ABB 3wdg TRAFO Data Sheet

Diunggah oleh

Kunik Swaroop0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

965 tayangan2 halamanThree winding data sheet

Hak Cipta

© © All Rights Reserved

Format Tersedia

PDF, TXT atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniThree winding data sheet

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

965 tayangan2 halamanABB 3wdg TRAFO Data Sheet

Diunggah oleh

Kunik SwaroopThree winding data sheet

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

Anda di halaman 1dari 2

ABB Oy 19.6.

2008 FN 1

Special Transformers

P.O.Box 688

FIN-65101 Vaasa, FINLAND

08Q424869 specification ABB rev 1.doc

THREE PHASE OIL-IMMERSED POWER TRANSFORMERS

Type KTPU 245NC110000

Rated power ONAF 110 / 55 / 55 MVA

ONAN 66 / 33 / 33 MVA ( 60 % )

Voltage ratio ( at no-load ) 242 / 13.8 / 13.8 kV

Voltage regulation ±2x2,5%, off-load tap changer on HV-side

Frequency 60 Hz

Connection YNd1d1

Design short circuit

apparent power HV/LV 230 kV side 20000 MVA , 13.8 kV side 500 MVA

Short circuit time 2s

Available aux. voltage : To be informed

Standards IEC 60076 1-8 latest edition IEC 60296 for ins. oil

Insulation level LI 950 AC 395 – AC 185 / LI 95 AC 38 / LI 95 AC 38

Highest system voltage Um 245 kV

Type of HV-side earthing a) Effectively earthed

Temperature rise oil/windings 50/55 °C

No-load losses approx. 49 kW

Load losses at nominal tap approx. 420 kW (at 110 MVA) 36%,36%,72% on

Total losses at full load ≤0.5% 110MVA base

Relative Impedance voltage approx. 18 % (HV-LV1 and HV-LV2 at 55 MVA)

At nominal tap

Total weight, prel. 110 t 18%,18%,36% on

Oil weight prel. 32 t 55MVA base

Transport weight, heaviest

part, prel. 92 / 67 t ( with / without oil )

Ambient conditions IEC 60076

Altitude Max. 1000 m ASL

Max momentary ambient temp: 50 °C

Max daily average temperature 40 °C

Max annual average temperature 30 °C

Maxumum relative humidity: Outdoor installation, high humidity

Earthquake capability 0.5 g

Wind velocity 240 km/h (3-second gust)

Construction:

1. Conservator type vacuum-proof tank with detachable radiators and Cu windings.

2. Conservator at least 10% oil volume

3. Conservator shut-off valve

4. Radiator shut of valves

5. Off-load tap changer CAPT or equal with hand wheel on cover.

6. HV-condenser bushings, LV porcelain bushings, creepage distance 31 mm/kV

7. HV / LV termination and connector bars for cable terminations on LV side, cable

connection from beneath up to 8 x 500 mm2 1c XPLE cables / phase,

8. Lifting hooks

9. Jacking lugs

10. Pulling eyes

11. Drain valve and filtering valve

12. Filling valve and filtering.

13. Earthing terminals 4 pcs

14. Rating and diagram plates

15. Painted tank RAL 7035 min 150µm, and hot dip galvanised radiators

16. HV bushing current transformers:

Phase: 300/1/1/1 15VA cl0.2, 20VA 5P20, 20VA 5P20

Neutral: 300/1/1 20VA 5P20, 20VA 5P20

17. Motor feeder panel for fans with anti condensation heater and control cabinet for

auxiliary equipment.

18. Sampling valves for top and bottom oil.

19. Silicagel breather

20. Buchholz relay with 1 NO alarm and 1 NO trip contact

21. Oil level indicator, contacts low 1NO and high 1NO level alarm

22. Oil thermometer with 1 NO alarm and 1 NO tripping contacts

23. Winding temperature indicator 2 pcs with 1 NO alarm and 1 NO tripping contacts

24. Additional thermometer pocket

25. Transformer base: flat base reinforced for skidding in any direction, prepared for

bolting to foundation + anchor bolts.

26. Welded transformer cover

27. One can of touch up paint.

28. Factory Routine testing according to IEC 60076.

29. Pressure relief valve with 1 NO trip contact.

30. Cooling Fans

31. Surge arresters as loose items for HV-phases including counter and cabling to

counter.

Rev. 1 HV voltage changed 230=>242 kV. Layout for surge arresters revised.

Ref.: 08Q424869

Anda mungkin juga menyukai

- ALSTOM Symbols and Signs On Electr Diagrams IEC - ANSIDokumen5 halamanALSTOM Symbols and Signs On Electr Diagrams IEC - ANSIHeather CarterBelum ada peringkat

- MES114 Modules: Logic Input / Output ModulesDokumen1 halamanMES114 Modules: Logic Input / Output ModulestuanudinBelum ada peringkat

- NEX 17.5KV InstructionsDokumen43 halamanNEX 17.5KV InstructionsThức VõBelum ada peringkat

- Data Bulletin Transformer Key Features: Dry-Type, Cast-Resin, and Liquid-Filled Transformers Class 7300Dokumen4 halamanData Bulletin Transformer Key Features: Dry-Type, Cast-Resin, and Liquid-Filled Transformers Class 7300Dinesh SelvakumarBelum ada peringkat

- Auxiliary Transformer DatasheetDokumen3 halamanAuxiliary Transformer DatasheetRigoberto UrrutiaBelum ada peringkat

- 110/30 kV transformer specsDokumen3 halaman110/30 kV transformer specsamulya00428Belum ada peringkat

- E ASY ASY RevbDokumen7 halamanE ASY ASY RevbVirajitha Maddumabandara0% (1)

- HAGER AutomationProductsDokumen32 halamanHAGER AutomationProductsMinos AsimakisBelum ada peringkat

- Automation Systems Modulex3 Line RelaysDokumen2 halamanAutomation Systems Modulex3 Line Relayseliut123Belum ada peringkat

- Tech Article - Control Cable Lengths For ContactorsDokumen8 halamanTech Article - Control Cable Lengths For ContactorsSandeep NairBelum ada peringkat

- Rudolf RTXDokumen15 halamanRudolf RTXNuengruthai WeerawattanaBelum ada peringkat

- OC& Earth Fault RelayEnglishDokumen3 halamanOC& Earth Fault RelayEnglishChandan KumarBelum ada peringkat

- Series ZYD Operation ManualDokumen11 halamanSeries ZYD Operation ManualDaniel SubelzaBelum ada peringkat

- AUMA Sar1 - IomDokumen32 halamanAUMA Sar1 - Iomloli2323100% (1)

- 6.2. F-MPC60B - Manual - English PDFDokumen68 halaman6.2. F-MPC60B - Manual - English PDFThủy Tiên100% (1)

- Instruction Manual: C650 Bay ControllerDokumen284 halamanInstruction Manual: C650 Bay Controllernguyen rinBelum ada peringkat

- Timers, Time, Switches, Hour Meters & Supply MonitorsDokumen24 halamanTimers, Time, Switches, Hour Meters & Supply MonitorsnogeshwarBelum ada peringkat

- Micom P630C: Transformer Differential Protection DeviceDokumen396 halamanMicom P630C: Transformer Differential Protection Devicemari78svksBelum ada peringkat

- VacClad W Metal Clad SwitchgearDokumen98 halamanVacClad W Metal Clad SwitchgearjokotsBelum ada peringkat

- F21 Epac 3000-173Dokumen12 halamanF21 Epac 3000-173Mit Sut CuiBelum ada peringkat

- Technical Note: Trip-Circuit Supervision (TCS)Dokumen30 halamanTechnical Note: Trip-Circuit Supervision (TCS)feromagnetizamBelum ada peringkat

- Crompton Greaves Limited: 12kV Indoor Vacuum Circuit BreakerDokumen3 halamanCrompton Greaves Limited: 12kV Indoor Vacuum Circuit BreakerRamesh AnanthanarayananBelum ada peringkat

- Sm1223 CadDokumen1 halamanSm1223 CadYEINER HERNAN ACUÑA VEGABelum ada peringkat

- 8BK88 O&M ManualDokumen36 halaman8BK88 O&M ManualsyamprasadBelum ada peringkat

- MFVU Alstom PDFDokumen8 halamanMFVU Alstom PDFkggganiBelum ada peringkat

- P127 OrderForm - V20 - 062017Dokumen8 halamanP127 OrderForm - V20 - 062017tandin.t6393Belum ada peringkat

- BORRI Industrial E3001e - E2001e - Training - 2023Dokumen42 halamanBORRI Industrial E3001e - E2001e - Training - 2023FarisFirdausBelum ada peringkat

- Ain Alpha Meter: High Accuracy MeteringDokumen2 halamanAin Alpha Meter: High Accuracy Meteringmareymorsy282250% (2)

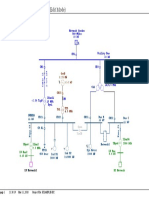

- One-Line Diagram - Study View (Edit Mode) : Network Feeder 500 Mvasc 33 KV Network Feeder 500 Mvasc 33 KVDokumen1 halamanOne-Line Diagram - Study View (Edit Mode) : Network Feeder 500 Mvasc 33 KV Network Feeder 500 Mvasc 33 KVBhavik PrajapatiBelum ada peringkat

- Chloride FP 40r Ds en GL 0616 Rev6Dokumen2 halamanChloride FP 40r Ds en GL 0616 Rev6Tanveer Ahmed100% (1)

- Circuit diagram of a remote control system with a transformer and power supply detailsDokumen2 halamanCircuit diagram of a remote control system with a transformer and power supply detailshassan hassanBelum ada peringkat

- Basler DECS 125-15 Digital Excitation Controller ManualDokumen71 halamanBasler DECS 125-15 Digital Excitation Controller ManualEugene RadulianBelum ada peringkat

- GIS - ToshibaDokumen4 halamanGIS - ToshibaIuri MontandonBelum ada peringkat

- Commissioning of DAVRDokumen70 halamanCommissioning of DAVRPMG Bhuswal Project100% (1)

- SYNCHROTACT Datasheet May 2018 3BHS901067E01 E PDFDokumen56 halamanSYNCHROTACT Datasheet May 2018 3BHS901067E01 E PDFJeep WillysBelum ada peringkat

- HI 800 357 E Device H7201Dokumen3 halamanHI 800 357 E Device H7201kailasamvvBelum ada peringkat

- ETS-50-00 Outdoor AIS AC Substation Common Conditions and Technical RequirementsDokumen8 halamanETS-50-00 Outdoor AIS AC Substation Common Conditions and Technical Requirementsraghavendran raghuBelum ada peringkat

- Magnetic Oil Level Indicator Provides Analog and Alarm SignalsDokumen27 halamanMagnetic Oil Level Indicator Provides Analog and Alarm SignalsPandrayar MaruthuBelum ada peringkat

- Generator Voltage Regulator ManualDokumen48 halamanGenerator Voltage Regulator ManualvjBelum ada peringkat

- AC Power Transducer User ManualDokumen4 halamanAC Power Transducer User ManualKhaled El-BeheryBelum ada peringkat

- Technical Specification Supply Monitoring DeviceDokumen2 halamanTechnical Specification Supply Monitoring DevicenareshBelum ada peringkat

- 4RB9512-8CD50 - Reaktif Kontrol Rölesi++Dokumen120 halaman4RB9512-8CD50 - Reaktif Kontrol Rölesi++omar omarBelum ada peringkat

- máy cắt sf6 abbDokumen7 halamanmáy cắt sf6 abbQuảng Thành NamBelum ada peringkat

- Siemens Surge Arrester Technical DatasheetDokumen2 halamanSiemens Surge Arrester Technical DatasheetWilliam CheungBelum ada peringkat

- Battery Sizing Sheet, As Per Ieee STD 485: NoteDokumen1 halamanBattery Sizing Sheet, As Per Ieee STD 485: NoteSaquib KhanBelum ada peringkat

- ABB REF542plus Manuale ENGDokumen32 halamanABB REF542plus Manuale ENGAbrakain69Belum ada peringkat

- Statron UPS Technology Shell 23042013Dokumen19 halamanStatron UPS Technology Shell 23042013John LioBelum ada peringkat

- Ka Ratings - Copper OnlyDokumen10 halamanKa Ratings - Copper OnlySanjeewa HemaratneBelum ada peringkat

- Excel ApodysDokumen4 halamanExcel ApodysjeremiahBelum ada peringkat

- Osisense Xs Xsav11801Dokumen2 halamanOsisense Xs Xsav11801jcadvBelum ada peringkat

- 110V Battery & Battery Charger Sizing Calculation For Payra 132/11Kv (Ais) Grid SubstationDokumen32 halaman110V Battery & Battery Charger Sizing Calculation For Payra 132/11Kv (Ais) Grid Substationarafin100% (1)

- KUVAG Indicating System CPI VI-3P R (10-52kV)Dokumen3 halamanKUVAG Indicating System CPI VI-3P R (10-52kV)registracijus100% (1)

- General Catalog LenoirElecDokumen164 halamanGeneral Catalog LenoirElecjipix7850% (2)

- L&T Lx7 Um001c en P (Lx7 - lx7s Series Controller)Dokumen86 halamanL&T Lx7 Um001c en P (Lx7 - lx7s Series Controller)JohnTP67% (3)

- 4Dokumen14 halaman4Balamurugan ArumugamBelum ada peringkat

- Technical specifications for AC UPS systems from 10-220 kVADokumen4 halamanTechnical specifications for AC UPS systems from 10-220 kVATerence WoodBelum ada peringkat

- TLF Catalogue Ringmaster 135Dokumen7 halamanTLF Catalogue Ringmaster 135Isaac VoonBelum ada peringkat

- 15 MVA Transformer-S012-2-12Dokumen30 halaman15 MVA Transformer-S012-2-12Neeraj SinghBelum ada peringkat

- Datasheet - VT12224 Appendixes Rev1Dokumen3 halamanDatasheet - VT12224 Appendixes Rev1Abdul KalimBelum ada peringkat

- 8.490428 A4-L 1.0 enDokumen129 halaman8.490428 A4-L 1.0 enDuc Nguyen VanBelum ada peringkat

- IWPP Code v1.2 March2017Dokumen168 halamanIWPP Code v1.2 March2017dexater007Belum ada peringkat

- Dear Parents, Please Find Below The Academic Schedule For Your ReferenceDokumen2 halamanDear Parents, Please Find Below The Academic Schedule For Your ReferenceKunik SwaroopBelum ada peringkat

- ZHU2018 Article DampingControlForATargetOscill PDFDokumen13 halamanZHU2018 Article DampingControlForATargetOscill PDFKunik SwaroopBelum ada peringkat

- Short Circuit Caculation-ManualDokumen4 halamanShort Circuit Caculation-ManualKunik SwaroopBelum ada peringkat

- Large Scale Grid IntegDokumen55 halamanLarge Scale Grid IntegMalay BhuniaBelum ada peringkat

- Parallel Generators SynchronizationDokumen16 halamanParallel Generators Synchronizationfelwood36100% (1)

- Generator Power FactorDokumen2 halamanGenerator Power FactorAliceAlormenuBelum ada peringkat

- Inrush Current StudyDokumen5 halamanInrush Current StudyTapasBelum ada peringkat

- Medium Voltage Technical Guide: Basics For MV Cubicle DesignDokumen84 halamanMedium Voltage Technical Guide: Basics For MV Cubicle DesignVasu Devan100% (3)

- Voltage Drop CalculationsDokumen11 halamanVoltage Drop CalculationsPravivVivpraBelum ada peringkat

- Comparing Load Estimation Methods for Improved Distribution System AnalysisDokumen4 halamanComparing Load Estimation Methods for Improved Distribution System Analysiskaliman2010Belum ada peringkat

- PFCED310003EN Web PDFDokumen96 halamanPFCED310003EN Web PDFKunik SwaroopBelum ada peringkat

- Arc FlashDokumen68 halamanArc FlashKunik Swaroop100% (2)

- Step Potential Voltage Hazards ExplainedDokumen1 halamanStep Potential Voltage Hazards ExplainedKunik SwaroopBelum ada peringkat

- Transformer Vector GroupsDokumen15 halamanTransformer Vector GroupsKunik Swaroop100% (1)

- Parallel Generators SynchronizationDokumen16 halamanParallel Generators Synchronizationfelwood36100% (1)

- Reactive Power Compensation via Underground Cables and Shunt ReactorsDokumen6 halamanReactive Power Compensation via Underground Cables and Shunt ReactorsKunik SwaroopBelum ada peringkat

- Power Quadrants and OBIS CodesDokumen8 halamanPower Quadrants and OBIS CodesKunik SwaroopBelum ada peringkat

- Making solar thermal power in India a realityDokumen9 halamanMaking solar thermal power in India a realityashim_scribdBelum ada peringkat

- Electrical Fault Level Calculation Using MVA MethodDokumen3 halamanElectrical Fault Level Calculation Using MVA MethodYip Mun Fai100% (2)

- Non Linear LoadDokumen1 halamanNon Linear LoadKikiyuBelum ada peringkat

- Empire List of 301 Blockbuster All TimeDokumen8 halamanEmpire List of 301 Blockbuster All TimeKunik SwaroopBelum ada peringkat

- Light Motor Handbook enDokumen78 halamanLight Motor Handbook enmanoj14feb100% (1)

- Application of Emerging TechnologiesDokumen49 halamanApplication of Emerging TechnologiesKunik SwaroopBelum ada peringkat

- PV BasicsDokumen286 halamanPV BasicsMahipal Singh RaoBelum ada peringkat

- Solar Power For Rural ElectrificationDokumen5 halamanSolar Power For Rural ElectrificationKunik SwaroopBelum ada peringkat

- The Basics of Solar Power For Producing ElectricityDokumen5 halamanThe Basics of Solar Power For Producing ElectricityJason HallBelum ada peringkat

- Motor Acceleration Analysis One-Line DiagramDokumen2 halamanMotor Acceleration Analysis One-Line DiagramKunik SwaroopBelum ada peringkat

- 2EHV Susbattions PSJG Apr11Dokumen22 halaman2EHV Susbattions PSJG Apr11G.RameshBelum ada peringkat

- Mechanic CV TemplateDokumen2 halamanMechanic CV Templateasmaa brkBelum ada peringkat

- Gretton, Hare, Catchpole - Psychopathy and Offending From Adolescence To Adulthood - A 10-Year Follow-UpDokumen10 halamanGretton, Hare, Catchpole - Psychopathy and Offending From Adolescence To Adulthood - A 10-Year Follow-UpMaria Isabel Trujillo MayaBelum ada peringkat

- Vitamin D DeficinyDokumen11 halamanVitamin D DeficinyسالمBelum ada peringkat

- ERAS DR - TESAR SP - AnDokumen26 halamanERAS DR - TESAR SP - AnAhmad Rifai R ABelum ada peringkat

- Face SerumDokumen10 halamanFace SerumLiliana CojocaruBelum ada peringkat

- One Stop English - Cornish Village - Pre-IntermediateDokumen5 halamanOne Stop English - Cornish Village - Pre-Intermediatec_a_tabetBelum ada peringkat

- Advantest R3131 Spectrum Analyzer Operator ManualDokumen277 halamanAdvantest R3131 Spectrum Analyzer Operator ManualMartin Argay100% (1)

- Multiple Bank Accounts Registration FormDokumen2 halamanMultiple Bank Accounts Registration FormAjith JainBelum ada peringkat

- Week 2 National Income-2Dokumen41 halamanWeek 2 National Income-2elijah thonBelum ada peringkat

- 10 B Plas List PPR Eng GreenDokumen15 halaman10 B Plas List PPR Eng GreenZakaria ChouliBelum ada peringkat

- JAFZA Construction Regulation - Third Edition 2003Dokumen73 halamanJAFZA Construction Regulation - Third Edition 2003Abdul JabbarBelum ada peringkat

- Cakes Amp Sugarcraft - April-May 2019 EditDokumen45 halamanCakes Amp Sugarcraft - April-May 2019 Editapi-197110397100% (1)

- Shell Alexia 40 cylinder oil designed for IMO 2020 complianceDokumen2 halamanShell Alexia 40 cylinder oil designed for IMO 2020 complianceStefas DimitriosBelum ada peringkat

- A-Plus Beyond Critical Shield & A-Plus Beyond Early Critical ShieldDokumen21 halamanA-Plus Beyond Critical Shield & A-Plus Beyond Early Critical ShieldGenevieve KohBelum ada peringkat

- The DrunktionaryDokumen239 halamanThe DrunktionaryRed Rex 2015Belum ada peringkat

- Experimental Animals Vol1Dokumen209 halamanExperimental Animals Vol1JohnBelum ada peringkat

- Adapted Sports & Recreation 2015: The FCPS Parent Resource CenterDokumen31 halamanAdapted Sports & Recreation 2015: The FCPS Parent Resource CenterkirthanasriBelum ada peringkat

- Ketamine Drug Study for AnesthesiaDokumen1 halamanKetamine Drug Study for AnesthesiaPRINCESS MARIZHAR OMARBelum ada peringkat

- Case Study - BronchopneumoniaDokumen45 halamanCase Study - Bronchopneumoniazeverino castillo91% (33)

- HVDC Vs HVAC TransmissionDokumen2 halamanHVDC Vs HVAC TransmissionBilal SahiBelum ada peringkat

- Análisis de Estabilidad de TaludesDokumen4 halamanAnálisis de Estabilidad de TaludesJosue Acosta EspinozaBelum ada peringkat

- Time ManagementDokumen30 halamanTime ManagementVaibhav Vithoba NaikBelum ada peringkat

- Fuel Gas Superheater 195-E-301 A/B: Mechanical - Data SheetDokumen3 halamanFuel Gas Superheater 195-E-301 A/B: Mechanical - Data SheetZulfikar N JoelBelum ada peringkat

- Analysis of Grape and WineDokumen116 halamanAnalysis of Grape and WineElenaTrofimBelum ada peringkat

- Liu030 Nepal Bans Solo Mountain ClimbersDokumen2 halamanLiu030 Nepal Bans Solo Mountain Climberssanti.miranda.parrillaBelum ada peringkat

- NPD High Level Status: Concept Development FeasibilityDokumen22 halamanNPD High Level Status: Concept Development FeasibilityRaviBelum ada peringkat

- MAstering IATFDokumen20 halamanMAstering IATFGyanesh_DBBelum ada peringkat

- Confined Space Planning ChecklistDokumen3 halamanConfined Space Planning ChecklistKB100% (1)

- Introduction To EmbryologyDokumen38 halamanIntroduction To Embryologymike3601144Belum ada peringkat

- Report Information From Proquest: February 24 2014 06:18Dokumen19 halamanReport Information From Proquest: February 24 2014 06:18Emma Elena StroeBelum ada peringkat

- Build Your Own Electric Vehicle, Third EditionDari EverandBuild Your Own Electric Vehicle, Third EditionPenilaian: 4.5 dari 5 bintang4.5/5 (3)

- Conquering the Electron: The Geniuses, Visionaries, Egomaniacs, and Scoundrels Who Built Our Electronic AgeDari EverandConquering the Electron: The Geniuses, Visionaries, Egomaniacs, and Scoundrels Who Built Our Electronic AgePenilaian: 5 dari 5 bintang5/5 (8)

- High Performance Loudspeakers: Optimising High Fidelity Loudspeaker SystemsDari EverandHigh Performance Loudspeakers: Optimising High Fidelity Loudspeaker SystemsPenilaian: 4 dari 5 bintang4/5 (1)

- Asset Integrity Management for Offshore and Onshore StructuresDari EverandAsset Integrity Management for Offshore and Onshore StructuresBelum ada peringkat

- Understanding Automotive Electronics: An Engineering PerspectiveDari EverandUnderstanding Automotive Electronics: An Engineering PerspectivePenilaian: 3.5 dari 5 bintang3.5/5 (16)

- Digital Gold: The Beginner's Guide to Digital Product Success, Learn Useful Tips and Methods on How to Create Digital Products and Earn Massive ProfitsDari EverandDigital Gold: The Beginner's Guide to Digital Product Success, Learn Useful Tips and Methods on How to Create Digital Products and Earn Massive ProfitsPenilaian: 5 dari 5 bintang5/5 (3)

- The Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionDari EverandThe Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionPenilaian: 4.5 dari 5 bintang4.5/5 (542)

- The Graphene Revolution: The Weird Science of the Ultra-thinDari EverandThe Graphene Revolution: The Weird Science of the Ultra-thinPenilaian: 4.5 dari 5 bintang4.5/5 (4)

- Off-Grid Projects: Step-by-Step Guide to Building Your Own Off-Grid SystemDari EverandOff-Grid Projects: Step-by-Step Guide to Building Your Own Off-Grid SystemBelum ada peringkat

- The Fast Track to Your Technician Class Ham Radio License: For Exams July 1, 2022 - June 30, 2026Dari EverandThe Fast Track to Your Technician Class Ham Radio License: For Exams July 1, 2022 - June 30, 2026Penilaian: 5 dari 5 bintang5/5 (1)

- C++ Programming Language: Simple, Short, and Straightforward Way of Learning C++ ProgrammingDari EverandC++ Programming Language: Simple, Short, and Straightforward Way of Learning C++ ProgrammingPenilaian: 4 dari 5 bintang4/5 (1)

- Electrical Principles and Technology for EngineeringDari EverandElectrical Principles and Technology for EngineeringPenilaian: 4 dari 5 bintang4/5 (4)

- 8051 Microcontroller: An Applications Based IntroductionDari Everand8051 Microcontroller: An Applications Based IntroductionPenilaian: 5 dari 5 bintang5/5 (6)

- Electronics All-in-One For Dummies, 3rd EditionDari EverandElectronics All-in-One For Dummies, 3rd EditionPenilaian: 5 dari 5 bintang5/5 (2)

- The Rare Metals War: the dark side of clean energy and digital technologiesDari EverandThe Rare Metals War: the dark side of clean energy and digital technologiesPenilaian: 5 dari 5 bintang5/5 (2)

- The Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionDari EverandThe Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionPenilaian: 4 dari 5 bintang4/5 (331)

- Industrial Piping and Equipment Estimating ManualDari EverandIndustrial Piping and Equipment Estimating ManualPenilaian: 5 dari 5 bintang5/5 (7)

- Automotive Electronic Diagnostics (Course 2)Dari EverandAutomotive Electronic Diagnostics (Course 2)Penilaian: 4 dari 5 bintang4/5 (2)

- Operational Amplifier Circuits: Analysis and DesignDari EverandOperational Amplifier Circuits: Analysis and DesignPenilaian: 4.5 dari 5 bintang4.5/5 (2)

- Wearable Sensors: Fundamentals, Implementation and ApplicationsDari EverandWearable Sensors: Fundamentals, Implementation and ApplicationsEdward SazonovBelum ada peringkat

- Winning in 2025: Digital and Data Transformation: The Keys to SuccessDari EverandWinning in 2025: Digital and Data Transformation: The Keys to SuccessBelum ada peringkat