviourpitapitulBelum ada peringkat